MEDENUS DF 100 Manual

© 05.2022

Cellular Gas Filter

DF 100

Operating and Maintenance Instructions

Subject to technical modifications! Reprint prohibited!

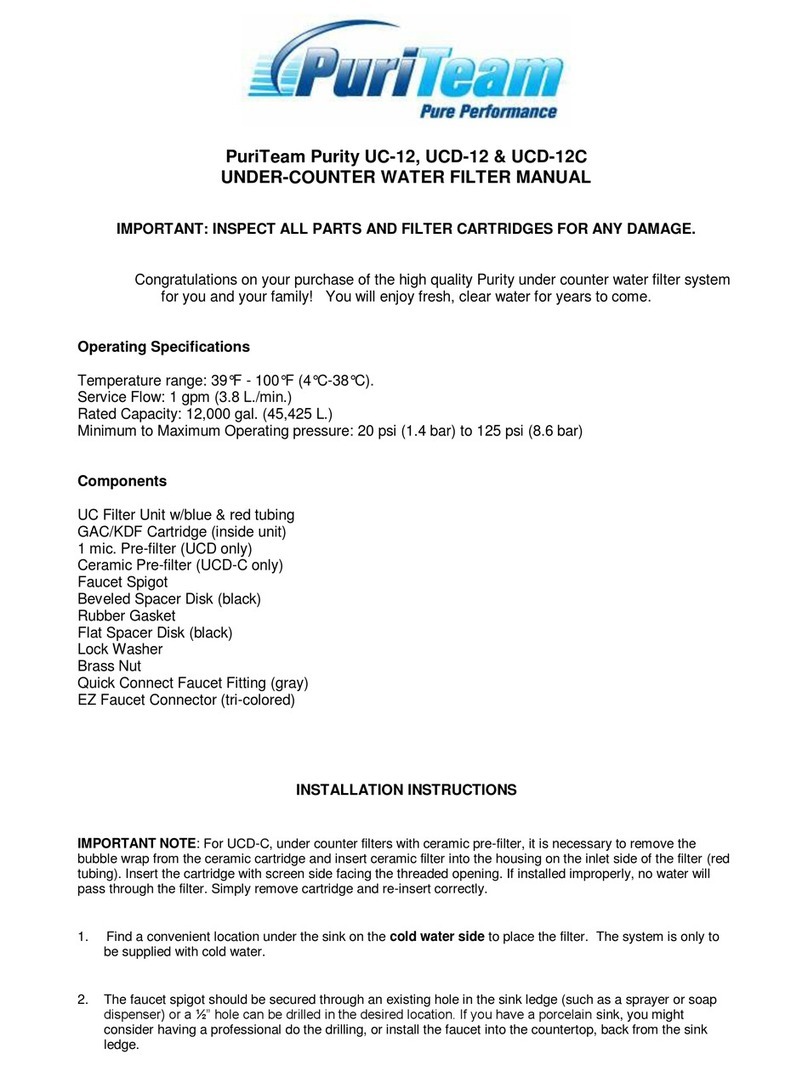

Design of the cellular gas filter DF 100

shown DN 50

Hood

Filter cartridge

Housing

Cover

Table of Contents

1 General Information 6

1.1 Warranty and Liability 6

1.2 Symbols, Notes 7

1.3 Terms, Abbreviations 7

2 Application, Characteristics 8

2.1 Application 8

2.2 Characteristics 8

2.3 Types of Models (Options) 8

3 Avoidance of Foreseeable Misuse 8

4 Safety Instructions 9

4.1 Hazards of Handling the Device 9

4.2 Personnel Requirements 9

4.3 Country-Specific Requirements 9

4.4 Handover of the Operating and Maintenance Instructions 9

4.5 Safety in Operation 10

4.6 What To Do in Case of Danger 10

5 Responsibility of the Operator 10

6 Transport, Storage and Packaging 11

6.1 Transport 11

6.2 Storage 11

6.3 Packaging 11

7 Mounting and Commissioning 12

7.1 Safety Instructions and Preparation 12

7.2 Mounting 12

7.3 Leakage Test (Test for External Leakage) 13

7.4 Initial Commissioning / Recommissioning 13

7.5 Decommissioning 13

8 Maintenance 14

8.1 Maintenance Plan 14

8.2 Maintenance Procedure 14

8.3 Table of Screw Tightening Torques MA15

8.4 Lubricants Table 16

Oxygen model 16

For oxygen models, a suitable grease which is approved for the use 16

with oxygen must be used. 16

9 Troubleshooting 16

10 Replacement and Disposal 16

11 Spare Parts 17

11.1 Spare Parts Drawing DF 100 17

11.2 Parts for Maintenance Work 17

O-rings 17

O-rings for low temperatures (-40°C) 17

Filter cartridge 17

Notes 18

12 Accessories / Options 19

12.1 Differential pressure gauge 19

Declaration of Conformity 26

Notes 27

6

© 05.2022

1 General Information

The personnel entrusted with installation, operation or maintenance of the cellular gas filter must

have completely read and understood beforehand the following documents:

