Belmash SDM-2000 User manual

EN Operating manual

FR Instructions d'utilisation originales

PL Oryginalna instrukcja obsługi

Multifunctional woodworking machine

Machine-outil multifonctionnelle du bois

Wielofunkcyjna obrabiarka do drewna

BELMASH SDM-2000

BELMASH SDM-2200

BELMASH SDM-2500

3

PL

EN

FR

Figures ..........................................................................................................................................................4

Contents.......................................................................................................................................................13

Warranty liabilities......................................................................................................................................33

Images..........................................................................................................................................................4

Contenu .......................................................................................................................................................35

Garantie........................................................................................................................................................57

Rysunki .........................................................................................................................................................4

Spis treści.....................................................................................................................................................56

Warunki gwarancji.....................................................................................................................................77

4

1

49 23 3 56 45 46 2 32 30 4 47

33

44

48

5049

17223511921383718a18

135131

20

15 7

25

57

58

40 53 26 14 54 27 25 10 39

11 5

12

41

36

6

243498522928

4243

16

5

1a

2

16

brown

brown

blue

blue

blue

black

black

black

green / yellow

green / yellow

green / yellow

white

red

6

3 4

5 mm max

3

51

31

32 2

30 32 30a 30b 30c

4

49 44 50

49

A

5

A B C

48 4b 4a 4c

7

6

7

4

25 40 26 9 52 828/29

24 26 41

42 43

A

B

44

44a

23 40 25 26 48 9 8 26 24 41

8

8

9

10

4 13 1332 37 18

23 47 47а

47b

53 39 54 11a 11b 55 10 12 5

9

11

12

13

32 56 56 182018

7

15

19 21 38

36 6 12 302

10

14

15 16

18

17

H

24

A

25

64

6362

61

62

mm

66 65 87

11

19

20

17

69a

69

AA

18

18

65

65

68

68а

20

20

21

66

19

12

Dear customer!

We sincerely thank you for choosing Belmash machine.

We are condent that the purchase of our product will fully

meet your expectations and you will never regret your choice.

Stringent and permanent quality control, rigid requirements related to suppliers,

up-to-date equipment and experienced personnel give us the utmost condence in the

quality of manufactured products.

Considering our consistent quality standards,

we have decided to increase the warranty terms for our products!

Fill in the questionnaire at www.belmash.by

and get an extra 1-year* warranty for Belmash machines!

* P.S. This offer is valid for the products with currently existing warranty only.

Always at your service,

team Belmash.

