Vitronics Soltec mySelective 6748 Quick start guide

Schematics & Parts

mySelective 6748

Version 48.1.0.007

VITRONICS SOLTEC BV

Visit adress Innovatiepark 12 - 4906 AA Oosterhout - the Netherlands

Mail adress P.O. Box 143 - 4900 AC Oosterhout - the Netherlands

Telephone +31-162-483000

Fax +31-162-483269

www.vitronics-soltec.com

ii

Rights

COPYRIGHT 2010 VITRONICS SOLTEC BV

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any

means, electronic, mechanical, photocopying, recording or otherwise, without the prior written permission of Vitronics Soltec BV.

This publication remains the property of Vitronics Soltec BV and may not be passed, loaned or given to any third party.

Vitronics Soltec BV reserves the right to make changes in design and specifications without notice.

EUROPE

VITRONICS SOLTEC BV VITRONICS SOLTEC GmbH

Innovatiepark 12 Udo-Lermann Str.10

4906 AA Oosterhout 97828 Marktheidenfeld

the Netherlands Germany

Tel. +31-162-483000 Tel. +49-9391-98820

Fax +31-162-483269 Fax +49-9391-988228

AMERICAS

VITRONICS SOLTEC Inc.

2 Marin Way

Stratham, New Hamphire 03885

USA

Tel. +1-603-772-7778

Fax +1-603-772-7776

ASIA PACIFIC

VITRONICS SOLTEC SHANGHAI VITRONICS SOLTEC (SUZHOU) Co. Ltd

Sales Office Manufacturing Plant

858 Zhujiang Lu 858 Zhujiang Lu

Building 2 Building 2

Suzhou New District, China 215129 Suzhou New District, China 215129

Tel. +86-21-5033-7855 Tel. +86-512-6841-3378

Fax +86-21-6360-9449 Fax +86-512-6841-3161

VITRONICS SOLTEC PTE LTD. VITRONICS SOLTEC KOREA

132 Joo Seng Road A-1001, Poonglim Iwant Bldg.

#03-01 Uniplas Building 255-1 Seohyun Dong,

Singapore 368358 Bundang Gu, Seongnam 463-862, Korea

Tel. +65-6484-3010 Tel. +82-31-783-7020

Fax +65-6484-1910 Fax +82-31-783-7021

VITRONICS SOLTEC MALAYSIA

8-2-5 Sunny Point Complex

Jalan Sultan Azlan Shah, Batu Uban,

11700 Penang, Malaysia

Tel. +60-4-658-4227

Fax +60-4-655-4227

Schematics & Parts mySelective 6748 iii

Preface

During the composition of this manual much attention is given to avoid errors

and mistakes. Also we aimed to give the contents a clear structure.

If during the use of this manual errors or incomplete descriptions are found, or

the reader considers that improvements are necessary to overcome any in-

accuracies, please inform us. We appreciate any comments which will help us to

improve this documentation.

For corrections or clarifications please contact:

