Bell and Gossett ecocirc 19-16 User manual

INSTRUCTION MANUAL

P2003557 Rev A

ecocirc®19-16

Table of Contents

1 Introduction and Safety............................................................................................ 3

1.1 Introduction........................................................................................................3

1.2 Safety...................................................................................................................3

1.2.1 Safety terminology and symbols............................................................. 4

1.3 User safety.......................................................................................................... 5

1.4 Protecting the environment............................................................................. 6

2 Transportation and Storage.....................................................................................8

2.1 Inspect the delivery........................................................................................... 8

2.1.1 Inspect the package.................................................................................. 8

2.1.2 Inspect the unit...........................................................................................8

3 Product Description.................................................................................................. 9

3.1 General description...........................................................................................9

3.2 Nomenclature.................................................................................................... 9

3.3 Operation specifications................................................................................ 10

4 Installation................................................................................................................13

4.1 Facility requirements.......................................................................................13

4.1.1 Pump location..........................................................................................13

4.2 Piping requirements....................................................................................... 14

4.3 Electrical requirements...................................................................................14

4.4 Pump installation requirements.....................................................................15

4.5 Electrical installation....................................................................................... 16

4.5.1 Precautions...............................................................................................16

4.5.2 Connect the wires....................................................................................16

5 Operation.................................................................................................................18

5.1 Preparation for startup....................................................................................18

5.2 Modes of operation.........................................................................................18

5.3 Switch between standard operating modes................................................18

5.4 Standby mode................................................................................................. 19

5.5 Activate the air purge function...................................................................... 19

5.6 Typical speed settings.................................................................................... 19

6 Maintenance............................................................................................................ 20

6.1 Precautions.......................................................................................................20

6.2 Disassemble the pump...................................................................................20

7 Troubleshooting......................................................................................................21

7.1 Display messages............................................................................................ 21

7.2 The pump is noisy........................................................................................... 21

Table of Contents

ecocirc®19-16 INSTRUCTION MANUAL 1

7.3 Excessive ambient temperature.................................................................... 21

8 Appendix..................................................................................................................22

8.1 Appendix.......................................................................................................... 22

9 Product warranty.....................................................................................................26

Table of Contents

2 ecocirc®19-16 INSTRUCTION MANUAL

1 Introduction and Safety

1.1 Introduction

Purpose of this manual

The purpose of this manual is to provide necessary information for:

• Installation

• Operation

• Maintenance

CAUTION:

Read this manual carefully before installing and using the

product. Improper use of the product can cause personal injury

and damage to property, and may void the warranty.

NOTICE:

Save this manual for future reference, and keep it readily

available at the location of the unit.

1.2 Safety

WARNING:

• The operator must be aware of safety precautions to prevent

physical injury.

• Operating, installing, or maintaining the unit in any way that

is not covered in this manual could cause death, serious

personal injury, or damage to the equipment. This includes

any modification to the equipment or use of parts not

provided by Xylem. If there is a question regarding the

intended use of the equipment, please contact a Xylem

representative before proceeding.

• Do not change the service application without the approval

of an authorized Xylem representative.

CAUTION:

You must observe the instructions contained in this manual.

Failure to do so could result in physical injury, damage, or

delays.

1 Introduction and Safety

ecocirc®19-16 INSTRUCTION MANUAL 3

1.2.1 Safety terminology and symbols

About safety messages

It is extremely important that you read, understand, and follow the safety

messages and regulations carefully before handling the product. They are

published to help prevent these hazards:

