Imdes DINO-CONDENS-IT User manual

IMDES CREATIVE SOLUTIONS Schulstrasse 21 D-48455 Bad Bentheim /Gildehaus Germany T:+49(0)5924-997337 E: info@imdes.de

www.imdes.de SKYPE marc.van Stralen © 2019 IMDES CREATIVE SOLUTIONS

1

.

DINO CONDENS-

IT PROFILER

The perfect method to solder SMD-components at the highest solder quality

Preliminary Owner's Manual

Version 2.0Tuesday, February 5, 2019

Mini Vapor Phase –Reflow –Soldering Machine

Ideal for Hobbyist, Laboratory, single pieces, proto-types and small quantities

www.imdes.de

IMDES CREATIVE SOLUTIONS Schulstrasse 21 D-48455 Bad Bentheim /Gildehaus Germany T:+49(0)5924-997337 E: info@imdes.de

www.imdes.de SKYPE marc.van Stralen © 2019 IMDES CREATIVE SOLUTIONS

2

Imdes Mini Condensation Reflow Soldering Systems

The

DINO-CONDENS-IT

Owner's Manual

© 2019 IMDES CREATIVE SOLUTIONS

All Rights Reserved

Reproduction of this document in any form is expressly forbidden unless explicitly

authorized in writing by IMDES CREATIVE SOLUTIONS

Information contained in this document may contain technical inaccuracies or

typographical errors. Information may be changed or updated without notice.

IMDES CREATIVE SOLUTIONS may make improvements and/or changes in the

materials/machine at any time without prior notice.

All materials are provided "as is". IMDES CREATIVE SOLUTIONS makes no

representations or warranties, expressed or implied to the accuracy of the

copyrighted materials. IMDES CREATIVE SOLUTIONS will not be liable for any

direct, indirect, special or consequential damages arising out of any use of the

document/machine.

IMDES CREATIVE SOLUTIONS

Schulstrasse 21 D 48455 Bad Bentheim Germany

Phone: +49(0)5924-997337• Fax: : +49(0)5924-997338

Email: [email protected]

Internet: www.imde.de

Editor: Marc van Stralen

IMDES CREATIVE SOLUTIONS Schulstrasse 21 D-48455 Bad Bentheim /Gildehaus Germany T:+49(0)5924-997337 E: info@imdes.de

www.imdes.de SKYPE marc.van Stralen © 2019 IMDES CREATIVE SOLUTIONS

3

Table of Contents

PAGE

1.0 Introduction

5

1.1 Technical data

5

1.2 Scope of the DINO-CONDENS-

IT

5

1.3 Introduction to Condensation Soldering

6

1.4 How Does it Work?

6

1.5 Features

6

1.6 Why Condensation Soldering

7

1.7 Benefits of Condensation Soldering

7

1.8 The advantages at a glance

8

1.9 Heat Level Adjustment Method

9

1.10 System Description DINO-CONDENS-

IT

11

1.11 Safety Features

11

1.12.1 Process chamber cover sensor

11

1.12.2 Steam Ceiling Height Sensor

11

1.12.3 Overheating sensor of heating surface temperature (fail Safe)

11

1.12.4 Cooling

12

1.12.5 Transport of the DINO-CONDENS-

IT

12

1.13 Inspection, unpacking, Installation & Commissioning

12

1.13.1 Unpacking and inspection for transport damage

12

1.13.2 Installation and commissioning

13

1.13.3 The stainless steel lid with glass observation window

13

1.14 Handling Tips

14

1.14.1 Handling of the DINO CONDENS-

IT

14

1.14.2 General operating instructions

14

1.15 Safety Instructions

15

1.15.1 Filling with Galden

16

1.15.2 Effect of adding large quantity of Galden to the process chamber

16

1.15.3 Effect of adding too small quantity of Galden to the process chamber

16

1.15.4 Open the Lid

16

1.15.5 Removing Soldered parts

17

1.15.6 Control Panel

17

2.0 Operating the IMDES DINO-CONDENS-IT

18

2.1 The proceedings at the IMDES DINO CONDENS-

IT

18

2.2 Programming and modifying Reflow Soldering Profiles

19

2.3 Operating and programming the machine

19

2.4 Attention

19

2.5 The Anti Tomb Stone Modus ATS

20

2.6 Hand Control

21

2.7 Procedure to drain Galden and clean medium with filters:

22

2.7.1 How to proceed

22

2.7.2 Medium Filtration

22

2.7.3 Cleaning the inside of the process chamber

23

2.8 Care of the cabinet

23

2.9 Model Variants

23

3.0 Warranty

23

3.1 Lead free soldering

24

3.2 Void free soldering

24

4.0 Tips for reflow soldering

25

IMDES CREATIVE SOLUTIONS Schulstrasse 21 D-48455 Bad Bentheim /Gildehaus Germany T:+49(0)5924-997337 E: info@imdes.de

www.imdes.de SKYPE marc.van Stralen © 2019 IMDES CREATIVE SOLUTIONS

4

4.1 Soldering Errors

25

4.1.1 Random Solder Balls

25

4.1.2 Wicking Effect

25

4.1.3 Tombstone Effect

25

4.1.4 Tombstoning comparing IR/Convection with/without N2/ Vapor Phase

26

4.1.5 Bridging (short circuits or bridges between pads)

26

4.1.6 Solder Beads

26

4.1.7 Pop Corning

28

4.1.8 Poor Wetting

28

4.1.9 Voiding

28

5.0 Double Sided Printed Circuit Boards

29

5.1 Curing of Adhesives

29

6.0 Cleaning and cleanliness of the printed circuit board

29

7.0 Dual Sided SMD Soldering

30

7.1 Assembly, Reflow Soldering Steps

30

7.2 Step1

30

7.3 Step 2

30

7.4 Screen Printing of the A side with large components

31

7.5 Reflowing Side A

32

7.6 Dual Sided Mixed (SMD/THT) assembly & Soldering

33

IMDES CREATIVE SOLUTIONS Schulstrasse 21 D-48455 Bad Bentheim /Gildehaus Germany T:+49(0)5924-997337 E: info@imdes.de

www.imdes.de SKYPE marc.van Stralen © 2019 IMDES CREATIVE SOLUTIONS

5

1. Introduction

Thank you for purchasing our IMDES DINO-CONDENS-

IT

,the compact reflow soldering machine.

This compact device is sufficient for most reflow solder purposes and is able to accept PCB´s up to double Euro

Card size.

Please read the entire instruction manual, before operating the unit safely and optimally.

The operation is basically very simple, but one shall always work with trained people or people who

are familiar with this machine.

With careful maintenance and proper operations you will be able to enjoy the benefits of this machine for many

years.

