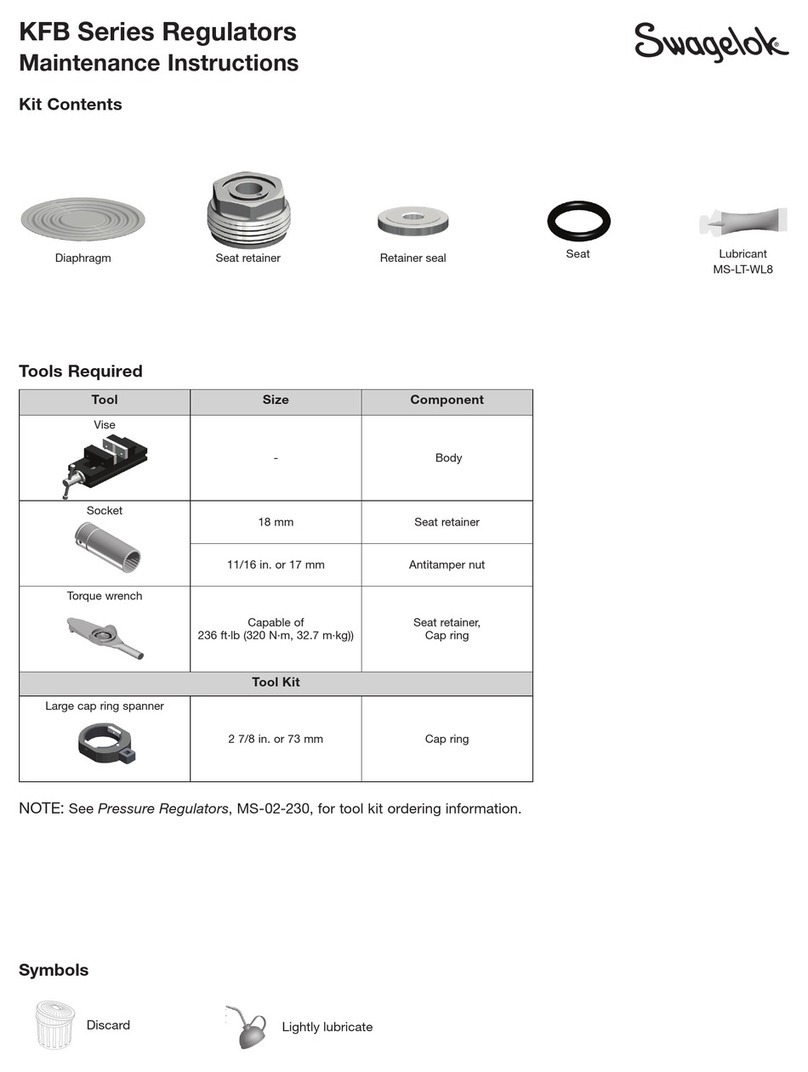

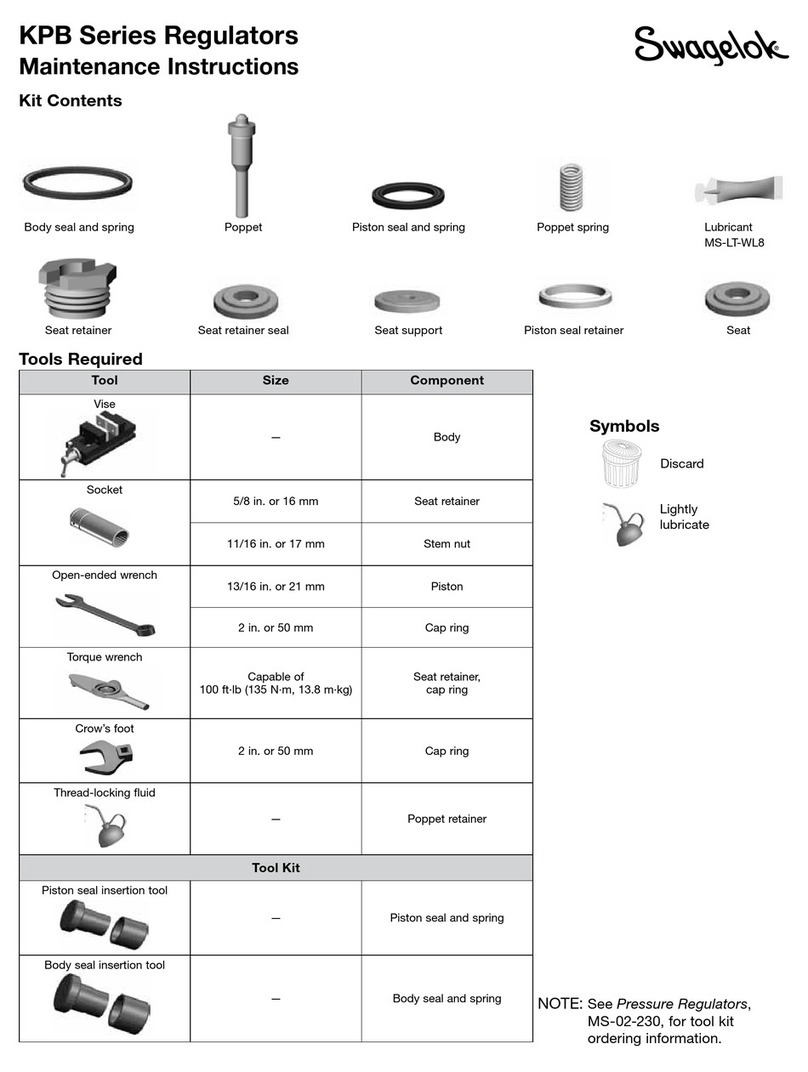

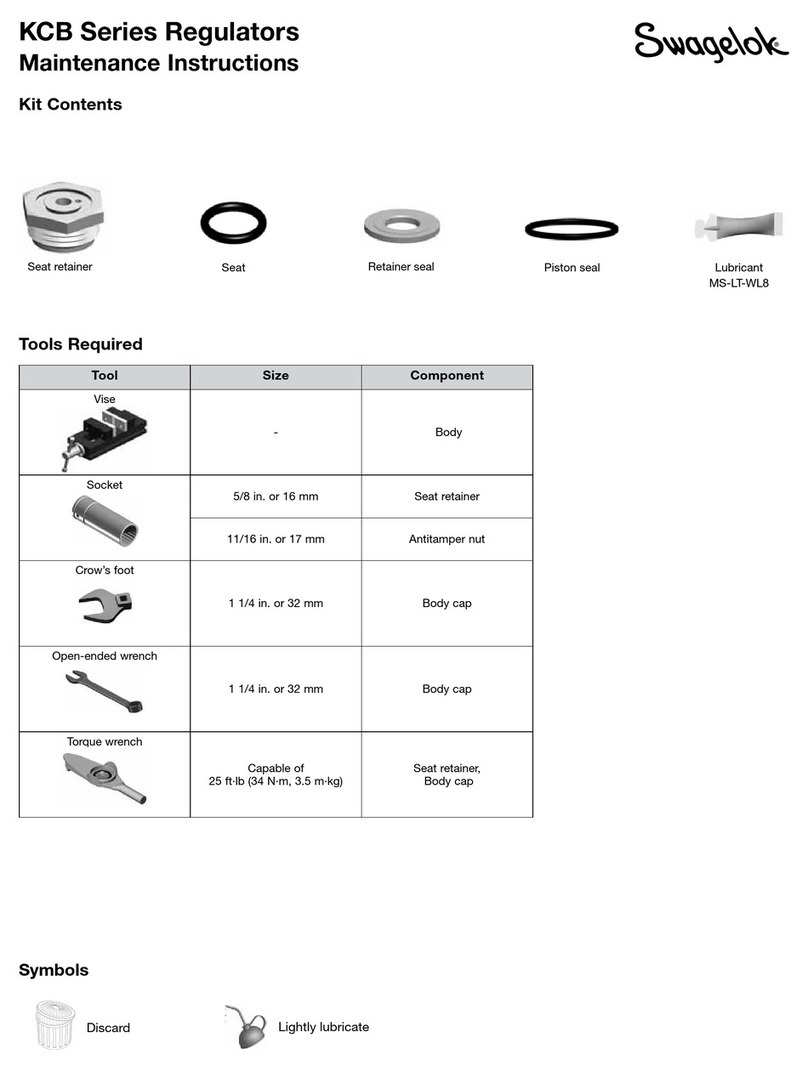

Body Reassembly

Note: Ensure the regulator body and all parts are

clean and free of damage.