• Product information of the cellular gas filter DF 100

The product information contains technical data, dimensions and a description of the design and the mode of

operation.

• Operating and maintenance instructions of the cellular gas filter DF 100

This document allows safe and efficient handling of the device and contains information on assembly,

commissioning, maintenance, troubleshooting, and repair according to regulations.

It is an integral part of the scope of delivery of the device, must be kept in close proximity of the device and

must be readily accessible to personnel at any time.

The basic prerequisite for safe working is compliance with all safety instructions and instructions for action

given in this manual. Accordingly, the information and instructions must be observed when working on the

device or on the gas line. In addition, the local occupational safety regulations and general safety regulations

for the application range of the device shall apply.

The figures in these instructions are provided for basic understanding and may differ from the actual design.

The contents of these instructions are protected by copyright. They may be used as part of operating the

device. Any other use and/or reproduction is not permitted without prior authorization by MEDENUS Gas-

Druckregeltechnik GmbH.

1.1 Warranty and Liability

Claims under warranty or liability for personal injury and material damage are generally void,

if one or several of the following conditions are not observed:

• Work on the device during the warranty period may only be performed in consultation with the manufacturer

• Designated use of the device in accordance with the established conditions of use

• Proper installation, commissioning, operation and maintenance of the device

• Operation of the device with properly installed and functioning safety devices only

• Operating and maintenance instructions of the device or of the system

• Compliance with the maintenance instructions

• Properly performed repairs

• Supply lines without defects

• The use of original MEDENUS©spare parts and lubricants listed in these instructions or

• Force majeure

It is generally prohibited

• To perform constructive modifications on the device

• To keep using the device despite the detection of a defect

7© 05.2022

1.2 Symbols, Notes

The instructions contain safety instructions marked with symbols to indicate possible consequences in case of non-

observance:

1.3 Terms, Abbreviations

Terms and abbreviations are explained below:

DN Nominal width

MTScrew tightening torque

MOP Maximum operating pressure in a system

DANGER

Note

ATTENTION

This combination of symbol and signal word indicates a potentially hazardous

situation which, if not avoided, may result in minor or moderate injury, damage

to the device, the breakdown of the system, and material or environmental

damage.

This combination of symbol and signal word indicates an imminent hazardous

situation which, if not avoided, will result in death or serious injury.

This signal word highlights useful tips, recommendations, and information for

efficient and trouble-free operation.

8

© 05.2022

2 Application, Characteristics

2.1 Application

Type DF 100 cellular gas filters are intended to separate gas impurities such as dust, rust, and other solids in gas-

carrying lines at a defined point. They are mainly used in gas systems and in front of such devices whose function is

impaired by contamination.

Can be used as an equipment component on gas consumption facilities as defined in Regulation (EU) 2016/426.

These filters can be used for gases according to DVGW work sheet G 260/G 262 and for neutral non-aggressive gases.

(other gases on request)

2.2 Characteristics

• Open-airmodelasstandard

• Easilyreplaceablefiltercartridgewithhydrophobicfiltermedium

• Highseparationefficiencythanktooptimizedflowguidance

2.3 Types of Models (Options)

• Oxygenmodel

• withdifferentialpressuregauge

3 Avoidance of Foreseeable Misuse

• TheDF100cellulargasfiltersmustnotbeusedforfilteringliquids.

• TheDF100cellulargasfiltersmustnotbeusedintemperaturerangesbelow-40°Corabove70°C

• TheDF100cellulargasfiltersmustnotbeusedforpressurerangeshigherthanthepressure“PS“indicated

on the nameplate.

• TheDF100cellulargasfiltersmayonlybeusedforthegasesspecifiedunderitem2.1Applicationinthese

operating instructions.

Other gases, such as oxygen or hydrogen, must be explicitly stated on the nameplate.

Please consult the manufacturer before use.

