Trelawny A70X User manual

A70 Industrial Dust Collector manual version - (ENDLESSBAG)

Operation and Maintenance Manual

www.trelawnyspt.co.uk

OPERATION

Foreword

Thank you for your purchase of the

TRELAWNY Professional use A70

Industrial Vacuum Cleaner.

This manual contains the necessary

maintenance information for you to

ensure proper operation and care for

this machine.

It is essential for you to read

through this manuals thoroughly.

In the unlikely event that you

experience problems with your A70

Vacuum, please do not hesitate to

contact your local Trelawny dealer or

agent. We always welcome

feedback and comments from our

valued customers.

General Information

Before operating, performing

maintenance or repairing the A70

Industrial Vacuum Cleaner, this

manual must be read and

understood by the operator, if in any

doubt, ask your supervisor before

using this equipment.

Local safety regulations must be

followed at all times. Failure to follow

these instructions could result in

damage to the A70 Vacuum and/or

personal injury.

Trelawny SPT Limited disclaims all

responsibility for damage to persons

or objects arising as a consequence

of incorrect handling of the machine,

failure to inspect the machine for

damage or other faults that may

influence the operation prior to

starting work, or failure to follow the

safety regulations listed or applicable

to the job site.

This machine is primarily designed

for the containment of nuisance dust

and dust collection.

HEPA filtered vacuum system is

available, which will contain 99.97%

(DOP) of all air borne dust when

removing toxic or contaminated

products.

It can be used both indoors and

outside in dry weather only.

This machine is not water proof,

avoid splashing with water if using to

collect fluid spills.

Safety

The person in charge of safety shall

be responsible for informing workers

about the risks associated with

vacuum cleaner operations.

Train operators in the correct use

and maintenance of the vacuum in

order to protect themselves and

others from hazards.

Failure to observe basic safety

regulations and precautions could

cause accidents during the vacuum

cleaners operation, maintenance or

repair.

Trelawny shall under no

circumstances be deemed liable for

accidents or damage caused by use

of the vacuum cleaner by personnel

not properly trained or who use it in

an improper manner.

The safety precautions and warning

notices are indicated in this manual

and on the product.

Unless these hazard messages are

heeded, the operator could become

involved in accidents with serious

consequences for him/herself and

others.

Trelawny cannot foresee all possible

circumstances capable of

representing a potential hazard,

therefore the warnings in this manual

and on the product should not be

deemed exhaustive.

Only ever use original Trelawny

spare parts

Trelawny declines all liability in

the event of non-original spare

parts being used.

In the event of tools, procedures or

work methods used that are not

explicitly recommended by Trelawny,

ensure no hazards exist for the

operators and others.

Further advice is available from our

Technical Department.

The employer must inform and train

the user according to the provisions

of applicable local laws.

Before using the machine, prepare

and train yourself by reading this

manual carefully.

Use of the machine by untrained and

unauthorised persons is forbidden.

Do not use the machine to vacuum

toxic substances unless it has been

equipped with the special filters

required for the specific type of dust.

Such filters must be explicitly

requested by you.

Do not vacuum flammable materials

or substances or which could cause

explosions (fuels, solvents, etc.). To

vacuum such materials, the machine

must be built with anti-explosion

motor and electric system and this

must be requested by you explicitly.

Do not vacuum corrosive substances

unless the machine is equipped with

containers suitable for this purpose

(Stainless-Steel AISI 304).

Use of the machine without the

supplied filters is not recommended.

If the machine is used to vacuum

toxic/harmful substances, the

container must be emptied and the

filters cleaned using adequate

Personal Protection Equipment.

This machines motor casing

contains electrical components

which must not be dismantled by the

user.

When using the machine, be aware

of other people around you.

Use the machine cautiously on

slopes and ramps. Do not change

direction on gradients.

Make sure the parked machine

remains stable by operating the

braked wheel.

Do not open the vacuum container

with the motor running.

Pre-Start Check

Check all bolts and screws for

tightness. Ensure that all fittings are

secure.

This specific vacuum cleaner model

has been designed, built and

protected for vacuuming dusts and

solids, also liquids, but only within

the capacity of the container.

SEE BELOW for filter options.

