Bell System Practices KS-14582 Operating and installation instructions

I

I

I

BELL SYSTEM PRACTICES SECTION 081-330-100

AT&TCo Standard Issue 4, May 1972

KS-14582 11 AND 12 SOLDERING COPPERS

AND KS-14768 HEAT UNITS

DESCRIPTION AND USE

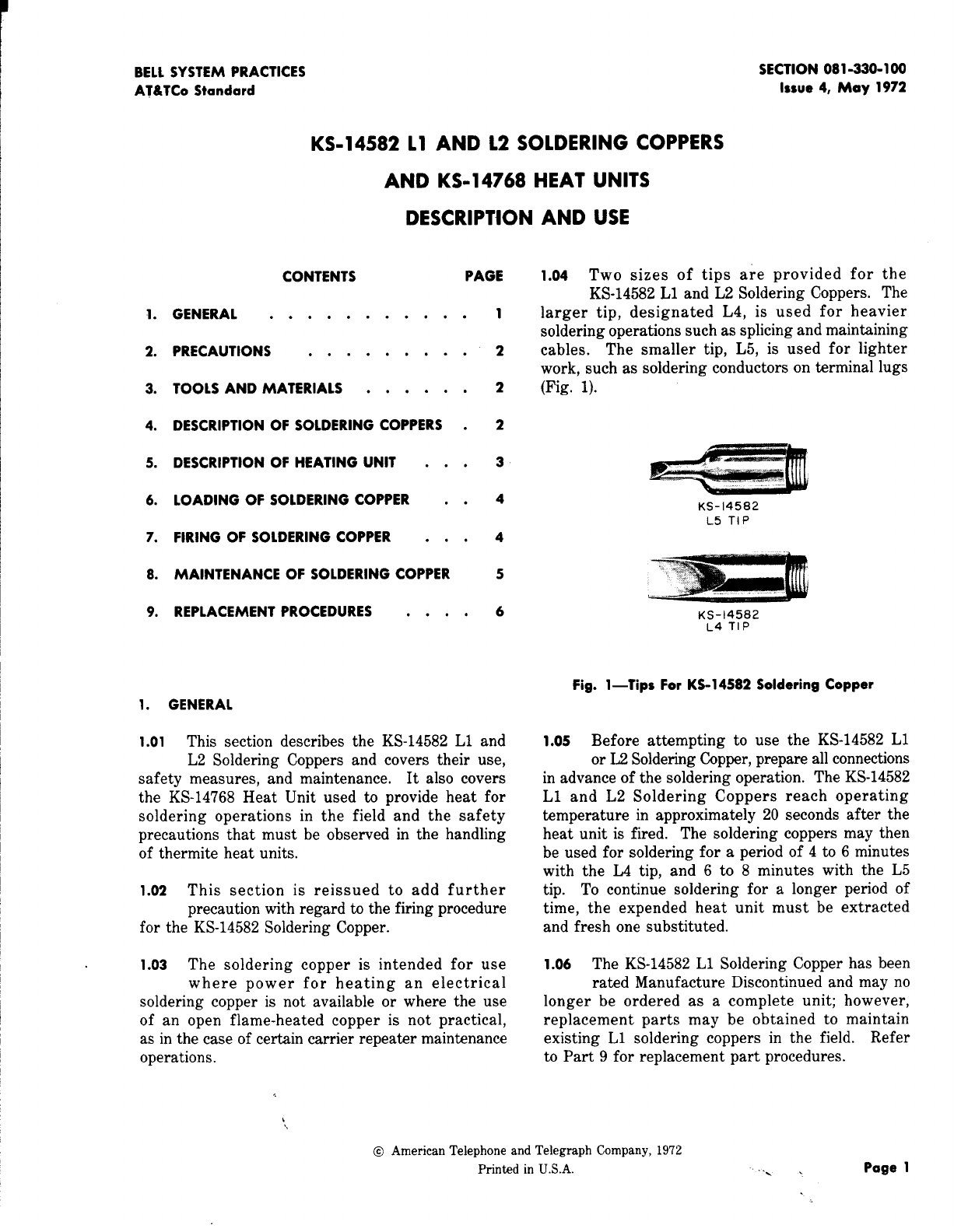

CONTENTS PAGE 1.o4 Two sizes of tips are provided for the

I. GENERAL ..........

2. PRECAUTIONS .....0. .

3. TOOLS AND MATERIALS .....

4. DESCRIPTION OF SOLDERING COPPERS

5. DESCRIPTION OF HEATING UNIT . .

6. LOADING OF SOLDERING COPPER .

7. FIRING OF SOLDERING COPPER . .

8. MAINTENANCE OF SOLDERING COPPER

9. REPLACEMENT PROCEDURES . . .

1. GENERAL

1.01 This section describes

L2 Soldering Coppers

.