• TheDF100cellulargasfiltersmustnotbeusedinhigh-temperatureareas(HTB)withoutanupstreamHTB

fuse.

9© 05.2022

4 Safety Instructions

National accident prevention regulations and the system operator's safety regulations are not superseded by these

operating and maintenance instructions and must be taken into consideration with priority (in Germany, see, among

others, DVGW work sheets G 600, G 459/II, G 491 and G 495).

When performing work on the device, the current general and

specific safety regulations must be observed.

The application limits of the device with respect to the medium, operating pressure and operating temperature can be

found on the nameplate affixed to the device or on the acceptance test certificate.

Using the device under different operating conditions must be agreed upon in consultation with

MEDENUS Gas-Druckregeltechnik GmbH.

The mechanical components of the device do not have any potential ignition sources of their own nor any hot surfaces

and are thus not covered by the scope of 2014/34/EU (ATEX). The electronic accessories used comply with the ATEX

requirements.

4.1 Hazards of Handling the Device

MEDENUS©devices conform with current standards and directives, the recognized technical rules,

and the recognized safety rules.

However, improper use can result in hazards to the user or to third parties. This can also result in damage to the device

or to the system.

This is why the device may only be used:

• in accordance with its designated use

• in perfect condition

• while observing the notes given in these operating and maintenance instructions, and inspection and

maintenance regulations, which apply to the functioning and safety of the overall system.

Malfunctions or faults must be eliminated immediately.

4.2 Personnel Requirements

The device may only be mounted by qualified personnel.

Only authorized personnel with the required qualification is allowed to perform settings or repairs on the device.

4.3 Country-Specific Requirements

The rules and regulations applicable at the place of use must be observed and complied with. They apply to:

• gas lines, installation of the gas system

• gas supply

• work on the gas system

• accident prevention

4.4 Handover of the Operating and Maintenance Instructions

The supplier of the system shall hand over these operating and maintenance instructions to the operator of the system

no later than during commissioning and training

of the operating personnel with the reminder to carefully store these instructions.

10

© 05.2022

4.5 Safety in Operation

The device may only be used when all protective devices on the device or in the system are fully functional.

At least once a year, the device must be inspected for externally visible damage and for proper functioning

by a representative of the manufacturer or by a qualified person.

A more frequent inspection may become necessary, depending on the system conditions.

4.6 What To Do in Case of Danger

Information on what is to be done in case of danger and in case of accidents can be found in the respective operator's or

specialist companies' work instructions.

5 Responsibility of the Operator

Operator An operator is a person who operates the device himself/herself for commercial or economic purposes

or leaves it to a third party for use/application and is legally responsible for the safety of the user, the

personnel or third parties during operation.

The device is used in the commercial sector. The operator of the device is therefore subject to the legal

obligations for occupational safety. In addition to the safety instructions contained in these instructions,

the established maintenance intervals must be observed, taking into account the respective national

standard (alarm and hazard prevention plan).

In particular, the following applies:

• The operator is obliged to perform work on MEDENUS©devices during the warranty period only

after consultation with the manufacturer. Otherwise the claims under warranty will become

void.

• The operator must obtain information on the current occupational safety regulations and

determine additional hazards resulting from the special work conditions at the place of use of

the device in a risk assessment. The owner must implement the results in the form of operating

instructions for the device.

• During the entire time of use of the device, the operator must check whether the operating

instructions issued by him/her conform to the current state of the regulations and, if necessary,

adapt them.

• The operator must clearly regulate and define the responsibilities for installation, operation,

troubleshooting, maintenance and cleaning.

• The operator must ensure that all persons handling the device have read and understood these

instructions. In addition, the owner must train the personnel at regular intervals and inform

them about the hazards.

• The operator must make available to the personnel the required protective equipment and

oblige them to wear the required protective equipment.

• Moreover, the operator is responsible for the device always being in technically perfect condition.

Therefore, the following applies:

• The operator must make sure that the maintenance intervals described in these instructions

are observed.

• The operator must have all safety devices checked regularly for functionality and completeness.

Operator

duties

11 © 05.2022

6 Transport, Storage and Packaging

6.1 Transport

The device is delivered with flange protection caps. They must be removed prior to installation.

Make sure that the device is transported horizontally using suitable lifting gear. The device must be

handled carefully and secured against impacts and knocks.

