Belanger CUBE User manual

Belanger® Equipment Owner’s Manual

Cube® Controller Programming & Operation

Copyright 2021

Belanger, Inc®

This manual and the accompanying equipment are protected by United States trademark, copyright, and patent laws. You may

make one copy of this manual. Do not make additional copies of this manual or electronically transmit it in any form whatsoever,

in whole or in part, without the prior written permission of Belanger, Inc.®

The registered trademarks used in this document are the property of their respective owners. The use of such trademarks is for

reference purposes only and does not imply sponsorship or approval of Belanger, Inc.®by these companies or any companies

affiliated with their respective owners.

CURRENT REVISION LOG

1MANUL964 Belanger, Inc. * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681

Rev

Release

Date

Page

Description

01

TBD

1-1

Updated the Warranty on Parts to 90 days

5-8

Updated Misc Screen image

Added explanation for: ENABLED –TOP INDEX ROTATE, ENABLED –SMALL BAY

MODE, and ENABLED –PUMP FAULT (per Project #10223)

6-6

Added explanation for: SIDE TOP RINSE to FRICTION = NONE (per Project #10223)

7-2

Added Saving Wheel Soap Chemical paragraph (per Project #10223)

7-4

Updated Foam Rain Typical Setup (per Project #10223)

CUBE® CONTROLLER

1MANUL964 Belanger, Inc. * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681

Table of Contents

Chapter 1 Introduction............................................................................................................... 1-1

Belanger Incorporated® Limited Warranty.................................................................................................1-1

Operational Warning..................................................................................................................................1-2

Important Safety Information......................................................................................................................1-3

Safety Symbols and Signal Words.............................................................................................................1-3

IMPORTANT Safety Information –MUST READ.......................................................................................1-4

Safety Warnings ........................................................................................................................................1-4

Chapter 2 General Machine Operation..................................................................................... 2-1

Typical Wash Structure..............................................................................................................................2-1

Entrance Features...................................................................................................................................................2-1

Wash ......................................................................................................................................................................2-1

Exit Features...........................................................................................................................................................2-1

Door Control ..............................................................................................................................................2-2

Typical Features of Wash..........................................................................................................................2-2

Non-Friction Applications ........................................................................................................................................2-2

Side Wheels............................................................................................................................................................ 2-2

Tire and Rim Cleaning ............................................................................................................................................2-2

Vehicle Flow ..............................................................................................................................................2-3

Special Considerations for Entrance Operation 1....................................................................................................2-3

Light Operation .......................................................................................................................................................2-3

Point of Sales Operation .........................................................................................................................................2-3

Chapter 3 General Methods of Using Operator Interfaces..................................................... 3-1

