Pregis AIRSPEED 5000 Guide

SAFETY, OPERATION, AND MAINTENANCE

Pregis AIRSPEED 5000

AIR CUSHION MACHINE

Version 3

OPERATING SAFETY

PREGIS AIRSPEED 5000

AIR CUSHION MACHINE

Operator safety and the safety of others in the work

area depends on the operator using common sense,

good judgment and reasonable care while operating

the machine. The Safety, Operation and

Maintenance manual, and warning labels affixed to

the machine, provide notification of specific poten-

tial hazards.

NOTE: Refer to the Safety Alerts instruction for

additional safety-related information.

Safety

The following instructions are only a guideline and

should be considered a supplement to your plant's

comprehensive safety program. Your business' pol-

icy supersedes these guidelines if at any time the

two contradict each other.

1. Read and understand the manual. If after read-

ing the manual you have questions, get

answers before working with the machine.

2. Read and understand all of the danger, warning

and caution statements in the manual and on

the signs attached to the equipment.

3. Never deface or remove factory installed

warning decals. If a decal ever becomes lost,

damaged or illegible, report this condition to a

supervisor and obtain a replacement decal.

4. Keep the work area clean and uncluttered.

Walking surfaces should always be free of

packing material and debris to prevent a slip-

ping or tripping hazard.

5. Ensure that all covers, guards and other safety

devices are in place. Never defeat a safety

device for any reason.

6. Follow the manufacturer's recommended startup

procedure.

7. Never leave the equipment unattended while

operating. Shut the machine off if you must

leave the work area.

8. Keep body parts and clothing away from mov-

ing components such as nip rolls, power trans-

mission components, sealing belts, etc. Never

reach into the machine for any reason while it

is in motion.

9. Understand what will happen when you oper-

ate the various controls.

10. Understand the proper web path and the safe

method for threading the web.

11. Learn the safe procedure for clearing the

machine of web wraps or jams.

12. Exercise extreme care whenever it is required

to inspect or adjust the machine while it is in

motion. NEVER reach into the machine for

any reason while it is motion.

13. Understand which adjustments are operator

adjustments; contact a maintenance person to

make all other adjustments.

14. Never operate or work around equipment if

you are under the influence of alcohol, drugs

or medications that can make you less alert or

affect your judgment.

SAFETY ALERTS

PREGIS AIRSPEED 5000

AIR CUSHION MACHINE

Operator safety and the safety of others in the work

area depends on the operator using common sense,

good judgment and reasonable care while operat-

ing the machine. The Safety, Operation and

Maintenance manual, and warning labels affixed to

the machine, provide notification of specific poten-

tial hazards.

Safety signs are used to alert operating and mainte-

nance personnel to potential hazards. The machine

manual also calls attention to potential hazards

with statements describing the hazard. Both the

safety signs on the machine and the warnings in the

manual use signal words to identify the seriousness

of the potential hazard. These signal words are

Danger, Warning and Caution.

The meanings of the signal words and the level of

potential hazards they represent must be clearly

understood before attempting to operate or main-

tain the machine. If, at any time, a safety sign on

the machine becomes lost, damaged or illegible,

contact Pregis to order replacement signs at no

charge.

A definitely hazardous situation that, if

not avoided, will result in serious injury or

death.

A potentially hazardous situation that, if

not avoided, could result in serious injury

or death.

A potentially hazardous situation that, if

not avoided, may result in minor injury (or

machine damage).

