Belanger Fusion X2 PRO User manual

Belanger® Equipment Owner’s Manual

Fusion™ Carwash Controller / X2 PRO

Copyright 2020

Belanger, Inc®

This manual and the accompanying equipment are protected by United States trademark, copyright, and patent laws. You may

make one copy of this manual. Do not make additional copies of this manual or electronically transmit it in any form whatsoever,

in whole or in part, without the prior written permission of Belanger, Inc.®

The registered trademarks used in this document are the property of their respective owners. The use of such trademarks is for

reference purposes only and does not imply sponsorship orapproval of Belanger, Inc.®by these companies or any companies

affiliated with their respective owners.

CURRENT REVISION LOG

Rev

Release

Date

Page

Description

01

02/01/2021

7-2

Added LOW AIR tothe Fault and Alarms Table

Reordered the Fault Codes Table inorder of thefault number

FUSION™CARWASH CONTROLLER

Belanger,Inc.* PO BOX 5470 * Northville,MI48167-5470 *Ph (248)349-7010 * Fax(248)380-9681

Table of Contents

Chapter 1 Introduction.......................................................................................................1-1

Belanger Incorporated® Limited Warranty......................................................................................................1-1

Operational Warning.........................................................................................................................................1-2

Important Safety Information............................................................................................................................1-3

Safety Symbols and Signal Words ..................................................................................................................1-3

IMPORTANT Safety Information –MUST READ ...........................................................................................1-4

Safety Warnings................................................................................................................................................1-4

Chapter 2 System Overview...............................................................................................2-1

Fusion™ Controller ...........................................................................................................................................2-1

Point of Sales (POS) Connections...................................................................................................................2-1

X2 PRO Overview.............................................................................................................................................2-2

Example of Usable Printer or Equivalent Printer Specifications ....................................................................2-4

Printer Setup RS-232 .......................................................................................................................................2-4

Chapter 3 General Methods of Using Operator Interfaces .................................................3-1

X2 PRO .............................................................................................................................................................3-1

Chapter 4 Operator Interface/Standard Wash Operation Screens......................................4-1

Queue................................................................................................................................................................4-1

Queue & Receipt .................................................................................................................................................................................................... 4-1

Queue / More Queue ............................................................................................................................................................................................. 4-2

Data...................................................................................................................................................................4-3

Data / Daily ............................................................................................................................................................................................................. 4-4

Data / Daily / Weekly .............................................................................................................................................................................................. 4-4

User ...................................................................................................................................................................4-5

User / Clear Wash .................................................................................................................................................................................................. 4-5

User / Wet Down .................................................................................................................................................................................................... 4-5

User / Force Outputs .............................................................................................................................................................................................. 4-5

User / Force Functions........................................................................................................................................................................................... 4-6

User / Force VFD ................................................................................................................................................................................................... 4-6

User / Force RGB................................................................................................................................................................................................... 4-6

User / Input Bypass ................................................................................................................................................................................................ 4-7

User / Power Up Choice......................................................................................................................................................................................... 4-9

User / Monitor Inputs .............................................................................................................................................................................................. 4-9

User / About ......................................................................................................................................................................................................... 4-10

Faults...............................................................................................................................................................4-10

Chapter 5 Operator Interface/Wash Setup Screens............................................................5-1

Setup .................................................................................................................................................................5-1

Setup / Packages ................................................................................................................................................................................................... 5-1

Setup / Options....................................................................................................................................................................................................... 5-2

Setup / Dynamic Functions/Select ......................................................................................................................................................................... 5-3

Setup / Basic Functions ......................................................................................................................................................................................... 5-7

Setup / Loading ...................................................................................................................................................................................................... 5-8

Setup / Bay Wet Down ......................................................................................................................................................................................... 5-11

Setup / POS (Point of Sales) ............................................................................................................................................................................... 5-12

Setup / Misc.......................................................................................................................................................................................................... 5-14

Setup / More......................................................................................................................................................................................................... 5-16

Chapter 6 Techniques in Wash Setup................................................................................6-1

Additional Information.......................................................................................................................................6-1

Recommended Initial Settings .........................................................................................................................6-2

Chapter 7 Faults and Alarms.............................................................................................7-1

