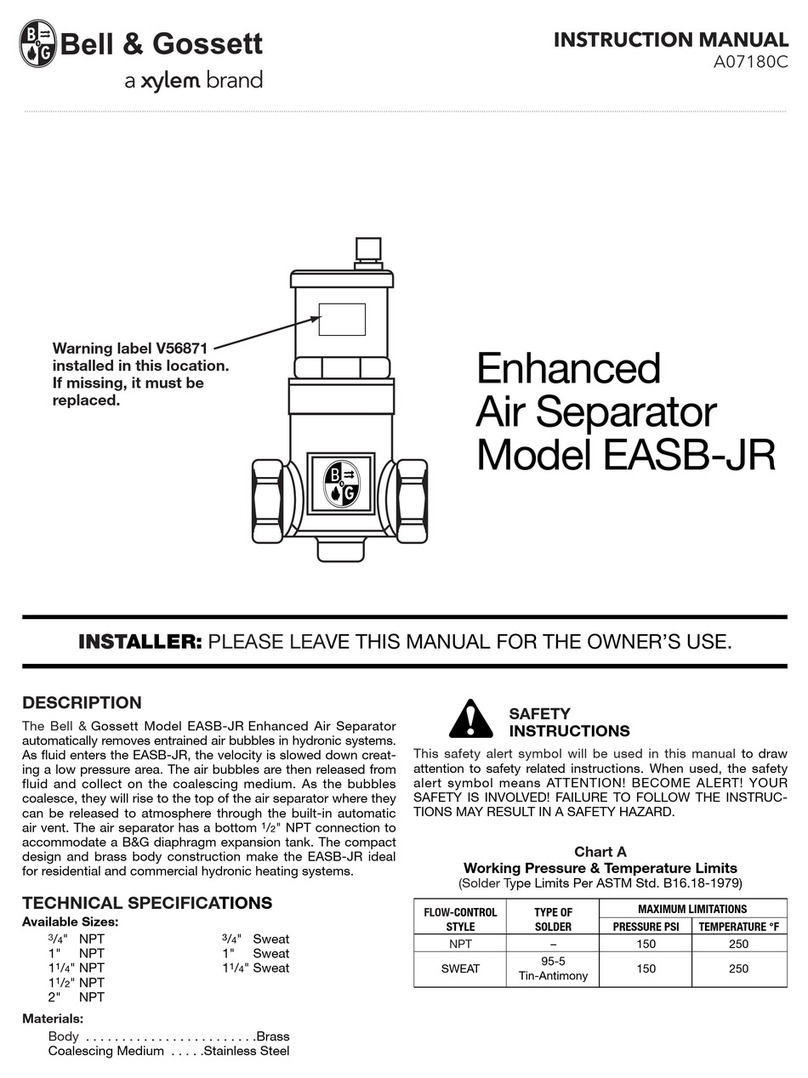

Bell and Gossett CRS Series User manual

Bell & Gossett ®

Instruction Manual V1000266

Series CRS

Coalescing Removal Separator

Installation, Operation and Service Instructions

INSTALLER: PLEASE LEAVE THIS MANUAL FOR THE OWNER’S USE.

WARNING: This product may contain chemicals known to the State of California to cause cancer, or birth

defects or other reproductive harm.

SAFETY INSTRUCTION: This safety alert symbol will be used in this manual to draw attention to safety related

instructions. When used, the safety alert symbol means ATTENTION! BECOME ALERT! YOUR SAFETY IS

INVOLVED! FAILURE TO FOLLOW THE INSTRUCTIONS MAY RESULT IN A SAFETY HAZARD.

Safety Message Level

DANGER:

WARNING:

CAUTION:

ELECTRICAL HAZARD:

NOTICE:

Indication

A hazardous situation, which if not avoided, will result in death or serious injury.

A hazardous situation, which if not avoided, will result in death or serious injury.

A hazardous situation, which if not avoided, will result in major or minor injury.

The possibility of electrical risks if instructions are not followed in a proper

manor.

• A hazardous situation, which if not avoided, will result in an indescribable

result or state.

• A practice not related to personal injury.