•Personal accidents and health problems

• Damage to the product and its surroundings

• Product malfunction

Hazard levels

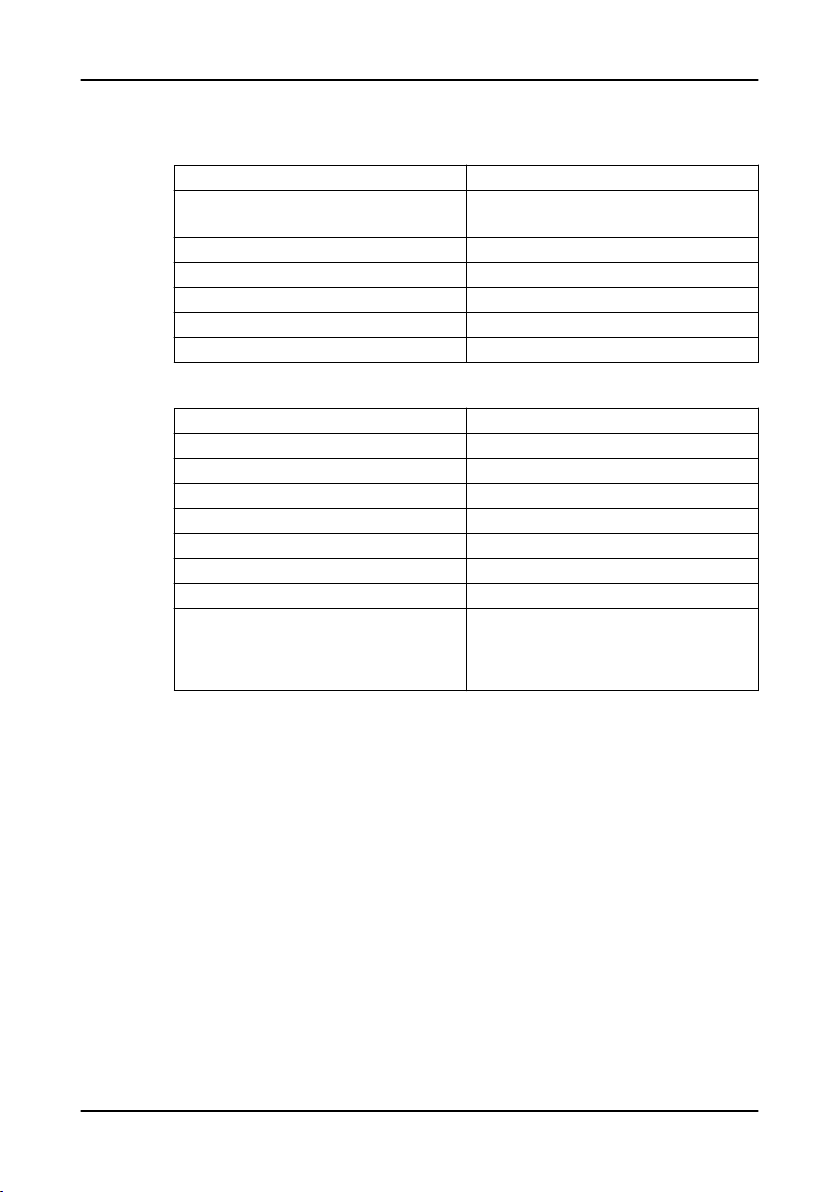

Hazard level Indication

DANGER: A hazardous situation which, if not avoided, will

result in death or serious injury

WARNING: A hazardous situation which, if not avoided, could

result in death or serious injury

CAUTION: A hazardous situation which, if not avoided, could

result in minor or moderate injury

NOTICE: Notices are used when there is a risk of equipment

damage or decreased performance, but not

personal injury.

Special symbols

Some hazard categories have specific symbols, as shown in the following table.

Electrical hazard Magnetic fields hazard

Electrical

Hazard:

CAUTION:

Hot surface hazard

Hot surface hazards are indicated by a specific symbol that replaces the typical

hazard level symbols:

CAUTION:

1 Introduction and Safety

4 ecocirc®19-16 INSTRUCTION MANUAL

Qualified personnel

WARNING:

This product is intended to be operated by qualified personnel

only.

1.3 User safety

General safety rules

These safety rules apply:

• Always keep the work area clean.

• Pay attention to the risks presented by gas and vapors in the work area.

• Avoid all electrical dangers. Pay attention to the risks of electric shock or arc

flash hazards.

• Always bear in mind the risk of drowning, electrical accidents, and burn

injuries.

Safety equipment

Use safety equipment according to the company regulations. Use this safety

equipment within the work area:

• Hard hat

• Safety goggles, preferably with side shields

• Protective shoes

• Protective gloves

• Gas mask

• Hearing protection

• First-aid kit

• Safety devices

NOTICE:

Never operate a unit unless safety devices are installed. Also

see specific information about safety devices in other

chapters of this manual.

Electrical connections

Electrical connections must be made by certified electricians in compliance with

all international, national, state, and local regulations. For more information

about requirements, see sections dealing specifically with electrical

connections.

Precautions before work

Observe these safety precautions before you work with the product or are in

connection with the product:

• Provide a suitable barrier around the work area, for example, a guard rail.

• Make sure that all safety guards are in place and secure.

• Make sure that you have a clear path of retreat.