.

.

.

.

.

.

.

the KS-14582 L1 and

and covers their use,

KS-14582 L1 and L2 Soldering Coppers. The

1larger tip, designated L4, is used for heavier

soldering operations such as splicing and maintaining

2cables. The smaller tip, L5, is used for lighter

work, such as soldering conductors on terminal lugs

2(Fig. 1).

2

3

4

4

5

6

KS-14582

L5 TIP

,,. “,.

KS-14582

L4 TIP

—

safety measures, and maintenance. It also covers

the KS-14768 Heat Unit used to provide heat for

soldering operations in the field and the safety

precautions that must be observed in the handling

of thermite heat units.

1.o2 This section is reissued to add further

precaution with regard to the firing procedure

for the KS-14582 Soldering Copper.

1.o3 The soldering copper is intended for use

where power for heating an electrical

soldering copper is not available or where the use

of an open flame-heated copper is not practical,

as in the case of certain carrier repeater maintenance

operations.

Fig. l—lips For KS-1 4582 Soldering Copper

1.o5 Before attempting to use the KS-14582 L1

or L2 Soldering Copper, prepare all connections

in advance of the soldering operation. The KS-14582

L1 and L2 Soldering Coppers reach operating

temperature in approximately 20 seconds after the

heat unit is fired. The soldering coppers may then

be used for soldering for aperiod of 4to 6minutes

with the L4 tip, and 6to 8minutes with the L5

tip. To continue soldering for alonger period of

time, the expended heat unit must be extracted

and fresh one substituted.

1.06 The KS-14582 L1 Soldering Copper has been

rated Manufacture Discontinued and may no

longer be ordered as acomplete unit; however,

replacement parts may be obtained to maintain

existing L1 soldering coppers in the field. Refer

to Part 9for replacement part procedures.

@American Telephone and Telegraph Company, 1972

Printed in U.S.A. ..,. Page 1

SECTION 081-320-100

2. PRECAUTIONS

2.01 Precautions To Be Observed With the

Soldering i%ppem:

(a) To avoid injury to personnel or damage to

the copper, do not open the copper for at

least 10 minutes after firing aheat unit.

(b) Do not hold the copper near the hands or

face to test its temperature; serious burns

may result. Use rosin core solder to check

whether the copper has reached soldering

temperature.

(c) Do not place aheated copper on the floor,

on equipment, or in any place other than a

suitable holder such as the 504A Soldering Copper

Holder. Do not remove the copper from its

holder to store it, as in atool kit, until the

copper has thoroughly cooled and the expended

heat unit has been removed. When the copper

is not in use, make sure the heat unit chamber

is empty.

(d) To prevent losing or damaging parts, make

sure the copper is assembled before storing

it.

(e) Never heat the copper over an open flame

to bring it to soldering temperature. This

would damage the copper.

2.o2 l?recautiom To Be Observed With Heat

units:

(a) Use only standard heat units equipped with

aprotective cap stamped KS-14768. Do not

use commercially available nonstandard heat units.

(b) Aheat unit should be fired only in the

copper and never by any other means. To

do otherwise is hazardous.

WARNING: Ignited outiide the soldering

.copper, the heat unit becomes white hoti

Molten thermi”temay splatter. Adhere to

operating instructions in Parts 6and 7

of this section.

(c) Do not store heat units near very hot objects.

(d) Do not remove heat tmits

until they are to be used.

Page 2

from the carton

3. TOOLS AND MATERIALS

CODE OR

SPEC NO.