Project: Bentonville Jr High #4

Contractor: Comfort Systems USA

Representative: Boone & Boone Sales

Description

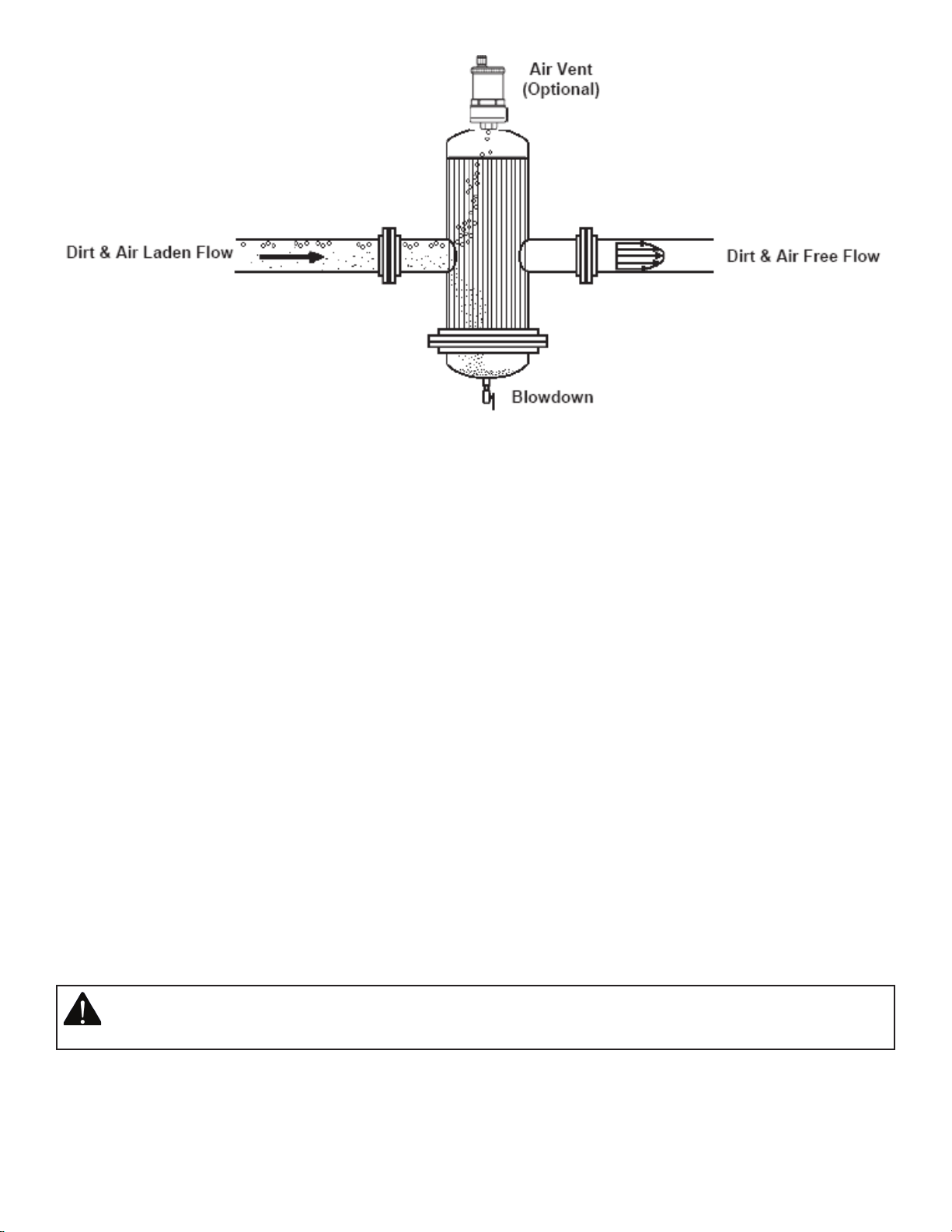

Bell & Gossett Series CRS Coalescing Removal Separators are designed to eliminate entrained air and separate debris

associated with start-up and maintenance of any hydronic system. The design incorporates an optional removable end

cover for coalescing medium access, and an optional air vent to automatically release air from the separator.