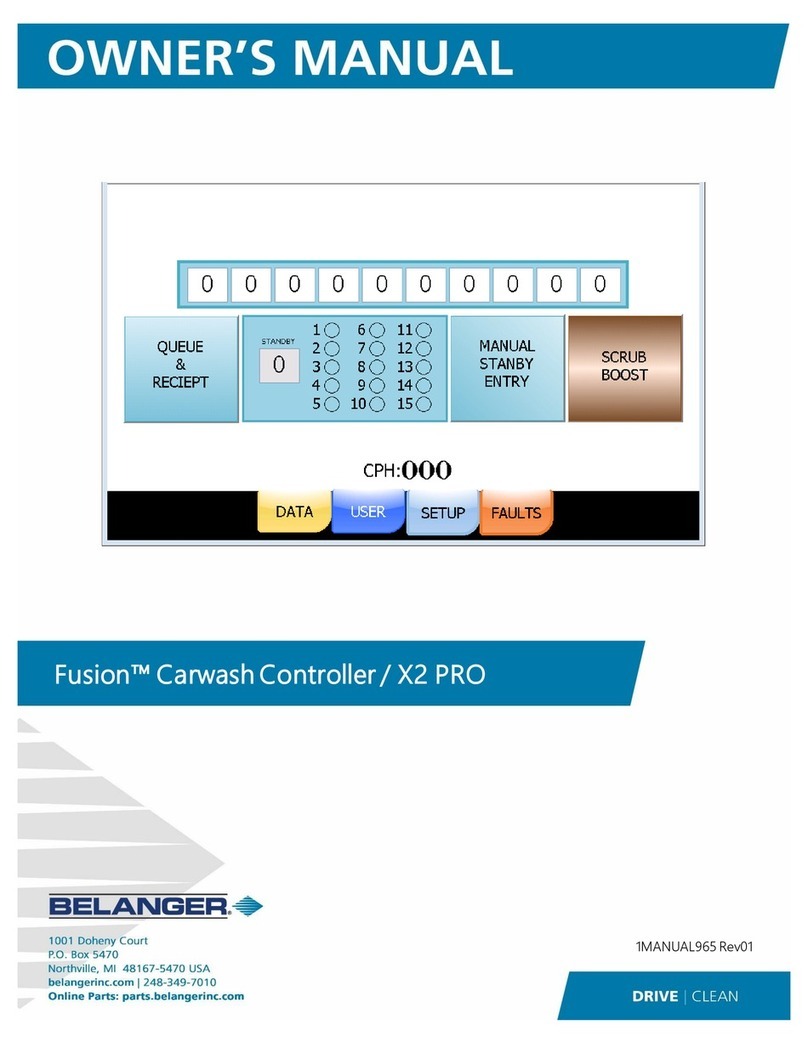

X2 PRO......................................................................................................................................................3-1

Screen Navigation...................................................................................................................................................3-1

Toggles................................................................................................................................................................... 3-1

Numeric ..................................................................................................................................................................3-1

Selections...............................................................................................................................................................3-2

Alpha/Numeric ........................................................................................................................................................3-2

Chapter 4 Operator Interface / Standard User Screens.......................................................... 4-1

Queue........................................................................................................................................................4-1

Data...........................................................................................................................................................4-2

User...........................................................................................................................................................4-3

User / Force............................................................................................................................................................4-3

User / Jog ...............................................................................................................................................................4-4

User / Monitor About............................................................................................................................................... 4-5

Faults.........................................................................................................................................................4-5

Faults / Alarms........................................................................................................................................................4-6

Faults / More (Capture)...........................................................................................................................................4-6

Chapter 5 Operator Interface / Programming.......................................................................... 5-1

Setup .........................................................................................................................................................5-1

Setup / Package 1 - 8..............................................................................................................................................5-1

Setup / Package Setup 1-8 / Package 1 Setup Screen............................................................................................5-2

Setup / Application Setup........................................................................................................................................ 5-3

Setup / Advanced Configuration.............................................................................................................................. 5-3

Setup / Entrance Operation.....................................................................................................................................5-4

Setup / Exit Operation.............................................................................................................................................5-5

Setup / Door Control ...............................................................................................................................................5-6

Setup / POS (Point of Sales)...................................................................................................................................5-7

Setup / Misc............................................................................................................................................................ 5-8

Setup / Misc / Sonar................................................................................................................................................5-9

Setup / Misc / CTA................................................................................................................................................ 5-10

Chapter 6 Operator Interface / Advanced Configuration........................................................ 6-1

Setup / Advanced Configuration................................................................................................................6-1

Advanced Configuration / Application Configuration................................................................................................6-1

Advanced Configuration / Output Naming ...............................................................................................................6-7

Advanced Configuration / Output “On With” Control ................................................................................................ 6-7

Advanced Configuration / Output “On With” Control / Pneumatic.............................................................................6-7

Advanced Configuration / Enter Wheel Setup..........................................................................................................6-8

Advanced Configuration / Top Wheel Setup............................................................................................................6-9

CUBE® CONTROLLER

1MANUL964 Belanger, Inc. * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681

Table of Contents

Chapter 7 Techniques in Programming....................................................................................7-1

Friction Passes from Exit to Entrance (Odd Pass Numbers)..................................................................... 7-1

Friction Passes from Entrance to Exit (Even Pass Numbers) ................................................................... 7-1

Techniques for Faster Cycle Time............................................................................................................. 7-2

Saving Wheel Soap Chemical................................................................................................................... 7-2