• Make sure that the product cannot roll or fall over and injure people or

damage property.

1 Introduction and Safety

ecocirc®19-16 INSTRUCTION MANUAL 5

• Make sure that the lifting equipment is in good condition.

• Use a lifting harness, a safety line, and a breathing device as required.

• Allow all system and pump components to cool before you handle them.

• Make sure that the product has been thoroughly cleaned.

• Disconnect and lock out power before you service the pump.

• Check the explosion risk before you weld or use electric hand tools.

Precautions during work

Observe these safety precautions when you work with the product or are in

connection with the product:

• Never work alone.

• Always wear protective clothing and hand protection.

• Stay clear of suspended loads.

• Always lift the product by its lifting device.

• Beware of the risk of a sudden start if the product is used with an automatic

level control.

• Beware of the starting jerk, which can be powerful.

• Rinse the components in water after you disassemble the pump.

• Do not exceed the maximum working pressure of the pump.

• Do not open any vent or drain valve or remove any plugs while the system is

pressurized. Make sure that the pump is isolated from the system and that

pressure is relieved before you disassemble the pump, remove plugs, or

disconnect piping.

• Never operate a pump without a properly installed coupling guard.

Wash the skin and eyes

Follow these procedures for chemicals or hazardous fluids that have come

into contact with your eyes or your skin:

Condition Action

Chemicals or hazardous

fluids in eyes

1. Hold your eyelids apart forcibly with your fingers.

2. Rinse the eyes with eyewash or running water for at least

15 minutes.

3. Seek medical attention.

Chemicals or hazardous

fluids on skin

1. Remove contaminated clothing.

2. Wash the skin with soap and water for at least 1 minute.

3. Seek medical attention, if necessary.

1.4 Protecting the environment

Emissions and waste disposal

Observe the local regulations and codes regarding:

• Reporting of emissions to the appropriate authorities

• Sorting, recycling and disposal of solid or liquid waste

• Clean-up of spills

1 Introduction and Safety

6 ecocirc®19-16 INSTRUCTION MANUAL

Exceptional sites

CAUTION: Radiation Hazard

Do NOT send the product to Xylem if it has been exposed to

nuclear radiation, unless Xylem has been informed and

appropriate actions have been agreed upon.

Recycling guidelines

Always follow local laws and regulations regarding recycling.

1 Introduction and Safety

ecocirc®19-16 INSTRUCTION MANUAL 7

2 Transportation and Storage

2.1 Inspect the delivery

2.1.1 Inspect the package

1. Inspect the package for damaged or missing items upon delivery.

2. Note any damaged or missing items on the receipt and freight bill.

3. File a claim with the shipping company if anything is out of order.

If the product has been picked up at a distributor, make a claim directly to

the distributor.

2.1.2 Inspect the unit

1. Remove packing materials from the product.

Dispose of all packing materials in accordance with local regulations.

2. Inspect the product to determine if any parts have been damaged or are

missing.

3. If applicable, unfasten the product by removing any screws, bolts, or straps.

For your personal safety, be careful when you handle nails and straps.

4. Contact a sales representative if there is any issue.

2 Transportation and Storage

8 ecocirc®19-16 INSTRUCTION MANUAL

3 Product Description

3.1 General description

The product is a shaft-less spherical motor pump, with energy-efficient,

electronically commutated permanent magnet synchronous motor. The

following features make it easy to install, operate, and service:

• A leak proof, integrated pump and motor design eliminates the need for

conventional mechanical seals or other shaft sealing devices.

• The product is lubricated with system fluid, and thus does not require

external lubrication.

• The product requires only a small amount of torque to start even after a long

period.

WARNING:

California Proposition 65 warning! This product contains

chemicals known to the state of California to cause cancer and

birth defects or other reproductive harm.

Intended applications

The product is intended for the following applications:

• Hot water heating systems

• Chilled water applications

• Heat pumps

• Solar systems

• Industrial water circulation and potable water

3.2 Nomenclature

ecocirc®19 16

Series name Maximum head 19 ft (~6 m) Maximum flow 16 GPM (~3500

L/H)

Port to port distance = 6 3/8” (162 mm)

The product is capable of satisfying heating systems of about 170,600 BTU/HR

(50 KW), which will be equivalent to:

• Radiator heating system for approximately up to 5,000 ft² (465 m²) of living

space.

•Under-floor heating systems for approximately up to 2,000 ft² (186 m²) of

floor space.