In case of transport damage, we will require the following information from the nameplate affixed to

the device:

• Device type

• Device model

• Year of construction/fabrication number

Note

6.2 Storage

Equipment and spare parts must be stored under the following conditions:

• Do not store outdoors.

• Store in a dry and dust-free location.

• Store on a flat surface.

• Do not expose to aggressive media.

• Do not expose to ozone or ionizing radiation.

• Do not store adjacent to direct heat sources.

• Avoid mechanical vibrations.

• Storagetemperature:0to25°C.

• Relative air humidity: < 55 %.

Spare parts:

• Components susceptible to corrosion must be provided with a suitable preservative.

• Do not store O-rings and seals for more than 5 years even if stored properly.

• Spare parts must be stored in their original packaging until use.

Storage period for devices:

• Storage of the device for up to one year:

Store the cellular gas filter in its original packaging and its original condition as delivered. All protective caps

of the device must remain mounted.

• Storage of the device for more than 1 year (e.g. as a spare device):

Store the device in its original packaging and its original condition as delivered and check it for damage once

a year. Check the housing surface for dirt, damage and corrosion. If necessary, clean all external parts. After

5 years, all O-rings and seals must be replaced.

6.3 Packaging

• The individual packaged items have been packaged in view of the transport conditions to be expected.

• The symbols on the packaging must be observed during transport and storage.

• Only environmentally friendly materials have been used for packaging.

• The packaging is designed for protecting the individual components from transport damage, corrosion and

other damage until mounting. This is why the packaging must not be destroyed and only removed just prior to

mounting.

12

© 05.2022

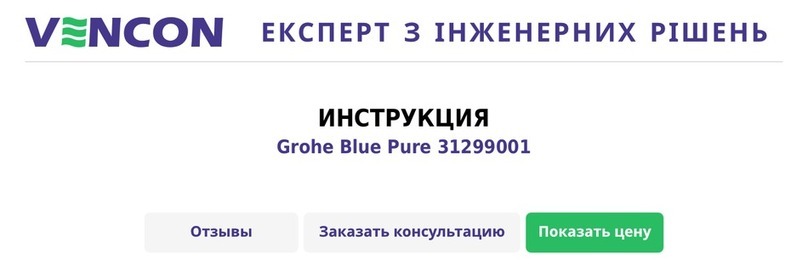

P1

P2

min. 5x DN

Inlet

Outlet

Range for

measuring points*

(approx. 3x DN P2)

Note

Note

7.2 Mounting

• Remove the packaging, flange protection caps and shipping braces.

• Check the device for wear and damage.

• Make sure that the device is installed free of stress. Make sure to observe the direction of flow

i.e., the arrow on the housing must point in the direction of flow.

Gas pressure regulators Flange tightening torques

Screw size Screw tightening

torque MA

Screw size Screw tightening

torque MA

M6 8Nm M12 60Nm

M8 18Nm M16 120Nm

M10 36Nm M20 190Nm

M12 62Nm

Tightening torques MA*)

*) For the assembly of the

flange connections, the maxi-

mum torques specified by the

flange and gasket manufac-

turers must be observed. The

values indicated here should

be considered as approximate

values.

7 Mounting and Commissioning

7.1 Safety Instructions and Preparation

Prior to starting work on pressurized components:

• Close all connections to the gas line.

• Depressurize all pressurized components. Also discharge residual energies.

• Defective components charged with pressure in operation must be replaced immediately by

an appropriate expert.

Prior to starting work, ensure sufficient clearance for mounting.

Before installing the device, check whether the performance data (nameplate) and the scope of

delivery coincide with the order or the system data, i.e., make sure that the provided devices are

suitable for their intended purpose. In particular, the inlet pressure of the system must be lower than

the maximum allowable pressure of the device.

Direct contact of gas valves and fittings, i.e., the control system, with hardening masonry, concrete

walls or floors is not permitted. Provide suitable supports, working materials and protective

equipment.

Take into account the minimum clearances for maintenance as stated in the product information.

Beforeinstallingthedeviceinthepipeline,checkwhetherashut-offdevicethatinterruptsthegas

flow supply to the device has been mounted upstream and downstream of the device to be installed.

Prior to commissioning, make sure that all installation work has been carried out and completed

in accordance with the data and information given in these instructions and that no unauthorized

persons stay in the danger zone.

DANGER

Note

Note

DANGER

13 © 05.2022

X

Y

Z

7.3 Leakage Test (Test for External Leakage)

The devices are subjected to a strength and leakage test ex works at MEDENUS Gas-Druckregeltechnik GmbH.