TOOLS

504A

AT-8420

KS-14164

R-1482

R-5850

—

—

—

MATERIALS

KS-2423

KS-7470

—

—

—

DESCRIPTION

Soldering Copper Holder (or

other suitable holder)

Combination Pliers, B

Brush

File

5/8- and 3/41nch Open Double

End Offset Hex Wrench

BR-34 Brush

}

Kemode Manu-

RM-12 Reamer facturing Co.

Carborundum Unfinished Stick,

4 by 1/2 Inch Square, Grading

C60-P-VUF, Carborundum Co. or

Equivalent

Cloth

oil

Pipe

Cleaners obtain locdy)

Standard Rosin Core Wire Solder

“Dag” Dispersion No. 41, AcheSon

Colloids Corp.

4. DESCRIPTION OF SOLDERING COPPERS

4.o1 The KS-14582 L1 and L2 Soldering Coppers

(Fig. 2and 3) are conventional appearing

soldering coppers which are heated by means of a

chemically charged heat unit (K$+14768)placed in

achamber in the tip of the copper. The heat

unit is actuated by afiring pin mechanism mounted

in the handle of the copper. The handle is similar

to that of the KS-8740 Electric Soldering Copper

so the copper may be stored in the 504A Soldering

Copper Holder.

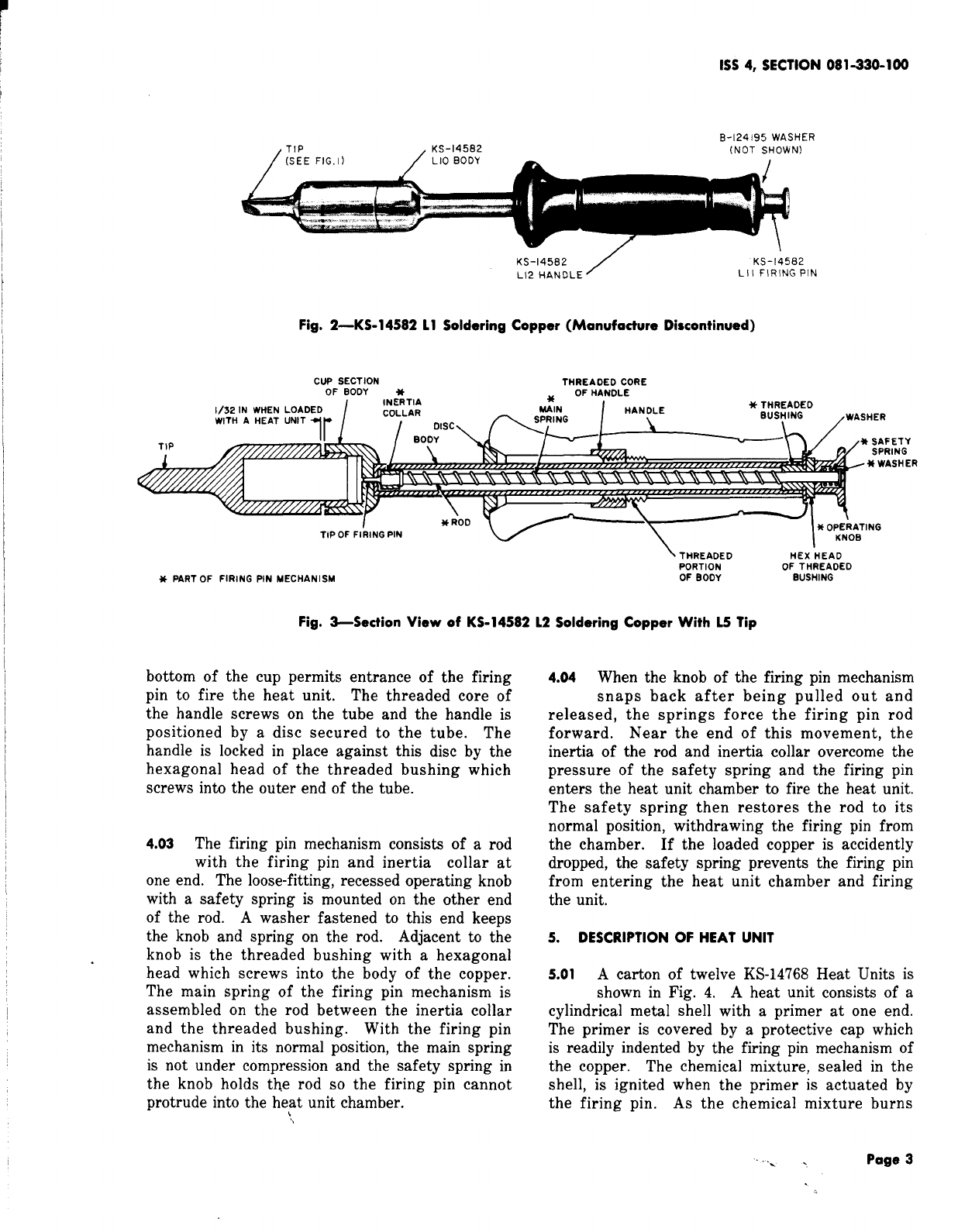

4.o2 Asection view of the KS-14582 L2 Soldering

Copper is shown in Fig. 3. The body of

the copper consists of atube having acupshaped

section at one end. The heat unit chamber of the

tip screws into this cup and asmall hole in the

., .

1SS4, SECTION 081-330-100

B-124195 WASHER

,TIP ,KS-14582 (NOT SHOWN)

KS-14582

L12 HANDLE /

Fig. 2—KS-1 458211 Soldering Copper (Manufacture

CUP SECTION THREAOEO CORE

OF BOOY *OF 14ANOLE

KS-14582

Lll FIRING PIN

Discontinued)

ETY

ING

SHER

\THREAOED HEX “HEAD

PORTION

*PART OF FIRING PIN MECHANISM OF THREAOEO

OF BOOY BUSHING