INTRODUCTION

PREGIS AIRSPEED 5000

AIR CUSHION MACHINE

Introduction

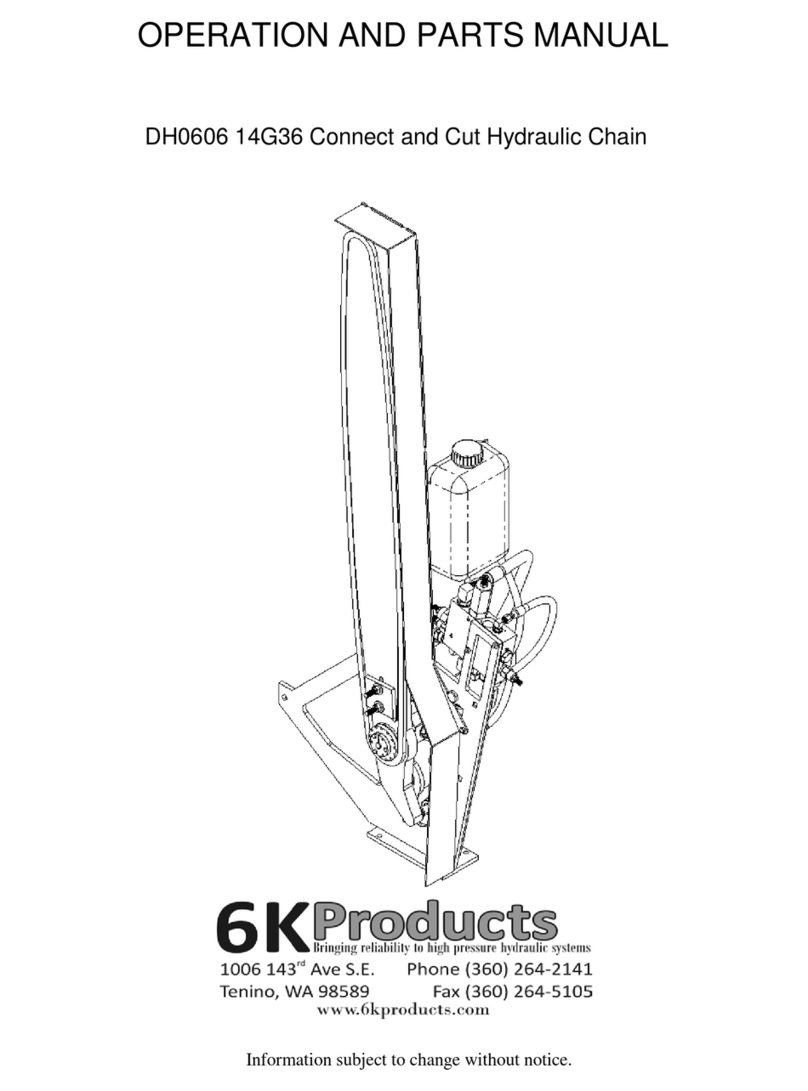

The Pregis AIRSPEED 5000 (Figure 1) produces

air-filled packing cushions in any quantity, as need-

ed. The ability to create packing cushions on

demand saves storage space and reduces packaging

material waste.

Packing cushions are created in strings of individ-

ual cushions. The string can be torn apart at perfo-

rations cut between each cushion. The perforation

repeats can be 6" or 8" on film webs 8.88" or

10.88". Cushions are created at a constant rate of

up to 75 feet per minute (fpm) of film feed. The

amount of cushions created per minute will vary

with the film cushion size.

Operation

Electrical shock or unexpected machine

movement can cause injury. DO NOT

operate machine with guards removed or

covers open.

For your safety, follow your company’s

lockout/tagout policy as required for each

task.

The film web is a continuous tube in which there are

pairs of cross seals, with a perforation placed between

them, spaced every four to eight inches. The cross

seals stop 0.56"-0.62" from one edge of the film. This

creates a gap or tube, in the film direction, along that

edge of the film.

.

DO NOT Operate

With Guards

Removed!

Fig 1

Pregis Air Speed 5000

The film is loaded onto the unwind shaft with the

seal gap edge facing the inside. The film is then

routed around the outside of a spring-loaded roller.

This roller maintains film tension by controlling

the amount of braking applied to the unwind shaft.

The seal gap edge of the film is then guided over

the end of the air injection tube. The air injectio

n

tube extends through the seal section, and past the

outfeed nip rollers. See Figures 2.

Figure 2

Front/Side View - DO NOT O

p

erate With Guards Removed!

Diverter rollers

Air Injection Slots

Belt Tension Roller

Sealing Guard

Guide Roller

Upper Seal Belt

See Fig. 3 for

Interior view

Tension Roller

Lower Seal Belt

Outfeed Nip Roller

Unwind Shaft

An upper and lower Teflon sealing belt are each

routed around a set of guide rollers, a spring-loaded

tensioning roller, and nip rubber rollers. Film is

pulled from the roll by the infeed and outfeed nips.