The system is intended for the soldering of printed circuit boards or ceramic substrates with leadless components

(SMD) up to a temperature of 240 °C (464 °F).

Other applications are not permitted.

The operating safety of DINO-CONDENS-

IT

supplied is guaranteed only when used as directed.

The limits specified in the technical data shall NOT be exceeded under any circumstances.

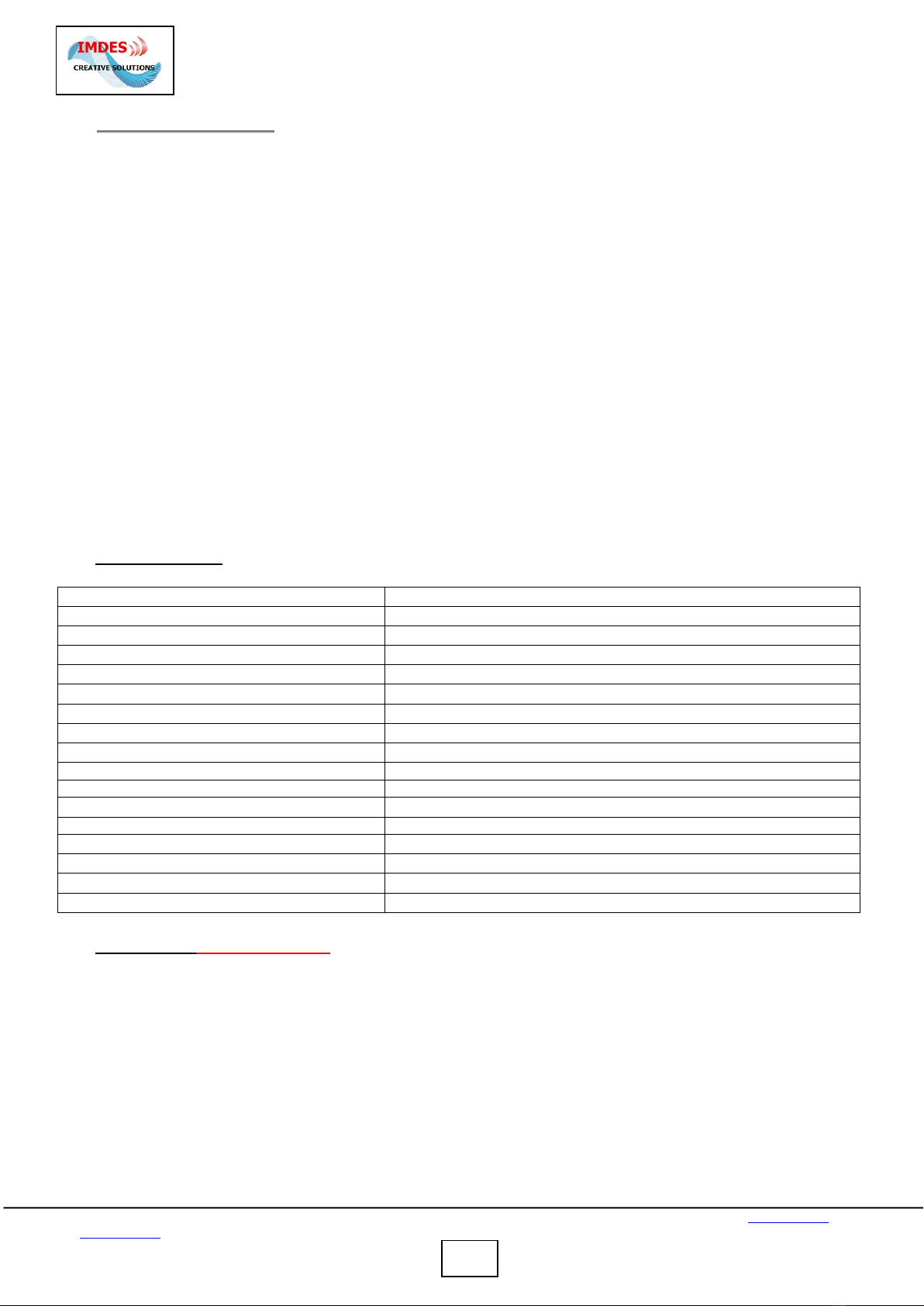

1.1Technical Data:-

Power Supply

Single phase 220-240 Volt / 50-60 Hz

Power Connector

Three Prong Power Connector

Max. heating capacity

2500 Watt (ca. 12 A)

Dimensions.

840 x 640 x 460 mm

(L x W x H)

max. solder product format

580 x 460 x 20 mm (

L x Wx H)

Standard cycle time

15-25 Minutes

(including heating up & cooling down

)

Standard Reflow Time (

TAL Time Above Liquids)

3 –50 Seconds

(max 70 Seconds)

Process temperature (depends on medium type)

150 °C up to 240 °C = 302 °F up to 464° F

Weight

12 kg

Solder Profiles

Adjustable temperature profiles in the pre-heating zone(CVPRS*)

TAL Time Above Liquid

Adjustable TAL Time Above Liquid

ATS

Anti Tomb Stone modus (ATS)

Micro USB interface

for the transfer of solder profile data to PC

Cooling

Forced Air cooling down to 70°C = 158°F

Storage Temperature

-1°C to +70 °C 30,2 °F to 158°F

Heat Transfer Medium

GALDEN LS with the boiling temperature as needed (max. 240 °C max. 464 ° F)

Medium basic filling quantity

ca. 1648 ml (1.65 Liter) 3 Kg GALDEN

1.2 Scope of the DINO-CONDENS-

IT

:

Soldering of single pieces and small numbers of SMD PCB’s.

Safe and high quality (lead-free) soldering of SMD prototypes PCB’s.

Quality control printed circuit boards and solder pastes.

Repair (de-soldering and soldering) of SMD components (large).

IMDES CREATIVE SOLUTIONS Schulstrasse 21 D-48455 Bad Bentheim /Gildehaus Germany T:+49(0)5924-997337 E: info@imdes.de

www.imdes.de SKYPE marc.van Stralen © 2019 IMDES CREATIVE SOLUTIONS

6

1.3 Introduction to Condensation soldering:

Condensation soldering also known as "Vapor Phase Reflow Soldering”is the use of hot vapor, submitted by a

special heat transfer medium, to transfer heat using the condensation principle on to a PCB with SMD components,

which then will be reflowed

Condensation soldering is a known technique that was first applied in the early eighties when the SMD technique

was introduced.

The heat transfer medium applied in those days had many disadvantages, mainly the chemical used were harmful

to health and the environment.

As a result, the condensation soldering lost popularity and infrared soldering became the standard.

