Cirs Doppler String Phantom 043 User manual

900 Asbury Ave • Norfolk, Virginia 23513 • USA • Tel: 757-855-2765 • WWW.CIRSINC.COM

USER GUIDE

Doppler String Phantom

Model 043

Table of Contents

OVERVIEW ......................................................................................................................................................... 1

Features of the Doppler String Phantom .............................................................................................................. 1

Starting a Quality Assurance Program ................................................................................................................. 1

SETUP INSTRUCTIONS ..................................................................................................................................... 2

Parts List ............................................................................................................................................................. 2

Using the Diffuser Mat ......................................................................................................................................... 3

Installing the String .............................................................................................................................................. 3

Filling the Tank..................................................................................................................................................... 3

Setting up the Clamp........................................................................................................................................... 4

Connecting the Controller.................................................................................................................................... 5

SPECIAL FEATURE

Using The ECG Output ....................................................................................................................................... 5

OPERATING INSTRUCTIONS ............................................................................................................................ 6

Using Constant Speeds....................................................................................................................................... 6

Using Preprogrammed Waveforms ...................................................................................................................... 6

RS-232 INSTRUCTIONS .................................................................................................................................. 7

Introduction ......................................................................................................................................................... 7

Getting Started.................................................................................................................................................... 7

Accessing the Help Menu.................................................................................................................................... 8

Selecting Velocities and Waveforms..................................................................................................................... 9

Setting Up for Quality Control Testing .................................................................................................................. 9

Locking the Settings.......................................................................................................................................... 10

Description of Commands Available Via RS-232................................................................................................ 10

MAINTENANCE INSTRUCTIONS ................................................................................................................... 11

Making String Loops ......................................................................................................................................... 11

Ordering String Loops ...................................................................................................................................... 11

Cleaning the Doppler String phantom ............................................................................................................... 11

Calibrating the Doppler String Phantom............................................................................................................. 11

Replacing a fuse................................................................................................................................................ 12

ACCESSORIES AND PARTS............................................................................................................................ 12

Carrying Case.................................................................................................................................................... 12

Preformed String Loops..................................................................................................................................... 12

Step Up and Down Transformer ........................................................................................................................ 12

WARRANTY ..................................................................................................................................................... 13

Non-Warranty Service........................................................................................................................................ 13

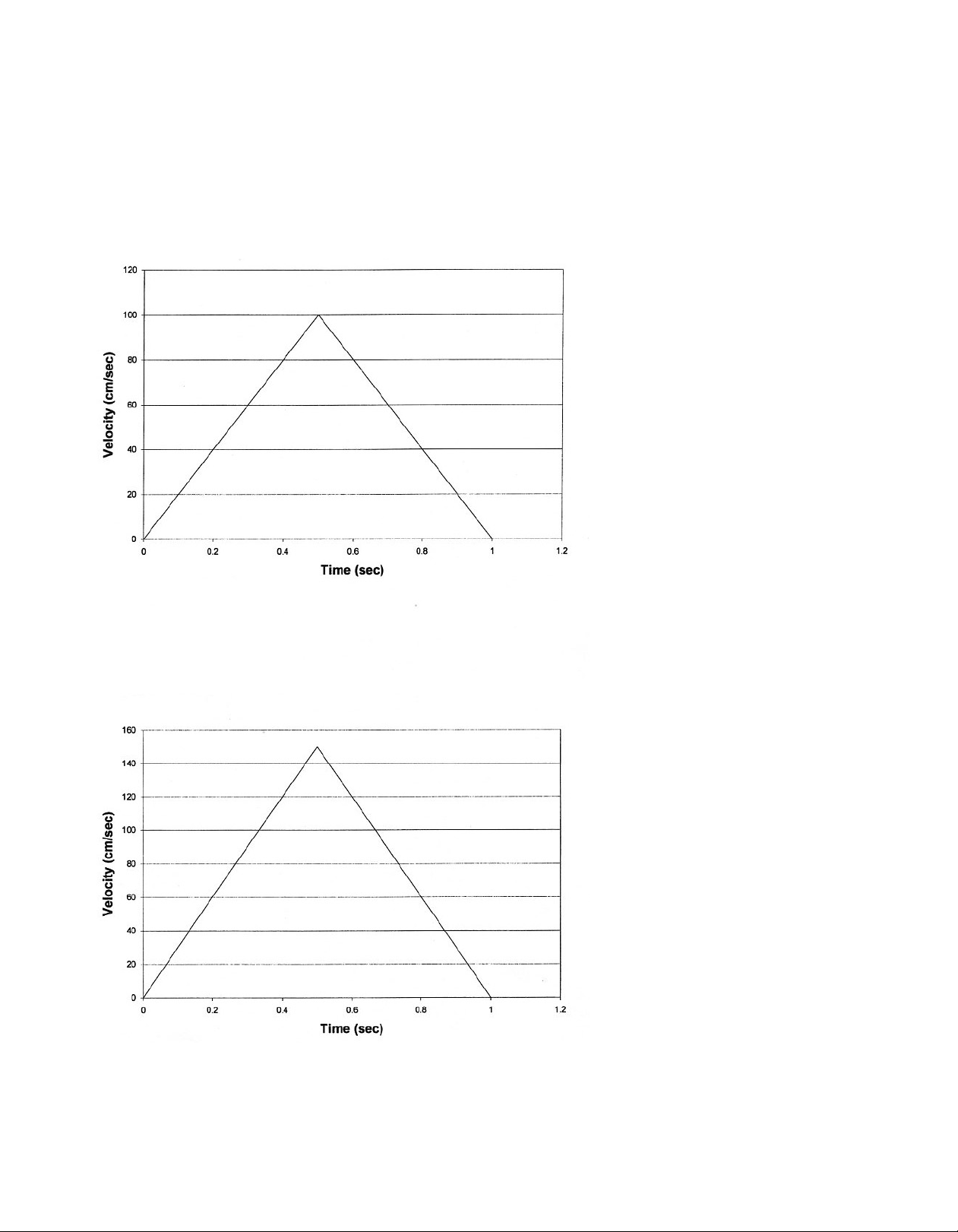

APPENDIX A GRAPHS OF WAVEFORMS....................................................................................................... 14

Test Waveforms................................................................................................................................................. 14

Physiological Waveforms ................................................................................................................................... 19

APPENDIX B SAMPLE QA FORM .................................................................................................................. 26

1

OVERVIEW

Features of the Doppler String Phantom

The Doppler String phantom is a very accurate device for testing Doppler ultrasound scanners. It is especially

useful for checking sample volume registration, color registration, directional discrimination, and Doppler velocity

accuracy.

