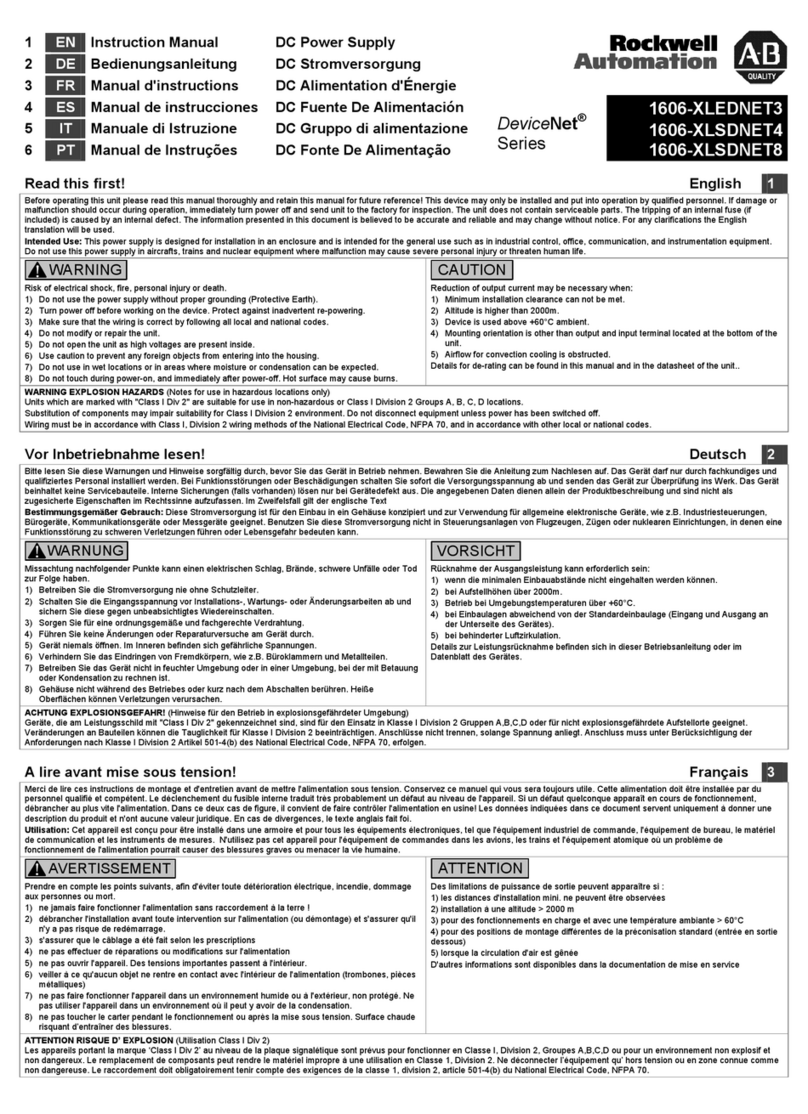

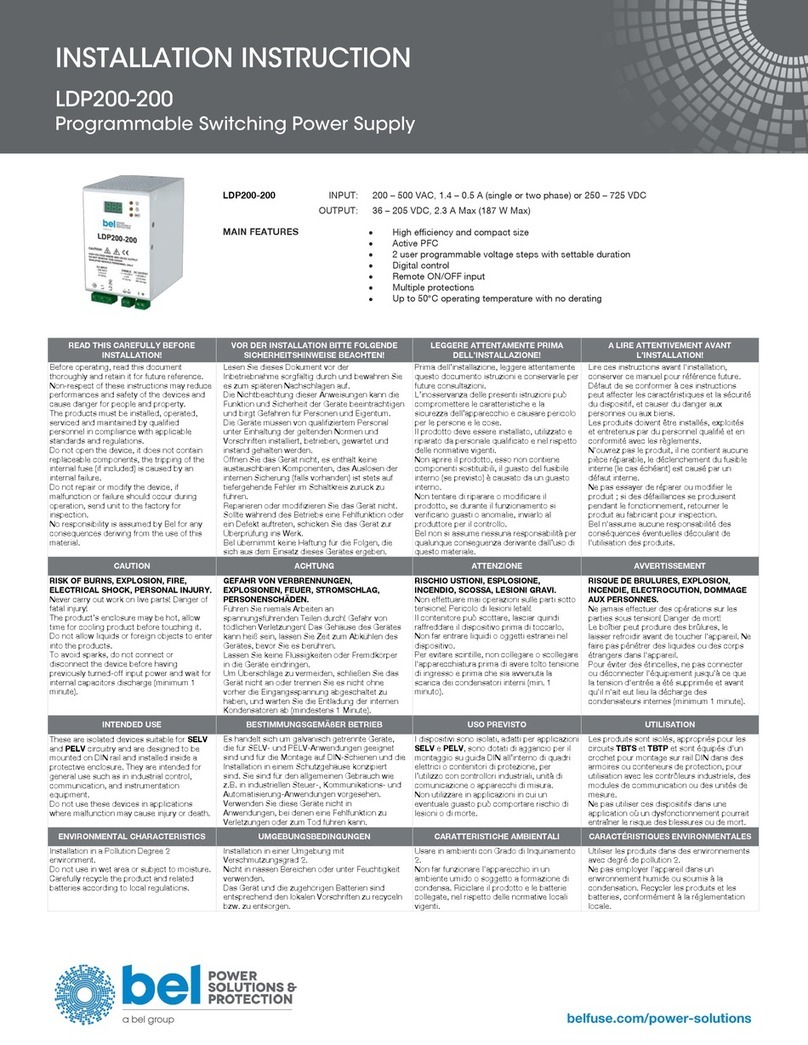

READ THIS CAREFULLY BEFORE

INSTALLATION!

VOR DER INSTALLATION BITTE FOLGENDE

SICHERHEITSHINWEISE BEACHTEN!

LEGGERE ATTENTAMENTE PRIMA

DELL’INSTALLAZIONE!

A LIRE ATTENTIVEMENT AVANT

L’INSTALLATION!