Fig. 3-Section View of KS-14582 12 Soldering Copper With 15 Tip

bottom of the cup permits entrance of the firing

pin to fire the heat unit. The threaded core of

the handle screws on the tube and the handle is

positioned by adisc secured to the tube. The

handle is locked in place against this disc by the

hexagonal head of the threaded bushing which

screws into the outer end of the tube.

4.o3 The firing pin mechanism consists of arod

with the firing pin and inertia collar at

one end. The loose-fitting, recessed operating knob

with asafety spring is mounted on the other end

of the rod. Awasher fastened to this end keeps

the knob and spring on the rod. Adjacent to the

knob is the threaded bushing with ahexagonal

head which screws into the body of the copper.

The main spring of the firing pin mechanism is

assembled on the rod between the inertia collar

and the threaded bushing. With the firing pin

mechanism in its normal position, the main spring

is not under compression and the safety spring in

the knob holds the rod so the firing pin cannot

protrude into the heat unit chamber.

L

4.o4 When the knob of the firing pin mechanism

snaps back after being pulled out and

released, the springs force the firing pin rod

forward. Near the end of this movement, the

inertia of the rod and inertia collar overcome the

pressure of the safety spring and the firing pin

enters the heat unit chamber to fire the heat unit.

The safety spring then restores the rod to its

normal position, withdrawing the firing pin from

the chamber. If the loaded copper is accidently

dropped, the safety spring prevents the firing pin

from entering the heat unit chamber and firing

the unit.