The Doppler String Phantom offers superior accuracy by using a string target that never changes (unlike sus-

pended scatterers in fluid flow phantoms) and a crystal-controlled motor. The motor speed is adjusted 1000

times per second, allowing realistic reproductions of human blood flow velocity patterns and a wide range of con-

stant velocities.

The Doppler String Phantom has been designed for ease of use. It can be set up quickly and easily with ordinary

tap water. It is simple to use and almost no maintenance is required. An RS-232 interface is also provided for

automated use, if desired. Ultrasound technologists, biomedical technicians, researchers and manufacturers all

rely on the Doppler String Phantom for hassle-free, reliable testing.

Starting a Quality Assurance Program

Each ultrasound lab will have different Quality Assurance (QA) needs depending on equipment, maintenance

agreements and applicable laws and policies. However, many technicians recommend performing QA tests

every 3 months. Of course, any time you suspect a problem with an ultrasound scanner, you will want to test it

immediately.

CIRS recommends using a standard form to record the results of your tests, so you can be sure that each testing

session is consistent and thorough. Recording your findings also provides written documentation of your QA

program. A sample QA form is provided in Appendix B of this User Guide.

2

SETUP INSTRUCTIONS

Parts List

When you unpack the Doppler String Phantom for the first time, you should find:

• Electronic Controller

• Acrylic tank with motor and pulleys attached

• Scanhead Clamp

• Set of 5 String Loops (not pictured)

• Rubber Diffuser Mat (not pictured)

• Power Cord (not pictured)

• Carrying Case (not pictured)

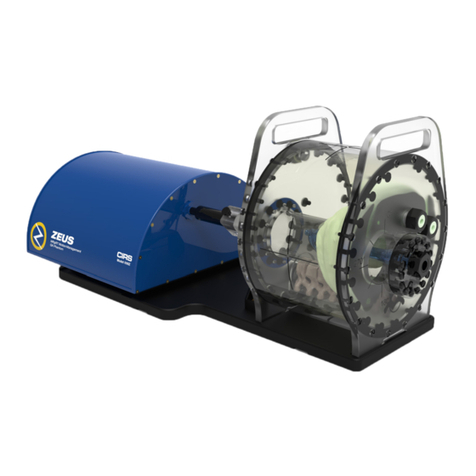

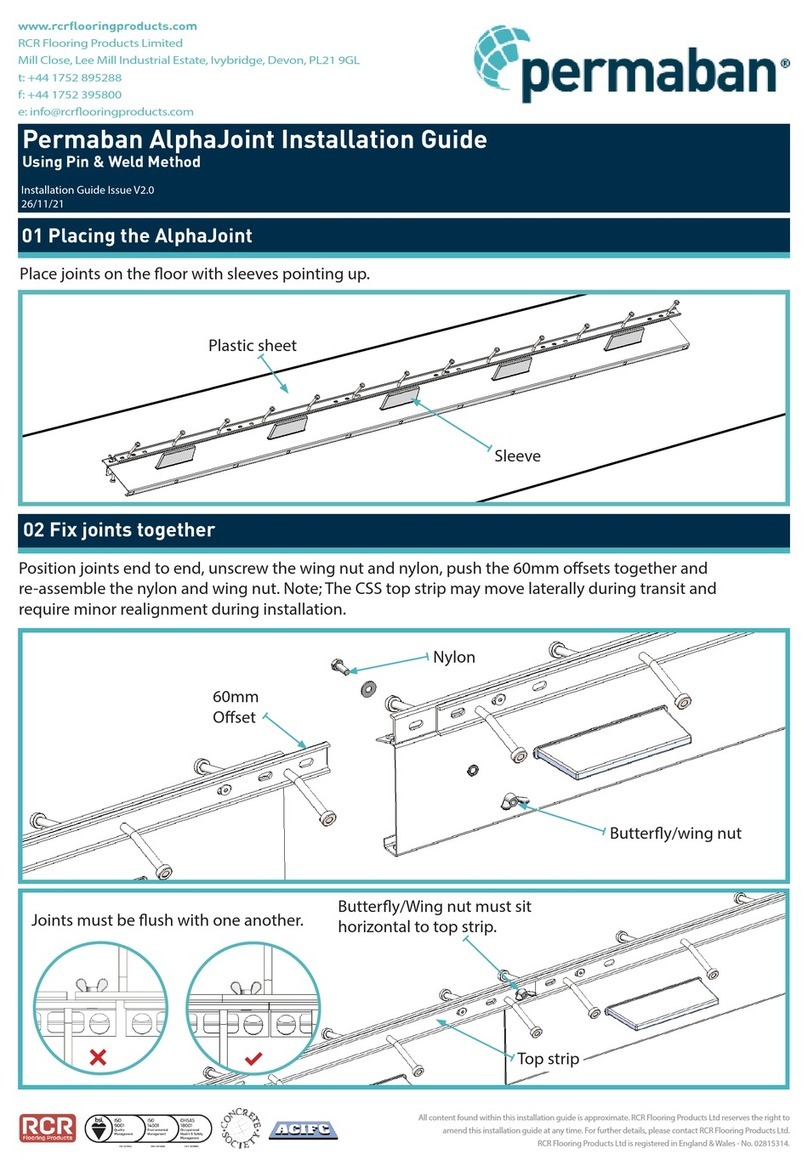

Figure 1: Doppler String Phantom

Electronic

Controller

Scanhead Clamp

Motor

Acrylic Tank

3

Using the Diffuser Mat

The black rubber Diffuser Mat is provided to reduce reverberations in the tank by absorbing and scattering the

ultrasound beam. Place the mat in the bottom of the tank with the ridges facing up, if desired.