By the arrival of Perfluorpolyeter *, the condensation soldering was rediscovered as an alternative to the

infrared "reflow" soldering.

Perfluorpolyeter * is manufactured and marketed by the company Solvay Solexis under the trade name Galden.

1.4 HOW DOES IT WORK?

The heat transfer medium is the chemical and electrical neutral liquid Perfluorpolyeter *.

In a closed space is a chemically inert and electrically neutral liquid heated to the boiling point.

When the liquid temperature exceeds the boiling point, it starts to evaporate and forms a saturated vapour above

the liquid with practically the same temperature as the boiling liquid.

When the assembled printed circuit boards is brought into this space, the vapor will condense on the surface,

because the circuit board has a lower temperature than the saturated vapor, and transfer the vapor’s temperature

to the PCB. This will happen until the entire surface of the circuit board will have the same temperature as the

vapor.

After that, the covering hot liquid will evaporate again. This is the same principle as if someone with glasses from

the cold outside air enters a warm room. At first the glasses will be covered by condensation than drops gradually

will evaporate.

The soldering alloys which have a lower melting temperature than the temperature of the vapor will melt and then

become entirely liquid.

When the heat transfer medium cools down, the solder solidifies, and then circuit board can be removed carefully

from the process chamber.

****Perfluorpolyeter * liquid polymers, which are exclusively built of carbon (C), Fluor (F) and oxygen (O)

atoms.

The connections present in the molecules are very stable. They belong to the most stable connections in the realm

of carbon chemistry.

1.5 Features:

High temperature resistance.

Under normal circumstances, inert to all chemicals, and does not react with acids alkaline or strong

oxidizers (substances that cause oxidation).

Tolerates all known plastics, metals and elastomers.

Highly resistant to reactive chemicals.

The Fluor atoms bound in the polymer chain in the framework of the display helps protect sensitive C-C

connections against chemical and thermal attack.

Good dielectric properties.

Low vapor pressure.

No flash point.

IMDES CREATIVE SOLUTIONS Schulstrasse 21 D-48455 Bad Bentheim /Gildehaus Germany T:+49(0)5924-997337 E: info@imdes.de

www.imdes.de SKYPE marc.van Stralen © 2019 IMDES CREATIVE SOLUTIONS

7

High vapor density.

Excellent heat transfer coefficient.

Low surface tension.

Good wetting properties (film adhesion).

There will be no harmful substances released during the process.

No chemical activity (perfluoriert, i.e. no H-or CI-Atom).

During the heating of the heat transfer medium under normal atmospheric pressure, all types Galden are

thermally stable.

Does not damage the ozone layer.

1.6 Why condensation soldering?

For contemporary complex BGA, FPGA and the new generation complex to solder SMD components, this solder

method is the only method which is relatively simple, even for the amateur and hobbyist to achieve perfect solder

results

Moreover, one can also easy remove, without damaging, major components such as FPGA’s using simple auxiliary

tools.

Reflow Soldering (called reflow technique) of Printed Circuit Boards with SMD components are/were mostly done in

an infrared oven, possibly, with nitrogen as shielding gas to prevent oxidization of solder joints.

On the introduction of lead-free soldering, it was found that this infrared soldering was sensitive to the occurrence

of defects at the connection between the components and the PCB.

Due the increasing requirements for higher quality and reliability of circuit boards, search was launched for better

solder methods and the "vapour phase" condensation soldering was rediscovered as an alternative method to the

infrared "reflow" soldering.

1.7 Benefits of condensation soldering

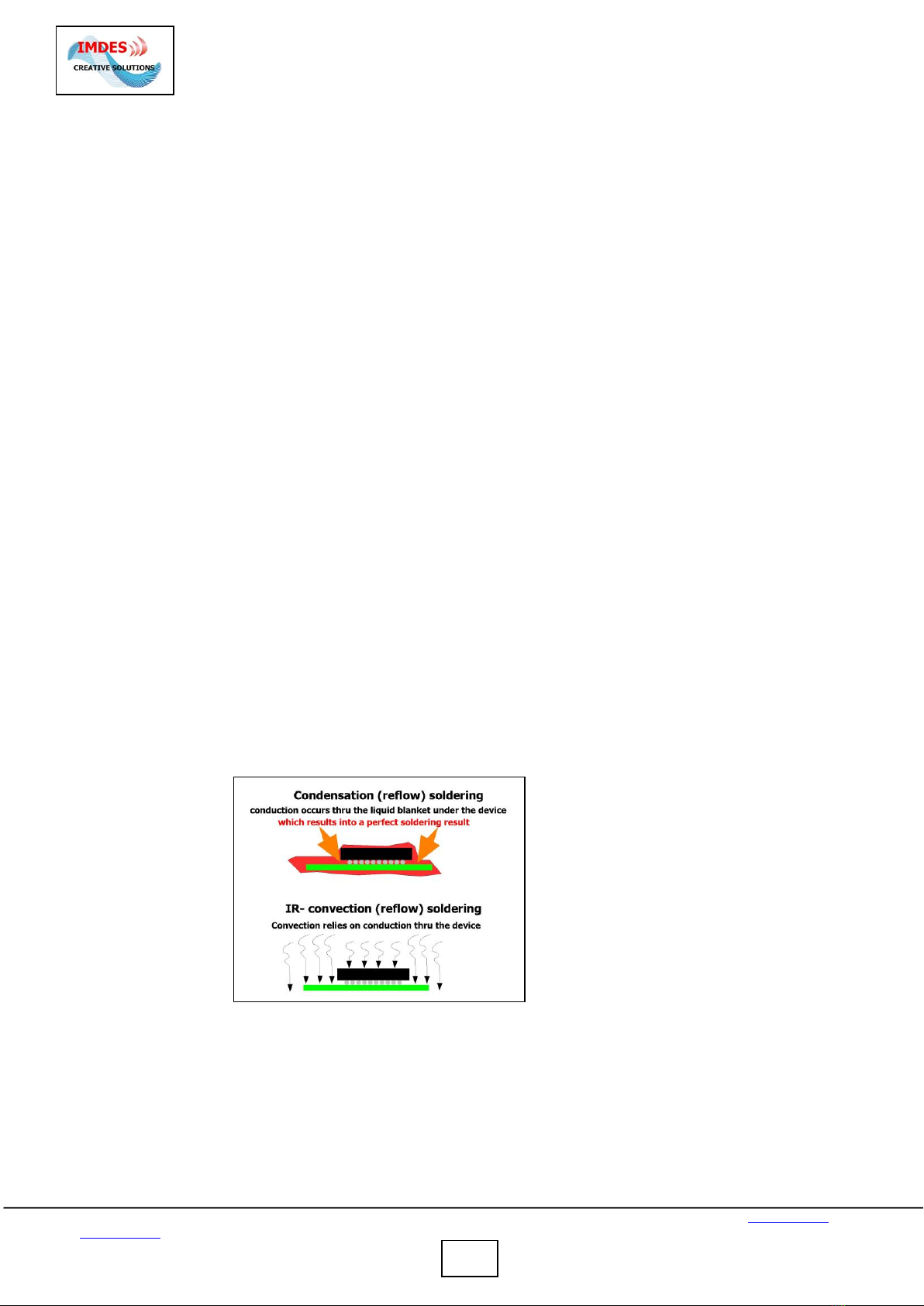

Soldering takes place in a space filled with inert gas, so no oxygen or other gases will be coming in contact with

the soldering surfaces and components. This is why a shielding gas such as nitrogen is no longer needed. The heat

transfer takes place by a fluid film, which is much more direct and more effective than radiation or air heating.