5. DESCRIPTION OF HEAT UNIT

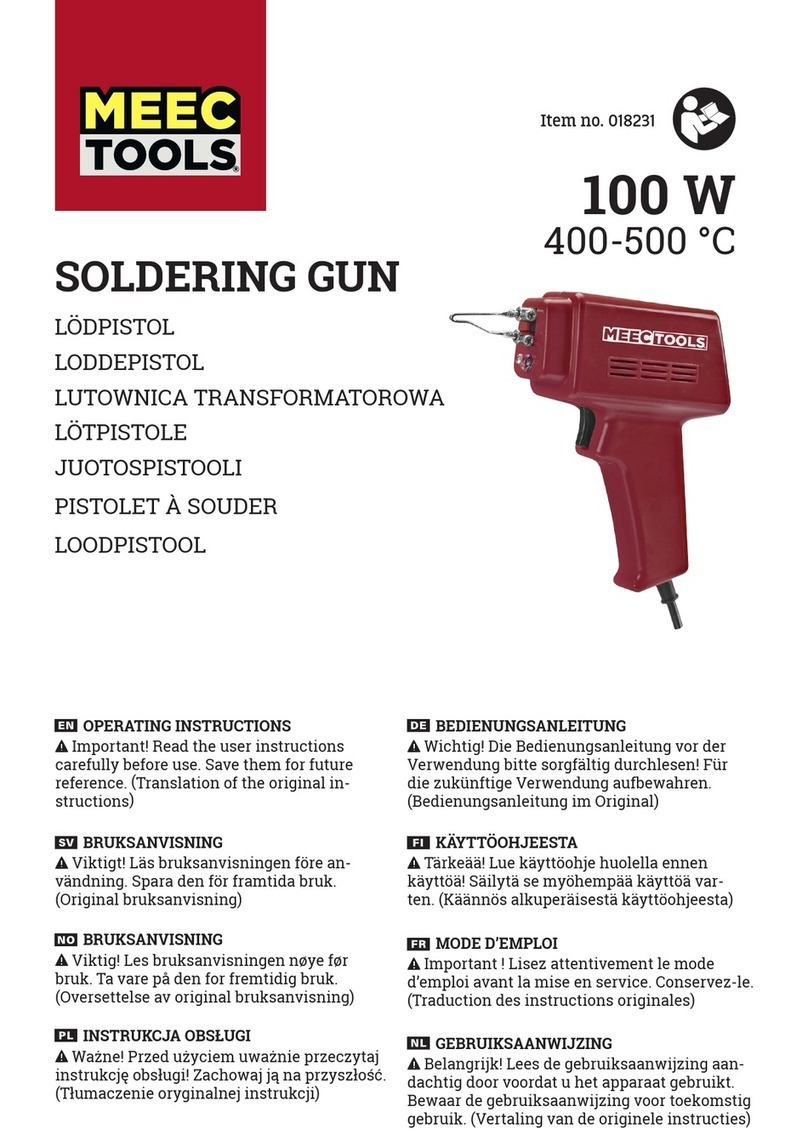

5.01 Acarton of twelve KS-14768 Heat Units is

shown in Fig. 4. Aheat unit consists of a

cylindrical metal shell with aprimer at one end.

The primer is covered by aprotective cap which

is readily indented by the firing pin mechanism of

the copper. The chemical mixture, sealed in the

shell, is ignited when the primer is actuated by

the firing pin. As the chemical mixture burns

... . Page 3

SECTION 081-330-100

without generating or releasing gases, the unit is

entirely safe for use within the copper. However,

should the unit be ignited outside the copper,

contact with the air would cause it to become

white hot and therefore, afire hazard.

PROTECTIVE CAP

COVERING PRIMER

\ I METAI

Fig. 4-KS-1 4768 Heat Units

Note: When inserting aKS-14768 Heat Unit

into aKS-14582 L1 or L2 Soldering Copper,

make certain the heat unit is firmly clamped

between the bottom of the heat unit chamber

(L4 or L5 tip) and the inside top of the cup

section of the body and that there is aspace

between the shoulders of the two, at least

l/32-inch, as shown in Fig. 3.

6. LOADING OF SOLDERING COPPER

6.01 While the tool is cold, check that the firing

pin mechanism and body are securely tightened

against the handle before loading the tool. If

necessary, tighten the body manually, and use the

R-5850 Wrench to tighten the threaded bushing of

the firing pin mechanism.

6.02 To load the copper when it is cold, unscrew

the tip and place the KS-14768 Heat Unit

into the hollow chamber of the tip with the primer

end of the unit facing outwards. Remount the tip

on the copper fingertight.

6.03 If it is necessary to reload the copper when

it is hot in order to a,ontinue soldering

operations, allow the copper to cool for at least

10 minutes after firing (2 or 3minutes after the

heat unit is expended), Earlier removal of the tip

may cause the heat unit to expand on contact with

the air to such an extent that it will be difficult

to remove. To remove the tip while hot, proceed

as follows: While holding the handle firmly in

one hand, grasp the tip just behind the wedgeshaped

end with the combination pliers, and loosen the

tip. Then hold the tip stationary with the pliers

and unscrew the body of the copper from the tip

by turning the handle manually. While doing this,

take care to hold the copper with the tip pointed

downwards to prevent the heat unit from dropping

out. When the tip is free of the body, invert the

tip over ametal receptacle, or on the ground at

some safe location, so the heat unit drops out of

the chamber.