To ensure the correct operation of

the vacuum cleaner, this must be

positioned protected against

atmospheric agents (rain, hail, snow,

fog, dusts in suspension, etc.) with

an environmental running

temperature between 5°C and 45°C

and relative humidity not above 70%.

The work environment must be

clean, well-enough lit and devoid of

explosive atmosphere.

The vacuum cleaner must not be

used in environments containing

substances in the form of liquids that

could vaporise at room temperature

and flammable dusts and gas.

All cables should be fully uncoiled

and never left wrapped around cable

reels or tied in loops.

OPERATION

When contacting Trelawny SPT Ltd

or thier agent, always quote the

details shown on the vacuum

cleaner serial plate.

To change the filter, switch off the

vacuum cleaner and remove the

plug from the power socket, release

and remove the upper cap and then

loosen nut (A).

HEPA Filter Cartridge Class H

303.5274

Operation:

Warning:

The vacuum is heavy but it will move

easily on flat ground.

If moving on any inclined ground

take extreme care that control is not

lost due to its weight.

Starting:

Always lock the castor wheel to

prevent run away.

Ensure the power plug is correctly

fitted in the power socket.

Ensure the power cable and any

extension cable is in good condition.

Fit the flexible hose with the selected

accessory.

Fit the supplied connector to the

vacuum and the vacuum hose.

Switch on machine (10).

Warning:

Before switching the vacuum back

on allow the motor to come to a

complete standstill.

OPTIONAL FILTERS

Besides the optional HEPA filter

(303.5262), and depending on the

dust to be vacuumed, the following

filters are also available:

Antistatic filter

For electrostatic dust.

Nomex filter

For hot dusts up to 240°.

Polyester filter cat.M

For very fine dusts, the polyester

filter are BIA institute certified.

OPERATION

Starting

Description of controls

4

3

6

5

2

10

Main Parts

1) Lid/Vacuum Top Connector

2) Release Fasteners

3) Filter Chamber

4) Collection Release Lever

5) Suction Inlet

6) Level Indicator

7) ENDLESSBAG

8) Fixed Wheels

9) Un-Braked Castor

1

Operation

To avoid voltage drop, always use

the shortest possible length of

extension cable.

Maximum length of cable 30 meters.

First fit the accessory required for

the type of vacuuming operation on

the opposite end of the hose.

Note: No standard accessories

(reducers, hoses, nozzles) are

included with the vacuum;

accessories must be specified and

ordered separately.

Fit the supplied connector on the

pipe union.

Fit the supplied pipe in the

connector.

Make sure the power supply

corresponds to the voltage and

frequency indicated on the vacuum

cleaner plate.

IMPORTANT: Do not plug in the

power socket with wet hands

In the event of an extension being

used, make sure this is in perfect

condition, in compliance with EC

standards and with cable cross

section suitable for the power input

of the vacuum cleaner.

Lock the front castor wheel (7).

Grip one end of the flexible hose

complete with selected accessory.

To start, switch on the motor, and

start vacuuming.

To stop the vacuum cleaner, return

the switch to the off position.

Dispose the contents of the

ENDLESSBAG into a special waste

disposal container in accordance

with local laws applicable in the

country where the vacuum cleaner is

used.

7

8

9

Caution:

Before switching the vacuum

cleaner back on, ensure the motor

has come to a complete halt.

After finishing work, disconnect the

vacuum cleaner from the power

supply.

Dust containment bag

This should be emptied when the

vacuumed material has reached 3/4

of its maximum capacity.

Procedure for revealing a new

section of the dust containment

bag.

Stop the vacuum motors by pressing

the relevant STOP switches and

disconnect from the power socket.

While performing this operation it is

best to wear a dust protection mask.

Use two ties at two points 3-5cm

apart just below the filter chamber

Cut the bag between the two ties.

Cut

between

ties.

OPERATION & MAINTENANCE

MAINTENANCE

This section describes the control

and special maintenance operations

crucial for keeping the vacuum

cleaner in perfect working condition.

Any other jobs which might be

necessary to eliminate operating

faults must be expressly authorised

by the manufacturer. In such cases,

always supply the identification

details of the cleaner.

In the case of major repairs, it is best

to contact an authorised dealer.

General safety

precautions

Maintenance jobs must always be

performed by skilled technicians,

trained to carry out their specific

jobs. In the case of this machine,

these are:

Mechanical maintenance

Electrical maintenance

The Safety Manager has the precise

duty of determining the professional

capacities and skills of such

persons.