E

x

t

r

a

1

-

y

e

a

r

w

a

r

r

a

n

t

y

F

i

l

l

i

n

t

h

e

q

u

e

s

t

i

o

n

n

a

i

r

e

a

t

o

u

r

w

e

b

s

i

t

e

EN

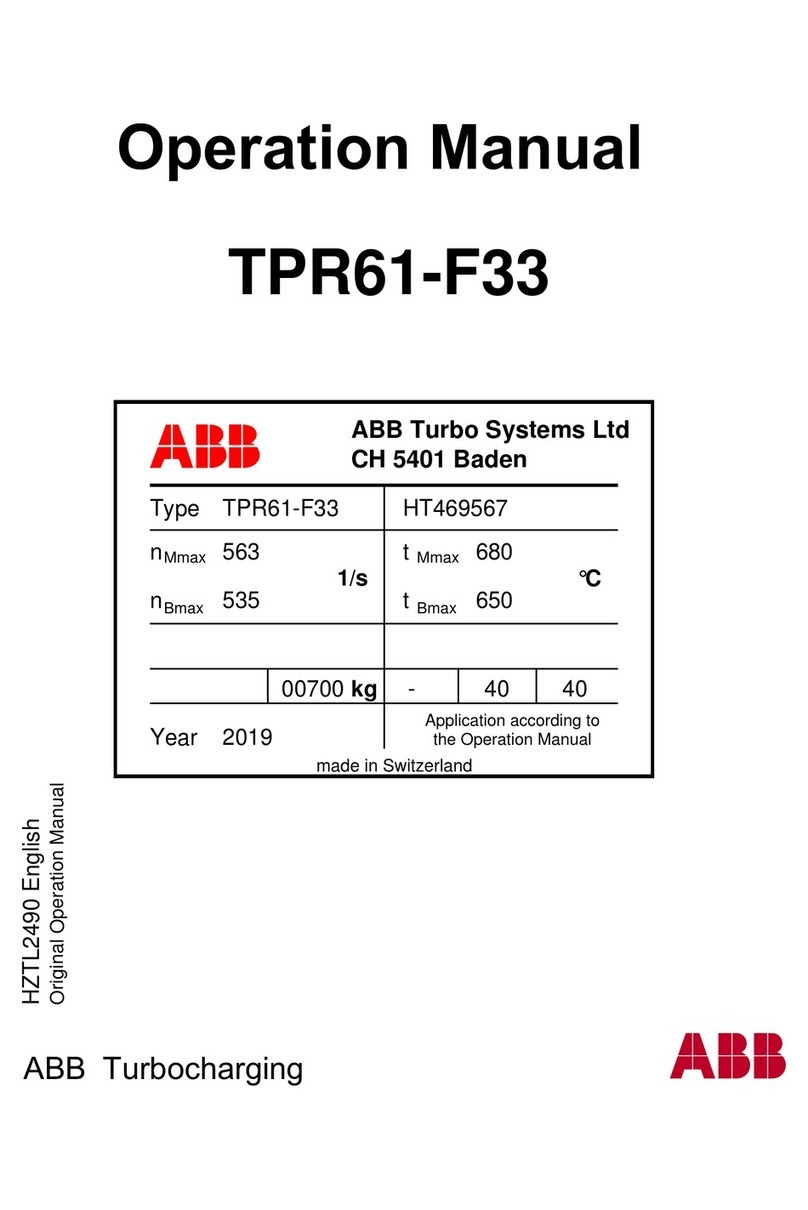

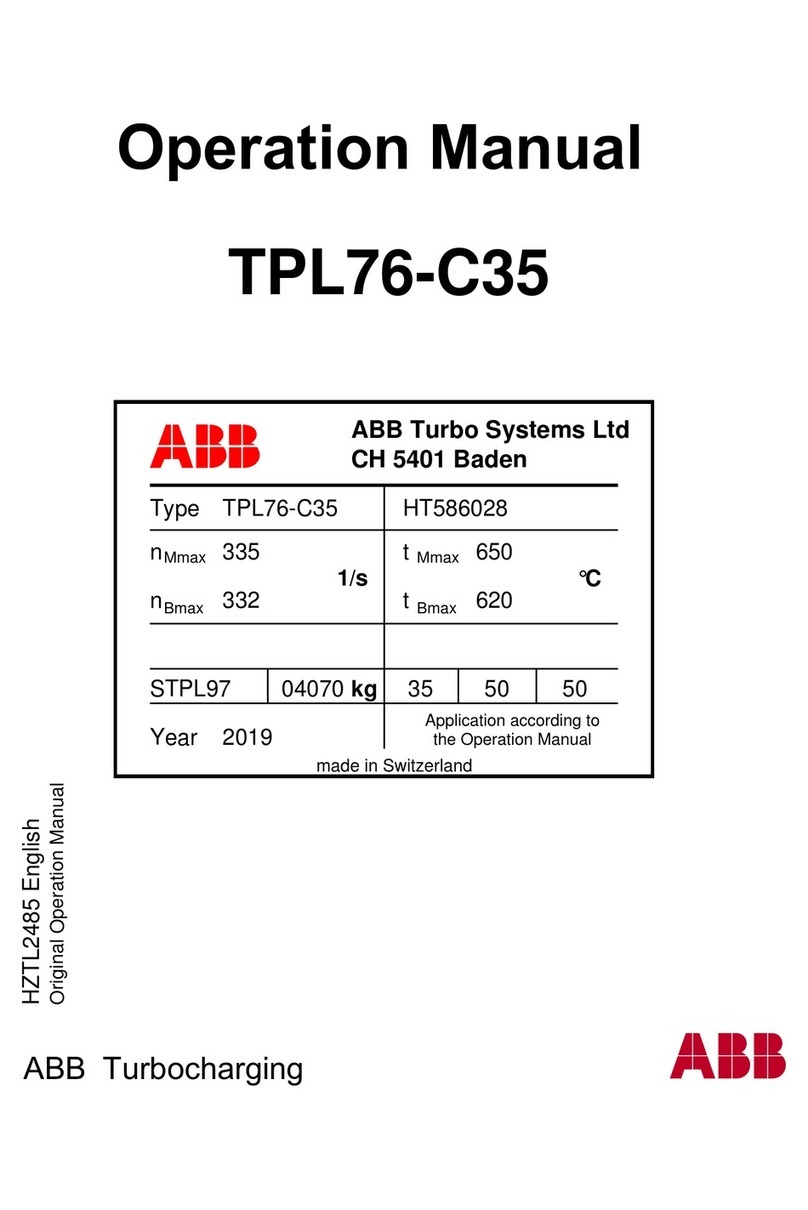

BELMASH SDM-2000, 2200, 2500

13

CONTENTS

Pictures ...............................................................................................................................................................4

Introduction........................................................................................................................................................14

1. Declaration of conformity ЕС/ЕЕА.........................................................................................................14

2. Intended use...............................................................................................................................................15

3. General information..................................................................................................................................15

4. Main parameters........................................................................................................................................16

5. Package contents.......................................................................................................................................17

6. Basic elements............................................................................................................................................19

7. Safety requirements .................................................................................................................................20

8. Marking and packaging ...........................................................................................................................22

9. Machine unit arrangement......................................................................................................................23

10. Prestarting procedures.............................................................................................................................24

11. Basic operations.........................................................................................................................................26

12. Technical maintenance and repair.........................................................................................................29

13. Troubleshooting..........................................................................................................................................30