Installing the String

If your Doppler String Phantom was shipped in a custom carrying case, the string target is already installed. If

not, you will need to install the string by doing the following:

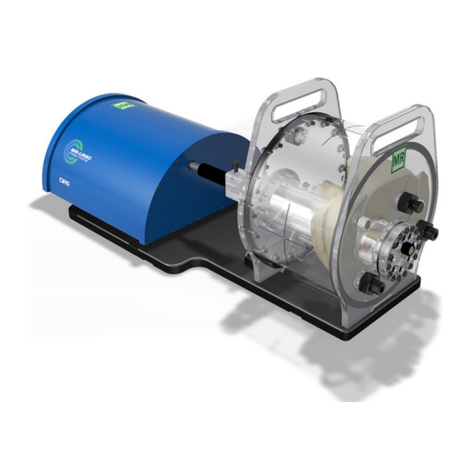

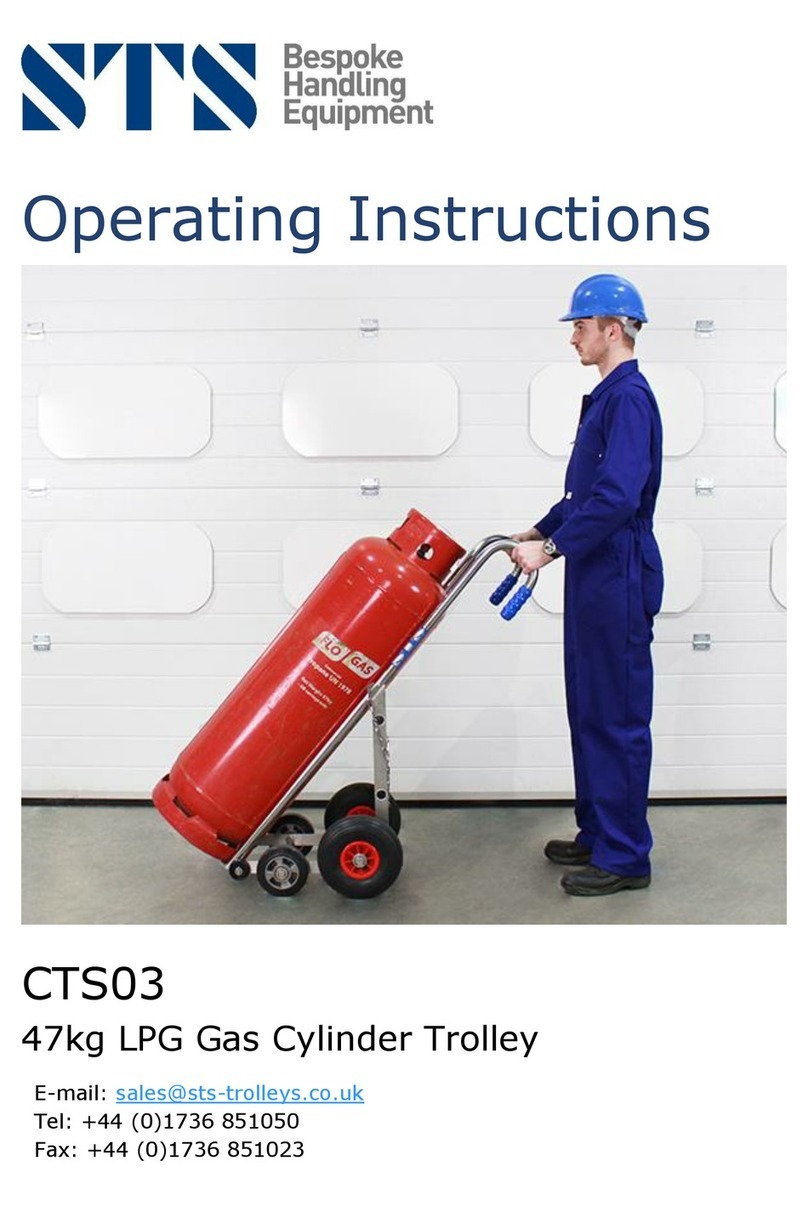

1. Loosen the adjusting screw on the two pulleys at the end of the tank opposite

the motor.

2. Take one of the string loops out of the bag and lay it over the pulley that is

attached directly to the motor (Motor Pulley).

3. Draw the string half-way around the Motor Pulley, behind the two Idler Pulleys

below the motor, and around the pair of Adjustable Pulleys at the other end of

the tank. (See Figure 2).

4. Adjusting the string tension by moving the Adjustable Pulleys until the string is

fairly tight, but not tight enough to break. The actual tension will not affect the

data.

Figure 2: String Installation

About Reverberations:

Water conducts ultrasound

more efficiently than the

human body, so it may be

necessary to reduce the

power level on your ultra-

sound scanner to a mini-

mum for best results.

FILLING THE TANK

Place the tank on a firm surface and fill it with either cold tap water or velocity-corrected fluid (see sidebar).

Fill the tank until the two small pulleys beneath the motor are just submerged. This depth works well, but it may

be changed to meet your needs.

After filling the tank, there will be dissolved air bubbles in the water. For best results, wait an hour before using

the Doppler String Phantom so the water can de-gas.