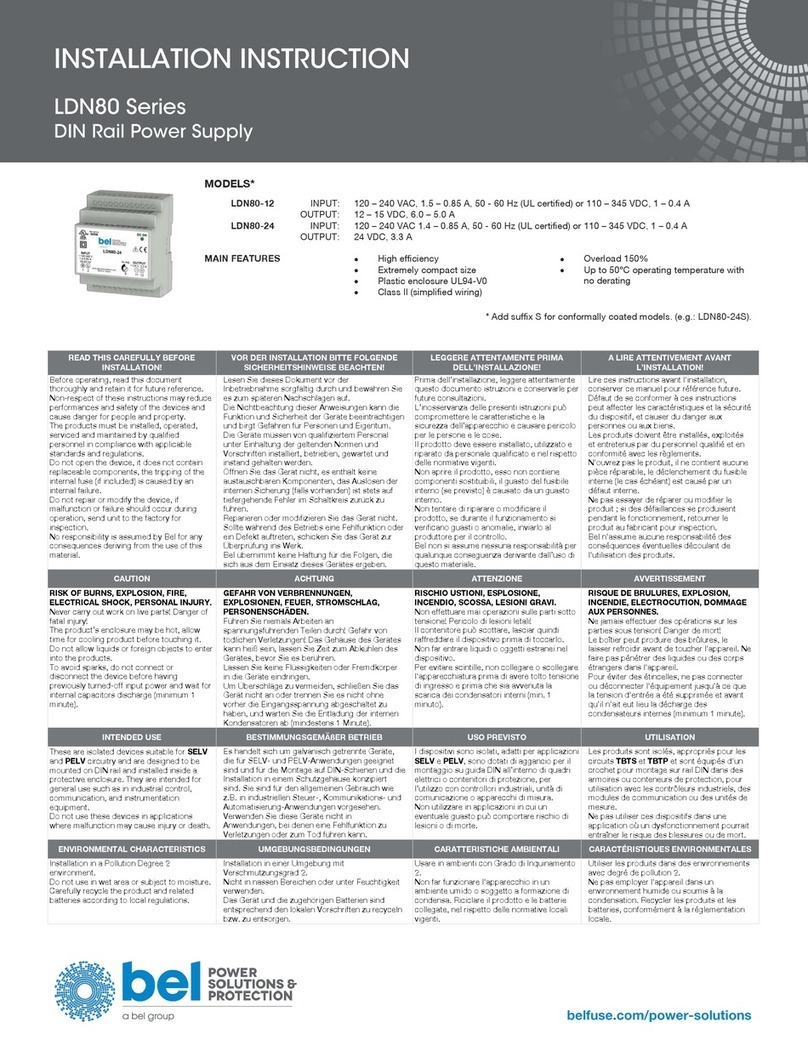

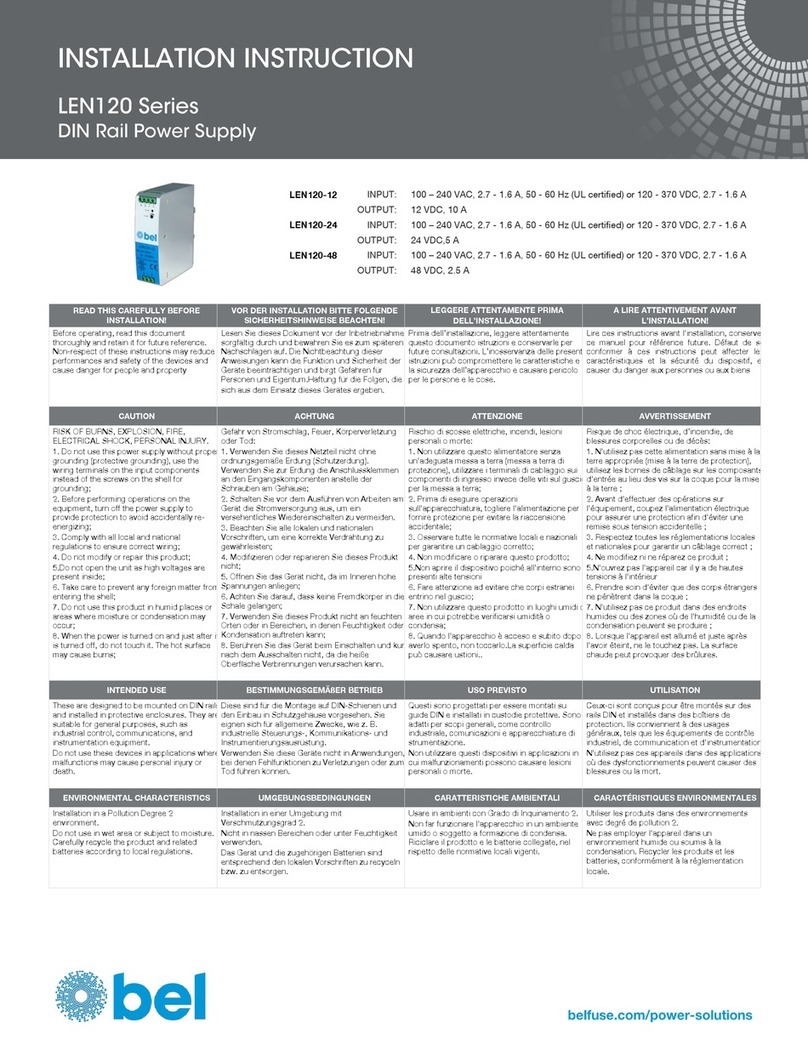

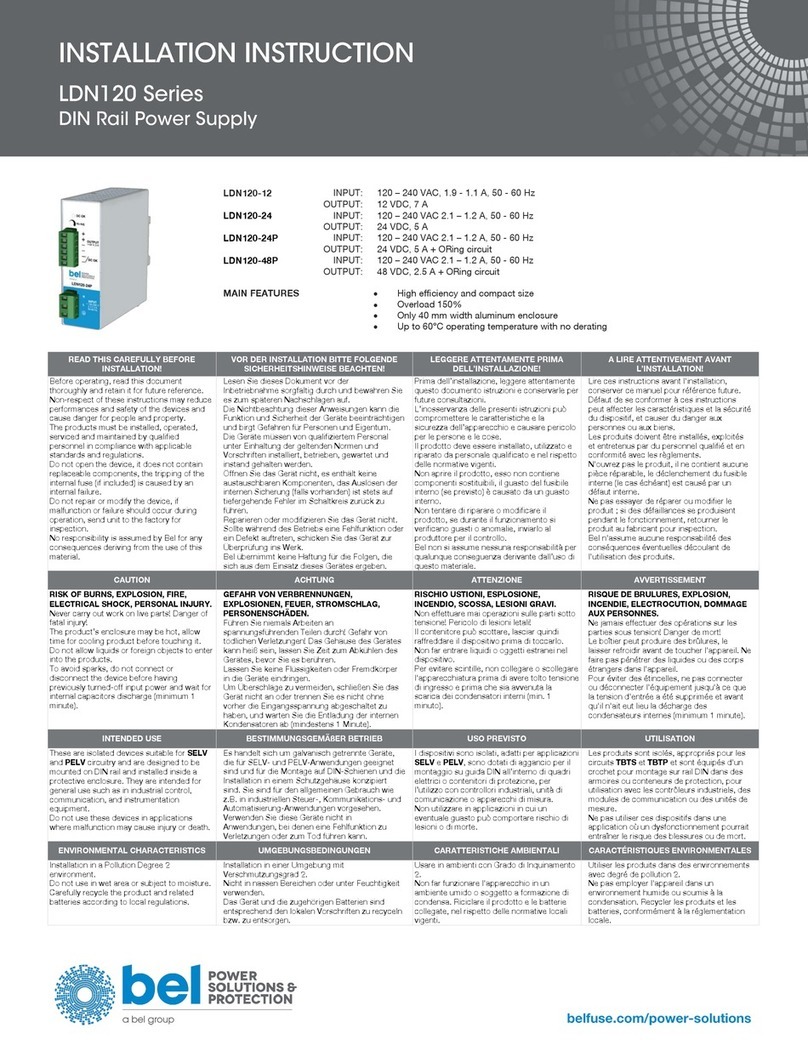

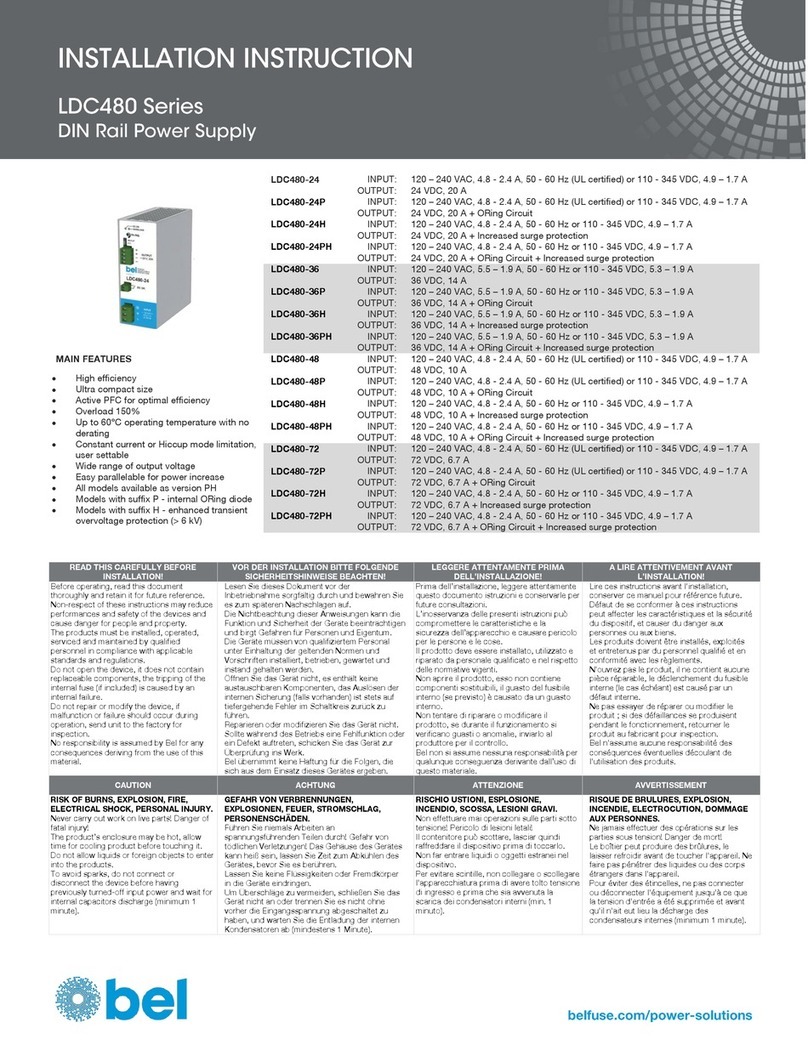

Before operating, read this document

thoroughly and retain it for future reference.

Non-respect of these instructions may reduce

performances and safety of the devices and

cause danger for people and property.

The products must be installed, operated,

serviced and maintained by qualified

personnel in compliance with applicable

standards and regulations.

Do not open the device, it does not contain

replaceable components, the tripping of the

internal fuse (if included) is caused by an

internal failure.

Do not repair or modify the device, if

malfunction or failure should occur during

operation, send unit to the factory for

inspection.

No responsibility is assumed by Bel Power