Before doing any maintenance job,

the safety manager must:

Make sure there are no unauthorised

persons in the work area.

Make sure the necessary tools are

on hand and that these are in good

condition.

Make sure that lighting is adequate.

Make sure the maintenance

engineer is equipped with all

approved individual protection

devices needed for the specific

operation (gloves, eyewear, shoes,

etc.)

Make sure the maintenance

engineer has carefully read the

instructions contained in this manual

and knows how the vacuum cleaner

works.

Using the filter cleaning

system.

These following operations must

only be performed with the machine

switched off once the motor has

come to a complete halt.

Before carrying out a maintenance

job, the maintenance engineer must:

Disconnect the plug from the power

socket.

Work done on motors or other

electrical component parts must only

be performed by a specifically

trained electrician, authorised by the

Safety Manager.

Always use tools that are in perfect

condition and specifically made for

the operation to be done.

The use of unsuitable tools or tools

not in good condition could cause

serious damage.

Maintenance checks

For efficient vacuum cleaner

operation, a number of controls

are best made periodically:

Check to see whether the filter is

worn or has become too permeable.

Make sure the sealing gaskets of the

motor head base and of the

filter-holder ring and of the container

are working efficiently.

The electrical parts (plugs, switches,

cables, etc.) must not be faulty.

The screws and nuts must always be

tight.

Make sure the container is not

overfull.

Check the integrity of the flexible

vacuum hose and accessories to be

used.

If the flexible hose is perforated, the

power of the cleaner will be reduced

and dust and liquids will leak into the

environment.

The filter cleaning system is best

operated every time before use and

after prolonged operation.

On the side of the vacuum cleaner

near the On/Off switch is a vacuum

meter indicating the degree of

vacuum inside the vacuum cleaner.

If, with the vacuum cleaner working

and the vacuum inlet free, the

vacuum meter lever indicates an

irregular depression level, the filter

will have to be shaken by means of

the special lever.

If the needle of the vacuum meter

stays in the low even after cleaning

the filter, the hose or suction

accessory could be blocked. In this

case, clean and remove the

blockage.

Release the levers that hold the

motor head.

MAINTENANCE

Lift the motor head by means of the

handles provided and rest this on a

support bench, take not to damage

the power cable.

Remove from underneath the

vacuum cleaner the pin (A) and

spring pin (B) that fasten the filter to

the shaking lever.

Lift out the filter complete with its

support.

Unscrew the clamp and remove the

support ring with seal.

Undo the tied knots from inside (A)

and the underside, then remove the

pocket filter.

Fit the new filter, put everything back

together carefully securing all ties

and fit the cap back on.

The container locking operation

must be performed by one person

only, who must lower the lever with

both hands to lock the canister in

position.

Replacing the filters

To replace the filters, proceed as

follows:

Turn off the vacuum cleaner by

pressing down the motor STOP

switches.

Disconnect the vacuum cleaner plug

from the power socket.

Ensure front wheels are locked.

Lift the lever that locks the

ENDLESSBAG hopper.

Remove the Hopper.

Important:

All material trapped and contained

within the filter must be disposed of

according the local legislation

NOTE:

Do not place hands on sides of

container near the guide pins

while re-installing.

Perform the container locking

operation by means of the lever

located on the front, USE BOTH

HANDS !!

A

B

A

DOWN

UP

RECOMMENDED PARTS AND FAULT FINDING

Machine Storage

Remove the filter and clean it, empty the container and store the vacuum cleaner in a place protected against

condensation and at a temperature between 0°C and 40°C.

Cover with a nylon sheet to prevent accumulation of dust.

Scrapping

In case of scrapping, all the component parts of the vacuum cleaner will have to be disposed of through adequate

disposal channels in accordance with applicable legislation.

Before scrapping, all plastic and rubber parts will have to be separated from the electrical material.

Most parts made from plastic, aluminium, copper or steel are suitable for recycling.

FAULT CAUSE ACTION

The cleaner fails to

start.

No power. Check the power mains supply.

Check the integrity of the plug and power

cable.

Thermal magnetic switch tripped Reset the thermal magnetic switch.

Loose wiring, incorrect voltage, or blown

fuse.

Check connections and power supply or

replace fuse.