Caution: Do not discard the hot heat

um”ton or near flammable materials.

6.04 Place the body of the copper in asuitable

holder such as the 504A Soldering Copper

Holder. While holding the tip with the pliers,

insert afresh heat unit into the chamber of the

tip with the primer end of the unit facing outward.

Screw the body of the copper on the tip. Take

care not to tighten the tip excessively as this would

make it difficult to remove if necessary to again

reload the hot copper to continue soldering.

Caution: likercise care to avoid touctig

the hot tip or body of the copper while

replacing the heat w“t as serious burns

may result

7. FIRING SOLDERING COPPER

7.OI To fire the copper, hold the handle firmly

in one hand and grasp the knob of the firing

pin mechanism between the thumb and forefinger

of the other hand.

Caution: As the tip of the copper heats

rapidkyafter tiring, take care to hold the

copper away tkm the body at about an

arms length and pointed so the handIe

end does not face the body.

$Pull the firing pin knob out as far as it will go

and allow it to snap back. When the firing pin

hits, it will actuate the primer in the heat unit.

There will not be a“pop” or “bang” but the heat

Page 4

1SS4, SECTION 081-330-100

unit will very likely have ignited and started heating

the copper. The soldering copper will be ready

for operation in about 20 seconds.+ The copper

may then be used for soldering for aperiod of 4

to 6minutes with the L4 tip and 6to 8minutes

with the L5 tip.

7.02 FaiZureof (%pper to Fire: If the copper

fails to become hot in approximately 20

seconds, repeat the firing procedure covered in

7.01. $Be sure to determine that the copper has

not started to heat before refiring or removing a

heat unit to avoid the danger of splattering molten

thermite.~ If the copper does not fire after three

or four attempts, the heat unit may be defective.

Remove the unfired heat unit and try anew heat

unit. If the copper still fails to fire, the firing

pin hole in the body of the copper may be blocked

or the firing pin mechanism may be worn. Clean

the body of the copper and firing pin mechanism

as covered in 8.08 through 8.14, If, after cleaning,

the copper frequently fails to fire, the firing pin

mechanism should be replaced as covered in 9.03.

Note: Defective heat units should be disposed

of along with other metallic trash. They

should not be thrown away with paper trash

or other combustible material.

8. MAINTENANCE OF COPPER

Tinning Soldering Copper

8.01 When necessary, tin the tip of the copper

as covered in 8.02 through 8,04.

8.02 With the copper cold, file the surface of

one side of the tip for adistance of

approximately 1/4 inch from the end until it is

bright and clean using the R-1482 file,

8.03 Luad the copper as covered in 6.02.

8.04 Fire the copper as covered in 7.01. When

the copper reaches soldering temperature,

quickly file the side of the point which was previously

cleaned, and apply rosin core solder, spreading

the solder by means of the wiping pad of the 504A

Soldering Copper Holder or similar tin plate surface.

Repeat this operation until the filed surface is well

tinned. Only one side of the copper tip should be

tinned. This tends to keep the hot solder in contact

with the surface to ,be soldered and prevents the

solder from collecting on the under side of the

copper when working on vertical terminals.

Cleoning lip Chomber

8.05 In order to permit easy removal of the

KS-14768 Heat Unit, clean the inside of the

tip chamber when soldering operations have been

completed and the copper has cooled.

8.06 To clean the chamber, unscrew the tip from

the body of the copper and dispose of the

expended heat unit. Hold the tip firmly in one

hand and insert the BR-34 Brush into the chamber

as far as it will go. Turn the brush in aclockwise

direction several times. Remove the brush and

shake the loosened foreign matter out of the

chamber. Repeat this procedure until the chamber

is clean. Check the threads on the tip and, if

necessary, clean them using the brush. After

cleaning and before remounting the tip, lubricate

the threads of the tip as covered in 8.07.

Note: Thorough cleaning of the tip chamber

is essential to prevent difficulty in removing

aspent heat unit.

Lubricating Threads of lip

8.07 Periodic lubrication of the threads of the tip

will facilitate removal of the tip. When

necessary to apply the lubricant, remove all traces

of old lubricant using the BR-34 Brush and apply

“Dag” Dispersion No. 41 to the threads with the

KS-14164 Brush. If the tip is worn so it is not

held securely to the body of the copper, replace

the tip.