This creates an extremely high efficiency. Overheating is impossible because the temperature of the vapour will

never exceed the boiling point of the liquid, which is fixed by the chemical composition of the liquid.

IMDES CREATIVE SOLUTIONS Schulstrasse 21 D-48455 Bad Bentheim /Gildehaus Germany T:+49(0)5924-997337 E: info@imdes.de

www.imdes.de SKYPE marc.van Stralen © 2019 IMDES CREATIVE SOLUTIONS

8

1.8 The advantages at a glance:

Environmentally friendly process.

Repeatable soldering process conditions.

No overheating of the PCB and its components.

Uniform warming of the PCB regardless of the shape or colour.

Absolute uniform heating of the PCB.

Condensation vapour causes a thin liquid film that penetrates to the smallest openings resulting in reliable

soldering of BGAs and FBGAs.

Good reproducible temperature profiles.

No oxide formation.

No protective gases required.

No more labour-intensive procedures to determine the desired temperature profiles.

Extremely high efficiency

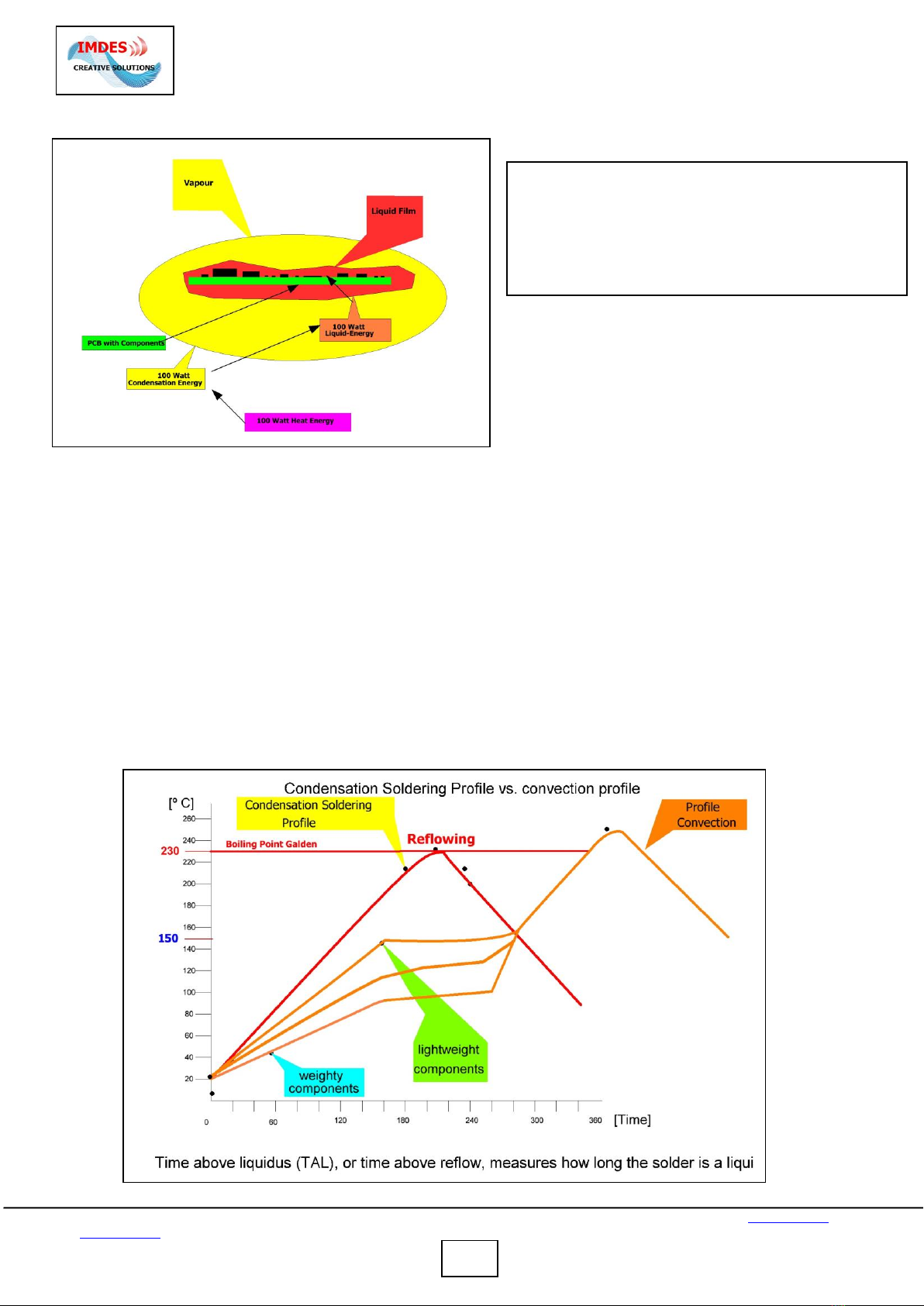

100 Watt heat energy from heating elements

Will generate:

100 watt condensation energy (vapor)

100 watt condensation liquid (liquid film during condensation)

IMDES CREATIVE SOLUTIONS Schulstrasse 21 D-48455 Bad Bentheim /Gildehaus Germany T:+49(0)5924-997337 E: info@imdes.de

www.imdes.de SKYPE marc.van Stralen © 2019 IMDES CREATIVE SOLUTIONS

9

1.9HEAT LEVEL ADJUSTMENT METHOD

The above described procedure of the JUMBO-CONDENS-

IT

condensation soldering machine works according to

the “HEAT LEVEL ADJUSTMENT METHOD”.

Refer the picture below.

Step 1

The heat transfer fluid (Galden) is not active.

1) The circuit boards are in the process chamber, a few centimetres above the heat transfer liquid at the bottom of

the process chamber.

2) Transfer liquid is heated to the boiling point.

Step 2

The heat transfer liquid (Galden) is active.