Solutions for any consequences deriving from

the use of this material.

Lesen Sie dieses Dokument vor der

Inbetriebnahme sorgfältig durch und bewahren

Sie es zum späteren Nachschlagen auf.

Die Nichtbeachtung dieser Anweisungen kann

die Funktion und Sicherheit der Geräte

beeinträchtigen und birgt Gefahren für

Personen und Eigentum.

Die Geräte müssen von qualifiziertem Personal

unter Einhaltung der geltenden Normen und

Vorschriften installiert, betrieben, gewartet und

instand gehalten werden.

Öffnen Sie das Gerät nicht, es enthält keine

austauschbaren Komponenten, das Auslösen

der internen Sicherung (falls vorhanden) ist stets

auf tiefergehende Fehler im Schaltkreis zurück

zu führen.

Reparieren oder modifizieren Sie das Gerät

nicht. Sollte während des Betriebs eine

Fehlfunktion oder ein Defekt auftreten, schicken

Sie das Gerät zur Überprüfung ins Werk.

Bel Power Solutions übernimmt keine Haftung

für die Folgen, die sich aus dem Einsatz dieses

Gerätes ergeben.

Prima dell’installazione, leggere attentamente

questo documento istruzioni e conservarle per

future consultazioni.

L’inosservanza delle presenti istruzioni può

compromettere le caratteristiche e la sicurezza

dell’apparecchio e causare pericolo per le

persone e le cose.

Il prodotto deve essere installato, utilizzato e

riparato da personale qualificato e nel rispetto

delle normative vigenti.

Non aprire il prodotto, esso non contiene

componenti sostituibili, il guasto del fusibile

interno (se previsto) è causato da un guasto

interno.

Non tentare di riparare o modificare il prodotto,

se durante il funzionamento si verificano guasti o

anomalie, inviarlo al produttore per il controllo.

Bel Power Solutions non si assume nessuna

responsabilità per qualunque conseguenza

derivante dall’uso di questo materiale.

Lire ces instructions avant l'installation,

conserver ce manuel pour référence

future.

Défaut de se conformer à ces

instructions peut affecter les

caractéristiques et la sécurité du

dispositif, et causer du danger aux

personnes ou aux biens.

Les produits doivent être installés,

exploités et entretenus par du personnel

qualifié et en conformité avec les

règlements.

N'ouvrez pas le produit, il ne contient

aucune pièce réparable, le

déclenchement du fusible interne (le cas

échéant) est causé par un défaut interne.

Ne pas essayer de réparer ou modifier le

produit ; si des défaillances se

produisent pendant le fonctionnement,

retourner le produit au fabricant pour

inspection.

Bel Power Solutions n'assume aucune

responsabilité des conséquences

éventuelles découlant de l'utilisation des

produits.