3 Product Description

ecocirc®19-16 INSTRUCTION MANUAL 9

3.3 Operation specifications

Materials of construction

Part Material

Pump housing Cast iron (GJL-200)

Stainless steel (AISI 304)

O-rings EPDM

Bearing PEEK/AI203)

All plastics, except for bearings PPE

All other wetted parts AISI 304 / AISI 316 L / AISI 316Ti stainless steel

Check valve Noryl

Technical specification

Rated voltage 115 V

Frequency 50/60 Hz

Power consumption 4–60 W

IP protection IP 44

Insulation class Class 155 (F)

Maximum system pressure 150 PSI (10 bar)

Maximum ambient temperature 104°F (40°C)

Permitted temperature range of pumped fluid¹ 14°F to 203°F (-10°C to +95°C)

Permitted pumping media² Water — in potable and domestic water

applications

Water/glycol mixtures up to 50% — in chilled water

applications

¹ For domestic hot water applications, the maximum fluid temperature is 185°F

(85°C). For chilled water applications, the fluid must not freeze. To avoid

condensation, the fluid temperature must always be higher than the ambient

temperature.

² Performance of the pump will noticeably change when pumping water/glycol

mixtures with concentrations higher than 20%.

3 Product Description

10 ecocirc®19-16 INSTRUCTION MANUAL

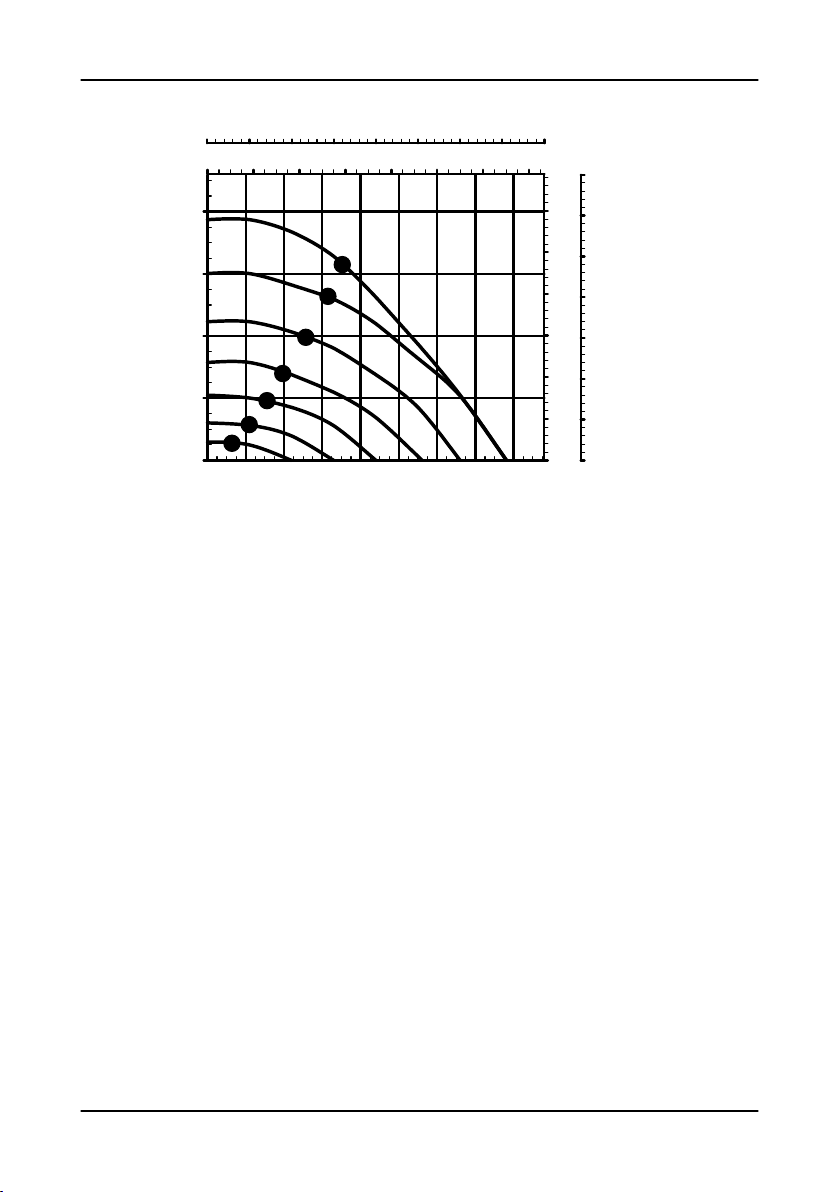

Performance curves

Q [m3/h]