Cleaning Body and Firing Pin Mechanism

8.o8 Clean the body and firing pin mechanism

at the end of each day if the copper has

been used continuously. However, if the copper

is used intermittently, ie, only several times aday,

clean the parts at least once aweek to obtain

proper operation of the firing mechanism. Clean

the parts only when the copper is cold.

8.09 Manually unscrew the tip. Remove the firing

pin mechanism using the R-5850 Wrench,

taking care that the washer in the recessed end

of the handle is not lost. To clean the body, fully

insert the RM-12 Reamer into the tube opening at

the handle end. Turn the reamer clockwise several

...,. Page 5

SECTION 081-330-100

r

times. Remove the reamer and shake out any

loosened foreign matter from the tube. Repeat

this procedure until no more foreign matter can

be shaken out. Clean the firing pin hole using a

pipe cleaner. Check the threads in the cup and

if necessary, clean them using the BR-34 Brush.

Note: Thorough cleaning of the body as

described above is essential, as an accumulation

of foreign matter at the firing pin hole end

may not allow proper penetration of the firing

pin into the heat unit chamber.

8.10 Brush the accessible parts of the firing pin

mechanism thoroughly with the BR-34 Brush,

paying particular attention to the turns of the main

spring: the firing pin, and the threads of the

bushing. Observe whether the tip of the firing

pin has become excessively flattened so that there

are sharp comers at the periphery of the tip. If

there are sharp corners at the periphery, round

them as covered in 8.15. After brushing, vvipe all

parts with aclean KS-2423 Cloth.

8.11 Place one end of the firing pin mechanism

on aflat surface, and while holding it in a

vertical position, manually compress the main spring.

While holding the spring compressed with one hand,

clean the exposed part of the rod using the BR-34

Brush and then wipe with aclean KS-2423 Cloth.

Invert the mechanism and repeat the procedure to

clean the other part of the rod.

8.12 Hold the firing pin mechanism with the knob

pointing downward. Hold the firing pin

end with one hand and with the other raise the

knob compressing the main spring until about an

inch of the rod is exposed. If the safety spring

has not dropped free of the knob, shake the spring

out of the knob onto the exposed part of the rod.

Hold the mechanism with the knob cocked against

the rod to prevent the safety spring from slipping

back into the knob. Clean the safety spring with

the BR-34 Brush and wipe with aclean KS-2423

cloth.

8.13 After the firing pin mechanism has been

cleaned, apply afilm of KS-7470 Oil to the

main and safety springs using aKS-2423 Cloth.

Obtain access to the safety spring by following

the procedure covered in 8.12. “Wipe off any excess

oil with aclean KS-2423 Cloth. ~,

8.14 After cleaning and oiling the firing pin

mechanism, remount it in the copper. Remount

the tip.

Rounding Periphery Around Tip of Firing Pin

8.15 Round the corners at the periphery of the

tip of the firing pin using the Carborundum

stick to obtain auniform radius of approximately

0.010 inch as gauged by the eye around the

periphery. Do not round the flat on the top. This

will shorten the tip and may result in failure of

the copper to fire.

9. REPLACEMENT PROCEDURES

9.o1 When ordering parts for replacement purposes,

give both the KS and Lnumber and name

of the part, for example: KS-14582 L11 Firing

Pin for KS-14582 L2 Soldering Copper. Do not

refer to the BSP number.

9.o2 To replace the tip, refer to 6.02 or 6.03

for removal of the tip from ahot or cold

soldering copper.

9.o3 Firing Pin and Waden To replace either

of these parts, hold the handle firmly in

one hand and apply the R-5850 Wrench to the

hexagonal nut at the rear of the handle. Remove

the firing pin and washer in the recessed end of

the handle by turning the firing pin counterclockwise

with the wrench. Substitute new parts as required

and mount the parts in the reverse order of removal.