Reducing Number of Site Photo-Eyes....................................................................................................... 7-2

OverGlow™ Typical Setup ........................................................................................................................ 7-3

Foam Rain Typical Setup.......................................................................................................................... 7-4

Chapter 8 Faults and Alarms .....................................................................................................8-1

Fault Codes and Names............................................................................................................................ 8-1

Fault Summaries....................................................................................................................................... 8-2

Drive Code Overview ................................................................................................................................ 8-3

Alarms....................................................................................................................................................... 8-4

Chapter 1 Introduction

Chapter 1

Introduction

CUBE® CONTROLLER

1MANUL964 Belanger, Inc. * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1-1

Chapter 1 Introduction

Belanger Incorporated® Limited Warranty

LIMITED WARRANTY:

Equipment:

Subject to the limitations stated below, Seller warrants that the Equipment sold hereunder, which is fabricated by Seller,

shall be free from defects in workmanship and material under normal use and service for a period of 1 year plus 30 days

from the date of invoice - CATPumps will be warranted for 2 years from the date of invoice.

Parts:

Subject to the limitations stated below, Seller warrants that the Parts sold hereunder, shall be free from defects in

workmanship and material under normal use and service for a period of 90 days from the date of invoice.

Limitations on All Warranties:

The warranties contained in this Section 13 are subject to the following limitations: (1) they are void if the factory

specifications for operation and maintenance, found in original equipment manuals, and component manuals, are not

followed, or if other than factory authorized erection, alterations or modifications are made to any Parts or Equipment; (2)

defective Parts are warranted to the Purchaser only for repair or replacement through an authorized Purchaser or

Distributor of Seller, or direct with Seller for a period of 13 months from the date of invoice; however, this warranty

excludes all claims for failure resulting from normal wear and tear, improper installation, omission of factory specified

preventative maintenance, misuse, abuse, negligence, third party damages, or acts of God and Purchaser agrees to

submit to and assist Seller or its authorized Purchaser or Distributor in conducting in-warranty inspections of the Goods

including inspection of any Equipment or Parts claimed to be defective by the Purchaser; (3) the cost of providing labor

or repair to replace Equipment and Parts warranted to Purchaser will be included within the warranty only if such claim is

made within 120 days from the date of invoice and then only during normal business hours through an authorized

Purchaser or Distributor of Seller, or direct with Seller, and labor and service provided beyond the labor warranty period

shall be subject to labor charges at the rates established by the local authorized Purchaser or Distributor or direct with

Seller; (4) the warranties shall be void for all Equipment failures and premature Part wear caused by the use of corrosive

chemicals in the wash process, and the following list includes some, but not all, of the particularly corrosive chemicals

that if used in conjunction with Equipment or Parts will void the warranty: Hydrofluoric Acid, Ammonium Bi-fluoride,

Bromic Acid, Muriatic Acid,Sulfonic Acid, Phosphoric Acid, Hydrogen Cyanide, Hydrochloric Acid, Sodium Hydroxideand

Chlorinated Solvents; (5) Seller makes no warranty, express or implied, with respect to the design or operation of any

entire system, in which Seller’s Equipment or Parts sold hereunder are mere components;(6) in no event shall Seller be

liable for any incidental, special, consequential, punitive or exemplary damages resulting from the furnishing, performance

or use of any Goods or services sold pursuant hereto, whether due to a breach of contract, breach of warranty, negligence

or any other claim at law or equity. Seller shall not be liable for any damages of any kind, including, but not limited to,

loss of business; inconvenience, or property damage of any kind; nor for any damages of whatever nature resulting in

any way from the Purchaser’s selection and use of any chemicals not manufactured exclusively by Seller but used with

the purchased Equipment or Parts; or for any service not expressly provided herein related to or arising from the

Equipment or Parts sold. Seller shall not be liable for damages resulting from Purchaser’s use of any engineering

recommendations, sales representations, technical assistance, advice or data other than that information contained in

Belanger manuals; (7) all warranties, express, implied, or statutory, pertaining to the Equipment and Parts apply to the

Purchaser only; are not transferable; are fully set forth herein; and no addition to or modification thereto shall be binding

upon the Seller, unless made in writing and signed by a duly authorized employee of Seller.