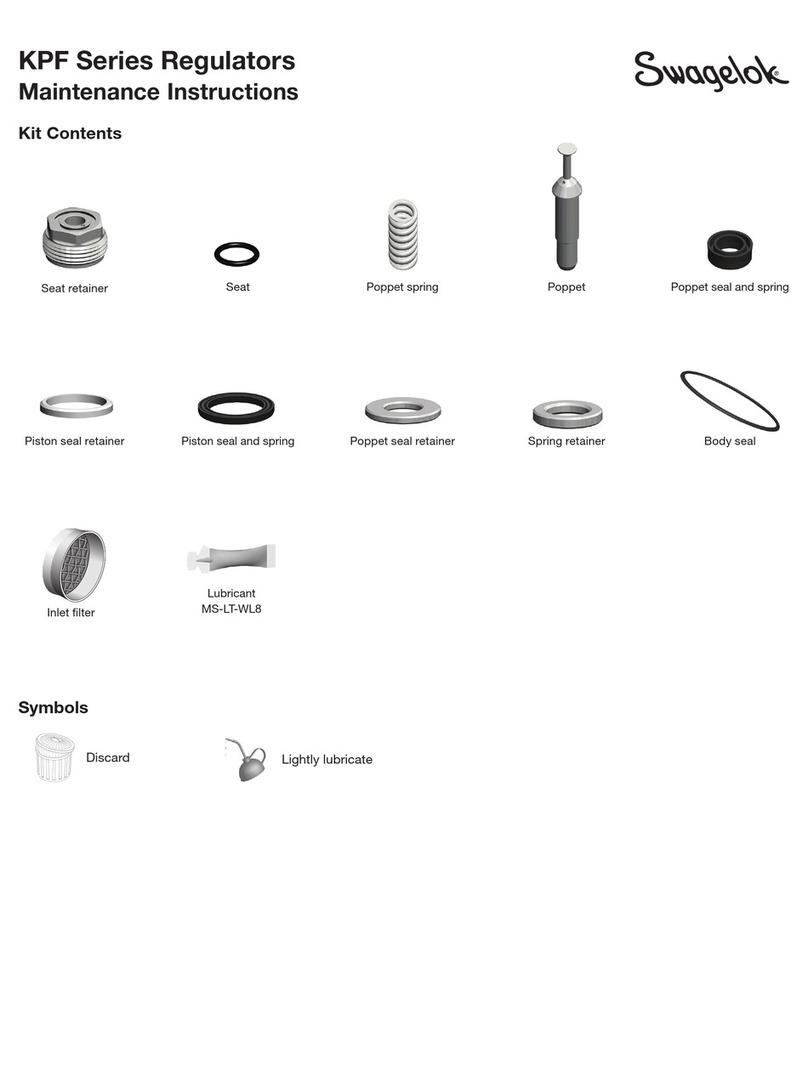

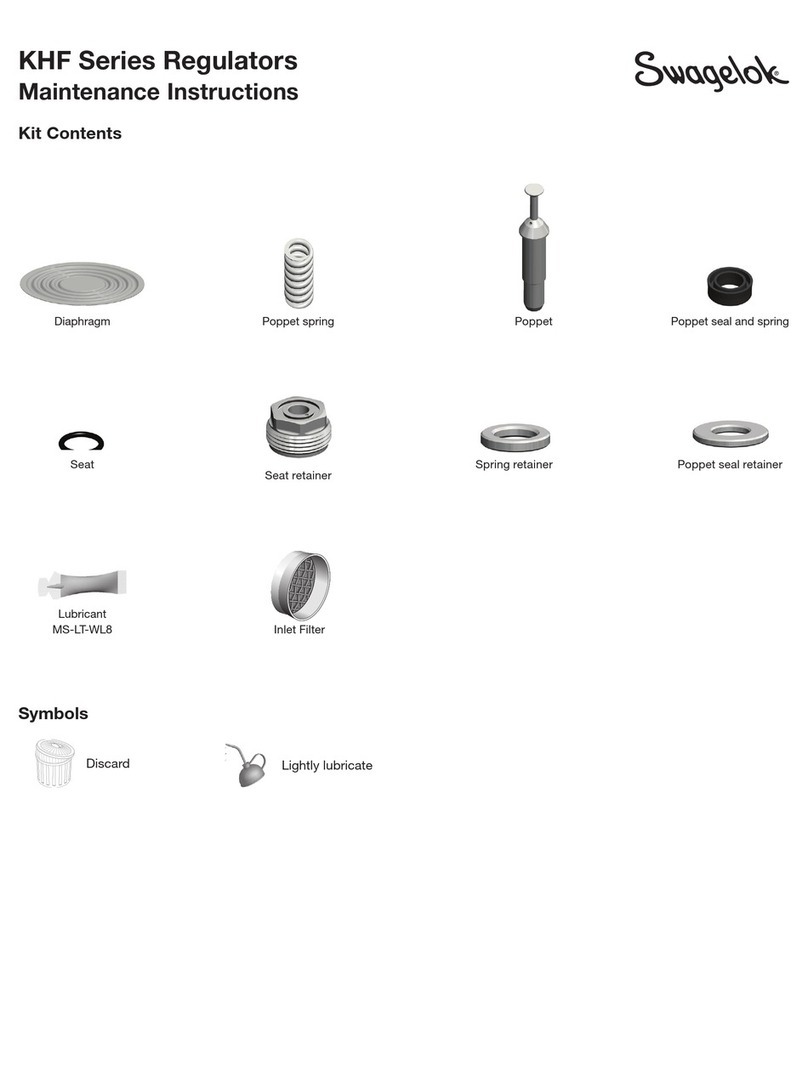

1. Place the new seat into the new seat retainer

with the ID groove or boss pointing away from the

seat retainer. Apply a very light coat of provided

lubricant to the seat retainer threads.

2. Slip the new poppet spring and new poppet

damper onto the thicker end of the new poppet.

Fit the flat face of the poppet damper against the

poppet spring.

3. Invert the seat retainer/seat assembly and place

the thinner end of the poppet in the center of the