Dust is leaking out Perforated vacuum pipe. Replace the pipe.

Perforated filter. Replace the filter.

Filter unsuitable for type of job. Fit a suitable filter for the type of material to be

vacuumed.

The vacuum cleaner

does not work as it

should.

Pipe perforated or blocked. Check the pipe and, if necessary, replace.

Container full Empty container.

Filter blocked. Replace filter.

Seals worn. Clean the filter and if necessary change it.

Air leak. Check for any air leaks out of closing

fasteners, tightening screws, container or filter

chamber.

If problem has not been cured by any of the above actions, contact your local Trelawny SPT dealership for assistance.

PART NUMBER DESCRIPTION

303.5267 Polyester Filter with 20 Pockets 20000 CM2 Ø500

303.5274 HEPA Filter

303.5289 Filter-Holder Seal Ø500

303.5493 Filter Clamp Ø500

303.5306 Adhesive Gasket

EXPLODED VIEW - MACHINE

Item Part No Description

1“Machine Body Kit

2303.5389 HEPA Filter Kit

3303.5271 20 Pocket “C” Polyester Filter

4303.5388 Chamber Kit (HEPA)

303.5384 Chamber Kit (Non HEPA)

5303.5399 ENDLESSBAG Hopper Kit

EXPLODED VIEW - FILTER UNIT

Item Part No Description

1303.5304 Adhesive Gasket

2303.5617 Spacer Ring

3303.5274 HEPA Filter

4303.5586 Grommet

5303.5415 Plain Washer

6303.5424 M8 x 150 Hexagon Bolt

EXPLODED VIEW - FILTER UNIT

Item Part No Description

1303.5289 Filter Gasket

2303.5507 Filter Holder Ring

3303.5493 Filter Clamp

4303.5544 Filter Cage

5303.5271 20 Pocket “C” Polyester Filter

6303.5502 Filter Shaker Cage

7303.5581 R-Clip

8303.5503 Clevis Pin

EXPLODED VIEW - FILTER CANISTER

Item Part No Description

1303.5611 Filter Chamber

2303.5490 Toggle Clamp (Non HEPA)

303.5558 Toggle Clamp (HEPA Filtered)

3303.5561 L/H Mounting Bracket

4303.4588 Handle

5303.5360 Gasket

6303.5489 Filter Shaker Flange

7303.5488 Filter Shaker Lever

8303.5492 Filter Shaker Lever Bellows

9303.5491 Filter Shaker Lever Knob

10 303.5500 Deflector

11 303.5302 Inlet Gasket

12 303.5499 Inlet

13 303.5508 Latch Pin

14 303.5506 Connector Latch

15 303.5504 Spring

16 303.5306 Adhesive Gasket

17 303.5562 R/H Mounting Bracket

EXPLODED VIEW - FILTER CANISTER

Item Part No Description

1303.5627 ENDLESSBAG Hopper

2303.5347 O’Ring

3303.5355 Flap Gasket

4303.5604 Flap

5303.5584 Spring

6303.5603 Flap Arm

7303.5583 Container ENDLESSBAG

8303.5602 Knob

9303.5605 ENDLESSBAG Container Hanger

10 303.5770 ENDLESSBAG

EXPLODED VIEW - MOTOR HEAD COMPONENTS

EXPLODED VIEW - MOTOR HEAD

Item Part No Description Item Part No Description

1303.5113 Cover 26 303.5438 150mm Wheel

2303.5301 Inlet gasket 27 303.5439 Castor Wheel (Unbraked)

3303.5552 Square Flange Inlet 28 303.5442 Castor Wheel (Braked)

4303.5531 Clamp 29 303.5618 Frame

5303.5733 Hose 30 303.6072 Electric Switchboard

6303.5532 Diffuser Filter 31 303.5210 Cable Fastener

7303.5533 Diffuser Filter Clamp 32 303.5211 Nut

8303.5587 Silencer Pipe (No valve) 33 303.5554 Cover

9303.5588 Silencer pipe (With valve) 34 303.5155 Vacuum Gauge

10 303.5780 Pressure Relief Valve 35 303.5212 Straight Connector (Push-in fit)