No Other Warranties:

THIS LIMITED WARRANTY FOR EQUIPMENT AND PARTS IS EXPRESSLY IN LIEU OF ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED, WHETHER STATUTORY OR OTHERWISE, INCLUDING ANY

IMPLIED WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR

PURPOSE. THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR PARTICULAR

PURPOSE CONTAINED IN THE UNIFORM COMMERCIAL CODE –SALES ARE EXPRESSLY

DISCLAIMED.

Copyright ©2021 by Belanger, Inc.® All rights reserved. No part of this work may be reproduced or transmitted in any

form or by any means, electronic or mechanical, including photocopying and recording, or by any information storage or

retrieval system, except as may be expressly permitted by the 1976 Copyright Act. Belanger reserves the right to change

or modify the Belanger Inc. Limited warranty without notice.

CUBE® CONTROLLER

1-2 Belanger, Inc. * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL964

Chapter 1 Introduction

Operational Warning

Formulations containing the chemicals listed below are particularly dangerous and should not be

used even at low concentrations:

•Hydrofluoric Acid

•Ammonium Bi-fluoride

•Bromic Acid

•Muriatic Acid

•Sulfonic Acid

•Phosphoric Acid

•Hydrogen Cyanide

•Hydrochloric Acid

•Chlorinated Solvents

Belanger, Inc., does not endorse or condone the use of chemicals that are potentially dangerous

to human health, the environment or property. Belanger recognizes that it is the right and sole

decision of the end user operators of our equipment as to the type and dilution ratio of the

chemicals used in their facilities. We strongly recommend that the end user does not select

products containing any of the chemicals listed above as an ingredient in the wash solutions. The

chemicals listed above are potentially dangerous to human health, and have a detrimental,

deteriorating effect on the equipment and the facility. Be advised that a portion of, or all of your

warranty will be voided if you determine to use any of the chemicals listed above as an ingredient

in the wash solutions in conjunction with your Belanger automatic car wash equipment:

Limitation (4), of Paragraph (8), Limited Warranty, of the Belanger Terms and Conditions of

Sales describes the potential limitation of warranty due to your chemical selection:

(4) This warranty shall be void for all equipment failures and premature component wear

caused by the use of corrosive chemicals in the wash process. The following list includes

some, but not all, of the particularly corrosive chemicals that if used in conjunction with

Belanger equipment will void the warranty: Hydrofluoric Acid, Ammonium Bi-fluoride, Bromic

Acid, Muriatic Acid, Sulfonic Acid, Phosphoric Acid, Hydrogen Cyanide, Hydrochloric Acid, and

Chlorinated Solvents. The Purchaser also agrees to accept the responsibility and liability for

the selection and use of any chemicals listed above;

However, should the end user decide to use formulations containing any of the above ingredients,

the end user should institute a comprehensive training program and implement detailed

operational parameters within their organization for the proper handling and treatment of such

products to minimize the potential dangers involved. Consult your chemical supplier for assistance

in establishing operational guidelines in the use of their products. MSDS (Material Safety Data

Sheet) should be obtained from the chemical supplier before using any chemical formulation.

CUBE® CONTROLLER

1MANUL964 Belanger, Inc. * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1-3

Chapter 1 Introduction

Important Safety Information

This section introduces the hazard and safety precautions associated with installing, maintaining or servicing this product.

Before performing any task on this product, read this safety information and the applicable sections in this manual, where

additional hazards and safety precautions for your task may be found. Electrical shock could occur and cause death or serious

injury if these safe service procedures are not followed.

Safety Symbols and Signal Words

Alert Symbol

This safety alert symbol is used in this manual and on warning labels to alert you to precautions, which

must be followed to prevent potential personal safety hazards. Obey safety directives that follow this

symbol to avoid possible injury or death.

Signal Words

The signal words used in this manual and on warning labels tell you the seriousness of particular safety hazards. The

precautions that follow must be followed to prevent death, injury or damage to the equipment.