RISK OF BURNS, EXPLOSION, FIRE,

ELECTRICAL SHOCK, PERSONAL INJURY.

Never carry out work on live parts! Danger of

fatal injury!

The product’s enclosure may be hot, allow

time for cooling product before touching it.

Do not allow liquids or foreign objects to enter

into the products.

To avoid sparks, do not connect or disconnect

the device before having previously turned-off

input power and wait for internal capacitors

discharge (minimum 2 minutes).

GEFAHR VON VERBRENNUNGEN,

EXPLOSIONEN, FEUER, STROMSCHLAG,

PERSONENSCHÄDEN.

Führen Sie niemals Arbeiten an

spannungsführenden Teilen durch! Gefahr von

tödlichen Verletzungen! Das Gehäuse des

Gerätes kann heiß sein, lassen Sie Zeit zum

Abkühlen des Gerätes, bevor Sie es berühren.

Lassen Sie keine Flüssigkeiten oder

Fremdkörper in die Geräte eindringen.

Um Überschläge zu vermeiden, schließen Sie

das Gerät nicht an oder trennen Sie es nicht

ohne vorher die Eingangsspannung

abgeschaltet zu haben, und warten Sie die

Entladung der internen Kondensatoren ab

(mindestens 2 Minuten).

RISCHIO USTIONI, ESPLOSIONE, INCENDIO,

SCOSSA, LESIONI GRAVI.

Non effettuare mai operazioni sulle parti sotto

tensione! Pericolo di lesioni letali!

Il contenitore può scottare, lasciar quindi

raffreddare il dispositivo prima di toccarlo.

Non far entrare liquidi o oggetti estranei nel

dispositivo.

Per evitare scintille, non collegare o scollegare

l'apparecchiatura prima di avere tolto tensione di

ingresso e prima che sia avvenuta la scarica dei

condensatori interni (min. 2 minuti).

RISQUE DE BRULURES, EXPLOSION,

INCENDIE, ELECTROCUTION,

DOMMAGE AUX PERSONNES.

Ne jamais effectuer des opérations sur

les parties sous tension! Danger de

mort!

Le boîtier peut produire des brûlures, le

laisser refroidir avant de toucher

l'appareil. Ne faire pas pénétrer des

liquides ou des corps étrangers dans

l'appareil.

Pour éviter des étincelles, ne pas

connecter ou déconnecter l'équipement

jusqu'à ce que la tension d'entrée a été

supprimée et avant qu'il n'ait eut lieu la

décharge des condensateurs internes

(minimum 2 minutes).

BESTIMMUNGSGEMÄßER BETRIEB

These are isolated devices suitable for ES1

and ES2 circuitry and are designed to be

mounted internally within a system. They are

intended for general use such as in industrial

control, communication, medical and

instrumentation equipment.

Do not use these devices in applications

where malfunction may cause injury or death.

Please see full spec of unit for further details.

Es handelt sich um galvanisch getrennte

Geräte, die für ES1- und ES2-Anwendungen

geeignet sind und für die Montage auf DIN-

Schienen und die Installation in einem

Schutzgehäuse konzipiert sind. Sie sind für den

allgemeinen Gebrauch wie z.B. in industriellen

Steuer-, Kommunikations- und

Automatisierung-Anwendungen vorgesehen.

Verwenden Sie diese Geräte nicht in

Anwendungen, bei denen eine Fehlfunktion zu

Verletzungen oder zum Tod führen kann.

I dispositivi sono isolati, adatti per applicazioni

ES1 e ES2, sono dotati di aggancio per il

montaggio su guida DIN all’interno di quadri

elettrici o contenitori di protezione, per l’utilizzo

con controllori industriali, unità di comunicazione

o apparecchi di misura.

Non utilizzare in applicazioni in cui un eventuale

guasto può comportare rischio di lesioni o di

morte.

Les produits sont isolés, appropriés

pour les circuits ES1 et ES2 et sont

équipés d'un crochet pour montage sur

rail DIN dans des armoires ou

conteneurs de protection, pour

utilisation avec les contrôleurs

industriels, des modules de

communication ou des unités de

mesure.