11 303.5215 Nylon Pipe 36 303.5201 Nut

12 303.5160 Swivel Elbow (Push in fitting) 37 303.5216 Cable Fastener

13 303.5536 Flange 38 303.5559 Upper Cover Plate

14 303.5298 Flange Gasket 39 303.5303 Gasket

15 303.5257 Suction Unit 40 303.5564 Push Handle

16 303.5563 Suction Unit Spacer 41 303.5556 20mm Plastic End Cap

17 303.5509 Plastic End Cap 42 303.5519 25mm Plastic End Cap

18 303.5537 Sliding Bracket

19 303.6531 Lever Fulcrum

20 303.5539 Column

21 303.5553 ENDLESSBAG Lever System

22 303.5255 Lever Safety Stop

23 303.5597 ENDLESSBAG Support Plate

24 303.5547 Plastic End Cap

25 303.5437 Axle Kit

TECHNICAL SPECIFICATIONS

This tool has been designed and produced in accordance with the following directives:

·2006/42/CE Machine directive

·2004/108/CE Electromagnetic compatibility directive

·2006/95/CE Low-voltage directive

If your company has any problem with our products or would like to discuss the possibility of an improvement being made

to them, then please do not hesitate to contact us. Your comments are both important and appreciated.

All rights reserved. Any unauthorised use or copying of the contents or part thereof is prohibited.

This applies to trademarks, model denominations, part numbers and drawings.

Use only genuine Trelawny spares.

The use of non-Trelawny spare parts invalidates the warranty.