0,0 0,5 1,0 1,5 2,0 2,5 3,0 3,5 4,0

H [m]

0

1

2

3

4

5

6

7

Q [US gpm]

0 2 4 6 8 10 12 14 16

H [ft]

0

5

10

15

20

Q [Imp gpm]

0 2 4 6 8 10 12 14

H [kPa]

0

10

20

30

40

50

60

7

1

2

3

4

6

5

Figure 1: Proportional pressure (factory default)

Q [m3/h]

0,0 0,5 1,0 1,5 2,0 2,5 3,0 3,5 4,0

H [m]

0

1

2

3

4

5

6

7

Q [US gpm]

0 2 4 6 8 10 12 14 16

H [ft]

0

5

10

15

20

Q [Imp gpm]

0 2 4 6 8 10 12 14

H [kPa]

0

10

20

30

40

50

60

7

1

2

3

4

6

5

Figure 2: Constant pressure

3 Product Description

ecocirc®19-16 INSTRUCTION MANUAL 11

Q [m3/h]

0,0 0,5 1,0 1,5 2,0 2,5 3,0 3,5 4,0

H [m]

0

1

2

3

4

5

6

7

Q [US gpm]

0 2 4 6 8 10 12 14 16

H [ft]

0

5

10

15

20

Q [Imp gpm]

0 2 4 6 8 10 12 14

H [kPa]

0

10

20

30

40

50

60

7

1

2

3

4

6

5

Figure 3: Constant speed

Dimensions and weight

See Figure 4: Dimensions and weight on page 22.

3 Product Description

12 ecocirc®19-16 INSTRUCTION MANUAL

4 Installation

Precautions

WARNING:

• Observe accident prevention regulations in force.

• Use suitable equipment and protection.

• Always refer to the local and/or national regulations,

legislation, and codes in force regarding the selection of the

installation site, plumbing, and power connections.

4.1 Facility requirements

4.1.1 Pump location

DANGER:

Do not use this unit in environments that may contain

flammable/explosive or chemically aggressive gases or

powders.

Guidelines

Observe the following guidelines regarding the location of the product:

• Make sure that the installation area is protected from any fluid leaks, or

flooding.

• If possible, place the pump slightly higher than the floor level.

• Provide shut-off valves on the suction and discharge sides of the pump.

• The relative humidity of the ambient air must be less than 95% non-

condensing.

• This pump is suitable for indoor use only.

• These pumps are electronically thermally overload protected.

CAUTION:

CAUTION: PROPERTY DAMAGE HAZARD. It is not advisable to

install circulators in an attic or upper floor over finished living

space. If the circulator must be installed over head, or over

expensive equipment, provide adequate drainage in the event

of leakage. Failure to follow these instructions could result in

property damage.

4 Installation

ecocirc®19-16 INSTRUCTION MANUAL 13

4.2 Piping requirements

Precautions

CAUTION:

• Use pipes suited to the maximum working pressure of the

pump. Failure to do so can cause the system to rupture, with

the risk of injury.

• Make sure that all connections are performed by qualified

installation technicians and in compliance with the

regulations in force.

• Do not use a shut-off valve on the discharge side in the

closed position for more than a few seconds. If the pump

must operate with the discharge side closed for more than a

few seconds, a bypass circuit must be installed to prevent

overheating of the water inside the pump.

Piping checklist

• Pipes and valves must be correctly sized.

• Pipe work must not transmit any load or torque to pump flanges.

• Be sure to minimize any pipe-strain on the pump:

– Support suction and discharge piping by the use of pipe hangers near

the pump.

– Line up the vertical and horizontal piping so that the bolt-holes in the

pump flanges match the bolt-holes in the pipe flanges.

– Do not attempt to spring the suction or discharge lines in position. This

may result in unwanted stress in the pump body, flange connections and

piping.

– The code for pressure piping (ANSI B31.1) lists many types of supports

available for various applications.

Install the check valve

The discharge nozzle is machined to accept a 1” Noryl check valve. If a check

valve is required for installation follow these steps:

1. Insert the O-ring end of the check valve into the discharge port of the pump

body.

2. Hand press the check valve body into place until it snaps into position.

The check valve will be shipped loose with each pump for field installation.