14. Storage.........................................................................................................................................................31

15. Environmental management .................................................................................................................31

16. Transportation.............................................................................................................................................31

Warranty liabilities.............................................................................................................................................32

EN

14

This operating manual establishes machine service instructions and rules of safe operation.

Please read all instructions contained in this operating manual before using the machine.

The woodworking machines, if not operated safely, may endanger human life and health.

Hazardous exposure: noise, vibration, dust and cutting wastes, electricity.

Compliance with the requirements, specied in the operating manual, ensures safety while in use

and helps to avoid problems during operation and maintenance.

This operating manual does not reect slight changes and modications in machines, made by the

manufacturer after the publication of this manual, as well as changes in component details and

documentation attached to it.

1. DECLARATION OF CONFORMITY ЕС/ЕЕА

Joint limited liability company “Belmash factory” declares that multifunctional woodworking

machines BELMASH SDM-2000, BELMASH SDM-2200, BELMASH SDM-2500 comply with

the following requirements of EU Directives, including changes:

2006/42/EC Machinery (MD)

2014/30/EC Electromagnetic Compatibility (EMC)

2011/65/EU Restriction of Hazardous Substances (RoHS)

A basis for concordance of the mentioned above devices with the EU Directives is their full

compliance with the applicable standards listed below:

EN 61029-1:2009+A11:2010; EN 61029-2-1:2012; EN 61029-2-3:2011;

EN 62233:2008 (incl. Corr: 2008); EN 55014-1:2017; EN 55014-2:2015; EN 61000-3-2:2014;

EN 61000-3-3:2013+A1:2018; EN 61000-3-11:2017; IEC 62321-1:2013; EN 62321-1:2013;

IEC 62321-2:2013; EN 62321-2:2014; IEC 62321-3-1:2013; EN 62321-3-1:2014; IEC 62321-4:2013;

EN 62321-4:2014; IEC 62321-5:2013; EN 62321-5:2014; IEC 62321-6:2015; EN 62321-6:2015;

IEC 62321-7-1:2015; EN 62321-7-1:2015; IEC 62321-7-2:2017; EN 62321-7-2:2017

01/343

Responsible for technical documentation - Director Mr. Shorikov D.V.