The leakage test in the fully assembled system must be performed prior to commissioning and following maintenance

work.

For the external leakage test in the fully assembled system, the following applies

For Germany:

According to the DVGW work sheet G 491, the fully assembled system must be subjected to a leakage test with air or an

inert gas at the installation site, using 1.1 times the maximum operating pressure of the system (MOP).

An exception is the room between the actuator of the gas pressure regulator installed in the system and the first shut-

off valve on the outlet side. This room must be checked using a test pressure corresponding to the maximum possible

setpoint of the gas pressure regulator. In this test, all detachable connections must be checked using a foaming agent.

For other countries:

The relevant national and international standards shall apply.

Procedure

• Close the ball valve upstream of the valves and fittings.

• Close the downstream shut-off devices (ball valves, solenoid or pneumatic valve).

• Depressurize the system.

• Connect the testing device to measuring points upstream and downstream of the filter.

• Always increase the test pressure slowly and steadily.

While doing so, you must ensure:

Pressure in outlet chamber ≤pressure in inlet chamber

Pressure build-up always from the inlet side (inlet chamber)

Pressure reduction always from the outlet side (outlet chamber)

7.4 Initial Commissioning / Recommissioning

For commissioning, please refer to the relevant manufacturer's documentation of the gas pressure regulator installed

in the system and the work instructions of the system operator.

7.5 Decommissioning

For decommissioning, please refer to the relevant manufacturer's documentation of the gas pressure regulator installed

in the system and the work instructions of the system operator.

Note

Connection

Abmessung /

dimension (mm) Nennweite /nominal size (DN)

Anschluss

Differenzdruck /

Connection differential

pressure

25 50 80 100 150 200

DF100

X 102 225 317 404 817 954

RP1/4“Y 80 116 138 188 195 225

Z 160 250 280 350 380 420

14

© 05.2022

8 Maintenance

8.1 Maintenance Plan

The following sections describe the maintenance work required for optimal and

trouble-free operation of the device. If increased wear is detected during regular inspections, the required

maintenance intervals must be shortened in accordance with the actual wear.

For any questions on maintenance work and intervals, please contact the manufacturer.

The intervals for monitoring and maintenance work are strongly dependent on the

operating situation and the condition of the gas. This is why no fixed intervals

can be given. For Germany, it is recommended that the maintenance periods as specified in the DVGW work sheet G 495

are observed initially.

For each system, this must be followed by determining the maintenance interval independently on a medium-term basis.

During maintenance work, the components must be cleaned and subjected to a thorough visual inspection. This is also

necessary if irregularities in the operating behavior have been detected during operation or during functional tests.

The check must cover in particular the filter insert and the seals.

Damaged parts and O-rings dismounted during dismantling must be replaced with new ones.

The item numbers mentioned in chapter 6.2 (Maintenance Procedure) correspond to those listed in the spare parts

drawings and spare parts lists.

It is recommended to stock the parts listed in chapter 9.5 on page 18 for maintenance work.

Interval Maintenance work Personnel

When necessary

Replacing the filter cartridge

Qualified person

Replacing the O-ring between the cover and the housing

Replacing the O-ring for sealing the filter cartridge

Replacing the O-ring for sealing the valve seat

Replacing the O-ring between the hood / spacer and the housing

Replacing the O-ring between the hood and the spacer

Replacing the sealing ring of the connection of the differential pressure

device

8.2 Maintenance Procedure

If components have been removed, make sure they are mounted correctly, reinstall all fastening

elements and observe the screw tightening torques.

Prior to recommissioning, observe the following:

• Make sure that all maintenance work has been carried out and completed in accordance

with the data and information given in these instructions.

• Make sure that no unauthorized persons stay in the danger zone.

• Make sure that all covers and safety devices have been installed and are working properly.

ATTENTION

DANGER

For recommissioning, please refer to the relevant manufacturer's documentation of the

gas pressure regulator installed in the system, the work instructions of the system operator, and the other

safety regulations of the system in which the filter has been installed.

15 © 05.2022

8.2 Maintenance Procedure

As a functional test, a pressure loss measurement for the flow resistance can be carried out. Limit

value for a contaminated filter cartridge: Δpmax= 0.8 to 1 bar

• Close fittings upstream and downstream of the filter. Depressurize the filter.

• Dismount the hood. To do so, unscrew the Allen screws on the hood. Exception for DN 25: Unscrew the hood.