See Figure 2.

The film is captured between the upper and lower

sealing belts as it travels through the sealing sec-

tion. The sealing head assembly is spring-loaded.

The sealing wire presses down against the inside of

the upper sealing belt. This downward pressure

forces the sealing belts, with the web sandwiched

between, against the lower platen.

The inflated web of inflated cusions is pulled

through the seal section by the outfeed nip roller.

See Fig 2

Seal Wire

Lower Platen Lower Block

U

pp

er Seal Guard/Clam

p

removed for clarit

y

Sealing Belt

Seal Wire

Air injection tube

Fig. 2

Infeed End View

Fig. 3

Optional Footswitch

OPERATORCONTROLSPREGIS AIRSPEED 5000 AIR CUSHION MACHINE

Controls

1. Operator Interface Screen

Used to monitor, select and adjust the air

cushion machine operating parameters.

2. Nip Open/Close Lever

Used to raise and lower nip drive rollers.

3. Power Switch

Used to turn electrical power on and off.

4. Input interface ports

Used to connect secondary equipment.

#1

#2

Fig. 1

Operator Control Panel

#3 #4

Operator Interface Touch screen

Main (Ready to Run)

This screen allows the operator to select the

machine operating mode. See Figure 5.

The three (3) operating modes include:

Normal Operation

The machine is started and runs continuously

until manually stopped, or film supply is

depleted. Machine operation is controlled by

the control panel START and STOP buttons,

See Figure 5.

Fig. 5

Main Screen - Normal Operation

Automatic Stop after xx ft.

Used to manually select a length of film to run.

The machine will stop once the proximity sen-

sor detects the set film length has been run.

The quantity of cushions created for the select-

ed film length will vary with the cushion size.

See Figure 6.

Touch the screen in the area of the “**FT.”

The screen will change to the keyboard. Use the

keyboard to select the footage required then

touch the enter key (bent arrow). See Fig. 9

The Basket with xx ft.

Used to select a length of film to automatically

run once the collection basket/bin is low. A

sensor mounted above the bin detects when the

bin is low, after which the selected length of

film is then run. See Figure 8.

After the sensor initially detects the bin as low,

there is a four second delay before the cushion

machine is started. This prevents the cushion

machine from pulsing on and off.

Once the preset length of film has been run,

the Main screen “RUNNING” message

changes to “PAUSED”, and the machine stops.

Touch the screen in the area of the “**FT.” The

screen will change to the keyboard. Use the

keyboard to select the footage required then touch

the enter key (bent arrow). See Fig. 9

Fig. 7

Main screen - Fill the Basket

A

uto Sto

p

Afte

r

15 FT.

Fig. 6

Main Screen –Auto stop

PAUSED

15 FT.

Fill Basket With

Fig. 8

Setup Screen

Setup the Machine

Selecting this function brings up the Advanced

Setup and Seal Temperature (Figure 8),

Seal Temperature

Selecting this function routes you directly to the

Seal Temperature screen. See Figure 10.

NOTE: Management may protect the seal tem-

perature setting by requiring a password

to be entered before allowing access to

the Seal Temperature screen. If so, the

Password screen (Figure 9) will appear.

ADVANCED SETUP Screens

All MACHINE SETUP screens list the current set-

ting, or selection for the specific parameter, as the

Actual value. If applicable, the unit of measure for

the values is listed at Units.

Seal Temperature

Used to set the sealing (wire) temperature. (Fig.10)

once a value has been entered and accepted, the

setup screen appears. Touch the “Main” button to

return to the main screen.

435

Fig 9

Password Screen

Fig.10

Seal Temperature

OPERATING PROCEDURE

PREGIS AIRSPEED 5000

AIR CUSHION MACHINE

Start-Up

Electric shock hazard. DO NOT open

cover. Do not touch moving components.

Failure to heed may result in injury.

1. Slide the roll of film, with the unsealed air

tube slot to the inside, over the shaft. The

inside of the core is gripped by the shaft

plungers.