1. By mail:

VITRONICS SOLTEC BV

HEAD OFFICE

TECHNICAL PUBLICATIONS

P.O. BOX 143

4900 AC OOSTERHOUT

THE NETHERLANDS

TEL NR. (31) - 162483000

FAX.NR. (31) - 162483285

OR

2. By e-mail:

techpub.nl@vsww.com

iv

Schematics & Parts mySelective.com v

Table of Contents

Preface iii

Table of Contents v

1Schematics 1-1

1.1 General . . . . . . . . . . . . . . . . . . . 1-1

2 Parts 2-1

2.1 PLC controller . . . . . . . . . . . . . . . . . 2-1

2.1.1 Configuration Controllers . . . . . . . . . . . 2-2

2.2 Servo controller . . . . . . . . . . . . . . . . 2-4

2.3 Frequency inverter controller . . . . . . . . . . . 2-5

2.4 Thermic protection relay . . . . . . . . . . . . . 2-6

2.5 Power supply . . . . . . . . . . . . . . . . . 2-7

2.5.1 Adjustment power supply . . . . . . . . . . . 2-7

2.6 Safety module . . . . . . . . . . . . . . . . . 2-8

2.6.1 Jumper settings safety module . . . . . . . . . . 2-8

2.7 E-stop module . . . . . . . . . . . . . . . . . 2-9

2.8 Interconnection module . . . . . . . . . . . . . 2-10

2.8.1 Drawing IMC2900 . . . . . . . . . . . . . 2-10

2.9 Opto modules . . . . . . . . . . . . . . . . . 2-11

2.10 Sensor PCB detect . . . . . . . . . . . . . . . 2-12

2.10.1 Working principle. . . . . . . . . . . . . . 2-12

2.10.2 Adjustment procedure . . . . . . . . . . . . 2-12

2.11 Sensor Infeed & outfeed protection . . . . . . . . . 2-13

2.12 Sensors Blockings . . . . . . . . . . . . . . . . 2-14

2.12.1 Adjustment sensor optical WLL260 . . . . . . . . 2-14

2.13 Sensors Pneumatic cylinders - type 1 . . . . . . . . . 2-15

2.13.1 Adjustment procedure sensors MultiWave . . . . . . 2-16

2.13.2 Adjustment procedure sensors SecureGrip . . . . . . 2-16

2.14 Sensors Pneumatic cylinders - type 2 . . . . . . . . . 2-17

2.14.1 Adjustment procedure sensors lifting unit transport system . 2-17

2.14.2 Adjustment procedure sensor SecureGrip . . . . . . 2-18

vi

2.14.3 Adjustment procedure sensors wave height measurement (WHM)

2-18

2.15 Sensors Doors control . . . . . . . . . . . . . . 2-19

2.16 Sensors Robot & MultiFlux positions . . . . . . . . . 2-20

2.17 Solderpot and Conveyor width limit switch . . . . . . . 2-21

2.18 Thermostat PT100 - Solderpot & Machine temperature . . 2-22

2.19 Impulse counter Conveyor & Solderpot pumps . . . . . . 2-23

2.20 SolderFeeder sensor . . . . . . . . . . . . . . . 2-24

2.21 Advanced SolderFeed sensor . . . . . . . . . . . . 2-25

2.22 SolderLevel sensor . . . . . . . . . . . . . . . 2-26

2.23 Flux vessel level . . . . . . . . . . . . . . . . 2-27

2.24 Teach camera & led spotlight . . . . . . . . . . . . 2-28

2.24.1 Version 1 . . . . . . . . . . . . . . . . 2-28

2.24.2 Version 2 . . . . . . . . . . . . . . . . 2-29

2.25 Pressure controls . . . . . . . . . . . . . . . . 2-30