It boils at 230 °C and is in active phase.

PCB with components is in the condensation vapour at 230 ° C.

(Galden LS 230 boils at 230 ° C for lead-free applications.)

1) The liquid starts to evaporate and the vapour starts to rise to the assembled PCB.

2) The PCB surface will condense the vapour, because it has a lower temperature than the vapour.

3) Once the PCB temperature equals that of the vapour, the reflow process will take place.

4) The reflow soldering time will take between 60 to 90 seconds and the total cycle time including loading, processing, cooling

and unloading will be approx. 10 minutes.

IMDES CREATIVE SOLUTIONS Schulstrasse 21 D-48455 Bad Bentheim /Gildehaus Germany T:+49(0)5924-997337 E: info@imdes.de

www.imdes.de SKYPE marc.van Stralen © 2019 IMDES CREATIVE SOLUTIONS

10

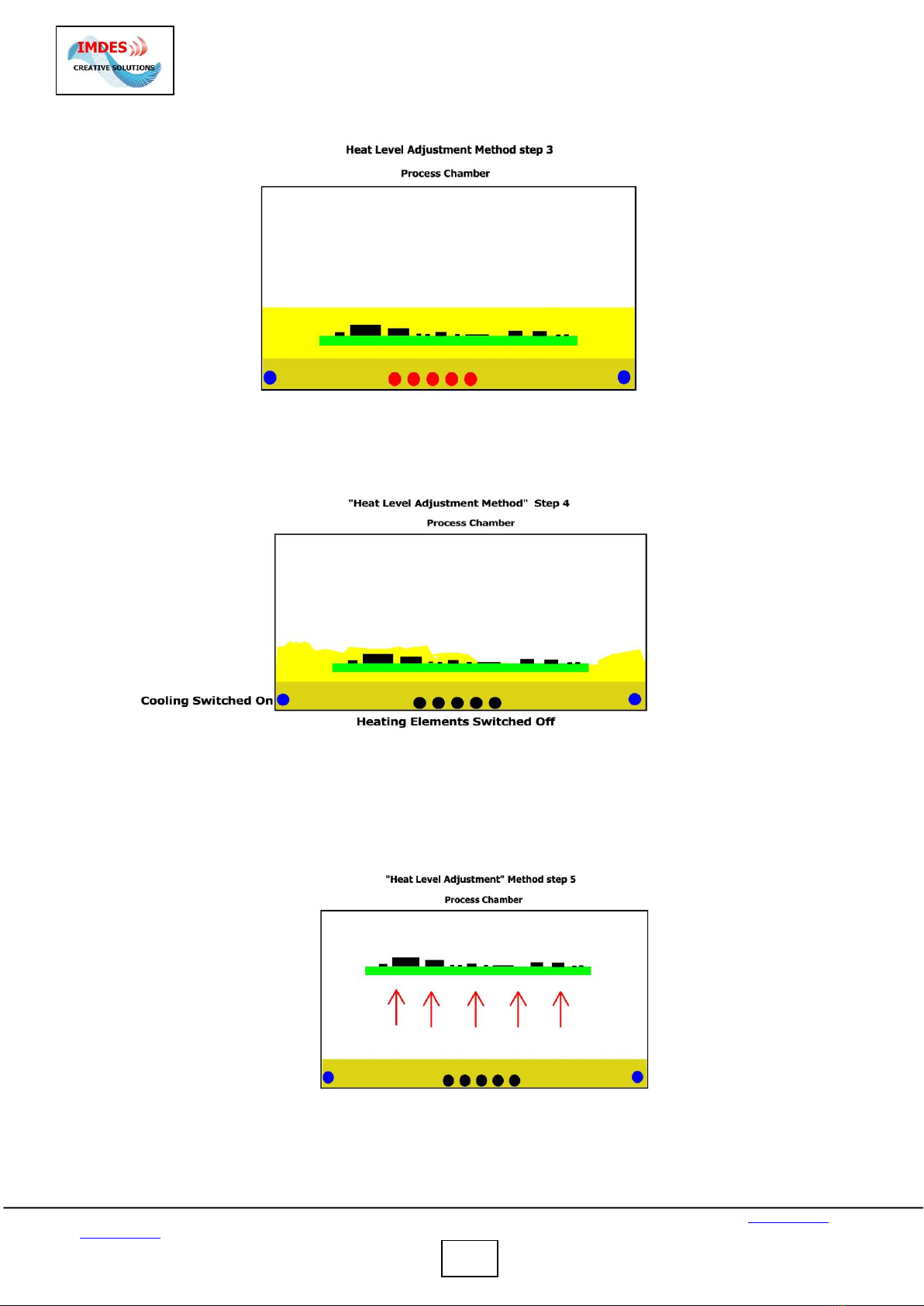

Step 3

1) Temperature of the assembled PCB reaches temperature of the transfer fluid.PCB temp. =Vapour temp.

2) Vapour starts to rise again.

Step 4

1) Reflow process will be terminated by switching off the heating elements.

2) Blowers placed under the process chamber will start to cool the process chamber and its transfer medium

Step 5

1) After the cooling process, the PCB can be removed

IMDES CREATIVE SOLUTIONS Schulstrasse 21 D-48455 Bad Bentheim /Gildehaus Germany T:+49(0)5924-997337 E: info@imdes.de

www.imdes.de SKYPE marc.van Stralen © 2019 IMDES CREATIVE SOLUTIONS

11

1.10 System Description DINO-CONDENS-

IT

.

The DINO-CONDENS-

IT

is intended to use for reflow soldering printed circuit boards on a smaller scale, i.e. for

individual pieces, prototypes and small series run.

It is specially designed to use for soldering of prototype PCB’s using BGAs, LGA’s components and stacked arrays.

Due the small footprint of the DINO-CONDENS-

IT

, forced air cooling and single phase power, you will able to

use the unit at almost any that place.

After proper installation and operation, DINO-CONDENS-

IT

will give high quality solder joints at all times.

Appropriate frequent checks and maintenance are required, due to the low GALDEN capacity.

Other applications than those described in this manual are not allowed!

1.12 safety Features:

1.12.1 Process chamber cover sensor.

A micro switch monitors if the process chamber cover is present and closed.

If you open the cover before the end of the process, the system is switched off.

When the there is no cover on to the process chamber, it is not possible to start the process.

1.12.2 Temperature Vapor/ ceiling height sensor.

1.12.3 Over heating sensor of heating surface temperature (fail safe)

A sensor/switch is mounted underneath the bottom of the process chamber to prevent overheating when there is

no heat transfer medium (fluid) at the bottom of the process chamber.

Caution!

In case of over temperature you must wait until the switch is closed again. Then you may fill the process chamber

with the transfer medium.