Once it is installed, it cannot be removed without damage.

See Figure 5: Parts on page 23 for proper installation of the check valve.

4.3 Electrical requirements

• The NEC, CEC and local codes must be followed at all times. If a branch

circuit is fitted with ground fault circuit breaker, ensure that the circuit

breaker is suitable for use with inverter-driven appliances.

4 Installation

14 ecocirc®19-16 INSTRUCTION MANUAL

Electrical connection checklist

Check that the following requirements are met:

• The electrical wires are protected from high temperature and vibration.

• The current type and power supply voltage connection must correspond to

the specifications on the name plate on the pump.

• Use wires at least 14 AWG to supply power to the pump. Follow all local and

NEC wiring codes and practices.

• The branch circuit supplying power to the pump shall be provided with a 15

Amps or less circuit breaker.

• Attach appropriate sized electrical connector to one f the 7/8" diameter

holes on the side of the conduit box.

• Connect ground wire to one of the ground screws inside the conduit box.

• Make sure electrical connections are tightly secured before replacing the

motor cover.

The electrical control panel checklist

NOTICE:

The electrical supply must match the electrical rating of the

pump. Improper combination could fail to guarantee protection

of the unit.

Check that the following requirements are met:

• The control panel circuit breaker is sized properly to protect the pump

against short-circuit.

• These pumps are electronically thermally overload protected. No additional

overload protection is required.

The motor checklist

Electrical supply and grounding wires must be suitable for at least 194°F (90°C).

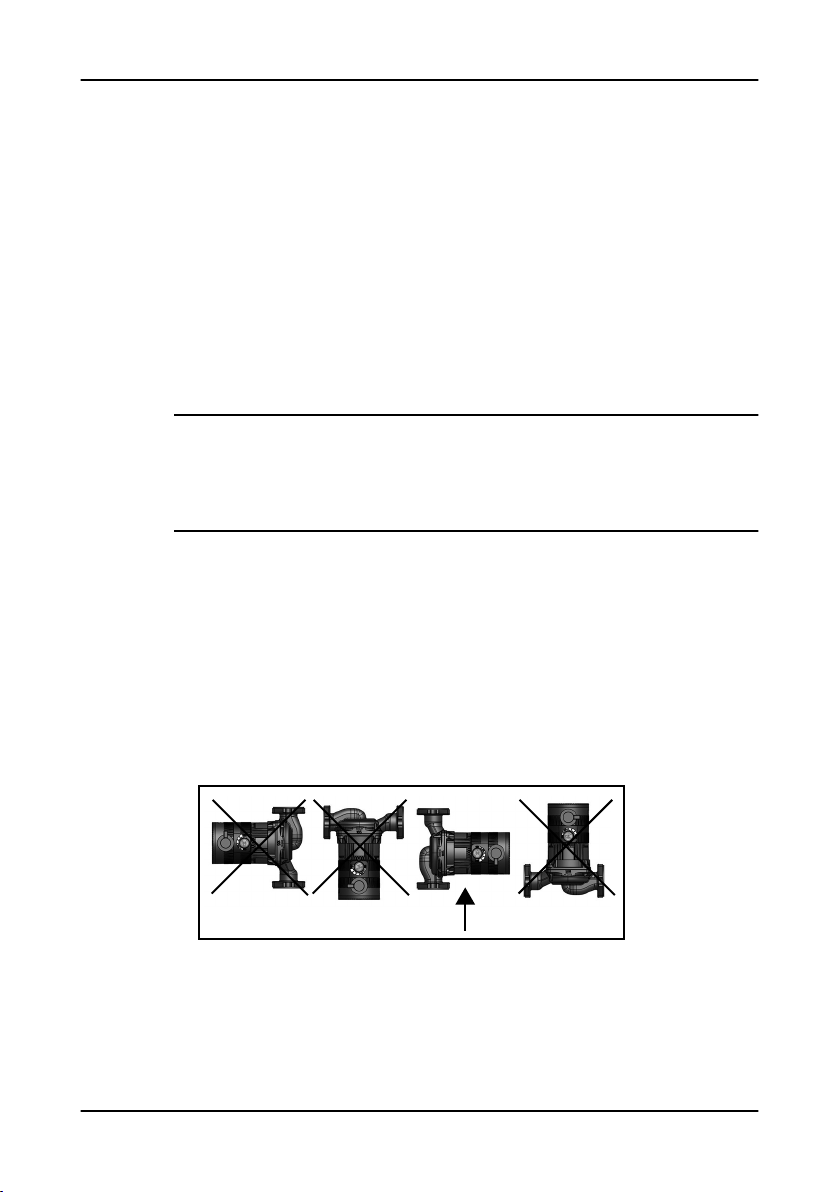

4.4 Pump installation requirements

• Install the pump according to the liquid flow direction arrows.