2.26 UPS system . . . . . . . . . . . . . . . . . . 2-32

2.26.1 General . . . . . . . . . . . . . . . . . 2-32

2.26.2 Working Principles . . . . . . . . . . . . . 2-32

2.26.3 Remarks. . . . . . . . . . . . . . . . . 2-33

2.26.4 Transport . . . . . . . . . . . . . . . . 2-33

2.26.5 Set-up . . . . . . . . . . . . . . . . . 2-33

2.26.6 Operation . . . . . . . . . . . . . . . . 2-33

2.26.7 Maintenance, servicing and faults . . . . . . . . . 2-34

2.26.8 Indicators and operating controls . . . . . . . . . 2-34

2.26.9 Back panel . . . . . . . . . . . . . . . . 2-36

2.26.10 Slide buttons output voltage . . . . . . . . . . . 2-36

2.27 Adjustment of universal SecureGrip . . . . . . . . . 2-37

2.28 Gripper Adjustment . . . . . . . . . . . . . . . 2-38

2.28.1 General information . . . . . . . . . . . . . 2-38

2.28.2 Tools . . . . . . . . . . . . . . . . . 2-38

2.28.3 Gripper . . . . . . . . . . . . . . . . . 2-39

2.28.4 Adjustment methods . . . . . . . . . . . . . 2-40

2.29 Cables Robot and MultiFlux units . . . . . . . . . . 2-44

3 Trouble Shooting 3-1

3.1 General . . . . . . . . . . . . . . . . . . . 3-1

3.2 UPS system . . . . . . . . . . . . . . . . . . 3-2

3.2.1 Front panel UPS system . . . . . . . . . . . . 3-2

3.3 Frequency inverter . . . . . . . . . . . . . . . 3-3

viii

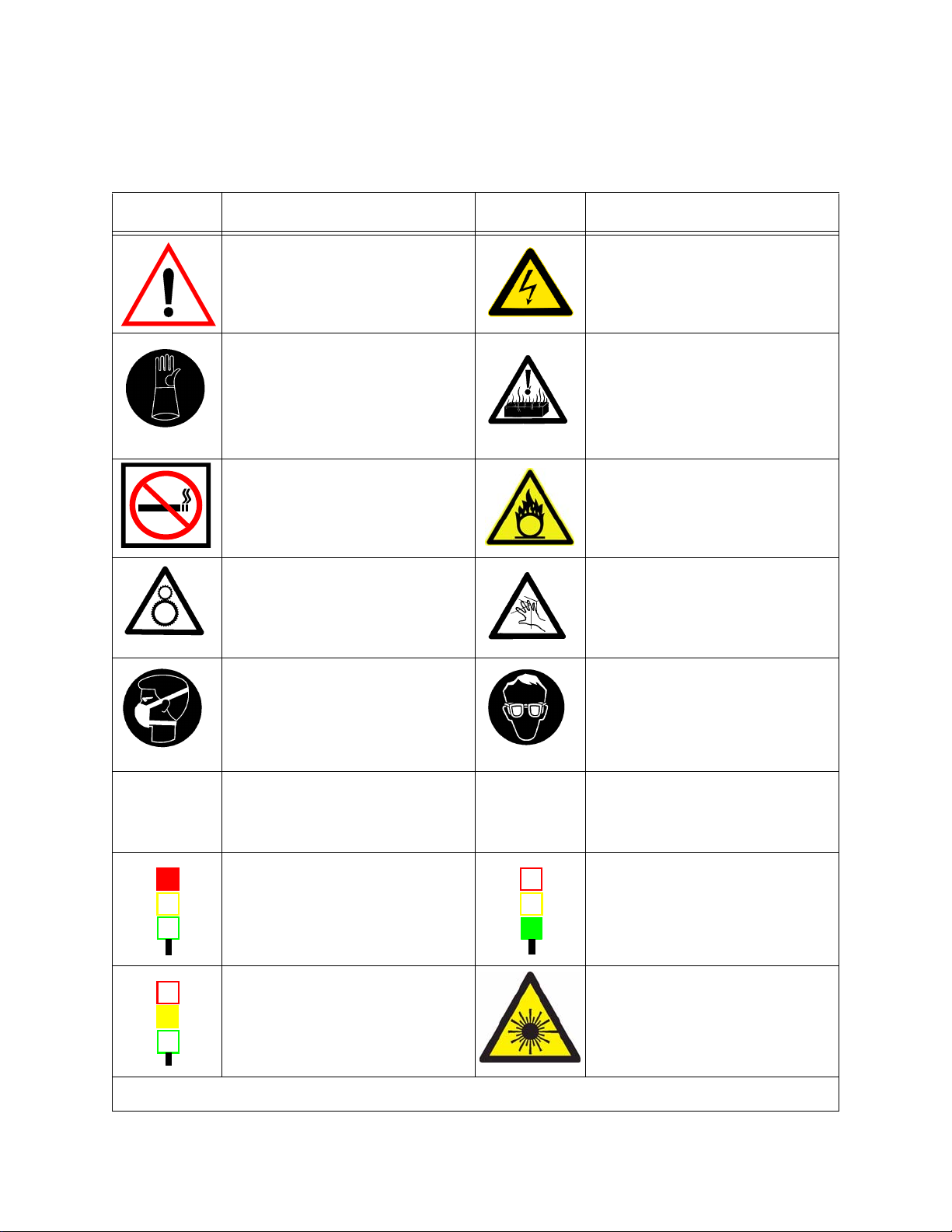

ICON DESCRIPTION ICON DESCRIPTION

Only Qualified personnel is allowed to work on the

equipment.

Never eat, drink or smoke while working on the

machine.

Wash thoroughly before eating, drinking or smoking.

High voltages are present on various parts of the sys-

tem.

Before working on the electrical circuit, turn main

power off and block the mainswitch with a padlock.

Always wear heat resistant gloves and protective

clothing when working on the machine.

If possible allow the machine to cool down before

starting working on the machine.

When burned, immerse in cold water immediately.

When the burn is severe, consult a physician as soon

as possible.

Always wear heat resistant gloves and protective

clothing when working on the machine.

If possible allow the machine to cool down before

starting working on the machine

When burned, immerse in cold water immediately.

When the burn is severe, consult a physician as soon

as possible.

No smoking or open fire near the machine.

Be sure a fire-extinguisher is in the surroundings of

the machine.

No smoking or open fire near the machine.

Be sure a fire-extinguisher is in the surroundings of

the machine.

All moving parts of the system, including pulleys,

belts, chains, coolingfans, sprocketwheels, vacuum-

doors and cylinders presents a potential danger.

Be careful with covers and doors. Always pay atten-

tion to opening and closing.