1.12.4 Cooling:

There is ONE large fan below the process chamber to cool the PCB and liquid in the chamber.

The height of the vapor in the process chamber is controlled by a thermal sensor

K-Element (T1) and a digital controller.

When the vapor maximum height is reached, the sensor automatically switches off

the heater and automatically starts the cooling process.

The end of the cooling process is reached when the fans have stopped.

IMDES CREATIVE SOLUTIONS Schulstrasse 21 D-48455 Bad Bentheim /Gildehaus Germany T:+49(0)5924-997337 E: info@imdes.de

www.imdes.de SKYPE marc.van Stralen © 2019 IMDES CREATIVE SOLUTIONS

12

1.12.5 Transport of the DINO-CONDENS-

IT

The system must not be tilted during transport.

If the DINO-CONDENS-

IT

will be transported over greater distances, and it filled with Galden, it should be

secured on a pallet or similar platform to prevent slipping or tripping over and losing the expensive Galden.

Caution: May be transported only in the cold state!

1.13 Inspection, Unpacking, Installation & Commissioning

1.13.1 Unpacking and inspection for transport damage.

Please check the system on delivery for transport damage.

For Visible transport damage, immediately inform your carrier and make a note on the delivery note of your

carrier.

Later, hidden transport damages must immediately put in writing to the freight forwarder and us.

Contents of the Carton

Inside the carton you should find the following items:

Table 1: Contents of Carton for each

DINO-CONDENS-

IT

Item

FLEX

"DINO-CONDENS-

IT

,-"

1 no.

Lid/Cover with glass window

1 no.

This owner`s manual

1 no.

AC Power cable

1 no.

Dipstick to measure the Galden Level in the process chamber

1 no.

Pump = 100 ml large hypodermic syringe for emptying

1 no.

Initial filling GALDEN (minimum quantity ca. 1648 ml 1.65

Liter)= 3 Kg GALDEN

1648 ml.

Gloves

1 set.

(Other items may be included that are not listed above. See the packing list in the carton for all the items in the

carton).

1.13.2 Installation and commissioning

The DINO-CONDENS-

IT

should be stored in place and operated where no excessive or condensing humidity is

present and the ambient temperature should never be below freezing point.

As the unit is air cooled, a higher ambient temperature will lead to a reduced cooling capacity and thus extend the

cooling time.

The DINO-CONDENS-

IT

must have a free space of at least 30 cm on both sides (ventilation slits side) to aid

sufficient air circulation.

Be warned that at the left and right side of the device are ventilation slits, where for a short time (immediately at

the end of a solder process) up to 140 °C 284 °F warm air can be blown out!

The device should be operated only on horizontal surfaces which are firm and non-slippery.

IMDES CREATIVE SOLUTIONS Schulstrasse 21 D-48455 Bad Bentheim /Gildehaus Germany T:+49(0)5924-997337 E: info@imdes.de

www.imdes.de SKYPE marc.van Stralen © 2019 IMDES CREATIVE SOLUTIONS

13

Chose a solid (working) table top with good lighting conditions and near a window which can be opened for

optimal ventilation, because heated solder paste will create pungent fumes.

The 4 rubber feet under the unit aid in exchange of air underneath the DINO-CONDENS-

IT

.

1.13.3 The stainless steel lid with glass observation window

GALDEN is an expensive liquid, and hence we have optimized the DINO-CONDENS-

IT

to have the lowest

possible evaporation loss.

This includes also proper handling!

-Open the lid only after the blower has been stopped after the cooling stage.

-Opening the DINO-CONDENS-

IT

at reflow temperature will increase the loss of GALDEN, as GALDEN steam

could escape from the chamber.

The lid is made of a stainless steel and has an integrated heat resistance glass window (up to 700 °C =1292 °F) to

observe the reflow process.

IMDES CREATIVE SOLUTIONS Schulstrasse 21 D-48455 Bad Bentheim /Gildehaus Germany T:+49(0)5924-997337 E: info@imdes.de

www.imdes.de SKYPE marc.van Stralen © 2019 IMDES CREATIVE SOLUTIONS

14

1.14 Handling tips:

Keep the stainless lid with glass observation window vertical above the tank, with a corner down, so the

GALDEN condensate left will flow back, in drops, in the process chamber.

A piece of cleaning paper or kitchen roll is a wonderful resource and should be always kept at hand to wipe

drops right away.

1.14.1 Handling of the DINO CONDENS-

IT

With the construction of DINO-CONDENS-

IT

great attention was given to a simple reliable and straightforward

design for ease of handling and low cost of ownership.

1.14.2. General operating instructions

When loading the product carrier, care should be taken that the maximum dimensions and weight of the PCB or

device are not exceeded.

The PCB/ Device may not stick out over or under the product carrier.

The DINO-CONDENS

-IT

stainless steel lid should be opened only to insert or remove a PCB to prevent

unnecessary loss of Galden.

The minimum level of the process medium must be monitored by the operator with the help of the

Dipstick (brass tube).

IMDES CREATIVE SOLUTIONS Schulstrasse 21 D-48455 Bad Bentheim /Gildehaus Germany T:+49(0)5924-997337 E: info@imdes.de

www.imdes.de SKYPE marc.van Stralen © 2019 IMDES CREATIVE SOLUTIONS

15

1.15 safety instructions

Please read carefully the safety instructions, to avoid damage to humans and DINO-CONDENS-IT.

Prior to operate the DINO-CONDENS-

IT

you MUST be read the Owner's Manual.

All information/operating instructions must be read carefully.

Never try to access the hot system or open the unit lid when the system is in operation.

The vapor is invisible and can cause serious burns.

Do not operate DINO-CONDENS-

IT

without process media.

The lid of the DINO-CONDENS-

IT

must always remain closed during operation.

Use the supplied cotton gloves to remove the soldering material.

The PCB´s and work piece carrier are still not completely cooled to temperature after the cooling has been

stopped!!

DINO-CONDENS-

IT

must be operated only as mentioned in this manual!

Installation, operation, maintenance must be carried out only by qualified and trained personnel.

Untrained persons, mentally handicapped and children must not operate the DINO-CONDENS-

IT

!

Comply with the electrical requirements!

The workpiece carrier and the PCB´s that comes out of the DINO-CONDENS-

IT

will still be hot.

Caution: burning risk!

(Use the cotton hand shoes delivered with the machine)

Never use the DINO CONDENS-IT in case of machine failures, errors and or defects these must be first

Eliminated before running the machine for production.

Immediately switch off the DINO-CONDENS-

IT

from the line voltage in case of faulty operation and

damage and secure the main switch against uncontrolled restart!

Open the system only after complete cooling.