Manufacturer's address:

JLLC Belmash factory, 212000 Belarus, Mogilev, Slavgorodskiy proezd 37

Place and date: Minsk, Belarus 27.06.2019

Director _______________ Shorikov D.V.

Conformity certicates are stored at the address: JLLC Belmash factory

37 Slavgorodskiy proezd, Mogilev, 212000, Republic of Belarus, [email protected].

EN

BELMASH SDM-2000, 2200, 2500

15

2. INTENDED USE

The machine relates to equipment for domestic individual use.

The hand-fed machines are used for processing wood and analogous hard materials

(cardboard, plywood, wood chipboards) by planing, cutting, milling, and drilling in order to

give them the required shapes and sizes.

Do not use the machine for other purposes. It is not allowed to process metals, stone, asbestos-

cement materials, soft plastic, and rubber-like materials.

With appropriate adjustment the machine can perform the following types of processing:

• planing on the surface or along ribs;

• angular planing, along ribs;

• longitudinal and cross-cutting;

• longitudinal angular cutting with the use of a guide;

• angular cross-cutting with the use of the device;

• milling with groove cutters;

• milling with end cutters;

• drilling.

3. GENERAL INFORMATION

The machine can be operated outdoors, under a cover, indoors, except for residential premises.

Climatic service conditions:

• altitude above the sea level – up to 1000 m;

• environment temperature from +5 to +40°С;

• environmental relative humidity – up to 80%, at a temperature of +20°С.

It is not allowed to operate the machine under the impact of drops and splashes, as well as

outdoors during rain, fog, snowfall, strong wing, and storm.

The power of the machine is supplied by a single-phase AC with (earth) wire.

BELMASH SDM-2200 and BELMASH SDM-2500 machines shall be used in the electrical grids

with a nominal impedance zmax=0,354 ohm. The operator should make sure that the power

line rated load capacity is appropriate.

Motor type – asynchronous, single-phase, with the working capacitor, intermittent operating

status – S6-40%.

The equivalent and maximum sound levels are as follows: 80 dBA and 90 dBA relatively.

The machine has a built-in disconnect device from the power supply during engine overheating.

Restarting of the machine can be performed after the electric motor has cooled down to the

ambient temperature.

To connect the external exhaust units in order to collect dust and cutting wastes, the

woodworking machine has three pipes:

• 63 mm on casing for chip removing 33 (g. 1);

• 38 mm on casing 57 of saw blade 32;

• 28 mm on fencing 2 of saw blade 32.

The external exhaust unit should be suitable for removing cutting wastes.

Operator should make sure that power line rated load capacity is appropriate.

EN

16

The average service life of the machine is at least ve years.

Machine serial number decoding:

4. MAIN PARAMETERS

The main parameters are specied in tables 1, 2 and 3.

Table 1

№Name

Parameters

BELMASH

SDM-2000

BELMASH

SDM-2200

BELMASH

SDM-2500

1Maximum planing width, mm 230 250 270

2Planing depth range, mm 0÷3 0÷3 0÷3

3Saw blade diameter, mm 250 280 315

4Maximum cutting depth, mm 85 100 117

5Groove cutter rated diameter, mm 125 125 125

6Rated bore diameter of saw

blade/groove cutter, mm 30 30 30

7Range of angles for cutting along the grain and planing

using the guide, degrees 0÷45 0÷45 0÷45

8Range of angles of cutting across bers using an

attachment, deg. –45÷45 –45÷45 –45÷45

9Rated cutting table size, mm 732×456 802×492 872×532

10 Rated size of tables when planing, mm 760×247 830×267 900×287

11 Milling table dimensions, mm 470×190 470×190 470×190

12 Rated cutter block speed at idle, min-1 7700 7700 7700

13 Rated cutter speed of circular saw blade and milling cutter

at idle, min-1 2850 2850 2850

14 Rated power consumption, W 2000 2200 2500

15 Rated voltage, V 230 230 230

16 Rated power-line frequency, Hz 50 50 50

17 Overall machine dimensions, L×W×H, mm, not more 888×625×445 960×660×460 1030×680×512

18 Machine weight, kg 64/68 68/72 73/77

Limit deviations of linear and angular dimensions do not exceed ±5%

Limit deviation of the rotating frequency does not exceed ±10%

Limit deviation of the power consumption ±10%

S014A.0117.0200

Original machine

number

Article Month, year of

manufacture

EN

BELMASH SDM-2000, 2200, 2500

17

5. PACKAGE CONTENTS

Package contents are specied in table 4.