The vapours in the board preparation module are

chemical. When the board is heated, a noxious

vapour will be liberated. This vapour must be

extracted. Also the dust on the surface of the solder-

pot is dangerous when inhaled.

Avoid inhaling this vapours / dust by using mouth

protection.

When working on the machine, always protect your

eyes with safety glasses.

Nitrogen

N2

Follow the safety precautions and procedures

described in the Material Safety Data Sheet of

the Nitrogen supplier.

UPS

Uninterruptible

Power Source

When mainswitch is switched OFF for a longer

period, switch the UPS to OFF.

Signal light RED

- E-stop Active

Signal light GREEN

- Steady = Machine Run,

- Flashing slow = Machine not at setpoint, machine

stop

Signal light ORANGE

- Steady = Overload (outfeed full), Machine will

block,

- Flashing slow = Alarm

- Flashing fast = Critical alarm. Machine will block

LASER RADIATION

Do not stare into beam.

Class 2 Laser product.

Only applicable for Soldering machines

equipped with laser measurement systems.

If these rules are not observed it can cause personal injury and/or damage to the machine

SAFETY RULES

GENERAL INFORMATION

.

Schematics & Parts mySelective.com CHAPTER 1 1

Schematics 1

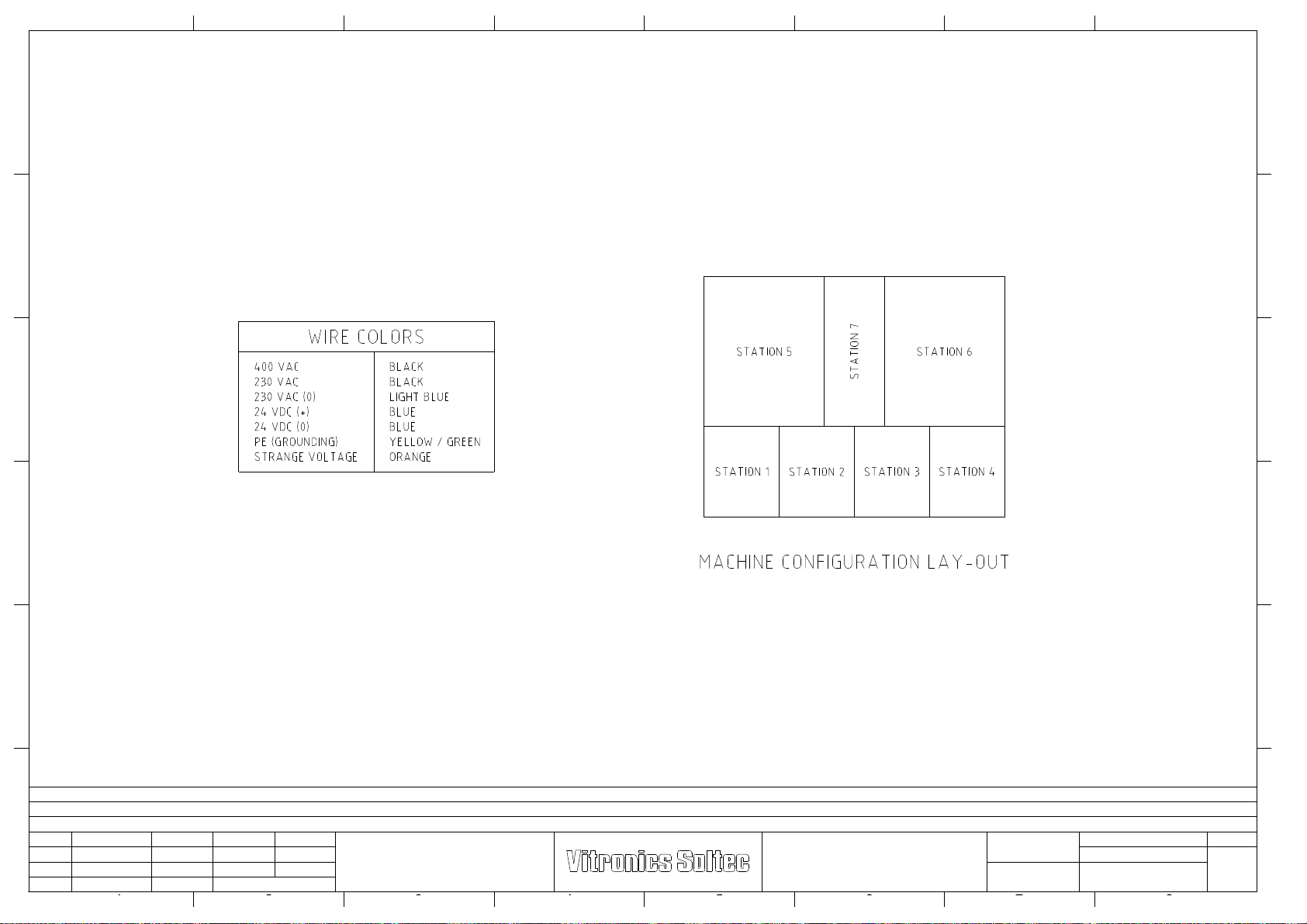

1.1 GENERAL

Included in this chapter are all the drawings and partlists that are part of the machine configura-

tion.