Ne pas utiliser ces dispositifs dans une

application où un dysfonctionnement

pourrait entraîner le risque des blessures

ou de mort.

ENVIRONMENTAL CHARACTERISTICS

CARATTERISTICHE AMBIENTALI

CARACTÉRISTIQUES

ENVIRONMENTALES

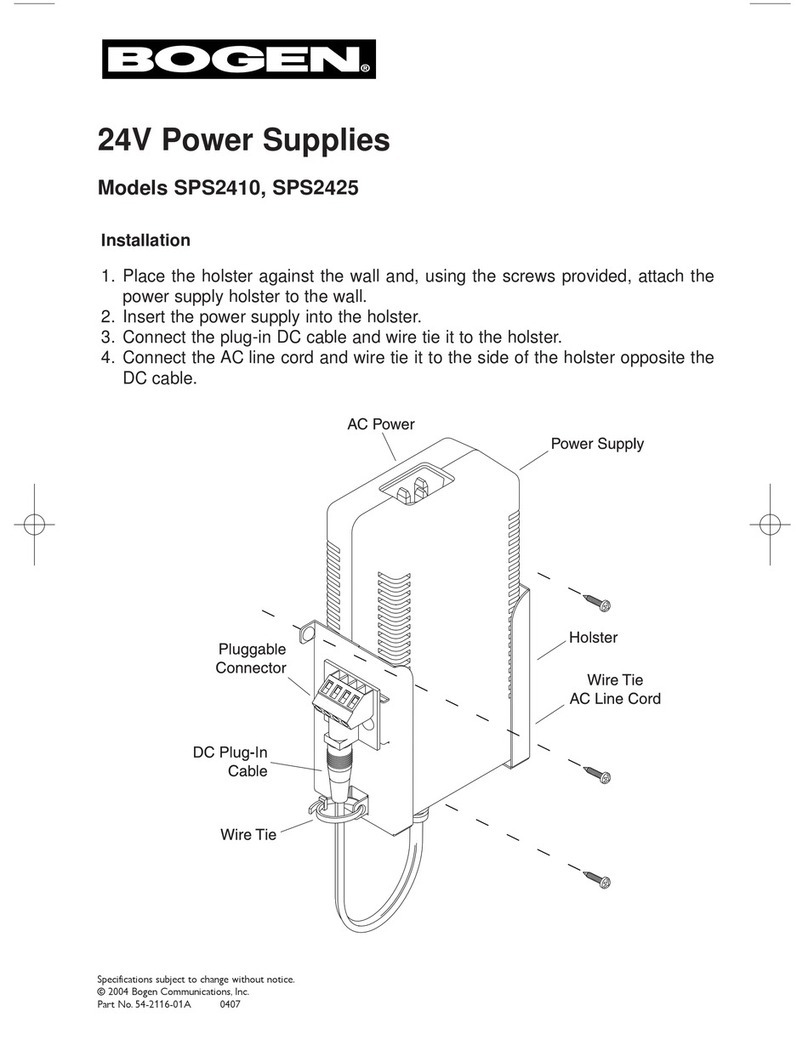

Installation in a Pollution Degree 2

environment.

Do not use in wet area or subject to moisture.

Carefully recycle the product and related

batteries according to local regulations.

Installation in einer Umgebung mit

Verschmutzungsgrad 2.

Nicht in nassen Bereichen oder unter

Feuchtigkeit verwenden.

Das Gerät und die zugehörigen Batterien sind

entsprechend den lokalen Vorschriften zu

recyceln bzw. zu entsorgen.

Usare in ambienti con Grado di Inquinamento 2.

Non far funzionare l'apparecchio in un ambiente

umido o soggetto a formazione di condensa.

Riciclare il prodotto e le batterie collegate, nel

rispetto delle normative locali vigenti.

Utiliser les produits dans des

environnements avec degré de pollution

2.

Ne pas employer l'appareil dans un

environnement humide ou soumis à la

condensation. Recycler les produits et

les batteries, conformément à la

réglementation locale.