The design and construction conforms to ASME Section VIII, Div.1. This product is intended for hot and chilled water

systems.

Installation

A. PRE-INSTALLATION

1. Visually inspect Series CRS separator and check

for damage prior to installation.

Separator Temperature Max Working Pressure

CRS -20°F (-29°C) to 450°F (232°C) 125 PSI (862 kPa)

Operational Limits

WARNING: Explosion or Rupture Hazard. A relief valve must be installed to prevent pressure in excess of local

code requirement or maximum working pressure designated in the Product Manual, whichever is less. Do not

expose Series CRS Coalescing Removal Separator to freezing temperatures or temperatures in excess of 450°F.

Failure to properly size the Product or follow these instructions may result in excessive strain on the system

and may lead to Product failure, serious or fatal personal injury, leakage, and/or property damage.

WARNING: Read carefully the product installation, operating and maintenance instructions. Failure to follow

the instructions and warnings in the manual may result in serious or fatal injury and/or property damage, and

will void the product warranty. This product must be installed by a qualified professional. Follow all applicable

local and state codes and regulations, in the absence of such codes, follow the current editions of the National

Plumbing Code and National Electric Code, as applicable.

WARNING: : This product, like most products under pressure, may over time corrode, weaken and burst or

explode, causing serious or fatal personal injury, leaking or flooding and/or property damage. To minimize risk,

a licensed professional must install and periodically inspect and service the Product. A drip pan connected to

an adequate drain must be installed if leaking or flooding could cause property damage. Do not locate in an

area where leaking could cause property damage.

WARNING: If the separator is damaged,

it must be replaced. Failure to follow this

instruction may result in serious personal

injury or death and property

damage.