• Remove the O-ring (item 8) inside the housing or hood. Clean the O-ring groove and insert a new greased

O-ring into the groove.

• Pull out the filter cartridge towards the top and check whether it is dirty. If necessary, the filter cartridge must

be cleaned or replaced.

• For DN 150 / DN 200: Dismount the spacer. To do so, unscrew the Allen screws (item 55) at the spacer. Remove

the O-ring (item 8) from the housing or from the spacer.

To lower the dismounting dimension for the nominal widths of DN 150 and DN 200, the filter cartridge

and the spacer should be removed together.

• Clean the O-ring grooves and insert new, greased O-rings into the grooves.

• Dismount the cover. To do so, unscrew the Allen screws (item 52) from the cover. It may be necessary to clean

the cover.

• Remove the O-ring (item 4) from the housing. Clean the O-ring groove and insert a new greased O-ring into

the groove.

• Remount the cover. To do so, screw down the Allen screws (item 52) at the cover crosswise, using a torque

wrench. (see Table 6.3)

• Place the cleaned or new filter cartridge in the valve seat. The filter cartridges DN 25 and DN 100 comprise a

centering ring at one end guaranteeing the correct fit of the cartridge in the valve seat. During installation, the

centering ring is located at the bottom inside the filter.

• For DN 150 / DN 200: Mount the spacer. To do so, screw down the Allen screws (item 55) at the spacer crosswise,

using a torque wrench. (see Table 6.3)

To lower the mounting dimension for the nominal widths of DN 150 and DN 200, the filter cartridge

and the spacer should be inserted together.

• Place the hood and tighten the Allen screws (item 50) crosswise, using a torque wrench. Exception for DN 25:

Screw in the hood (item 50) and tighten it, using a torque wrench. (see table 6.3) When screwing in, exert a

slight pressure on the hood. The filter cartridge is oversized and, due to the leak tightness to be achieved, it

must be slightly compressed.

• The maintenance parts in the differential pressure measuring instrument are only replaced when necessary.

• Open the valves and fittings upstream and downstream of the filter and check for leak tightness (using a

foaming agent).

To guarantee smooth operation, we recommend always keeping a maintenance set in reserve.

Note

Note

Note

Note

8.3 Table of Screw Tightening Torques MA

Item

no. DF100 / 025 DF100 / 050 DF100 / 080

DF100 / 100 DF100 / 150 DF100 / 200

50 M12/62Nm M10/36Nm

52 M8/18Nm M10/36Nm M10/36Nm M12/62Nm M12/62Nm

55 M10/36Nm M8/18Nm M12/62Nm M10/36Nm

The screw positions are shown on page 17.

16

© 05.2022

9 Troubleshooting

Description of the error Possible cause Elimination Personnel

Differential pressure

across the filter too high Filter cartridge dirty Replace filter cartridge

Qualified

person

Dust in the system Filter cartridge defective Replace filter cartridge

O-ring damaged Replace O-ring

Leakage towards the

outside O-ring damaged Replace O-ring

Faulty differential pressure

display Pressure gauge or reed contact is defective

Replace pressure

gauge* or reed contact

10 Replacement and Disposal

After the device has reached the end of its useful life, it must be dismounted and disposed of in an environmentally

friendly manner.

During dismounting, components that may present a risk of injury by contamination,

depending on the medium, are removed. The components must be properly decontaminated

depending on the processed medium. Diffusible components (filter cartridge, O-ring etc.)

may have to be taken to a special disposal unit, depending on the medium used.

If no return or disposal agreement has been signed, disassembled components should be recycled:

• Metals should be scrapped

• The remaining components should be disposed of after sorting according to material.

For technical information, please contact our customer service:

MEDENUS Gas-Druckregeltechnik GmbH

Im Langen Feld 3

D-57462 Olpe

Phone +49 (0) 2761 / 82788-0

Fax +49 (0) 2761 / 82788-9

E-mail [email protected]

Internet www.medenus.de

ATTENTION

8.4 Lubricants Table

Components (apply a thin layer) Lubricants Article no.