4

Setting up the Clamp

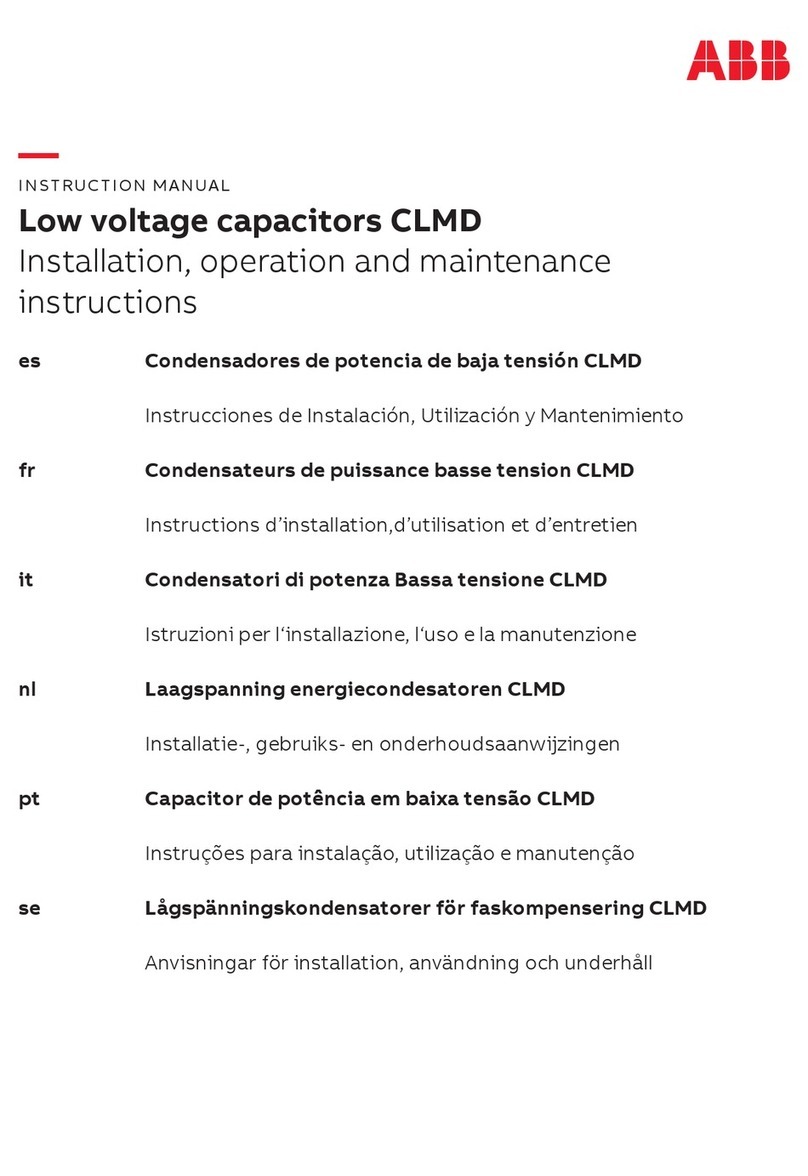

The Doppler String Phantom is shipped with a scanhead clamp system con-

sisting of a clamp (see Figure 3), an "arm" with a center joint and an arm at-

tachment fixture, which is bolted to the tank. If your Doppler String Phantom

was shipped in a custom carrying case, the clamp will have been set up at the

factory and you should skip step 1.

1. The arm attachment fixture on the tank has two sockets.

Insert one end of the arm into either of the sockets and tighten the

thumbscrew.

2. Turn the clamp adjusting knob to open or close the clamp so that it

fits your scanhead.

3. Adjust the clamp and articulated arm so that the transducer end of the

scanhead is in the water. (See Figure 4). Make sure your scanhead is at the

desired angle with respect to the string.

Note: Although the scanhead clamp can be placed in water temporarily, it should

be stored in a dry location to prevent corrosion.

Figure 3: Scanhead Clamp

Clamp

Adjusting

Knob

About Velocity Corrected

Fluid:

The speed of sound is 1480

meters per second in water

and 1540 meters per second

in the human body. Doppler

scanners are calibrated for

1540 meters per second, so

some ultrasound profession-

als prefer to use a water/gly-

col mix that also has a speed

of sound of 1540 meters per

second. This mix is called

velocity corrected fluid.

The Doppler String Phantom

has been designed to work

with either plain water or

velocity-corrected fluid (H2O/

Glycol). When you turn on

the power, the Doppler String

Phantom will ask you which

type of fluid you are using.

When set for use with water,

the Doppler String Phantom

compensates for the different

speed of sound by adjust-

ing the speed of the string

and the display indicates the

speed your scanner should

be detecting. When set for

use with velocity-corrected

fluid, the Doppler String Phan-

tom moves the string at the

actual speed indicated on the

display.

5

Connecting the Controller

You are now ready to connect the controller to the motor and the power supply.

1. Before plugging in the controller make sure the power switch on the back is turned off.

2. Plug the motor cable into the Drive Motor receptacle on the back of the controller.

3. Plug the power cable into the AC Receptacle and into an AC power source. If using in a country other than

the United States you will need to connect the transformer as well. This can be purchased for an additional

price.

SPECIAL FEATURE

Using the ECG Output

The ECG (electrocardiogram) output is an output that the user can elect to use to synchronize the waveforms to

the ultrasound scanner. It is located on the rear panel of the phantom. This is a rarely used feature that can aid

ultrasound researchers as they test new ultrasound machines. Since most users of this phantom do not deal

with that aspect it may be simply ignored.

When used, this output will generate a signal pulse at the very beginning of each test or physiological waveform.

That pulse is 10 milliseconds long and rises from zero volts up to five volts and then back down. This may be

used to tell the ultrasound researcher exactly when the waveform started and is useful for internal adjustments to

the ultrasound scanner.