2. Route the film web around the bottom of the

film roller. See Figure 1.

3. Slide the unsealed edge slot of the film over

the air injection tube, up to the outfeed nip

(first) rubber rollers.

4. If not already closed, turn nip Open/Close lever

to close the tape drive nips.

NOTE: Jogging the film will not initiate infla-

tion.

5. Touch the JOG button until the end of the film

is fed through the sealing section, slitter, out-

feed end nip and belt rollers.

The film has a tendency to bunch up on the

slitter blade. The film must be pulled through

the machine by hand while pressing the JOG

button.

NOTE: Refer to the Operator Controls instruc-

tion for touch screen operation.

Figure 1

Film Web Thread-Up

8. Press the START button to create air cushions.

6. Touch the top line button to change to the

desired operating mode:

Normal Operation starts and runs film con-

tinuously until a stop is pressed.

Automatic Stop after *** ft runs an amount of

film, set by the operator, and then stops.

Fill Basket With *** ft uses optional

sensors in a basket or bin to start/stop as

required to keep the bin full.

7. If the Automatic Stop mode is selected, touch

the area on the screen *** Ft. Screen will

change to a key board. Select length and touch

the enter key.(Bent Arrow Key)

Set the air volume, by touching the “AIR” button.

The screen will change to “Air Volume” screen

(Fig.2). Adjust air volume by using the + or –

buttons.

NOTE: To test for proper inflation of cushions,

gently squeeze cushion with both hands

while viewing it from the perf edge.

There should be a 0.75"-1.0" gap

between the forefinger and thumb on

both hands.

9. Press the STOP button to stop the machine.

Fig. 2

Cushion Inflation Volume

Enter Key

Fig. 3

Belt Thread – Up Diagram

SEALING BELT REPLACEMENT

PREGIS AIRSPEED 5000

AIR CUSHION MACHINE

Introduction

Expected sealing belt life is approximately 100-200

hours (9,000-18,000 meters). The upper belt will

wear faster than the lower belt due to sealing wire

contact. To extend belt life by up to 20%, each belt

may be flipped around as explained in the follow-

ing description.

After both edges of the upper belt are completely

worn through, transfer the lower belt to upper belt

position. Discard the worn out upper belt. Install

a new lower belt. The belt transferred to the upper

position is again put through the same cycle of use.

Belt Replacement

Electrical shock or unexpected machine

movement can cause injury. DO NOT operate

machine with guards re moved or covers

open.

For your safety, follow your company’s

lockout/tagout policy as required for each

task.

To replace the sealing belt(s):

On/Off Switch

Outfeed Nip Roller Open/Close

See Fig . 3

Outfeed Nip Roller

Do Not Operate

with Guards

Removed

Fig. 2

Outfeed End

Fig. 1

Infeed End

Turn both nip Open/Close levers up to open

the belt drive nips. See Figures 1 and 2.

1. Remove the front upper and lower guard cov-

ers by removing the fasteners.

2. Lift the upper guard/clamp and seal wire

assembly off the lower clamp block and plat-

en, while turning the cam shaft. Turn the shaft

until the high side of the cam is at the top,

holding the guard/clamp and seal wire assem-

bly up. See Figure 3.

3. For both the upper and lower belt, push the

tensioner roll to create the slack required to

remove the sealing belt. See Figures 2 and 4.

4. Remove the belts from between both sets of

nip wheels and the infeed side belt diverter

rollers. See Figure 4.

5. Remove the sealing belts.

6. Install the belts between the outfeed nip wheels

and the infeed side belt diverter rollers. Use

belt thread-up diagram if needed.

7. For each sealing belt, push the associated ten-

sioner roller inward, collapsing its spring, to

allow the sealing belt to be fitted around all

rollers. See Figures 2 and 4.

8. 10. Lift the upper guard/clamp and seal wire

assembly while turning the cam shaft. Turn

the shaft until the low side of the cam is at the

top, allowing the guard/clamp and seal wire

assembly to drop down onto the lower clamp

block and platen. See Figure 3.