Table 4

Bearing code Basic

dimensions Mounting place Quantity

80104 20×42×12 Pitch pulley 2

Cutter block 2

Table 2

Table 3

Name Code Quantity

V-belt 8PJ508 1

According to the accuracy standards, the machine must meet the following requirements:

1) the atness tolerance of the working surface of the guide is 0.5 mm; bulge is unacceptable;

2) the atness tolerance of the planing tables working surface is 0.5 mm; bulge is unacceptable;

3) the tolerance of parallelism of the cutting table is 0.5 mm along the length of the back table;

the inclination of the working surfaces of the tables towards the cutter block is not allowed;

4) the tolerance of parallelism of the cutter block and the surface of the back table - 0.3 mm;

5) the atness tolerance of the cutting table is 1.6 mm.

№Item, gure Name of items

Quantity (pieces)

BELMASH

SDM-

2000

BELMASH

SDM-

2200

BELMASH

SDM-

2500

Mechanisms, attachments, guards

1 Fig. 1 Multifunctional woodworking machine 1 1 1

2Item 2, 3, 45, 46,

g. 1 Saw blade guard assembled with riving

knife 1 1 1

3Item 4, g. 1 Guide 1 1 1

4Item 5, g. 1 Stop 1 1 1

5Item 6, g. 1 Vertical holder 1 1 1

6Item 7, g. 1 Box-end wrench 1 1 1

7Item 8, g. 1 Cutter block guard 1 1 1

8Item 9, g. 1 Cutter block guard bracket 1 1 1

9Item 10, g. 1 Milling table 1 1 1

10 Item 11, g. 1 End mill guard 1 1 1

11 Item 12, g. 1 Thumb screw 4 4 4

12 Item 15, g. 1 Open-end wrench 1 1 1

13 Item 16, g. 1 Pusher 1 1 1

14 Item 20, g. 1 Milling pad 1 1 1

15 Item 33, g. 1 Casing for dust extraction when planing 1 1 1

16 Item 36, g. 1 Vertical holder bracket 1 1 1

17 Item 47, g. 1 Cross-cutting device 1 1 1

EN

18

18

Item 17, gure 19

Item 18, gure 20

Item 19, gure 20

Item 20, gure 20

Item 21, gure 20

Item 65, gure 20

Item 66, gure 20

Item 68, gure 20

Item 68а, gure 20

Item 69, gure 19

Item 69a, gure 19

Clamping device

Spring box

Right support

Left support

Axis of rotation

Clamp axis

Clamp handle

М8 nut

Spring washer 8

М5×12 screw

Spring washer 5

1

1

1

1

1

1

4

2

4

2

1

1

1

1

1

1

4

2

4

2

1

1

1

1

1

1

4

2

4

2

Standard items

19 Item 32, gure 1 Saw blade 250×3,2/1,8×30 mm 24Т 1

20 Item 32, gure 1 Saw blade 280×3,2/2,2×30 mm 24Т1

21 Item 32, gure 1 Saw blade 315×3,2/2,2×30 mm 24Т 1

22 gure 16 Planer knife 230×2×20 mm 2

23 gure 16 Planer knife 250×2×20 mm 2

24 gure 16 Planer knife 270×2×20 mm 2

25 Item 14, gure 1 Drill chuck 13-М12×1,25 1 1 1

26 Item 58, gure 1 Hexagon wrench 3 mm DIN 911 1 1 1

27 Item 57, gure 1 Hexagon wrench 4 mm DIN 911 1 1 1

28 – Fixing hardware 1 set 1 set 1 set

Documentation

29 –Operating manual 1 1 1

EN

BELMASH SDM-2000, 2200, 2500

19

6. BASIC ELEMENTS

1 – machine frame

2 – saw blade guard

3 – riving knife

4 – guide

5 – stop

6 – vertical holder

7 – box–end wrench

8 – cutter block guard

9 – cutter block guard bracket

10 – milling table

11 – end milling cutter guard

12 – thumb screws

13 – cutting depth adjustment handle

14 – drill chuck

15 – open–end wrench

16 – pusher

17 – switch

18 – thumb nut for saw blade securing

18а – screw М5×12

19 – saw blade casing

20 – milling pad

21 – saw blade casing securing screws

22 – rotary control panel

23 – cutting table

24 – receiving planing table

25 – feeding planing table

26 – thumb nut

27 – shaft end guard

28 – spring washer 5

29 – М5×12 screw

30 – cutting table insert

31 – М8 nut

32 – saw blade

33 – casing for dust extraction when

planing

34 – thumb screw

35 – thumb screw

36 – vertical holder bracket

37 – cutting depth scale