plastic seat.

4. Keeping the poppet/seat retainer assembly

inverted, invert the body and thread the new

seat retainer into the body. Tighten to 12.9 ft·lb

(17.5 N·m, 1.8 m·kg) torque with a 5/8 in. socket

on the torque wrench.

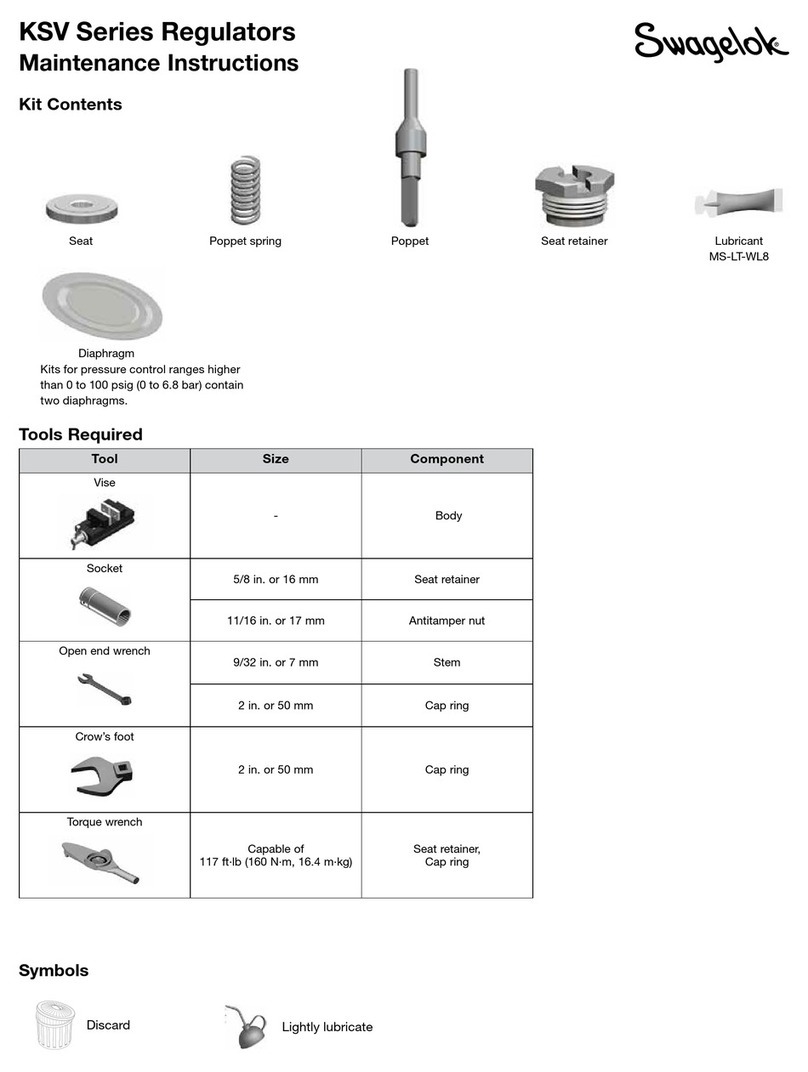

5. Install the new diaphragm

into the body with the large

convolution facing down into

the body. For 0 to 250 psig

and 0 to 500 psig regulators,

which use two diaphragms,

both diaphragms have the

same orientation.