DANGER

This signal word is used to alert you to a hazard or unsafe practice which WILL RESULT IN

DEATH OR SERIOUS INJURY

This alerts you to a hazard or unsafe practice which COULD RESULT IN DEATH OR

SERIOUS INJURY

CAUTION

This signal word designates a hazard or unsafe practice, which MAY RESULT IN MINOR

INJURY

CAUTION

When used by itself, CAUTION designates a hazard or unsafe practice which MAY RESULT IN

PROPERTY OR EQUIPMENT DAMAGE

Before You Begin

Only trained or authorized individuals knowledgeable in the related procedures should install, inspect, maintain or

service this equipment.

Read the Manual

Read, understand and follow this manual and any other labels or related materials supplied with this equipment. If you

do not understand the procedure, call a Belanger, Inc. representative at 248-349-7010. It is imperative to your safety

and the safety of others to understand the procedures before beginning work.

CUBE® CONTROLLER

1-4 Belanger, Inc. * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL964

Chapter 1 Introduction

IMPORTANT Safety Information –MUST READ

Safety Warnings

DANGER

DISCONNECT MAIN POWER SUPPLY PRIOR TO

SERVICING OR MAINTAINING EQUIPMENT

Belanger recommends that all workers observe the OSHA (U.S. Department

of Labor Occupational Safety and Health Administration) Lockout / Tag out

procedure prior to performing service or maintenance on machinery and

equipment. Doing so will prevent unexpected energization, startup, or

release of hazardous energy while maintenance and servicing activities are

being performed.

BE SURE TO OBSERVE OPERATING ENVELOPE.

EQUIPMENT MAY START UNEXPECTICALLY. OVERHEAD,

ROTATING AND/OR MOVING COMPONENTS COULD

RESULT IN SERIOUS INJURY OR DEATH.

BE AWARE OF FOREIGN OBJECTS IN THE AREA

SURROUNDING A ROTATING PIECE OF EQUIPMENT.

OBJECTS MAY BECOME TANGLED WITH EQUIPMENT AND

COULD RESULT IN SERIOUS INJURY OR DEATH.

CAUTION

BE AWARE OF HAZARDS ASSOCIATED WITH

EQUIPMENT INSTALLED ON THE FLOOR

THAT MAY BE A TRIP HAZARD.

It is imperative to your safety and the safety of others to always follow safe work

procedures.

Chapter 2 General Machine Operation

Chapter 2

General Machine

Operation

CUBE® CONTROLLER

1MANUL964 Belanger, Inc. * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 2-1

Chapter 2 General Machine Operation

Typical Wash Structure

Entrance Features

The system is equipped with three Entrance Features that the vehicle receives from the time the Wash Package is

selected until soon after the vehicle arrives at the treadle position. The configuration of these features/functions is very

dynamic. Refer to Chapter 5 Operator Interface/Programming section Setup / Entrance Operation of this manual

to check if these functions are available and can accommodate your special needs. Some examples of the types of

equipment controlled by these features/functions are as follows: CTA, Undercarriage, Soap Arch, Bug Manifold, etc.

Check if equipment to meet your needs is available.

Wash

The wash begins with the Cube® Carriage at the exit of the bay when the vehicle pulls onto the treadle position. The

Carriage will traverse on the frame rails, each motion of the Carriage from (front to back) or (back to front) is considered

one pass. The machine moves back and forth over the full length of the vehicle in pass order determined by the

Package. The pass order of each Package may be changed. When all the passes are complete, the machine will

instruct the driver to pull forward. If the machine is not at the exit when the wash is finished it will move rapidly to the

exit position.

Exit Features

The system is equipped with three Exit Features. These are features/functions that the vehicle receives as it is pulling

out of the bay after wash is complete. The configuration of these functions is very dynamic. Refer to Chapter 5

Operator Interface/Programming section Setup / Exit Operation of this manual to check if these functions are

available and can accommodate your special needs. Some examples of the types of equipment controlled by these

features/functions are as follows: Dryer, Wax Arch, Spot Free Arch, etc. Check if equipment to meet your needs is

available.

