B.

B.

B.

B. Function

Function

Function

Function of

of

of

of LCD

LCD

LCD

LCD IC

IC

IC

IC Controller

Controller

Controller

Controller

This

This

This

This is

is

is

is for

for

for

for RO-50/75/100G-C01,

RO-50/75/100G-C01,

RO-50/75/100G-C01,

RO-50/75/100G-C01, C02

C02

C02

C02 ,

,

,

, C

C

C

C 03,

03,

03,

03, C

C

C

C 04

04

04

04 Series

Series

Series

Series

1. P ower l amp is bright when starting machine, after 5 seconds , machine work s and automatically flush for 1

minute and 40 seconds, then display “ ” , w ater quality detector counts down to Zero.

2. A nd then enters into the stat e of producing water, display “ ” , the digital change s circularly. Display the

current water quality: If TDS surpasses 38PPM, system alarm s ; and should inspect the problem , flush or change

the membrane.

3. When producing water full, display “ ” , after the pump work for more 20 seconds the machine stop

working. (After water used, enters into the water producing stat e again.) Display the current water quality .

4. Lack water source or water pressure not high enough, system alarm s automatically , display ” ┫” , TDS display

“---- ”, and attend by “ di---di--- ” alarm s continuously .

5. After the machine producing water accumulative ly amount to 7.5 hours , enter s into the flushing state

automatically , flush es for 1 minute and 40 seconds . Water quality detector counts down to Zero. ( Circularly )

6. If the machine longtime working doesn ’ t stop, the machine alarm s and stops automatically , display “ ” , water

quality display “ ” , and “ di---di--- ” alarm s continuously . ( Note : Please make the machine stop

working, examine & repair or exchange the Membrane .)

7. Pressure the “ strong flush ” button, display “ ” , automatically flushes for 1 minute and 3 0 seconds and then

enter into water producing state , w ater quality detector counts down to Zero.

Ⅸ.

.

.

. STARTING

STARTING

STARTING

STARTING UP

UP

UP

UP YOUR

YOUR

YOUR

YOUR RO

RO

RO

RO SYSTEM

SYSTEM

SYSTEM

SYSTEM

1.

1.

1.

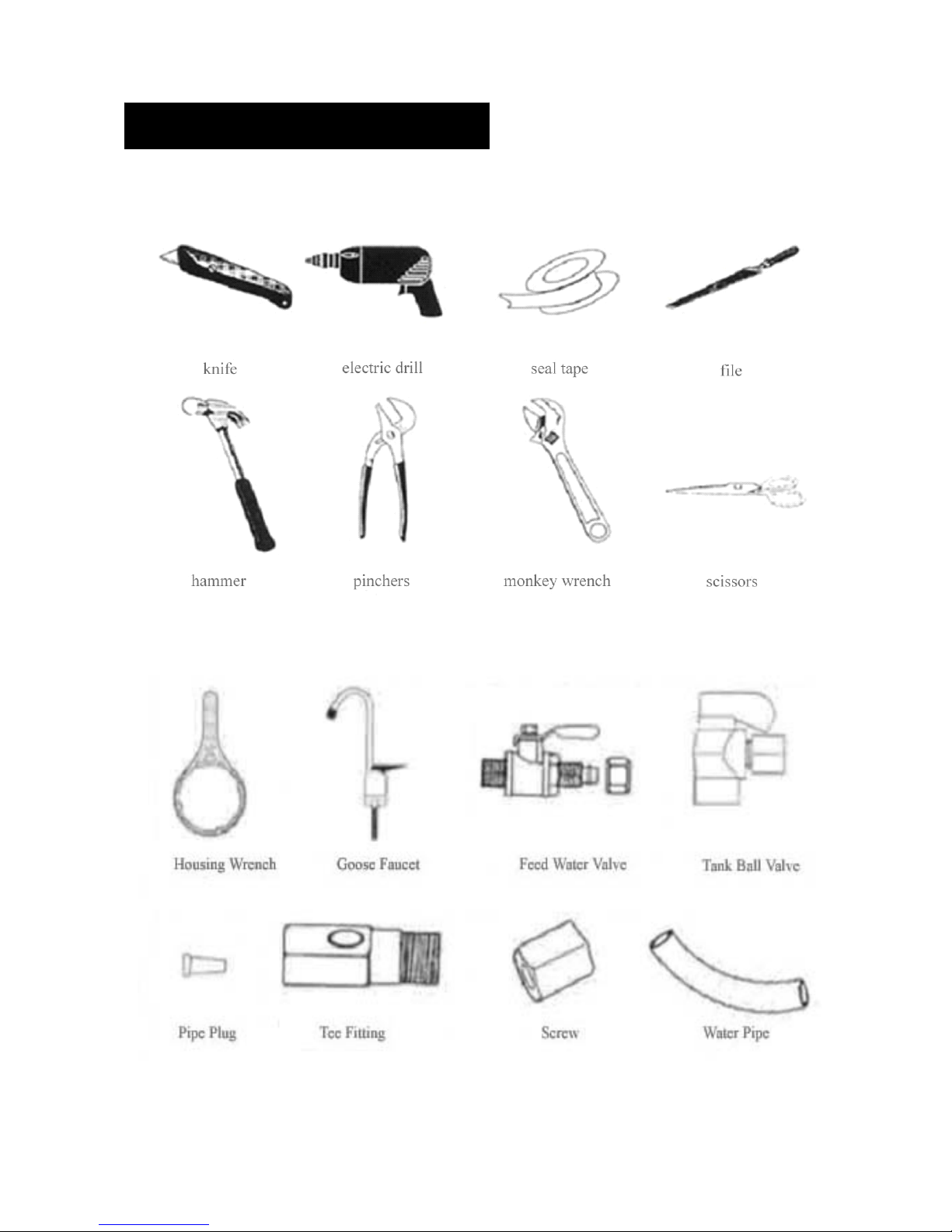

1. Turn on cold water supply valve and feed water valve, but close the tank ball valve.

2.

2.

2.

2. Open the goose faucet. (Pull the b lack handle to the open position).

3.

3.

3.

3. Check the system, whether leak or not.

4.

4.

4.

4. After about 5 minutes, the water starts dripping out of the goose faucet, and let it drip for about 10 minutes,

push the handle to the closed position. It will take several hours (about 3.5) for filling up the pressure tank

depending on local water pressure.

DO NOT DRINK THE

WATER

OF THE FIRST TANK PRODUCED BY YOUR NEWLY PURCHASED

SYSTEM.

5.

5.

5.

5. When the tank is full (you will know the water producing stop), flush the system by pilling the goose faucet to

the open position until the water is completely discharged.

6.

6.

6.

6. Upon completely discharging the water of pressure tank, push the handle to closed position on goose faucet,

and then start the water producing process again . This process should take about 2-2.5 hours until full.

7.

7.

7.

7. After the second tank is filled, now you can enjoy the purified water.

8.

8.

8.

8. Check for leaking daily at the first week and periodically after one week.

9.

9.

9.

9.

You

may notice milky colored water at the first week. It is the air bubble in the water. It is normal and safe.