VERSION 2005 December

SCHEMATICS

2CHAPTER 1

8

7

6

5

4

3

2

1

EN 60204-1

+

=

DateVersion Name Norm

Last mod

Checked

Author

Sheet

of

MACHINETYPE DESCRIPTION

INSERT SHEET FOR

PROJECT CODE

1 2

1

3 4

DRAWING LIST

03/12/2008

5678

A

B

C

510583

DRAWINGS

78

D

E

MYSELECTIVE 6748

6748

F

ELECTRIC CIRCUIT DIAGRAM

SHEET SHEET DESCRIPTIONDESCRIPTION

8

7

6

5

4

3

2

1

EN 60204-1

+

=

DateVersion Name Norm

Last mod

Checked

Author

Sheet

of

MACHINETYPE DESCRIPTION

INSERT SHEET FOR

PROJECT CODE

12345678

A

B

C

D

E

F

1 DRAWING LIST

2 MACHINE CONFIGURATION

3 MAIN SUPPLY

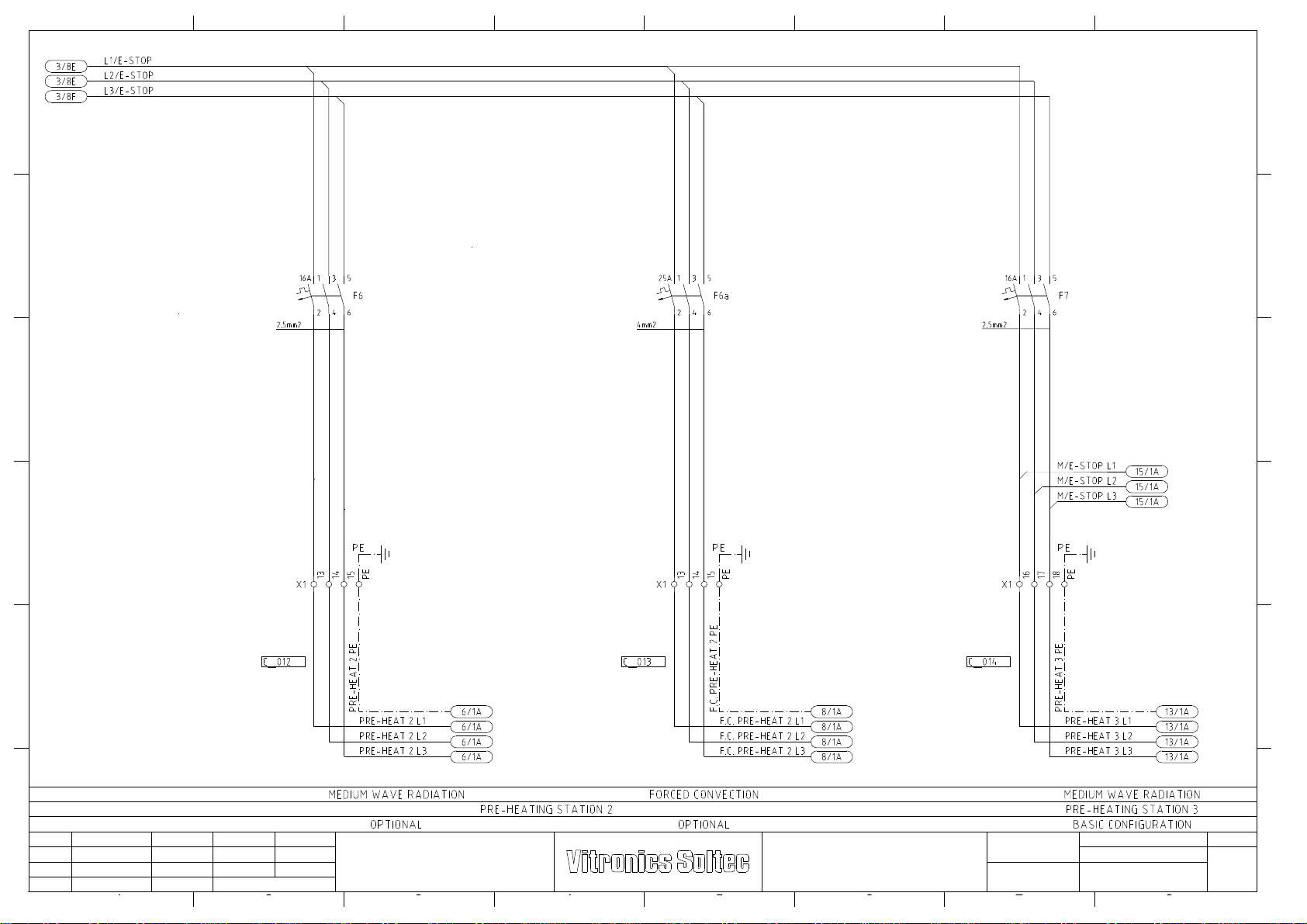

4 MAIN SUPPLY PRE-HEATING STATION 2 AND 3

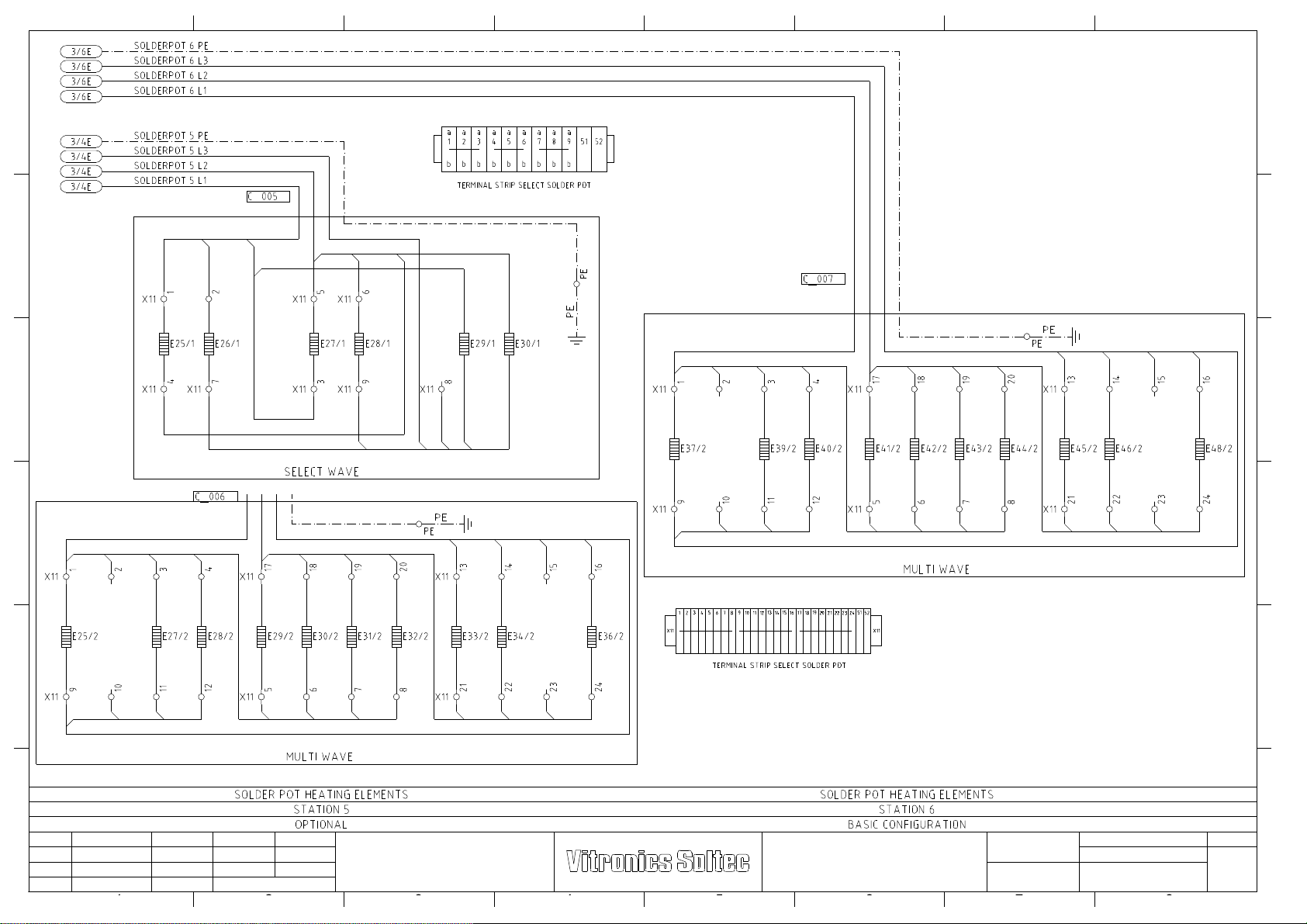

5 MAIN SUPPLY SOLDER POT HEATERS STATION 5 AND 6

6 400 VAC CIRCUIT PREHEATER STATION 2

7 I/O MODULE 5 PREHEATER STATION 2

8 400 VAC CIRCUIT F.C. PREHEATER STATION 2

9 400 VAC CIRCUIT F.C. PREHEATER STATION 2

10 400 VAC CIRCUIT F.C. PREHEATER STATION 2

11 I/0 MODULE 5 F.C. PREHEATER STATION 2

12 I/0 MODULE 14 F.C. PREHEATER STATION 2

13 400 VAC CIRCUIT PREHEATER STATION 3

14 I/O MODULE 6 PREHEATER STATION 3

15 NOZZLE PLATE ELEVATION

16 ADVANCED SOLDER DRAINAGE

17 ADVANCED SOLDER DRAINAGE

18 UPS SYSTEM AND 230VAC POWER DISTRIBUTION

19 SERVO CONTROLLERS X-Y

20 SERVO CONTROLLERS U-Z

21 FREQUENCY INVERTERS CONVEYER