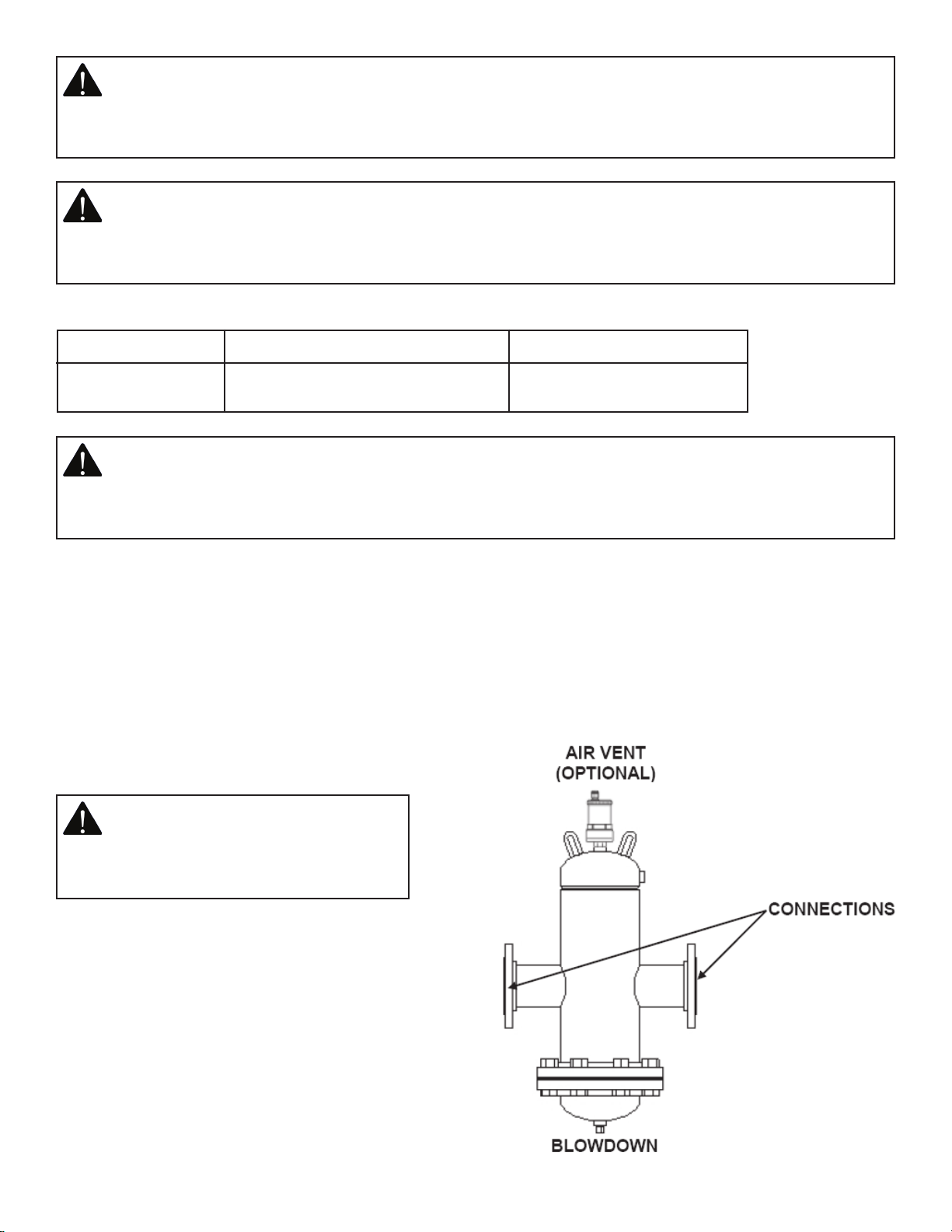

2. In order to protect the Series CRS separator

from shipping damage, some components are

shipped unattached and in a protective box. These

components are to be added to the Series CRS

separator on site. See Figure 1.

fig. 1

WARNING: System fluid under pressure and/or at high temperatures can be very hazardous. Before servicing,

reduce system pressure to zero or isolate the vessel from the system. Allow system to cool below 100°F and

above 35°F. Failure to follow this instruction may result in serious personal injury and/or property damage.

B. INSTALLATION

It should be noted that the solubility of air into water decreases as pressure drops and/or as temperature rises. Placing

the Bell & Gossett Series CRS separator before the pump inlet will also help pump performance and increase seal life.

CAUTION: Installation and maintenance must be performed by a qualified professional. Service should not

be performed on any component in an active hydronic loop. Before attempting to make any required adjust-

ments, properly isolate and drain the branch loops that require service and allow the valves to reach a safe

handling temperature and zero pressure condition. Use proper safety equipment including gloves, goggles,

or similar tools to avoid contact with system fluids and common hazards. Failure to follow these instructions

could result in personal injury and property damage.

The separator must be installed vertically.

Do not install on a dead end pipe or in an overhead joist space.

fig. 2 - Air Elimination

Figure 2 shows suggested mounting locations for a heating or cooling system.

WARNING: RUPTURE OR EXPLOSION HAZARD - Like most pressurized tanks, this tank can over time corrode,

weaken, and burst or explode. Failure to follow this instruction may result in serious personal injury or death

and property damage.

WARNING: CHLORINE & AGGRESSIVE WATER HAZARD - The water quality can significantly influence the life of

your product. You should test for corrosive elements, acidity, total solids, and other relevant contaminants, in-

cluding chlorine and treat your water appropriately to insure satisfactory performance and prevent premature

failure. Failure to follow this instruction may result in serious personal injury or death and property damage.

Before filling and starting the operation of a HVAC system, a properly applied and sized pressure relief valve must be

installed and in good operating order.

During filling and start-up after servicing, the system pressure should be closely monitored to ensure the pressure does

not exceed the pressure relief valve rating.

Consult the applicable pressure relief valve manufacturer’s instructions as necessary.

System Venting and Purging

After initial venting and purging of air from the system, more air will be released from the water as it is heated. An

optional Bell & Gossett No. 98 Air Vent may be assembled at the top of the Series CRS separator.

If the system has multiple loops or zones, the supply water for all loops and zones must pass through the Series CRS

separator for complete and continuous air removal. In case the piping arrangement does not permit the installation of

a single separator on the main, additional separators should be installed on each loop or zone. In this event, only one

expansion tank is required for the system.