6. Install the stop plate onto

the new diaphragm with

the boss on the stop plate

facing up, away from the diaphragm.

7. For 0 to 500 psig

regulators, place the

spring button into the

cap assembly with

the boss facing away

from the handle,

coned side up. Place the range spring into the

cap.

8. Lightly lubricate the body threads and place the

cap assembly on the body.

9. Thread the cap ring onto the body. Tighten cap

ring to 129 ft.·lb (175 N·m, 17.8 m·kg) torque

with a 2 in. wrench adapter on the torque wrench

using the flats to grip the cap ring.

10. Test the regulator for proper operation.

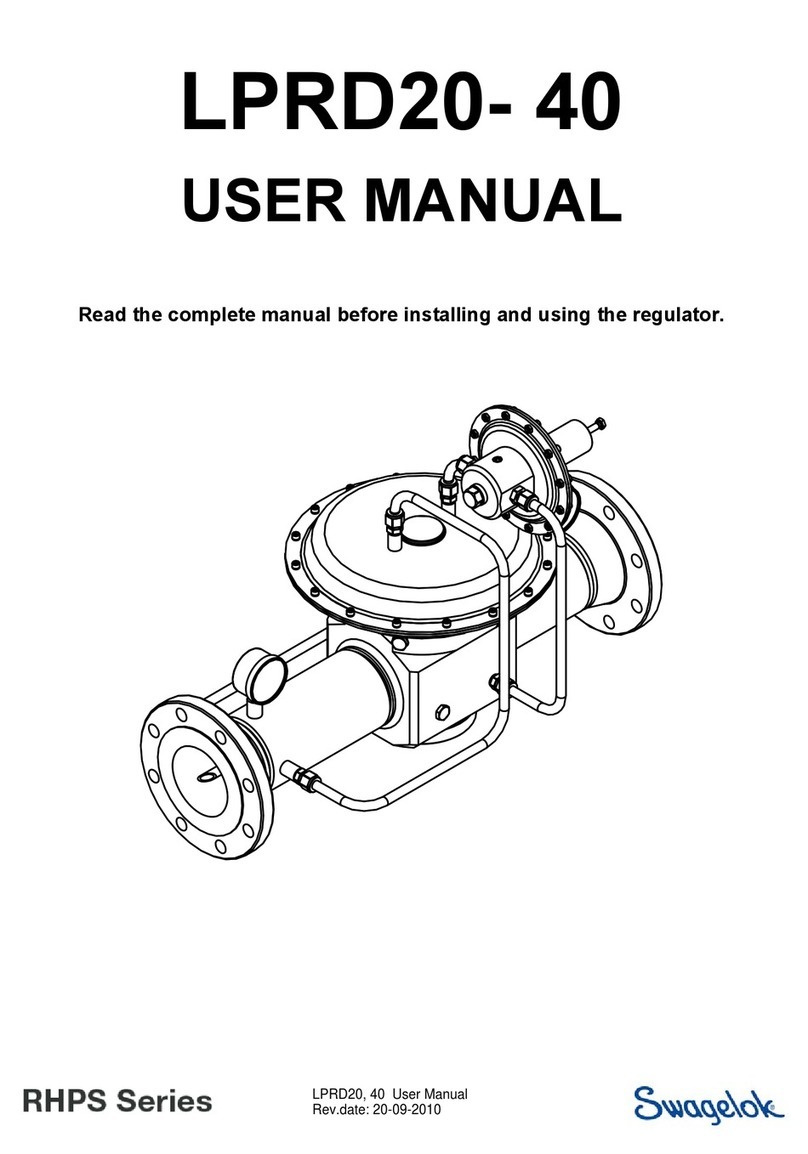

Swagelok—TM Swagelok Company

© 2004 — 2015 Swagelok Company

October 2015, R4

MS-CRD-KPRMAINT

Filter Reassembly

1. Insert the new inlet filter in the inlet port

(marked ‘HP’) using the filter insertion tool.

NOTICE

Do not insert the inlet filter with a sharp tool.

Damage to the filter could result.

Convolution on

diaphragm

Boss on

stop plate

Boss on

spring button Range spring

ID groove or boss on seat Seat in seat retainer

Lubricate

threads

For additional information, see www.swagelok.com.

Cap ring

Handle

Cap assembly

Stop plate

Diaphragm

Seat retainer (lightly lubricate threads)

Seat

Poppet

Poppet spring

Poppet damper

Body (lightly lubricate threads)

Inlet filter

Inlet port (marked ‘HP’)

Inlet port

Inlet lter

Filter insertion tool

HP