38 – milling depth scale

39 – М8×20 bolt

40 – handle-lever of feeding table

41 – handle-lever of receiving table

42 – planing depth pointer

43 – planing depth scale

44 – tilt angle scale

45 – special screw

46 – М5 nut

47 – cross-cutting device

48 – cutting width scale

49 – guide

50 – clamping handle

51 – pressing plate

52 – thumb screw

53 – bracket

54 – thumb nut

55 – handle-lever of milling table

56 – saw blade securing nut

57 – hexagon wrench; s = 4 mm

58 – hexagon wrench; s = 3 mm

EN

20

7. SAFETY REQUIREMENTS

Before operation, study the safety requirements. Follow all the requirements of

the present manual

Getting started the machine usage, the operator should consider his physical condition, level

of qualication and complexity of the tasks performed. Machine operation is allowed only for

personnel of 18-year age or older having studied the present operating manual.

IT’S PROHIBITED TO:

• work under the inuence of alcohol, drugs or other intoxicants;

• operate the machine under the inuence of water drops and splashes as well as in open

areas during the rain or snowfall;

• leave the machine connected to power line unattended;

• assign the machine operation to persons unable to use it properly;

• use the machine inappropriately;

• shape metals, asbestos-cement materials, stone, plastic, rubber etc.

IT’S PROHIBITED TO operate the machine in case of detection of any of the following

malfunctions during operation:

• damage of electrical cord plug connection;

• damage of grounding circuit;

• appearance of aming insulation smell or smoke;

• switch malfunction;

• generation of noise, knocking or vibrations;

• malfunctions or cracking of machine parts, guards or cases.

The machine should be switched OFF in case of sudden stop (moving parts wedging etc.).

During work breaks the switch should be covered.

When connecting the machine use automatic circuit breaker or cutout fuse with rated operating

current of 16 A.

The machine should be disconnected from power line with plug connector in the following cases:

• tools replacement (saw blade, knives etc.), attachments mounting and adjustment;

• moving the machine from one place to another;

• during work breaks or after operation;

• during technical maintenance;

• when removing chips and saw dust.

The electrical cord of the machine should be protected from occasional damage (it’s

recommended to hang it). Direct contact of electrical cord with hot and oiled surfaces is not

allowed.

When operating in open areas use only appropriate and properly marked extension cord.

Always ensure that the processed material is free from nails or other foreign objects.

Do not wear loose clothes and jewelry. It’s prohibited to wear gloves during operation as they

may be entangled by moving machine parts. Use personal protective equipment and head wear.

To provide high-quality and safe operation, cutting parts of working tools should be sharpened

and clean. To replace the equipment, follow the present operating manual.

Other manuals for SDM-2000

2

This manual suits for next models

2

Table of contents

Languages:

Other Belmash Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

IDENTEC SOLUTIONS

IDENTEC SOLUTIONS i-B2 S/NA user guide

Pregis

Pregis AIRSPEED 5000 Safety, operation and maintenance manual

Graco

Graco SERIES J Instructions-parts list

Kobelt

Kobelt 5020-M Series Owner's Operation, Installation & Maintenance Manual

Van Beest

Van Beest Green Pin instruction manual

Meiwa

Meiwa RP300X Operation, maintenance and parts manual