Even with a No. 98 air vent installed on the separator, it is recommended that additional Bell & Gossett air vents be

installed on high points in the system.

CAUTION: Uncontrolled venting of water can occur with automatic air vents if foreign material prevents vent

from closing. Unwanted flow should be directed to a drain. Failure to follow these instructions could result in

property damage and/or moderate personal injury.

NOTICE: Never use the separator itself as a form of piping support. Please support separator and piping ac-

cording to the local building code. Failure to follow these instructions may result in property damage.

A manual blow down valve can be added to the blow down connection at the bottom of the separator. The function of

the blow down valve is to facilitate the purging of sediment from the vessel.

CAUTION: Use unit lifting lugs only to lift unit as shipped from factory. Unit must be empty and disconnected

from pipe, and other restraints. Use proper rigging procedures. Failure to follow these instructions could result

in injury or property damage.

Be aware of water weight in the separator and connected piping when installing your system. The wet filled weight of

the Series CRS separators can exceed the strength of the supports used. Make sure that provisions are made to properly

support the wet filled separator.

Welding to the pressure vessel boundary will void the ASME stamp.

Upon initial start up, the blow down valve should be operated frequently. At each blow down operation, document the

amount of sediment collected and the amount of time since the previous blow down operation. Use this information to

determine and adequate blow down schedule for your system.

The selection, application, installation and servicing of this product should be performed by a qualified professional

within all applicable safety and code requirements.

Service Instructions

Check the Series CRS separator periodically for signs of external leakage or corrosion. If any is found, the separator

must be replaced.

WARNING: Signs of leakage or corrosion are indications the Series CRS separator may have failed. Periodically

check the expansion tank for signs of external leakage or corrosion. If found, the tank must be replaced.

Failure to follow these instructions may result in serious personal injury or death and property damage.

1. The system water contains air bubbles, entrained air, and dirt particles.

2. Large air bubbles quickly rise to the top of the vessel and into the vent. Micro-bubbles coalesce and form larger

bubbles. Entrained air is pulled out of solution and forms micro bubbles.

3. The air vent releases air fast as it can be separated.

4. Dirt particles are strained or filtered from the water and collect in the bottom of the vessel.

5. The coalescing medium/filter separates the air and dirt from the water. Stainless steel construction provides durability

and long life.

6. Should the need to clean the coalescing medium arise, the standard removable bottom cover provides ease of

removal and cleaning.

7. Collected sediment can be flushed out through the blow down valve.

fig. 3 - Series CRS Operation

Operating Instructions

fig. 4

2. Open the blow down valve for a few seconds. This should dislodge accumulated dirt or sediment from the medium.

If it does not, then the coalescing medium must be removed from the Series CRS separator for cleaning. This can be

accomplished by closing the isolation valves to isolate the separator from the system. Make sure that the system water

was allowed to reach a safe handling temperature, and the separator to reach a zero pressure condition. Open the

blow down valve on the bottom of the separator to drain the unit. Make sure that all flow from the blow down valve

has stopped. If water continues to flow, the isolation valves must be repaired or replaced before proceeding.

3. For Series CRS separators with removable heads, remove the flange bolts that hold the coalescing medium housing

cover (head) in place on the bottom of the separator.

4. Clean the medium and reinstall in the Series CRS separator. Replace the cover head gasket with a new one and

reinstall the cover making sure that the flange bolts are tightened. The bolts should be torqued incrementally to 30%,

60%, and then to 100% of the appropriate value shown on the table on the next page. The bolts should be torqued in

the sequential order of the appropriate pattern shown in Figure 4.

WARNING: System fluid under pressure and/or at high temperatures can be very hazardous. Before servicing,

reduce system pressure to zero or isolate the vessel from the system. Allow system to cool below 100°F and

above 35°F. Failure to follow this instruction may result in serious personal injury and/or property damage.

The coalescing medium in the Series CRS separator may need to be cleaned periodically. This is true during the initial

start-up period. The need to clean the coalescing medium will be evidenced by a high pressure drop across the

separator or by pump cavitation problems. To clean the medium:

1. Allow the system water to reach a safe handling temperature

5. Once the cover has been reassembled to the Series CRS separator and the bolts have been appropriately tightened,

close the blowdown valve at the bottom of the separator and open the isolation valves to return the separator to

normal operation.