Disconnect the DINO-CONDENS-

IT

from the power during maintenance work.

NEVER by-pass, Modify, Change or manipulate the protection devices.

The JUMBO-CONDENS-

IT

must not be modified or altered in any way without prior consultation with

IMDES CREATIVE SOLUTIONS.

Use personal protection while operating the system.

Observe all applicable national regulations and safety regulations for accident prevention and

environmental protection.

Operate the system only with completely enclosed area and not in the open.

Electrical components are NOT protected against splashing water, appropriate protection measures must

be taken by the operator.

Do not operate the unit with a lid with broken glass Window.

There is danger of cutting on broken glass of the lid. Wear suitable protective gloves when handling

broken pieces of glass.

The Safety manager has to instruct the operator on the risk of injury if he operates the machine with a

damaged or broken window.

Use only approved heat transfer mediums which are approved by IMDES CREATIVE SOLUTIONS

Process mediums, substances and materials must be investigated prior to use on their process capability.

Be aware of slipping danger by accidental leaking of reflow medium on the ground.

Cordon off the affected area and ensure that leaked medium is absorbed with a suitable bonding agent

and removed, or cleaned up.

Hot medium has a high risk for burns, the operator must, therefore, let the media cool down.

DO NOT Touch hot medium in any case. Allow the DINO-CONDENS-

IT

to cool down completely

before removing it from the system.

Wear sealed protective clothing and gloves during cleaning and provide adequate ventilation and exhaust.

Read and follow the safety instructions and regulations of the used cleaner and the used medium.

To drain the used medium USE suitable containers. Ensure that the used medium dumped into the drain or

into open field.

Read the safety and disposal instructions from the manufacturers of soldering pastes, PCB´s and

component.

Eating, drinking and smoking during operating near the DINO-CONDENS-

IT

is not permitted.

Wash your hands after working with the system thoroughly with Soap and water.

If the system should be scrapped, the process fluids have to be drained and disposed of as per

regulations.

Filter materials must be disposed as hazardous waste.

IMDES CREATIVE SOLUTIONS Schulstrasse 21 D-48455 Bad Bentheim /Gildehaus Germany T:+49(0)5924-997337 E: info@imdes.de

www.imdes.de SKYPE marc.van Stralen © 2019 IMDES CREATIVE SOLUTIONS

16

1.15.1 Filling with GALDEN

Take off the stainless steel /glass lid of DINO-CONDENS-

IT

.

Fill the stainless process chamber until the middle of the bottom the stainless process chamber is completely

covered with approx. 1.65 liter Galden = 3 kg such that there is at least 8- 10 mm= 0.31”-0.39” of Galden

in the bottom.

Use the supplied dipstick (brass or aluminum tube)

Never fill the process chamber if the temperature of the liquid is above 100 °C. 212 °F

1.15.2 Effect of adding large quantity of Galden to the process chamber:

A larger capacity leads to slower heating and cooling and this results in higher energy consumption, but otherwise

has no adverse effect on the soldering process.

1.15.3 Effect of adding too small quantity of Galden to the process chamber: DANGEROUS!!!.

As the bottom of the process chamber, when heaters are present, sometimes bulges out into the chamber, it may

occur, that at some point of time these bulges will rise above the liquid level and cause the temperature to rise

above 300°C. This may result in damaged heaters and release of dangerous fumes due the Galden See Message

below.

Warning!

GALDEN decomposes when heated above 295 °C =563 °F into harmful components!

The DINO-CONDENS-

IT

does NOT check automatically if there is sufficient level of GALDEN in the

process chamber.

Therefor you have to check the GALDEN level on a regular and conscientious basis with the

Supplied dipstick (brass tube/aluminium).

If you notice low level of Galden during the soldering process, press stop/cooling button, leave the glass lid

closed, and keep a distance from the unit and ensure good ventilation. This will lower its temperature as quickly as

possible.

When the machine has cooled down to less 100 °C = 212 °F , you can refill GALDEN

1.15.4 Open the lid

The lid of the DINO-CONDENS-

IT

is an important part of the safety, and should always be closed if no

manipulation in the process chamber (inserting/removing of boards, cleaning) are required.

Due the built-in micro switch the soldering process could be only be started when the lid is closed!

The other advantage of the glass in the lid is to minimize the escape of GALDEN vapor while allowing observation

of the soldering process, without breathing the ascending vapors.

Never open the lid during the process of soldering! The GALDEN vapor escaping out of the chamber is extremely

hot and can cause severe burns! (In case of an emergency exercise great caution while opening the lid in mid

process.)

If you open the lid or move during an ongoing process of soldering the soldering process will be interrupted and

the heating system switched off!

IMDES CREATIVE SOLUTIONS Schulstrasse 21 D-48455 Bad Bentheim /Gildehaus Germany T:+49(0)5924-997337 E: info@imdes.de

www.imdes.de SKYPE marc.van Stralen © 2019 IMDES CREATIVE SOLUTIONS

17

1.15.5 Removing Soldered parts:

The lid may be removed when the fans have stopped at the end of the cooling process; the soldered parts on the

product carrier are cooled down to about 70 °C. –158 ° F

As the soldered parts and product carrier are not at room temperature, use cotton gloves supplied to remove the

soldered part and product carrier.

We strongly discourage the use of pliers, tweezers or similar tools to remove the soldered parts as they may slip

from the tool and fall into the liquid Galden.

In case the soldered part falls into the liquid Galden, do not try to "Save’’ the soldered part fallen in to the

GALDEN. The result for such actions will be burns.

As the liquid GALDEN has now cooled on a non-critical components temperature of 160°C=320°F

(or less), the components on the circuit board will suffer no thermal damage.

Simply turn off the DINO-CONDENS-

IT

and wait until the machine has completely cooled off.

No you can safely remove the soldered part.

1.15.6 Control panel

IMDES CREATIVE SOLUTIONS Schulstrasse 21 D-48455 Bad Bentheim /Gildehaus Germany T:+49(0)5924-997337 E: info@imdes.de

www.imdes.de SKYPE marc.van Stralen © 2019 IMDES CREATIVE SOLUTIONS

18

2.0 Operating the DINO-CONDENS-

IT

2.1 The proceedings at the IMDES CONDENS-IT Profiler

1. Turn on the main switch.

2. Blue LED at the front of the machine will turn on after switching on and the green LED at the control panel

will start to glow a few seconds later if the lid is in place on top of process Chamber.

3. Open the cover of the system, and then place the work piece onto the product carrier.

4. Close the cover lid.

5. Press the Start switch Green Button to execute the "reflow process”.

6. Yellow and RED LED Start to Burn

7. When the RED LED does not start to burn the LID is not good closed micro switch is not

activated and the heater will not switched in

8. System heats up the applied "heat transfer" liquid to its boiling point. The resulting vapour rises up and

condenses on the surface of the work piece to be soldered and transfers its thermal energy to the work

piece.