Faults.................................................................................................................................................................7-1

Chapter 1 Introduction

Chapter 1

Introduction

FUSION™CARWASH CONTROLLER

1MANUL965 Belanger,Inc.* PO BOX 5470 * Northville,MI48167-5470* Ph(248) 349-7010 * Fax(248) 380-9681 1-1

Chapter 1 Introduction

Belanger Incorporated® LimitedWarranty

LIMITED WARRANTY:

Equipment:

Subject to the limitations stated below, Seller warrants that the Equipment sold hereunder, which is fabricated by Seller,

shall be free fromdefects in workmanship and material under normal use and service for a period of 1 year plus 30 days

fromthe date of invoice - CATPumps will be warranted for 2 years from the date of invoice.

Parts:

Subject to the limitations stated below, Seller warrants that the Parts sold hereunder, shall be free from defects in

workmanship and material under normal use and service for aperiod of 30 days fromthe date of invoice.

Limitations on All Warranties:

The warranties contained in this Section 13 are subject to the following limitations: (1) they are void if the factory

specifications for operation and maintenance, found in original equipment manuals, and component manuals, are not

followed, or if other than factory authorized erection, alterations or modifications are made to any Parts or Equipment; (2)

defective Parts are warranted to the Purchaser only for repair or replacement through an authorized Purchaser or

Distributor of Seller, or direct with Seller for a period of 13 months from the date of invoice; however, this warranty

excludes all claims for failure resulting from normal wear and tear, improper installation, omission of factory specified

preventative maintenance, misuse, abuse, negligence, third party damages, or acts of God and Purchaser agrees to

submit to and assist Seller or its authorized Purchaser or Distributor in conducting in-warranty inspections of the Goods

including inspection of any Equipment or Parts claimed to be defective by the Purchaser; (3) the cost of providing labor

or repair to replace Equipment and Parts warranted to Purchaser will be included within the warranty only if such claim is

made within 120 days from the date of invoice and then only during normal business hours through an authorized

Purchaser or Distributor of Seller, or direct with Seller, and labor and service provided beyond the labor warranty period

shall be subject to labor charges at the rates established by the local authorized Purchaser or Distributor or direct with

Seller; (4) the warranties shall be void for all Equipment failures and premature Part wear caused by the use of corrosive

chemicals in the wash process, and the following list includes some, but not all, of the particularly corrosive chemicals

that if used in conjunction with Equipment or Parts will void the warranty: Hydrofluoric Acid, Ammonium Bi-fluoride,

Bromic Acid, Muriatic Acid, SulfonicAcid, Phosphoric Acid, Hydrogen Cyanide, Hydrochloric Acid, Sodium Hydroxide and

Chlorinated Solvents; (5) Seller makes no warranty, express or implied, with respect to the design or operation of any

entire system, in which Seller’s Equipment or Parts sold hereunder are mere components;(6) in no event shall Seller be

liable forany incidental, special, consequential, punitive orexemplary damages resulting fromthe furnishing,performance

or use of any Goods orservices sold pursuant hereto,whether dueto a breach of contract, breach of warranty, negligence

or any other claim at law or equity. Seller shall not be liable for any damages of any kind, including, but not limited to,

loss of business; inconvenience, or property damage of any kind; nor for any damages of whatever nature resulting in

any way from the Purchaser’s selection and use of any chemicals not manufactured exclusively by Seller but used with

the purchased Equipment or Parts; or for any service not expressly provided herein related to or arising from the

Equipment or Parts sold. Seller shall not be liable for damages resulting from Purchaser’s use of any engineering

recommendations, sales representations, technical assistance, advice or data other than that information contained in

Belanger manuals; (7) all warranties, express, implied, or statutory, pertaining to the Equipment and Parts apply to the

Purchaser only; are not transferable; are fully set forth herein; and no addition to or modification thereto shall be binding

upon the Seller, unless made in writing and signed by a duly authorized employee of Seller.

No Other Warranties:

THIS LIMITED WARRANTY FOR EQUIPMENT AND PARTSIS EXPRESSLY IN LIEU OF ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED, WHETHER STATUTORY OR OTHERWISE, INCLUDING ANY

IMPLIED WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR

PURPOSE. THE IMPLIED WARRANTIESOF MERCHANTABILITY AND FITNESS FOR PARTICULAR

PURPOSE CONTAINED IN THE UNIFORM COMMERCIAL CODE –SALES ARE EXPRESSLY

DISCLAIMED.