Receive none or up

to 3 Entrance

Features

Wash package

selected

Get to

treadle

Position

Receive wash

Receive none or up

to 3 Exit Features

Wash package selected may

be performed in many ways.

Some typical methods are as

follows:

•POS (Point of Sales)

•Push Buttons

•Fleet Loader Photo-Eye

The three entrance features can

be turned on or off with many

combinations of the following:

•Wash Package Selected

•Make or break beam of up to

3 Photo-Eyes

•Max Time

•Treadle Position

The three exit features can

be turned on or off with

many combinations of the

following:

•Wash End

•Make or break beam

of up to 2 Photo-Eyes

•Any point in wash

•Max Time

•Treadle

Wash can be configured by

selecting pass order of pre-

defined applications such as:

Soap, Rinse, Drying Agent,

Sealer Wax, etc.

The system has 12 different

user-defined applications.

CUBE® CONTROLLER

2-2 Belanger, Inc. * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL964

Chapter 2 General Machine Operation

Door Control

The system has two means of controlling the doors. 1st is the built-in door controls; 2nd is to program one Entrance

Function and one Exit Function as Door Up Outputs. If the Enter / Exit Functions are programmed as UP commands,

an external door control system is responsible for closing the doors. If Built-In Door Controls are used, they can open

and close the doors. Built-In door controls can open wash in the morning and close it at night. It can also open the

doors during warm temperature and cycle them in cold temperature. When Built-In Door Control is utilized the door

control Photo-Eyes may also be used for any other wash feature that requires a Photo-Eye. Equipment locations

should be considered when using a single Photo-Eye for multiple purposes.

Typical Features of Wash

Non-Friction Applications

These are applications such as Soap, Spot Free, Triple Foam, Drying Agent, etc. these applications will typically turn

on, wait for Fill Time and finally move Carriage full travel. The Carriage speed will change for front, middle and back

as configured per that package. The positions of the speed changes can be modified via the Advanced Configuration

screens. If the Smart Spray (PIVOT) is active, the carriage will travel further back to apply the chemical solution spray

to the back center of the vehicle.

Top Wheel

From Front –If application started at the front of the vehicle the Top Wheel will turn on and lower as soon as the

application has started. It will remain on for the entire length of the vehicle unless the vehicle is a pick-up truck. When

the Top Wheel is on, the Carriage will travel further backward than normal to ensure that the Top Wheel covers the

entire top surface. The system will turn the Top Wheel off at the back of a cab if the vehicle is detected as a pickup-

truck.

From Back –If application started at the back of the vehicle the Top Wheel will be omitted. It will be omitted even if

the application has the Top Wheel Function on.

Side Wheels

From Front –The Side Wheels will turn on and move in front of the vehicle. The D/S wheel will begin to wash the

front of the vehicle first. Once the D/S wheel is far enough out of the way, the P/S wheel will begin to wash the front

of the vehicle. When both wheels are done the carriage will begin to move backward with the wheels washing the

sides of the vehicle. The Side Wheels will angle, lower end inbound, for better rocker panel cleaning near the mirror

position. The pass will complete with the wheels angled in this position.

From Back –The Side Wheels will turn on and the P/S wheel will move behind vehicle and begin to clean it. Once

the P/S wheel is far enough out of the way the D/S wheel will begin to clean the back of vehicle. If the vehicle is a SUV

the D/S wheel will pivot to clean the upper glass as it returns to the driver side. If the vehicle is not an SUV the D/S

wheel will simply move rapidly back to the driver side. After cleaning the back of the vehicle, the carriage will move

forward with wheels cleaning the side surfaces. Once in the position where the back windshield raises for cab

(occupant compartment), the wheels will angle, lower end outbound, for better upper surface cleaning. After the wheels

are angled with the lower end outbound the carriage will move forward until the wheels are near the rearview mirrors.

At the mirrors the wheels will rapidly move outward and turn off then the carriage will rapidly move toward home.