• Install the pump according to the allowed pump positions.

• Make sure that the pump is adequately supported by the piping system and

properly aligned to eliminate any stress on the pump or the piping

• Install the pump at a point closest to the highest static pressure point but

above the absolute lowest point in the system to avoid dirt and sediment

build-up.

4 Installation

ecocirc®19-16 INSTRUCTION MANUAL 15

• If required by application and code, install a safety relief valve to protect

against over temperature and over pressure.

• Do not install with the motor above the impeller. This installation can cause

the pump to run dry leading to premature failure of the pump and voids the

warranty.

4.5 Electrical installation

4.5.1 Precautions

WARNING:

• Make sure that all connections are performed by a qualified

electrician in accordance with all applicable codes,

ordinances and good practices. Failure to follow these

instructions could result in serious injury, death and/or

property damage.

• Before starting work on the unit, make sure that the unit and

the control panel are isolated from the power supply and

cannot be energized.

• Risk of Electrical Shock. To reduce the risk of electric shock,

connect only to a properly grounded, grounding type

receptacle. This warning applies to pumps fitted with flexible

cord connections.

• Electrical Grounding Hazard. Adequate electrical grounding

is required for the safe operation of B&G pumps. The use of

grounded metal conduit assures this requirement. If the

means of connection to the supply-connection box (wiring

compartment) is other than grounded metal conduit, ground

the pump back to the service. Use copper wire at least the

size of the wires supplying power to the pump. Connect the

ground wire to the ground terminal in the wiring

compartment. Failure to follow these instructions could

result in serious personal injury, death and or property

damage.

4.5.2 Connect the wires

1. Loosen the screw that secures the motor cover and remove the screw and

cover.

See Figure 6: Electrical connections on page 24 for more information.

2. Attach an appropriately sized electrical connector to one of the 7/8”

diameter holes on the side of the conduit box.

4 Installation

16 ecocirc®19-16 INSTRUCTION MANUAL

3. Connect the ground wire to one of the ground screws inside the conduit

box.

4. Make sure that the electrical connections are tightly secured before

replacing the motor cover.

4 Installation

ecocirc®19-16 INSTRUCTION MANUAL 17

5 Operation

5.1 Preparation for startup

Follow these precautions before startup:

• The system must be thoroughly rinsed to prevent the presence of unwanted

objects and impurities which could block the pump.

• Fill completely with pumped media (water or water/glycol mixture).

• Purge the entrained air.

– See Activate the air purge function on page 19.

– The air purge function can be activated at any time during operation,

when presence of air is suspected in the system.

– The air purge function can be repeated several times in a sequence if

necessary.

– Audible flow noise indicates presence of air that is entrained in the pump.

5.2 Modes of operation

The product has three standard and two auxiliary modes of operation.

Proportional

pressure (PP)

Turn the knob to any position between 1 and 7, with 7 being

the highest, to set the speed of the pump. The pump

automatically decreases its speed at low flow, thus providing

energy savings. This mode is the default setting.

Constant

pressure (CP)

Turn the knob to any position between 1 and 7, with 7 being

the highest, to set the speed of the pump. The preset

pressure remains constant, independent of the flow.

Constant speed

(CS)

Turn the knob to any position between 1 and 7, with 7 being

the fastest, to set the speed of the pump. The preset speed

remains constant, independent of the flow rate.

Automatic air

purge

This mode is used to purge air that is trapped in the pump

housing. See Activate the air purge function on page 19 for

instruction.

Standby This mode is used to keep power consumption low (<1 W),

when pump operation is not required.

5.3 Switch between standard operating modes

1. Turn the knob to the lowest setting.

2. Turn the know back to the desired setting within 5 seconds.

Pump indicates mode change by color of the knob LED:

Mode LED color

Proportional pressure (PP) Blue

Constant pressure (CP) Green

Constant speed (CS) White

5 Operation

18 ecocirc®19-16 INSTRUCTION MANUAL

Table of contents