22 FREQUENCY INVERTERS STATION 5

23 FREQUENCY INVERTERS STATION 6

24 230 VAC CIRCUIT

25 SERVO CONTROLLERS MULTI FLUXER STATION 1

26 OPTO COUPLER MULTIFLUXER STATION 1

27 SERVO CONTROLLERS MULTI FLUXER STATION 2

28 OPTO COUPLER MULTI FLUXER STATION 2

29 24 VDC CIRCUIT

30 24 VDC CIRCUIT

31 EMERGENCY STOP AND SAFETY CIRCUIT

32 CONVEYER WIDTH AND PLATE HEIGTH ADJ.

33 OPTO COUPLER 24 VDC TTL

34 OPTO COUPLERS SERVO CONTROLLERS

35 OVERTEMPERATURE PROTECTION CIRCUIT

36 PROCESSOR UNITS

37 MAIN - SLOT 1 ANALOG INPUT (PT100)

38 MAIN - SLOT 2 ANALOGE INPUT UNIVERSAL

39 MAIN - SLOT 3 DIGITAL INPUT (24VDC)

40 MAIN - SLOT 4 DIGITAL INPUT (24VDC)

41 MAIN - SLOT 5 (SPARE)

42 MAIN - SLOT 6 DIGITAL OUTPUT (24VDC)

43 MAIN - SLOT 7 DIGITAL OUTPUT (24VDC)

44 MAIN - SLOT 8 DIGITAL OUTPUT (24VDC)

45 MAIN - SLOT 9 SERIAL COMMUNICATION

46 SLAVE 1 - SLOT 1 DIGITAL INPUT (24VDC)

47 SLAVE 1 - SLOT 2 DIGITAL INPUT (24VDC)

48 SLAVE 1 - SLOT 3 DIGITAL INPUT (24VDC)

49 SPARE

50 SLAVE 1 - SLOT 5 DIGITAL OUTPUT (24VDC)

51 SLAVE 1 - SLOT 6 DIGITAL OUTPUT (24VDC)

52 SLAVE 1 - SLOT 7 DIGITAL OUTPUT (24VDC)

53 SPARE

54 I/O MODULE 1 N2/AIR & MULTI WAVE

55 I/O MODULE 2 N2/AIR & MULTI WAVE

56 I/O MODULE 3 N2/AIR & SELECT FLUXER

57 I/O MODULE 7 FLUX SUPPLY UNIT

58 I/O MODULE 8 SMEMA

59 I/O MODULE 9 CONVEYOR

60 I/O MODULE 10 CONVEYOR

61 I/O MODULE 11 GRIPPER