9.o4 Hadle: Remove the firing pin as covered

in 9.03, taking care not to lose the washer

in the recessed end of the handle. Remove the

handle by unscrewing it from the body. If the

handle cannot be easily removed, hold it firmly in

one hand, grasp the body just forward of the

handle with the combination pliers, and loosen the

handle. Apply asmall amount of KS-6824 Sealing

Compound to the threads of the body that screw

into the handle with the KS-14164 Brush and mount

the new handle. Remount the firing pin making

sure the washer is in place in the recess in the

handle.

9.OS Body: Remove the tip and handle as covered

in 9.02 and 9.04. Substitute the new body,

applying KS-6824 Sealing Compound to the threads

that screw into the handle using the KS-14164

Page 6..,?

1SS4, SECTION 081-330-100

Brush. Remount the parts in the reverse order

of removal.

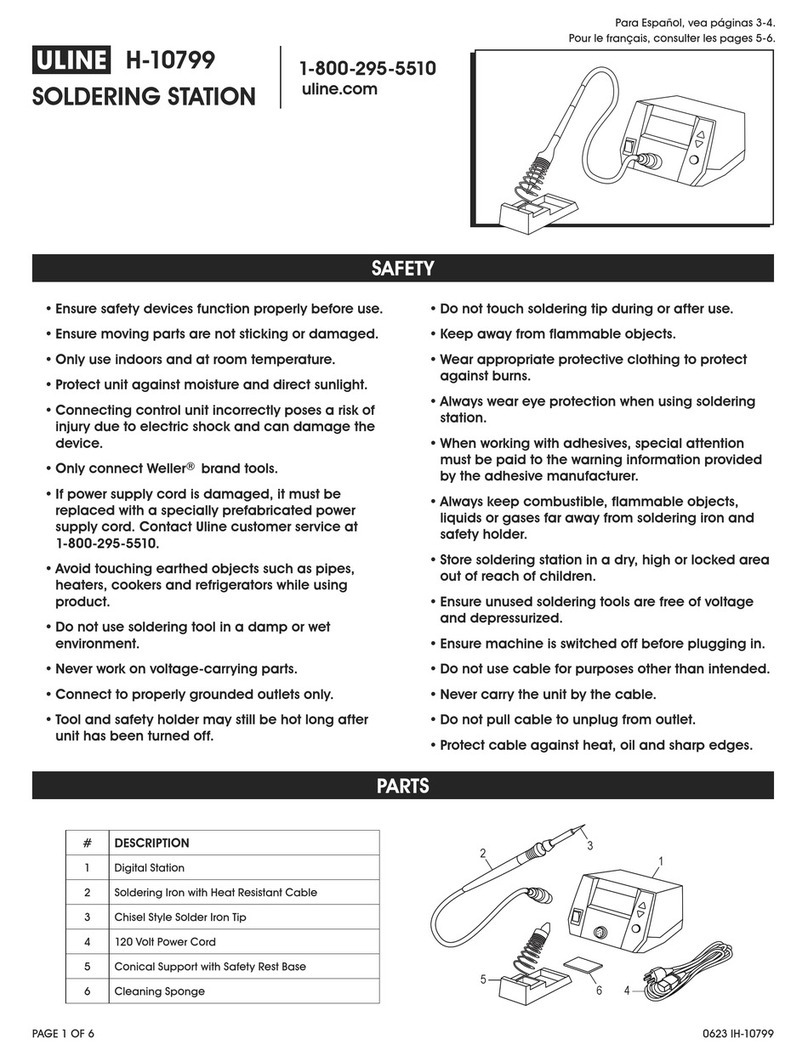

9.06 Fig. 5illustrates the components of the

KS-14582 L2 Soldering Copper and associated

I

KS-14582

L14 BODY

TIP [SEE NOTE \

NOTE :

part numbers for the purpose of ordering replacement

parts. Note that the tips, firing pin, and B-124195

Washer are interchangeable for either the L1 or

L2 Soldering Coppers. See Fig. 2.

B-124195 wASHER

KS-14582 tNOT SHOWN)

L13 HANOLE \

KS-14%82 Lll

FIRING PIN

THE KS-14582 L2 SOL OERING COPPER

IS FUR NISHEO WITH TIP, WHICH MUST BE

SPECIFIED IN THE ORDER.

Fig. 5-KS-1 458212 Soldering Copper

., . Page 7

7Pages

This manual suits for next models

1

Table of contents