Copyright ©2013 by Belanger, Inc.® All rights reserved. No part of this work may be reproduced or transmitted in any

formor by any means, electronic or mechanical, including photocopying and recording, or by any information storage or

retrieval system, except as may be expressly permitted by the 1976 Copyright Act. Belanger reserves the right to change

or modify the Belanger Inc. Limited warranty without notice.

FUSION™CARWASH CONTROLLER

1MANUL965 Belanger,Inc.* PO BOX 5470 * Northville,MI48167-5470* Ph(248) 349-7010 * Fax(248) 380-9681 1-2

Chapter 1 Introduction

Operational Warning

Formulations containingthechemicals listedbelow are particularly dangerous and should not be

used even at low concentrations:

•Hydrofluoric Acid

•Ammonium Bi-fluoride

•Bromic Acid

•Muriatic Acid

•Sulfonic Acid

•Phosphoric Acid

•Hydrogen Cyanide

•Hydrochloric Acid

•Chlorinated Solvents

Belanger, Inc., does not endorse or condone the use of chemicalsthat are potentially dangerous

to human health, the environment or property. Belanger recognizes that it is the right and sole

decision of the end user operators of our equipment as to the type and dilution ratio of the

chemicals used in their facilities. We strongly recommend that the end user does not select

products containing any of thechemicalslistedabove as an ingredientin thewashsolutions. The

chemicals listed above are potentially dangerous to human health, and have a detrimental,

deteriorating effect on the equipment and the facility. Beadvised that a portion of, or all of your

warranty will be voided if youdetermine to use any of thechemicals listedabove as an ingredient

in thewash solutions in conjunctionwith your Belanger automatic car wash equipment:

Limitation (4), of Paragraph (8), Limited Warranty, of the Belanger Terms and Conditions of

Sales describes the potential limitationof warranty due to your chemicalselection:

(4) This warranty shall be void for all equipment failures and premature component wear

caused by the use of corrosive chemicals in the wash process. The following list includes

some, but not all, of the particularly corrosive chemicals that if used in conjunction with

Belanger equipment will void the warranty: Hydrofluoric Acid, Ammonium Bi-fluoride, Bromic

Acid,Muriatic Acid,Sulfonic Acid,Phosphoric Acid, HydrogenCyanide, Hydrochloric Acid,and

Chlorinated Solvents. ThePurchaser also agrees to accept the responsibility and liability for

the selectionand use of any chemicalslistedabove;

However, shouldtheend user decideto use formulationscontainingany of the above ingredients,

the end user should institute a comprehensive training program and implement detailed

operational parameters within their organization for the proper handling and treatment of such

products tominimizethepotential dangersinvolved. Consultyourchemicalsupplierforassistance

in establishing operational guidelines in the use of their products. MSDS (Material Safety Data

Sheet) shouldbe obtained from the chemicalsupplier before using any chemicalformulation.

FUSION™CARWASH CONTROLLER

1MANUL965 Belanger,Inc.* PO BOX 5470 * Northville,MI48167-5470 *Ph (248)349-7010* Fax (248)380-9681 1-3

Chapter 1 Introduction

Important Safety Information

This section introduces the hazard and safety precautions associated with installing, maintaining or servicing this product.

Before performing any task on this product, read this safety information and the applicable sections in this manual, where

additional hazards and safety precautions for yourtask may be found. Electrical shock could occur and cause deathor serious

injury if these safe service procedures are not followed.

Safety Symbols and Signal Words

Alert Symbol

This safety alert symbol isused in this manual and on warning labels to alert you to precautions, which

must be followed to prevent potential personal safety hazards. Obey safety directives that follow this

symbol to avoid possible injury or death.

Signal Words

The signal words used in this manual and on warning labels tell you the seriousness of particular safety hazards. The

precautions that follow must be followed to prevent death, injury or damage to the equipment.