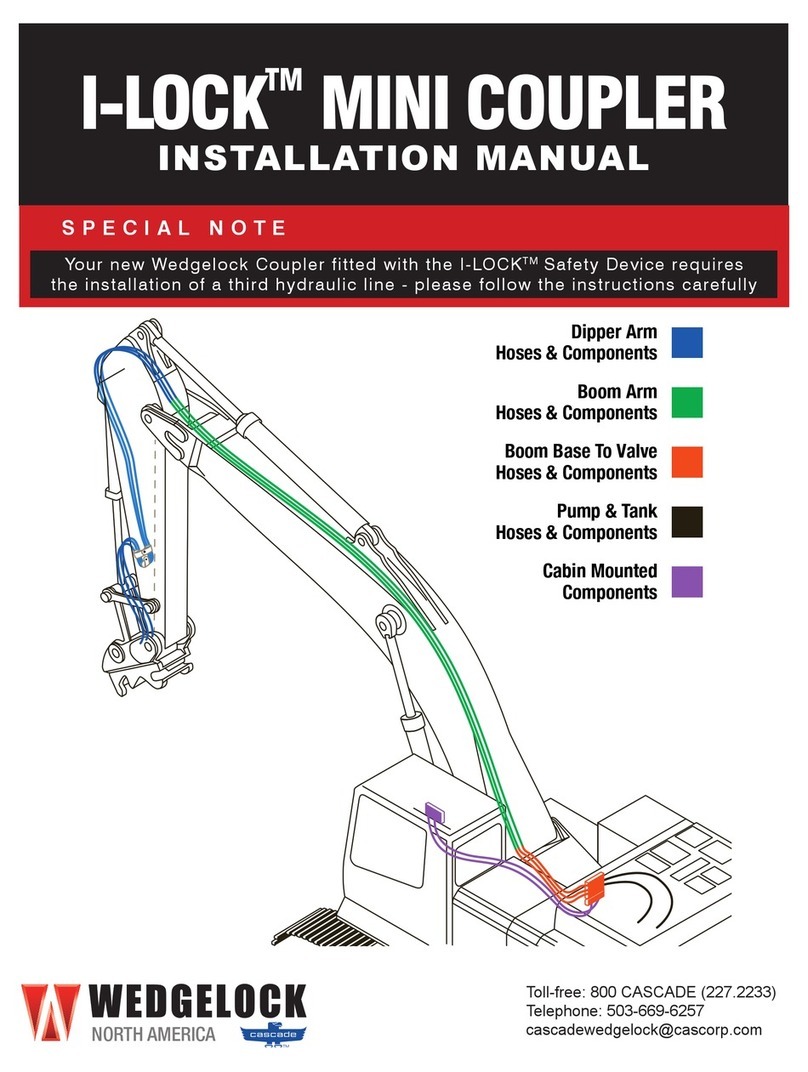

Figure 4: Scanhead clamp and articulated arm

About Scanning Angles:

The best angle for most Doppler

ultrasound scans is 60°.

The string target in the

Doppler String Phantom is set

at an angle, so that a scanhead

aimed straight down will be at

a 60° angle to the string. Of

course, you should scan at the

angle that is needed for your

tests.

6

OPERATING INSTRUCTIONS

Using Constant Speeds

The Doppler String Phantom can be set for constant string speeds ranging from 20 to 200 cm/sec. Constant

speeds are useful for a quick check to verify that your scanner is reporting correct image registration and target

velocity for the scanning angle you’re using. You can also detect false data caused by a broken transducer or a

loose connection.

1. After setting up the Doppler String Phantom, turn on the power switch (located on the back of the controller).

The display reads UP=H2O DOWN=H2O/GLYCOL.

2. If the tank is filled with water, press UP. If the tank is filled with velocity-corrected fluid, press DOWN.

(See About Velocity-Corrected Fluid on page 4 for more information.)

The display reads SELECT A FUNCTION.

3. Press CONST. SPEED; then press UP or DOWN to select the desired speed.

Note: Holding down either the UP or DOWN button causes the display to scroll faster.

The motor starts automatically.

4. To reverse the direction of simulated flow, press FLOW REV at any time.

An arrow in the bottom right corner of the display indicates the flow direction.

5. To change functions (for example, to switch from constant speeds to test waveforms), press ESCAPE.

The display reads SELECT A FUNCTION.

Using Preprogrammed Waveforms

The Doppler String Phantom has several preprogrammed waveforms to help you test your ultrasound scanner

under realistic conditions with velocity fluctuations you might expect in a patient. Each waveform has 1000 data

points to provide accurate simulations. The waveforms are divided into two groups: test waveforms and physi-

ological waveforms. Graphs of all the waveforms are included in Appendix A of this User's Guide.

The test waveforms are:

• Sine waves with peak speeds of 100, 150, and 200 cm/sec

• Triangle waves with peak speeds of 100, 150, and 200 cm/sec

• Stepped ramp wave with stops at 1, 20, 40, 60, 80, and 100 cm/sec

The physiological waveforms are:

• Adult common carotid

• Adult aortic

• Adult femoral

• Pediatric umbilical

• Stenotic common carotid

• Pediatric renal

• Pediatric ductus arteriosus

• Pediatric middle cerebral

• Pediatric descending thoracic

7

After setting up the Doppler String Phantom, turn on the power switch (located on the back of the controller).

The display reads UP=H2O DOWN=H2O/GLYCOL.

1. If the tank is filled with water, press UP. If the tank is filled with velocity-corrected fluid, press DOWN.

(See About Velocity-Corrected Fluid on page 4 for more information.)

The display reads SELECT A FUNCTION.

2. Press TEST or PHYSIOLOGICAL to select a waveform group.

The display shows a waveform.