9. The solder Oxidation is avoided as vapour is chemically inert and no oxygen present in this zone. The work

piece surface is heated to the temperature of the boiling liquid vapour. The temperature of the vapor is

determined by the temperature of the boiling point of liquid and will not exceed.

10. After reaching the boiling temperature (= the vapour temperature) of the liquid, vapour rises until it

reaches the vapour temperature sensor and the heating elements are turned off.

11. The cooling fans start cooling process chamber and as the temperature of the vapours come down, it

starts to condense to liquid form and collects at the bottom of the process chamber. The remaining

condensate remains on the work piece and will evaporate by the own heat of the work piece.

12. When the blowers are stopped the cooling procedure comes to an end.

13. Next open the lid of the system and remove the soldered work piece from the product carrier.

The entire procedure takes approximately 10 to 15 minutes.

The consumption of the Galden medium is minimal, especially if the work piece is adequately cooled after reflowing

and the lid remains closed during the process.

In the DINO-CONDENS-

IT

is a micro switch built into the top of the unit so the "reflow process" can only be

started up if the lid is closed.

Basically no harmful vapours are generated during the reflow process other than the flux fumes during the reflow

process, which can be exhausted out.

IMDES CREATIVE SOLUTIONS Schulstrasse 21 D-48455 Bad Bentheim /Gildehaus Germany T:+49(0)5924-997337 E: info@imdes.de

www.imdes.de SKYPE marc.van Stralen © 2019 IMDES CREATIVE SOLUTIONS

19

2.2 Programming and modifying the Soldering Profiles

Your CONDENS- IT Profiler reflow soldering machine is from the factory pre-programmed for use with Galden

230 lead-free applications.

If you have ordered the machine for for lead containing solder alloys, the machine is pre-programmed for Galden

200 or Galden 210.

• The "default" Preheat heater temperature is set to: 150 °c (Galden 230 lead-free applications)

• Preheat heating "Default Time” is set to: 30 seconds (Galden 230 lead-free applications)

• "Default boiling Time” TAL "Time Above Liquid" is set to: 30 seconds.

• "Default value" AntiTombStTime + menu (not activated) and is set to 0 Sec but you can

activate it by changing the time span from 0 Seconds to for example into 30 seconds

• "Default value" of the tomb Temp + 200 ° C (for lead-free application)

"Default value" of the tomb Temp + 160 ° C (for leaded applications

2.3 OPERATING & PROGRAMMING THE MACHINE

Power up the Machine by activating the Black Switch on the left side at front of the machine

The Blue LED under the main power switch will be illuminated now!

On the display appears :

IMDES CREATIVE SOLUITIONS

Copy right Paul Keizer Ver. 1.15 (or an other Ver. = Version release No.)

When pressing the green key, the soldering process starts with the last saved profile in Eeprom and starts to

warm up the machine to go through the entire solder and cooling process.

If you want to have a different solder profile.

You need to press the RED key!

Then appears in the display

Galden boiling point = (boiling point Galden)

PLEASE NOTE!!!

This will be determined by the type of Galden you want to use:

LS 200

Maximum solder temperature 200°C

for lead containing solder alloys

LS 210

Maximum solder temperature 210°C

for lead containing solder alloys

LS 215

Maximum solder temperature 215°C

for lead containing solder alloys

LS 230

Maximum solder temperature 230°C

for lead free solder (SnCuAg)

XS 235

Maximum solder temperature 235°C

for lead free solder (z.B. Sn100C,SnCu)

HS 240

Maximum solder temperature 240°C

for lead free solder (z.B. SnCu)

HS 260

Maximum solder temperature 260°C

for lead free solder (special lead free product)

2.4 Attention!

If you have entered the new values, you want in the menu, you must press the green and red key

simultaneously to confirm and entering in to the next menu.

If you do not want to change anything in a menu, you must also press the green and red key

simultaneously to skip and entering into the next menu.

The last saved values in the EEPROM are indicated in the display.

For example:

Gal 230

°

Pht 150

Prof 30s GrB=ok

IMDES CREATIVE SOLUTIONS Schulstrasse 21 D-48455 Bad Bentheim /Gildehaus Germany T:+49(0)5924-997337 E: info@imdes.de

www.imdes.de SKYPE marc.van Stralen © 2019 IMDES CREATIVE SOLUTIONS

20

GaldenBoilingPt the boiling point of the Galden to be

This can be changed by using the green and red key

(in steps of 5 degrees from 200 °c

<-> 260 °c)

• Green Key for lower value

• Red key for a higher value

Profile Choice Sets the preheating time of the solder profile in steps of 30

seconds of entry (0 seconds is a lineair profile)

PreheatTemp PreheatTemp in this menu you can change the preheating

temperature in steps1 degree.

BoilingTime

(=this is time above liquid)

In this menu you are able to enter the

boiling Time Above Liquid (TAL) in steps of 1 second when the galden vapor has

reached its boiling temperature ( for example 230 degrees)

2.5 The Anti-Tombstone mode (ATS) is not activated by default!

(ATS) can be activated if he tombstone effect occurs during the solder reflow process

If you do not want to change anything in the menu AntiTombStTime you need to press the green and red key

simultaneously to enter the next menu.

If you want to activate the Anti-tombstone mode, you must enter values into the

AntiTombStTime”

Menu

If you do not want to change anything in a menu, you must press the green and red keys simultaneously to

enter the next menu.

The machine will then automatically switch to the Reflowsolder mode according to the parameters you have

entered.

If you do not wish this

Press the black RESET button the machine will restart.

The display then displays the boot menu showing the last saved data (for example).

By pressing the Green key the reflow process will start using the saved data in EEPROM.

If all data is entered correctly, you can save the data in EEPROM by pressing the

Redbutton

PreheatTemp +

150

°

C -

GaldenBoilingPt+

230

°

C

Profilechoice +

0 sec -

BoilingTime +

30 sec -

Gal 230

°

Pht 150

Prof 60s GrB=ok

AntiTomb Temp +

200

°

C -

AntiTombStTime +

54 sec -

AntiTomb Temp Default values in the menu are already entered::

AntiTomb Temp + 200 ° C

(for lead free solder alloys)

AntiTomb Temp + 160 ° C

(for lead containing solder alloys)

You have to enter a value >then 0 Seconds.

The total “

AntiTombStTime”

must be entered in increments of 1 Second

Then press green and red key simultaneously and you come into the menu

Write to Eeprom?

Red button= Yes

Table of contents