DANGER

This signal wordis usedto alert youto a hazardor unsafe practice which WILLRESULT IN

DEATH OR SERIOUS INJURY

This alerts youto a hazardor unsafe practicewhich COULDRESULT IN DEATH OR

SERIOUS INJURY

CAUTION

This signal worddesignates a hazardor unsafe practice,which MAYRESULT IN MINOR

INJURY

CAUTION

When usedby itself,CAUTIONdesignates a hazardor unsafe practicewhich MAYRESULT IN

PROPERTY OR EQUIPMENT DAMAGE

Before You Begin

Only trained or authorized individuals knowledgeable in the related procedures should install, inspect, maintain or

service this equipment.

Read the Manual

Read, understand and follow this manual and any other labels or related materials supplied with this equipment. If you

do not understand the procedure, call a Belanger, Inc. representative at 248-349-7010. It is imperative to your safety

and the safety of others to understand the procedures before beginning work.

FUSION™CARWASH CONTROLLER

1MANUL965 Belanger,Inc.* PO BOX 5470 * Northville,MI48167-5470* Ph(248) 349-7010 * Fax(248) 380-9681 1-4

Chapter 1 Introduction

IMPORTANT Safety Information –MUST READ

Safety Warnings

DANGER

DISCONNECT MAIN POWER SUPPLY PRIOR TO

SERVICING OR MAINTAINING EQUIPMENT

Belanger recommends that all workers observe the OSHA (U.S. Department

of Labor Occupational Safety and Health Administration) Lockout / Tag out

procedure prior to performing service or maintenance on machinery and

equipment. Doing so will prevent unexpected energization, startup, or

release of hazardous energy while maintenance and servicing activities are

being performed.

BE SURE TO OBSERVE OPERATING ENVELOPE.

EQUIPMENT MAY START UNEXPECTICALLY. OVERHEAD,

ROTATING AND/OR MOVING COMPONENTS COULD

RESULT IN SERIOUS INJURY OR DEATH.

BE AWARE OF FOREIGN OBJECTS IN THE AREA

SURROUNDING A ROTATING PIECE OF EQUIPMENT.

OBJECTS MAY BECOME TANGLED WITH EQUIPMENT AND

COULD RESULT IN SERIOUS INJURY OR DEATH.

CAUTION

BE AWARE OF HAZARDS ASSOCIATED WITH

EQUIPMENT INSTALLED ON THE FLOOR

THAT MAY BE A TRIP HAZARD.

It is imperative to your safety and the safety of others to always follow safe work

procedures.

Chapter 2 System Overview

Chapter 2

System Overview

FUSION™CARWASH CONTROLLER

1MANUL965 Belanger,Inc.* PO BOX5470 * Northville,MI 48167-5470*Ph(248)349-7010* Fax(248)380-9681 2-1

Chapter 2 System Overview

Fusion™Controller

This system is made up of the Fusion™(Controller), X2 PRO (User Interface) and the Operator Station (for Attended Sites).

The system can be purchased with one or two light controllers. The system allows the user to set up 15 packages and 15

options. The options can select/deselect functions of the user-selected packages. Options cannot run as stand-alone

washes without first selecting a package. Package and options can be selected froma variety of different operator/customer

interfaces. The possible interfaces include the Belanger 15-15 Operator Station, any push-button or contact closures, and

a variety of aftermarket point of sale terminals with contact closures for wash selection. The point of Sales can operate

direct selection of packages, binary selection of packages or pulsed count selection of packages.

When utilized with light controllers, LED lights can be used for active site marketing and PACKAGE CONFIRMATION™

and feature confirmation. PACKAGE CONFIRMATION™is when each package has its own associated color. Feature

confirmation is when color is not activated unless feature selected for that package. Flash forward will turn on all power

supplies forward of vehicle up until back bumper of previous vehicle. Flash forward will also leave LED light color trail until

another vehicle load after it.

Point of Sales (POS) Connections

The Belanger® Fusion™System is designed to work with most POS systems on the market today. The following

information will explain the basic connections required to work with most systems.

These instructions should make it clear which typical inputs and outputs are available to the field for the POS installation.

Following that, the responsibility is on the installers to be able to integrate our product with a third-party POS.

Review the SETUP/POS screen for alternative methods and additional information.