3. Press UP or DOWN to select a waveform. (See Appendix A for graphs of waveforms.)

4. Press EXECUTE to start the motor.

5. To select a different waveform, you may press UP or DOWN at any time while the motor is running.

6. To reverse the direction of simulated flow, press FLOW REV at any time.

An arrow in the bottom right corner of the display indicates the flow direction.

7. To change functions (for example, to switch from physiological waveforms to constant speeds), press

ESCAPE. The display reads SELECT A FUNCTION.

RS-232 INSTRUCTIONS

Introduction

The remote control software allows all of the same functions that are available from the front panel. It is primarily

a serial communications feature for use with automatic testing equipment, but may be used by anyone wanting

to control the phantom for standardized testing. It may be controlled by a laptop, desktop, or a process control

computer.

To establish the link between the Doppler String Phantom controller and your computer, any common RS-232

communications program such as Pro-Comm Plus, Teraterm Plus, Microsoft Hyperterminal, etc., may be used.

The communications program must be set to 9600, N, 8, 1. Use hardware flow control. If your computer does

not have an RS-232 port, you can use an adapter available locally that will convert a standard USB port to RS-

232.

Getting Started

To begin using the remote control feature:

1. Ensure the Doppler String Phantom controller is powered off (rear panel switch).

2. Plug the power cable into the AC Receptacle and into an AC power source. The label on the AC

Receptacle indicates 120 volts. If using with 220 volts, use step down controller (Model 901-C, sold sepa-

rately).

3. Plug the custom RS-232 cord (supplied with the Doppler String Phantom) into the RS-232 receptacle

on the back of the controller.

4. Plug the motor cable into the Drive Motor receptacle on the back of the controller.

5. Start the communications program.

6. Turn on the power on the controller (rear panel switch).

8

The following text should appear on your computer screen:

MARK 4 DOPPLER PHANTOM

MARK 4 MENU

C - CONSTANT SPEED

S - SET CONSTANT SPEED, CM/S

T - TEST WAVES

P - PHYSIOLOGICAL WAVES

U - UP KEY

D - DOWN KEY

E - EXECUTE KEY

Enter - EXECUTE KEY

R - REVERSE FLOW

Esc - ESCAPE KEY

^H - COMMAND MENU

^Z - RESTART PROGRAM

^L - LOCKOUT FRONT PANEL KEYS

^U - UNLOCK FRONT PANEL KEYS

SELECT H2O OR H20/GLYCOL

FOR THE FLUID IN THE TANK

UP= H20 DOWN=H20/GLYCOL

*

If this text does not appear check all connections and try again. When the text appears the system is ready to test.

Notes: When entering commands either upper or lower case may be used. Upper case is used in this manual for easier

reading. Between each command wait until the controller responds that it's ready for the next command.

Accessing the Help Menu

The Help Menu (shown below) can be displayed at any time by entering <Ctrl>+H. The Help Menu is also

displayed automatically upon power-up.

MARK 4 MENU

C - CONSTANT SPEED

S - SET CONSTANT SPEED, CM/S

T - TEST WAVES

P - PHYSIOLOGICAL WAVES

U - UP KEY

D - DOWN KEY

E - EXECUTE KEY

Enter - EXECUTE KEY

R - REVERSE FLOW

Esc - ESCAPE KEY

^H - COMMAND MENU

^Z - RESTART PROGRAM

^L - LOCKOUT FRONT PANEL KEYS

^U - UNLOCK FRONT PANEL KEYS

9

Selecting Velocities and Waveforms

Constant Speeds

The following example demonstrates how to generate various Doppler target velocities:

To create a constant flow at 52 cm/sec the following steps must be taken:

1. Turn the controller on or enter <Ctrl> Z to restart the program.

2. Issue Uor Dto select the type of fluid in the tank.

3. Issue Cto select Constant speeds.

4. Issue S52 to select a speed of 52 cm/sec.

Note: Only whole numbers are allowed for velocities.

Test Waveforms

To select a changing velocity profile such as a sine wave that ranges from -100 cm/sec to +100 cm/sec the fol-

lowing steps must be taken:

1. Turn the controller on or enter <Ctrl> Z to restart the program.

2. Issue Uor Dto select the type of fluid in the tank.

3. Issue Tto select Test waves. The screen displays '100 Sine'.

4. To select a different waveform issue Uto move up the list. Continue issuing Uor Duntil the desired

waveform is displayed.

5. Issue an <Enter> command to execute the selected waveform.

Human Waveforms

To select a human Doppler waveform such as the "Common Carotid' waveform the following steps must be

taken:

1. Turn the controller on or enter <Ctrl> Z to restart the program.

2. Issue Uor Dto select the type of fluid in the tank.

3. Issue Pto select Physiological waves. The screen displays 'Common Carotid'.

4. To select a different waveform issue Uto move up the list. Continue issuing Uor Duntil the desired

waveform is displayed.

5. Issue an <Enter> command to execute the selected waveform.

Flow Reversal

To reverse the flow direction of any constant speed or waveform first execute the desired speed or waveform

and then issue an R. The target string will stop and then accelerate up to the desired speed or waveform in the

opposite direction.

Setting up for Quality Control Testing

The following example demonstrates how to test ultrasound machines for Doppler accuracy at 100 cm/sec at

the end of the manufacturing process.

1. Insert the ultrasound machine’s probe into the holder on the tank.

2. Prepare the ultrasound machine to send Doppler data to the process controller machine. Enter the

insonation angle to the process controller if not already done.

3. Turn on the Doppler phantom or issue a cold start with <Ctrl> Z.

10

4. Issue the following commands:

U

C (motor starts at 10 cm/sec)

S100

<Enter>.

5. The controller will increase the velocity from the initial 10 cm/sec to 100 cm/sec and hold. Read in the velocity

data from ultrasound machine and compare to the phantom. This completes the procedure.