Model 230/400v

Power (Watts) 5.5kW

Vacuum rate (Mm/H2O) 2300

Max. Air flow (M3/h) 500

Noise level dB(A) 76

Filter type/ material Polyester

Filtering surface (cm2)30,000

Capacity (Lt) 100

Vacuum inlet Ø 80

Dimensions (cm.) 62 x 110

Height (cm.) 190

Weight (Kg) 150

Package size / weight 73 x 136 x180mm 170kg

Vibration Vibration transmitted by this machine is less than 2.5m/s2

NOTES

Trelawny SPT Ltd

13 Highdown Road, Sydenham Industrial Estate, Leamington Spa,

Warwickshire, CV31 1XT, United Kingdom

Telephone: +44 (0)1926 883781 - Fax: +44 (0)1926 450352

Email: sales@trelawny.co.uk

© TSPT UK 2017 Part No: 735.6060 issue 3.6.17 www.trelawnyspt.co.uk

This manual suits for next models

1

Table of contents

Other Trelawny Dust Collector manuals

Popular Dust Collector manuals by other brands

Storch

Storch Cover Quick Wall installation manual

Husqvarna

Husqvarna DC 3000 manual

Donaldson Torit

Donaldson Torit Vibra-Shake VS-550 Installation and operation manual

Gardena

Gardena S 36 Propane Operator's manual

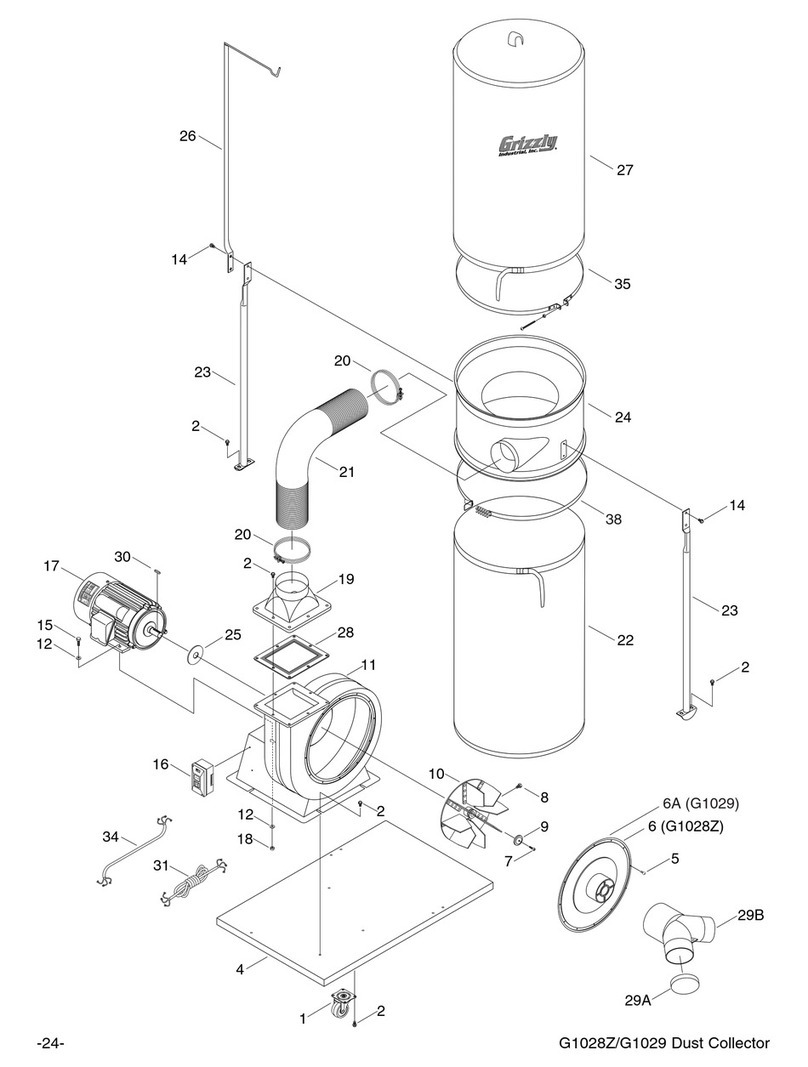

Grizzly

Grizzly G1029Z parts manual

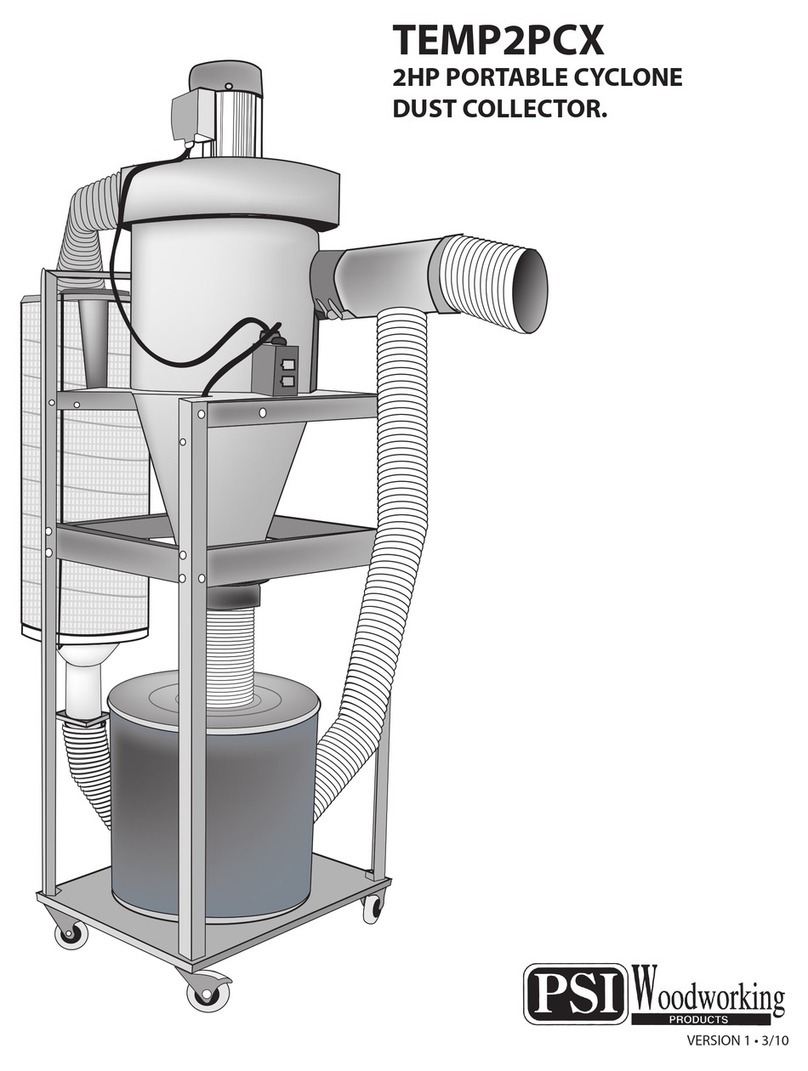

PSI Woodworking Products

PSI Woodworking Products TEMPEST TEMP2PCX manual