Service Instructions - Accessories

The Series CRS separator may have optional accessories assembled at the factory, or by the installer at the job site.

These components include a Bell & Gossett No. 98 Air Vent; a blowdown valve; or a skim valve. The factory installed

components come pre-assembled with a leading industrial thread sealant, Loctite 567, and are tightened to

appropriate levels. With that in mind, the following information should help to clarify questions regarding the

adjustment, servicing, or field installation of those components when required.

Any field adjustment of factory installed components will break the original thread seal and could cause leakage. This

will necessitate the removal, cleaning, and resealing of those parts per the instructions below.

Should any adjustment or servicing of air vents, blowdown valves, skim valves, drain plugs, or other accessories be

required, please take the following steps:

1. Completely remove the desired component from the Model CRS Separator.

2. Taking care not to damage any threads on the component or the separator, clean off all of the old thread sealant.

Use a wire brush and gentle abrasion if necessary. Allow the valve and the component to dry. Note: If the component

or valve appears to have been damaged, replace it.

3. Starting with the second thread of the NPT male component, apply a 360° bead of Loctite 567 thread

sealant/lubricant as shown below. Follow Loctite handling precautions as noted on the product labeling.

4. If Loctite 567 is unavailable, recommends RectorSeal No. 5 pipe thread sealant for all non-glycol based

applications, or any PTFE thread sealing tape. Be sure to follow the manufacturer specific handling precautions and

application instructions as noted on the product labeling.

5. Thread component into valve until it is finger tight.

6. Apply torque to the following specification:

CAUTION: Installation and maintenance must be performed by a qualified professional. Service should not

be performed on any valve in an active Hydronic loop. Before attempting to make any required adjustments,

properly isolate and drain the branch loops that require service and allow the valves to reach a safe handling

temperature and zero pressure condition. Use proper safety equipment including gloves, goggles, or similar

tools to avoid contact with system fluids and common hazards. Failure to follow these instructions could

result in personal injury and property damage.

Component Separator Size Connection Size Torque

Skim Valve 2” Through 12” 1/2” NPT 9.0 ft.-lbs + 3.0 ft.-lbs. / -0

Blowdown Valve 2” Through 6” 1/2” NPT 9.0 ft.-lbs + 3.0 ft.-lbs. / -0

8” Through 12” 1” NPT 12.0 ft.-lbs + 4.0 ft.-lbs. / -0

Air Vent 2” Through 12” 1/2” NPT 9.0 ft.-lbs + 3.0 ft.-lbs. / -0

Plug 2” Through 12” 1/2” NPT 9.0 ft.-lbs + 3.0 ft.-lbs. / -0

2” Through 12” 1” NPT 12.0 ft.-lbs + 4.0 ft.-lbs. / -0

Copyright © 2010

8200 N. Austin Ave.

Morton Grove, IL 60053

Tel: (847) 966-3700

Fax: (847) 966-9052

www.bellgossett.com

7. Properly assembled separator components will immediately seal to moderate pressure (100 PSI or less). For maximum

pressure resistance, allow the Loctite 567 or RectorSeal No. 5 thread sealant to cure for 24 hours. PTFE tape typically

does not require curing to achieve maximum pressure resistance.

Loctite and Loctite 567 are registered trademarks of Henkel AG & Co. RectorSeal No. 5 is a registered trademark of

RectorSeal Corporation.

NOTICE: Over application of torque may cause damage to the Separator or accessory component.

Table of contents

Other Bell and Gossett Water Filtration System manuals

Popular Water Filtration System manuals by other brands

Royal Doulton

Royal Doulton Elite installation instructions

Clean Water Systems

Clean Water Systems 7500 Series Installation & start?up guide

Hayward

Hayward AquaRite + owner's manual

BestWater

BestWater Jungbrunnen 66-10 user manual

MEDENUS

MEDENUS DF 100 Operating and maintenance instructions

BWT

BWT BWT bestaqua 24 HQ Fitting and operating instructions