Note 1:

See your supplied 3rd Party POS manual for Wash-In-Use coil voltage. Connection to PIN 11 of the WASH IN USE

Relay may need to be changed.

3rd Party POS

Belanger® Fusion™

728: Wash-In-Use Signal

338 (0VDC)

(See Note 1)

338: (0VDC)

X10: Package Select 1

X11: Package Select 2

X12: Package Select 3

X13: Package Select 4

A1

A2

(See Note 1)

Wash 1

Wash 2

Wash 3

Wash 4

These inputs

may also be

utilized in

BINARY to get

15 packages

FUSION™CARWASH CONTROLLER

2-2 Belanger,Inc.* PO BOX 5470 *Northville,MI48167-5470 *Ph(248)349-7010* Fax (248)380-9681 1MANUL965

Chapter 2 System Overview

X2 PRO Overview

Thefollowingwill giveabriefexplanation of thefunctionality of the 4 Function Keys fortheMAIN screen

ONLY. Theywill be covered in more detail later in this document.

Pressingthecorrespondingfunction keys will shiftscreen to desired locations.

Thefunction keys change for all other screens.

QUEUE: This section allows editing Queue and Printing receipts.

DATA: This section allows viewing, emailing, and printing of Shift, Daily and Weekly

reports.

USER: This section contains all the operations necessary for the user to operate the

wash. See below.

•Clear Wash –Provides the ability to clear the entire wash

•Bay Wet Down –initiates a Bay Wet Down

•Monitor Inputs –displays current status of all inputs.

•Power Up (E-Stop) Choice –Lets the Operator change or accept wash status after E-Stop /

Power Up

•Force Function –Manually turns on and monitors functions

•Force VFD –Manually turns on and monitors VFD’s

•Force Outputs –Manually turns on and monitors outputs

•Force RGB –Manually turns on and monitors LED lights

•About –displays software version currently running

•Input Bypass –allows user to temporarily bypass Inputs

Screen Key:

•For standard Attended operation, use the separate Operator Station

to enter Packages and options into the Queue. This screen can

provide visual feedback

•The ESTOP is only displayed when the system is in the “ESTOP”

condition

•The display box shows the currently selected stand-by Package. If

any Options are associated with a selected Package, the

corresponding oval will be filled

•The long rectangular box displays the 10 washes in the Queue

FUSION™CARWASH CONTROLLER

1MANUL965 Belanger,Inc.* PO BOX5470 * Northville,MI 48167-5470*Ph(248)349-7010* Fax(248)380-9681 2-3

Chapter 2 System Overview

X2 PRO Overview

SETUP1: The Setup screen is used to program the system to your desired operation. The setup area has

many functions that will be explained in detail later in this manual. These functions include:

•Options –Function select or de-select for option upgrades

•POS (Point of Sales) –Package/Option and Accept input configuration

•Packages –Functions forpackage offering

•Misc. –Miscellaneous data configuration

•Loading –Configuration of vehicle loading and Dollie tasking

•Bay Wet Down –Set up for functions to be enabled during wet-down

•Basic Functions –Configuration of simple output functions

•Dynamic Functions –Configuration of dynamic Output, LED, VFD functions.

SETUP2: The Setup screen is used to program the system to your desired operation. The setup area has

many functions that will be explained in detail later in this manual. These functions include:

•Options –Function select or de-select for option upgrades

•Input Naming –user naming of inputs

•Output Naming –user naming of outputs

•Fault Naming –user naming of faults

•Function Naming –user naming of functions

•Supply Naming –user naming of power supplies

•Water/Chem Savings –Configuration of some output’s duty cycle

•Scrub Boost –Configuration of slower conveyor speed area.

•VFD Operations –setup of VFD’s and gearbox ratios.

•Input Select –assign inputs to specific functions

•Prep Jet –setup Prep Jet System™, choose output

•Horn –setup horn, choose output

•With Conveyor –choose outputs on with conveyor

•Enter Wind Door –setup Wind Door, choose output

FAULT: Here you can view and reset current fault status. You can also view the fault history by pressing

the Alarm key.