Locking the Settings:

To prevent the phantom settings from being changed at the front panel while operating via remote control, issue

a <Ctrl> L command from the remote computer. To unlock the settings, issue a <Ctrl> U command. Unlocked

mode is the default setting at startup and after restarting with <Ctrl> Z.

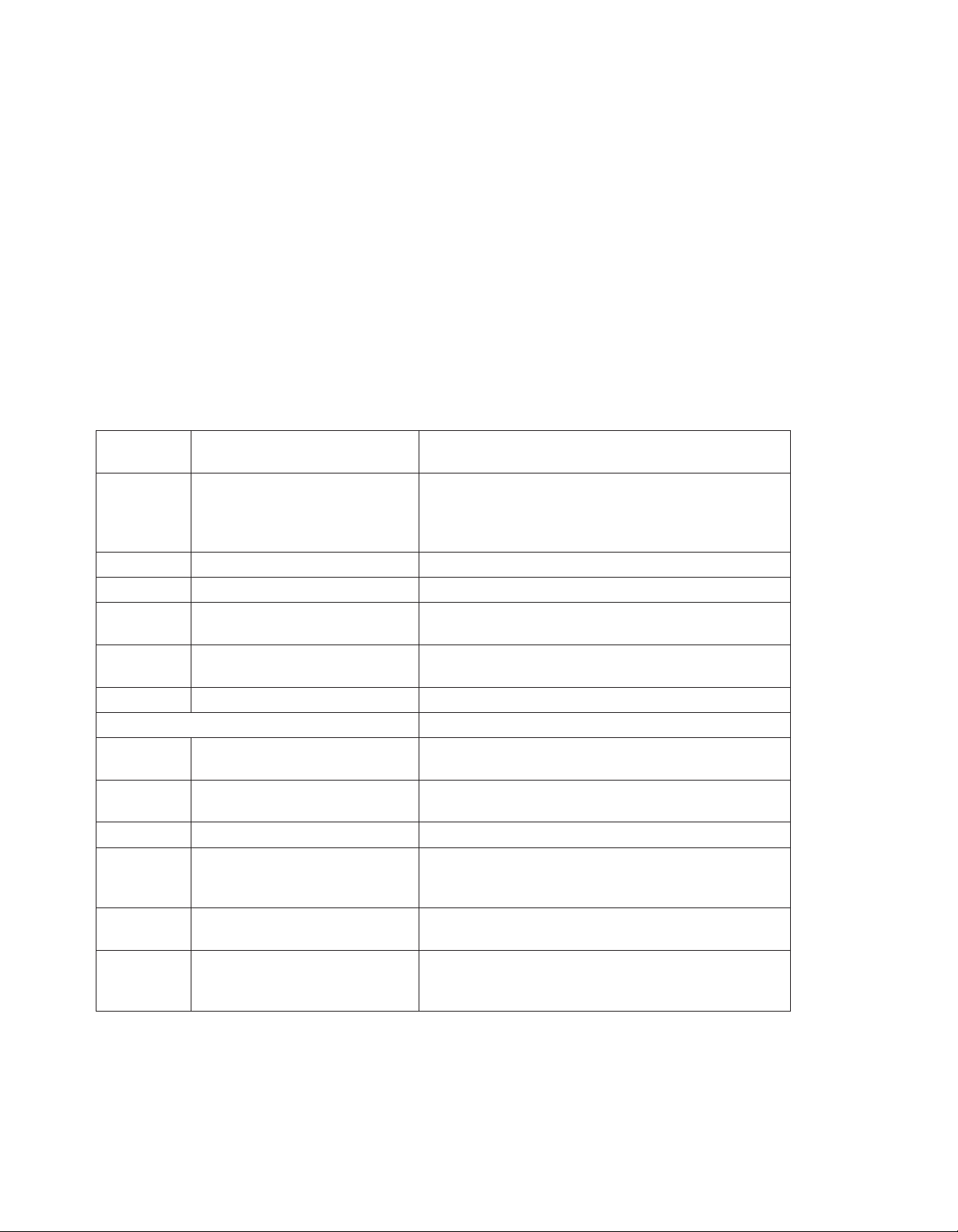

Description of Commands Available Via RS-232

CCONSTANT SPEED Used to select constant velocity. Velocities must be

whole numbers; decimal numbers are not allowed.

SSET CONSTANT SPEED, CM/S Used only when controller is already in constant speed

mode. Issue an S command followed immediately by

a whole number between 10 and 200, for example

S52<Enter>. Decimal numbers are not allowed.

TTEST WAVES Used to access test waveforms.

PPHYSIOLOGICAL WAVES Used to access physiological waveforms.

UUP KEY Used to select water type in tank, move up in the

menus and to increase constant speeds.

DDOWN KEY Used to select water type in tank, move down in the

menus and to decrease constant speeds.

EEXECUTE KEY Used to select options currently displayed.

<Enter> Same as EXECUTE button.

RREVERSE FLOW Used to reverse the direction of the Doppler target

string in all modes.

Esc ESCAPE KEY Used to shut down motor driving the Doppler target

string and go back to basic mode selection.

^H HELP MENU Used to display the list of available commands.

^Z RESTART PROGRAM Used to cancel and clear all entries and start over.

This is equivalent to dropping power to the unit and

turning it back on.

^L LOCK OUT FRONT PANEL

KEYS

Used to block all commands from front panel of con-

troller. While in Lockout mode all buttons are ignored.

^U UNLOCK FRONT PANEL KEYS Used to allow commands to be entered from the

front panel of the controller. This is the default startup

condition.

11

MAINTENANCE INSTRUCTIONS

Making String Loops

Occasionally, string loops break and need to be replaced. You can order sets of 20 preformed loops from CIRS

(See Preformed String Loops for more information) or make your own loops using these instructions. In general

you want your string loop to have a small unobtrusive knot that will roll smoothly over the pulleys in the tank.