All O-rings Syntheso Proba 270 Syntheso Proba 270

All fastening and locking screws Anti Seize AS 450 AS-450

Oxygen model

For oxygen models, a suitable grease which is approved for the use

with oxygen must be used. ATTENTION

In addition, we are always interested in information, suggestions and experience resulting from the

application and which can be valuable for improving our products. Note

17 © 05.2022

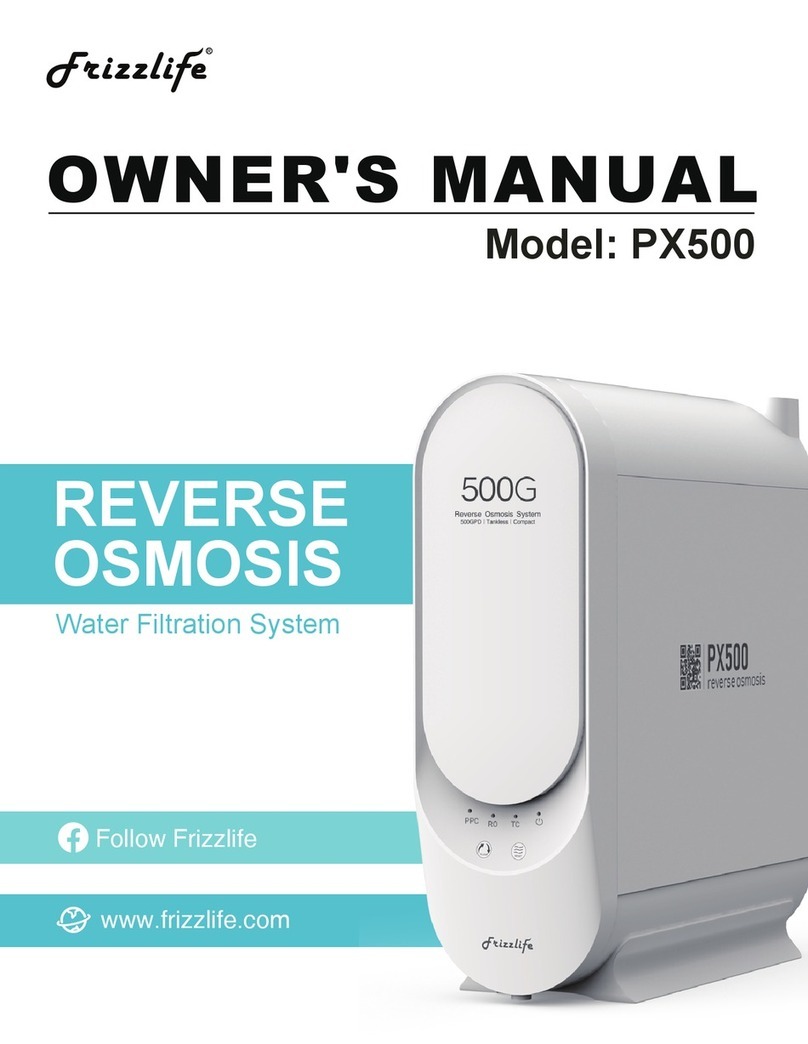

8

4

52

55

50

9

11 Spare Parts

11.1 Spare Parts Drawing DF 100

11.2 Parts for Maintenance Work

O-rings

Item

no.

Name Quantity

pcs.

DF100 / 025 DF100 / 050 DF100 / 080 DF100 / 100 DF100 / 150 DF100 / 200

4 O-ring 1 O-036 O-036 O-044 O-045 O-045

2 O-014

8 O-ring 1 O-016 O-021 O-023 O-027

2 O-030 O-041

9 O-ring 1 O-051

O-ring set order number: OS-041 OS-042 OS-043 OS-044 OS-045 OS-046

Low temperature O-rings (-40°C)

Item

no.

Name Quantity

pcs.

DF100 / 025 DF100 / 050 DF100 / 080 DF100 / 100 DF100 / 150 DF100 / 200

4 O-ring 1 O-036-T O-036-T O-044-T O-045-T O-045-T

2 O-014-T

8 O-ring 1 O-016-T O-021-T O-023-T O-027-T

2 O-030-T O-041-T

9 O-ring 1 O-051-T

O-ring set order number: OS-141 OS-142 OS-143 OS-144 OS-145 OS-146

Filter cartridge

Item

no.

Name Quantity

pcs.

DF100 / 025 DF100 / 050 DF100 / 080 DF100 / 100 DF100 / 150 DF100 / 200

60 Filter cartridge 1 FP-101 FP-102 FP-103 FP-104 FP-105 FP-106

DF 100 DN 150

shown

60

Filter cartridge

Spacer

Housing

Cover

Hood

18

© 05.2022

..............................................................................

..............................................................................

..............................................................................

..............................................................................

..............................................................................

..............................................................................