62 I/O MODULE 12 GRIPPER

63 PARTSLIST PAGE 1

64 PARTSLIST PAGE 2

65 PARTSLIST PAGE 3

66 PARTSLIST PAGE 4

67 PARTSLIST PAGE 5

68 PARTSLIST PAGE 6

69 PARTSLIST PAGE 7

70 PARTSLIST PAGE 8

71 PARTSLIST PAGE 9

72 PARTSLIST PAGE 10

73 PARTSLIST PAGE 11

74 PARTSLIST PAGE 12

75 PARTSLIST PAGE 13

76 PARTSLIST PAGE 14

77 PARTSLIST PAGE 15

78 PARTSLIST PAGE 16

8

7

6

5

4

3

2

1

EN 60204-1

+

=

DateVersion Name Norm

Last mod

Checked

Author

Sheet

of

MACHINETYPE DESCRIPTION

INSERT SHEET FOR

PROJECT CODE

1 2

2

3 4

MACHINE CONFIGURATION

03/12/2008

5678

A

B

C

510583

CONTR.PANEL

78

D

E

MYSELECTIVE 6748

6748

F

ELECTRIC CIRCUIT DIAGRAM

8

7

6

5

4

3

2

1

EN 60204-1

+

=

DateVersion Name Norm

Last mod

Checked

Author

Sheet

of

MACHINETYPE DESCRIPTION

INSERT SHEET FOR

PROJECT CODE

1 2

3

3 4

MAIN SUPPLY

03/12/2008

5678

A

B

C

510583

CONTR.PANEL

78

D

E

MYSELECTIVE 6748

6748

F

ELECTRIC CIRCUIT DIAGRAM

MHW

8

7

6

5

4

3

2

1

EN 60204-1

+

=

DateVersion Name Norm

Last mod

Checked

Author

Sheet

of

MACHINETYPE DESCRIPTION

INSERT SHEET FOR

PROJECT CODE

1 2

4

3 4

MAIN SUPPLY PRE-HEATING

03/12/2008

5

STATION 2 AND 3

678

A

B

C

510583

CONTR.PANEL

78

D

E

MYSELECTIVE 6748

6748

F

ELECTRIC CIRCUIT DIAGRAM

MHW

8

7

6

5

4

3

2

1

EN 60204-1

+

=