Tire and Rim Cleaning

The Cube® machine utilizes touch-less technology to clean tires and rims. The machine uses the vehicle profile to

approximate the wheel positions. Tire wash applications are not performed during the first pass because the vehicle

shape is still being evaluated. Generally, the CTA is applied on an earlier pass than the high-pressure wash application

though. If possible, utilize the CTA and high-pressure on non-friction passes.

CUBE® CONTROLLER

1MANUL964 Belanger, Inc. * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 2-3

Chapter 2 General Machine Operation

Vehicle Flow

Special Considerations for Entrance Operation 1

Entrance Operation “ON” status MUST be programmed for wash to operate. This is true even if none of the

Packages utilize it. The ON conditions of Entrance Operation 1 determines when the Package is shifted from Loader

to the Wash. If not configured, the vehicles Package will never be loaded into the wash.

Note: If Enter features utilized (Entrance Operations 1 –3), Entrance Operation 1 must be the

first feature encountered by the vehicle.

Light Operation

Enter Slow (DRIVE FORWARD) Lamp

This lamp will turn on when a Package is entered into the Loader (POS has sent the package selection). It will

remain on until the vehicle pulls on to the treadle position. Once on the treadle position the Entrance Slow lamp

will turn off and the Entrance Stop (WAIT) lamp will turn on.

Enter Stop (WAIT) Lamp

This lamp will turn on if the wash cycle is in progress, if the vehicle just finished wash cycle and is being evaluated

for leaving the bay (vehicle exchange active), or if the machine is Homing the Carriage.

Exit Stop Lamp

This lamp will turn on when the vehicle is in the treadle position and the wash cycle is active.

Exit Drive Forward Lamp

This lamp will be latched on as soon as the vehicle enters the bay (Wash Package shifted from Loader to Wash).

It will remain latched on until the vehicle is in treadle position. It will come on again when the vehicle is being

evaluated for leaving the bay (Vehicle Exchange active).

Exit Back Up Lamp

This lamp will turn on if vehicle pulls forward of treadle position during cycle.

Point of Sales Operation

Input Operation

The system is equipped with four inputs that a POS may utilize to select a wash package (insert package into

Loader). These inputs can be used in direct or binary mode. Most commercial POS systems unitize the direct

mode. In direct mode, each of the four inputs inserts a different package into the Loader. Each of the inputs can

be toggled to run one of two Packages. The Packages for the direct inputs are: (Input X13 is Package 1 or 5),

(Input X14 is Package 2 or 6), (Input X15 is package 3 or 7) and (Input X16 is Package 4 or 8). If the system is in

binary mode, each input is given a value. When one or multiple inputs come on at the same time, the sum of the

value associated with each input is added up and the total is the Package number inserted into the Loader.

Output Operation

The system is equipped with an output that signals the POS in one of two different methods. These methods are:

(Wash In Use) and (Wash Done). If Wash In Use is selected, the output will typically turn on when the vehicle

enters the bay (Wash Package shifted from Loader to wash), and then turns off when that vehicle is no longer

being evaluated for leaving the bay (Vehicle Exchange active). If the Wash Done is selected, the Output will be on

most of the time, it will turn off for two seconds as soon as the wash cycle is done.

Other manuals for CUBE

1

Table of contents

Other Belanger Controllers manuals

Popular Controllers manuals by other brands

Halma

Halma ALICAT SCIENTIFIC PCD operating manual

Cypress

Cypress PowerPSoC CY3268 quick start guide

Drip Drop

Drip Drop PC-2000-W user manual

AvL Technologies

AvL Technologies AAQ Maintenance Server Setup & operation guide

ASTRO

ASTRO U100-C operating instructions

Rosenberg

Rosenberg D805 Hand Operating instruction

Extron electronics

Extron electronics HD CTL 100 Setup guide

Swagelok

Swagelok KPR Series Maintenance instructions

Norac

Norac UC4+ SPRACOUPE 4000 Series installation manual

Airwell

Airwell CCM30/BKE-A Installation & owner's manual

Apollo Seiko

Apollo Seiko OMEGA instruction manual

Mitsubishi Electric

Mitsubishi Electric MELSEC iQ-F Series Programming manual