..............................................................................

..............................................................................

..............................................................................

..............................................................................

..............................................................................

..............................................................................

..............................................................................

..............................................................................

..............................................................................

..............................................................................

..............................................................................

..............................................................................

..............................................................................

..............................................................................

..............................................................................

..............................................................................

..............................................................................

..............................................................................

Notes

19 © 05.2022

12.1 Differential pressure gauge

12.1.2 Application / Function

The appropriate national safety regulations (e.g. EN 837-2 "Selection and installation recommendations for pressure

gauges") must be observed when installing, commissioning and operating these devices.

In the HIGH and LOW media chambers, pressures p1 and p2 are present, separated by the magnetic piston under

pressure. The difference in pressure causes an axial movement (deflection) of the piston supported by the measuring

range spring. The deflection resulting from this is taken up by a magnet located on the instrument pointer and

appropriately displayed.

This design combines the advantages of complete separation of the measuring system and the indication while

eliminating any leakage to the exterior. Due to the constructive design, the volumetric flow from the HIGH to the LOW

side of the media chamber is very low and is therefore not an issue.

12.1.1 Use

The differential pressure gauge DP 900 has been designed to monitor differential

pressures on the cellular gas filter DF100.

12.1.3 Technical Data

Measuring range:

0 - 2.5 bar / 0 - 36.30 psi Type F

Double scale:

All devices are provided with a double scale. (see above)

Max. operating pressure / overload:

Max. static pressure: 350 bar (both sides) (without special pressure test)

Max. static pressure: 450 bar (both sides) (with special pressure test)

Test pressure: 130 bar (both sides) (with ATC: EN 10204/3.1 or factory certification: EN 10204/2.2 or

certificate of compliance 10204/2.1)

Pressure connection:

According to the general technical regulations for pressure gauges (e.g. EN 837-2 "Selection and installation

recommendations for pressure gauges"). The differential pressure gauges are normally equipped with threaded

pipe connections e.g. ERMETO, Swagelok or equivalent. When screwing the devices in, the force required for sealing

must not be applied through the case or the cable terminal box. It must be fastened with the help of a tool using the

spanner flats provided for this purpose.

Ingress protection IP 54 (EN 60 529 / IEC 60 529)

Accuracy: +/- 3 % (of full scale value)

Weight : without reed contact 650 g

with reed contact 750 g

12 Accessories / Options

20

© 05.2022

Vibration load:

(Permissible vibration load at the installation site.)

The devices should always be installed in locations free from vibration. If necessary, it is possible to isolate the device

from the mounting point by installing a flexible connection line between the measuring point and the device and

mounting the device on a suitable bracket. If this is not possible, the following limit values must not be exceeded:

Frequency range < 160 Hz

Acceleration < 0.6 g (6 m/s²)

Maximum values:

Uo 13.5 V

Io 23 mA

Performance Po 76 mW

Ci negligible

Li negligible

Connector, mating connector, make Binder

Sensor connectors Series 713 (screw terminal connection

0.75mm²)

Number of poles 4

Cable outlet (mm) 4-6 (handle, black) (other cable sizes

upon request)

Protection class IP 67

Temperature -40°C ... +85°C

Materials:

Wetted parts: AlCuMgPb rd (anodized) (measuring chamber with pressure connection)

Magnetic piston: AlCuMgPb rd (anodized) Ms 58, (according to the measuring range) hard

ferrite

Gaskets: VITON

Screw plugs: Ms 58

Dial and pointer: Aluminum

Indication case: Plastic (PPH)

Inspection glass: Acrylic glass

Reed contact, mating connector

Max. contact loading capacity 3 VA, 28 V, 0.25 VA

Connection in potentially explosive

atmospheres Zone 1, Zone 2

Technical data of the Ex(i) relay: Only for connection to certified intrinsically safe circuits.

Contact adjustment

Fig. 1. Reed contact connection

Other manuals for DF 100

2

Table of contents

Other MEDENUS Water Filtration System manuals

Popular Water Filtration System manuals by other brands

Pentair

Pentair INTELLICHLOR COMSYS-16 installation guide

Hellenbrand

Hellenbrand H200M HE-16 owner's manual

Hellenbrand

Hellenbrand Water Conditioning System H-125 Series Specification sheet

Hydro Action

Hydro Action AP-500 Operation & maintenance manual

SUPREME

SUPREME SOFT installation manual

Raypak

Raypak RPSFP16 Installation and operation manual