FUSION™CARWASH CONTROLLER

2-4 Belanger,Inc.* PO BOX 5470 *Northville,MI48167-5470 *Ph(248)349-7010* Fax (248)380-9681 1MANUL965

Chapter 2 System Overview

Example of Usable Printer or Equivalent Printer Specifications

Brand: Epson

Model: C31CA85084

If your cabledoes not work, try a null modem 9-pin adapter.

Printer Setup RS-232

Page Length

60

Hand Shake

XON / XOFF

New Line Character

CR / CF

Baud Rate

9600

Parity

None

Data Bits

8

Stop Bits

1

Chapter 3 General Methods of Using Operator Interfaces

Chapter 3

General Methods of

Using Operator

Interfaces

Table of contents

Other Belanger Controllers manuals

Popular Controllers manuals by other brands

Mitsubishi Electric

Mitsubishi Electric Melservo JE Series instruction manual

Emerson

Emerson Unidrive HS30 quick start guide

RadioLink

RadioLink BYME-D instruction manual

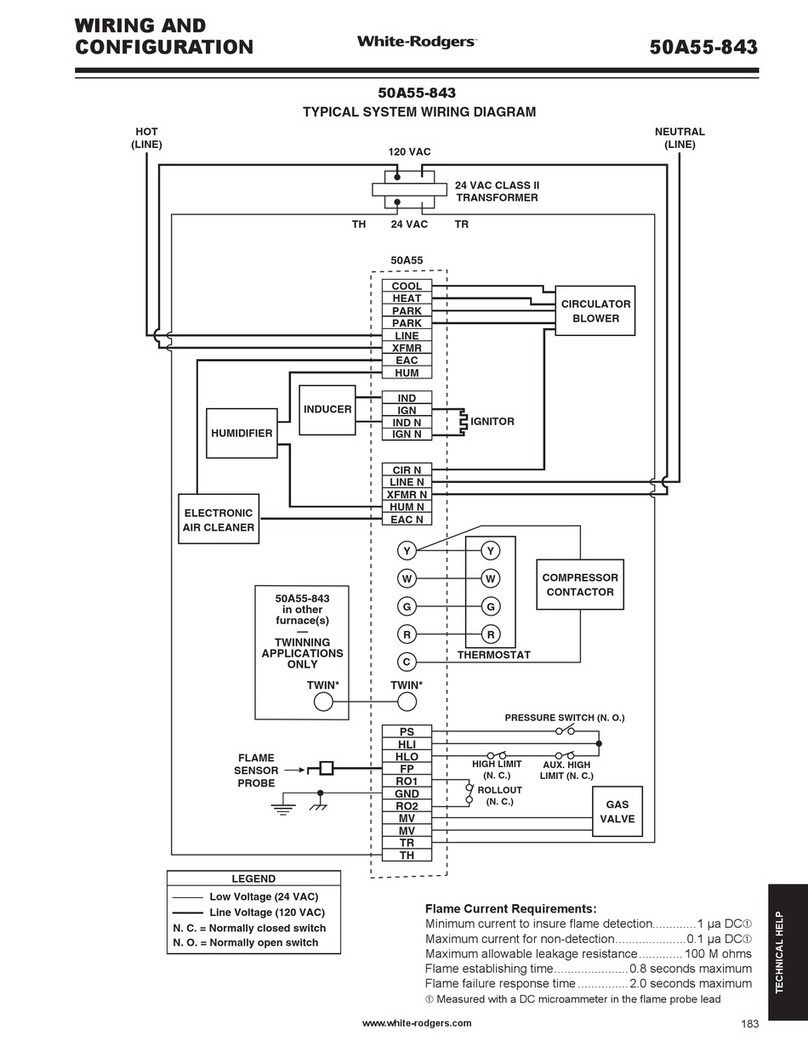

White Rogers

White Rogers 50A55-843 Wiring And Configuration Guide

parr

parr 4857 Operating instructions manual

Freefly

Freefly M?VI Controller user guide

Siemens

Siemens SIRIUS 3RW30 operating instructions

Extron electronics

Extron electronics MLC 60 Series user guide

Notifier

Notifier FTM-1 Installation and maintenance instructions

Xilica Audio Design

Xilica Audio Design Mini Series quick start guide

Lambario

Lambario LAMBARIO-RF-SMARTLINE-RGB user manual

EWIKON

EWIKON motion CONTROL SD operating manual