1. Set up two pins 15 3/16 inches (38.5 cm) apart. Push pins on a wooden measuring stick works well.

2. Form a loop of string around the pins. Any type of string will work but 3-0 surgical silk is recommended

because of its ultrasound scattering properties.

3. Tie a knot to secure the loop and trim the ends to about 1/4 inch (6 mm) long.

4. Put a very small dot of super glue on the knot. The glue should not soak into the ends of the string and make

them stiff.

5. After the super glue has dried roll the ends of the string between your fingers to separate the threads as

much as possible.

6. Apply rubber cement to the knot and string ends allow it to dry slightly and then roll the knot between your

fingers to form a smooth ball.

Ordering String Loops

You can order a pack of 20 preformed string loops made from 3-0 surgical silk. The Part number is 043SL.

Please call for current prices.

Cleaning the Doppler String Phantom

The Doppler String Phantom is designed to be virtually maintenance-free. You can clean the controller and tank

with a soft cloth dampened with water and mild detergent. Do not use disinfectants or solvent-based cleaners or

sprays. Avoid using solvents because they could weaken the tank.

Calibrating the Doppler String Phantom

The Doppler String Phantom is computer-controlled so you don't need to make any adjustments. However,

many customers choose to send their Doppler String Phantom back to CIRS each year for calibration certifica-

tion. The string speeds are checked at a variety of settings, using instruments that are certified according to

the National Institute of Standards and Technology (NIST). After verifying that the Doppler String Phantom is

functioning correctly, CIRS provides a calibration certificate and a complete test report. Contact CIRS for more

information regarding calibration service.

12

ACCESSORIES AND PARTS

Carrying Case

To protect your investment, the Model 043 comes standard with a foam-lined, rigid carrying case. The case is

hermetically sealed and includes castors and a retractable handle for easy transport. The carrying case is highly

recommended for customers who plan on travelling with or shipping their Doppler String Phantom.

Preformed String Loops

You can order a pack of 20 preformed string loops made from 3-0 surgical silk. The Part number is 043SL.

Please call for current prices.

Step Up and Down Transformer

CIRS offers a 220V step up/down transformer to be used with the Doppler String Phantom, when using outside

of the USA. The Part number is 043C. Please call for current pricing.

How to replace a fuse

The Doppler String Phantom contains a fuse that may need to be replaced periodically. If the unit does not

power up, first check the cord and power source. If all of the connections are properly in place then the fuse

may need to be replaced.

Unplug the unit from the power

source and locate the 4 screws

on the bottom of the controller.

Remove these screws.

Open the controller. The fuse is found in the back, right

side of the controller.

Use a screwdriver to flip up one

end of the fuse and remove it.

Replace the fuse (2A 250V). Ensure fuse is properly

seated and replace the top of the controller. Replace

the screws into the bottom of the controller.

13

WARRANTY

All standard CIRS products and accessories are warranted by CIRS against defects in material and workmanship

for a period as specified below. During the warranty period, the manufacturer will repair or, at its option, replace,

at no charge, a product containing such defect provided it is returned, transportation prepaid, to the manufac-

turer. Products repaired in warranty will be returned transportation prepaid.

There are no warranties, expressed or implied, including without limitation any implied warranty of merchantability

or fitness, which extend beyond the description on the face hereof. This expressed warranty excludes coverage

of, and does not provide relief for, incidental or consequential damages of any kind or nature, including but not

limited to loss of use, loss of sales or inconvenience. The exclusive remedy of the purchaser is limited to repair,

recalibration, or replacement of the product at manufacturer’s option.

This warranty does not apply if the product, as determined by the manufacturer,

is defective because of normal wear, accident, misuse, or modification.

Non-Warranty Service

If repairs or replacement not covered by this warranty are required, a repair estimate will be submitted for ap-

proval before proceeding with said repair or replacement.

Returns

If you are not satisfied with your purchase for any reason, please contact your local distributor prior to returning

the product. Visit https://www.cirsinc.com/distributors/ to find your local distributor. If you purchased your

product direct through CIRS, call Customer Service at 800-617-1177, email [email protected], or fax an RMA

request form to 757-857-0523. CIRS staff will attempt to remedy the issue via phone or email as soon as

possible. If unable to correct the problem, a return material authorization (RMA) number will be issued. Non-

standard or “customized” products may not be returned for refund or exchange unless such product is deemed

by CIRS not to comply with documented order specifications. You must return the product to CIRS within 30

calendar days of the issuance of the RMA. All returns should be packed in the original cases and or packaging

and must include any accessories, manuals and documentation that shipped with the product. The RMA number

must be clearly indicated on the outside of each returned package. CIRS recommends that you use a carrier that

offers shipment tracking for all returns and insure the full value of your package so that you are completely

protected if the shipment is lost or damaged in transit. If you choose not to use a carrier that offers tracking or

insure the product, you will be responsible for any loss or damage to the product during shipping. CIRS will not

be responsible for lost or damaged return shipments. Return freight and insurance is to be pre-paid.

With RMA number, items may be returned to:

CIRS

Receiving

900 Asbury Ave,

Norfolk, Virginia, 23513 USA

Product Warranty Period

Model 043 - Doppler String Phantom 24 Months

14

APPENDIX A - GRAPHS OF WAVEFORMS

TEST WAVEFORMS

Sine Wave, 100 cm/sec

15

APPENDIX A - GRAPHS OF WAVEFORMS

Sine Wave, 150 cm/sec

16

Sine Wave, 200 cm/sec

APPENDIX A - GRAPHS OF WAVEFORMS

17

Triangle Wave, 100 cm/sec

Triangle Wave, 150 cm/sec

APPENDIX A - GRAPHS OF WAVEFORMS

Table of contents

Other Cirs Industrial Equipment manuals