DateVersion Name Norm

Last mod

Checked

Author

Sheet

of

MACHINETYPE DESCRIPTION

INSERT SHEET FOR

PROJECT CODE

1 2

5

3 4

MAIN SUPPLY SOLDER POT

03/12/2008

5

HEATERS STATION 5 AND 6

678

A

B

C

510583

MAIN CNTRL BOX

78

D

E

MYSELECTIVE 6748

6748

F

ELECTRIC CIRCUIT DIAGRAM

MHW

8

7

6

5

4

3

2

1

EN 60204-1

+

=

DateVersion Name Norm

Last mod

Checked

Author

Sheet

of

MACHINETYPE DESCRIPTION

INSERT SHEET FOR

PROJECT CODE

1 2

6

3 4

400 VAC CIRCUIT

19/02/2009

5

PREHEATER STATION 2

678

A

B

C

510583

PREHEATER

78

D

E

MYSELECTIVE 6748

6748

F

ELECTRIC CIRCUIT DIAGRAM

MHW

8

7

6

5

4

3

2

1

EN 60204-1

+

=

DateVersion Name Norm

Last mod

Checked

Author

Sheet

of

MACHINETYPE DESCRIPTION

INSERT SHEET FOR

PROJECT CODE

1 2

7

3 4

I/O MODULE 5

11/12/2008

5

PREHEATER STATION 2

678

A

B

C

510583

PREHEATER

78

D

E

MYSELECTIVE 6748

6748

F

ELECTRIC CIRCUIT DIAGRAM

MHW

8

7

6

5

4

3

2

1

EN 60204-1

+

=

DateVersion Name Norm

Last mod

Checked

Author

Sheet

of

MACHINETYPE DESCRIPTION

INSERT SHEET FOR

PROJECT CODE

1 2

8

3 4

400 VAC CIRCUIT

19/02/2009

5

F.C. PREHEATER STATION 2

678

A

B

C

510583

PREHEATER

78

D

E

MYSELECTIVE 6748

6748

F

ELECTRIC CIRCUIT DIAGRAM

MHW

Other manuals for mySelective 6748

1

Table of contents

Other Vitronics Soltec Soldering Gun manuals