9. Turn nip Open/Close lever down to close

the tape drive nips. See Figures 1 and 2.

10. Install the front upper and lower guard covers

with fasteners.

11. Set the air cushion machine power to ON with

the switch. See Figure 1.

Fig. 3

Seal Wire Lift Cam

Cam Shaft

Fig .4

Seal Belt Routing

MAINTENANCE SCHEDULE

PREGIS AIRSPEED 5000

AIR CUSHION MACHINE

Electrical shock or unexpected machine

movement can cause serious injury or

death. For your safety, follow your compa-

ny’s lockout/tagout policy as required for

each task.

Daily Maintenance

1. Check the condition of the sealing belts, trans-

port rollers, and nip rollers. Flip or replace

belts if worn 75% through, or if the splice is

peeling or pulling apart more than 0.03" (0.76

mm).

Weekly Maintenance

1. Clean the sealing belts, guide rollers, nip

rollers, seal wire, lower platen, slitter blade,

and counter wheel of any contamination

and/or debris.

2. Ensure that all parts turn freely, including all

belt rollers, the film dancer roller and pivot

shaft, and the unwind shaft (with brake off).

3. Ensure the unwind shaft brake mechanism

works properly. The brake must be able to go

from totally free to a tight grip on the shaft.

Monthly Maintenance

1. Check all components for excessive wear,

including the nip plastic drive gears, rubber

nip rollers, and the slitter blade.

2. Check fasteners for looseness.

3. Clean the blower of any debris.

4. Check the alignment of the seal wire with the

platen and the upper guard/clamp with the

lower block.

5. Inspect the sealing surface (green) of the lower

platen for wear and replace if necessary.

Semi-Annual Maintenance

1. Apply axle grease (Exxon Ronex MPTM or

equivalent) to the face of nip actuation cams.

Also apply grease to the mating surfaces

where the cams contact and actuate the upper

rollers of the outfeed nips.

NOTE: Refer to the Introduction instruction for

the lubrication location.

TROUBLESHOOTING

PREGIS AIRSPEED 5000

AIR CUSHION MACHINE

Electrical shock or unexpected machine

movement can cause serious injury or

death. For your safety, follow your compa-

ny’s lockout/tagout policy as required for

each task.

1. Problem: Machine will not start.

Cause: Machine not set-up properly.

Solution: Turn power ON.

Press RESET button.

Press START button.

Read message at top of screen.

Text will read Ready to Run,

Paused, or Running.

Thread up film so encoder

wheel turns. Machine will not run

more than a few seconds if the

counter wheel does not turn.

2. Problem: Cushion does not inflate.

Cause: Machine not ready.

Solution: Jogging machine will not start

inflation, use START button.

Increase Air Volume, as required

for cushion size being run.

Cause: Insufficient injection air.

Solution: Check if air injector tube is plugged

or disconnected.

Check if blower is operating

properly.

Cause: Poor quality seal or no seals.

Solution: Refer to Problem 5 Solutions.

Cause: Too much air in cushion blows seals

open.

Solution: Reduce the inflation volume from

“air Volume” screen.

NOTE: To test for proper inflation of cushions,

gently squeeze cushion with both hands

while viewing it from the perf edge.

There should be a 0.75"-1.0" gap

between the forefinger and thumb on

both hands.

3. Problem: Film jams.

Cause: Cushion release slit not being cut

properly.

Solution: Clean or replace the slitter blade.

Cause: The operator is not pulling the film

through the machine while pressing

the JOG button for web thread-up.

Solution: During film thread-up, pull the film

past the slitter while pressing the

JOG button.

Cause: Film burn through.

Solution: Turn down the sealing temperature.

3. Problem: Film jams. (Cont’d.)

Cause: Film not being pulled evenly.

Solution: Ensure the infeed nips are closed.

Cause: Film slipping.

Solution: Check nip wheels and sealing belts

for contamination and clean as

necessary.

Check that the unwind shaft brake

system releases and the parent roll

turns freely.

Cause: Gap in film is too small for air

injector tube.

Solution: Replace the roll of film if the gap is

smaller than 0.56"

Cause: Film waste clogging slitter.

Solution: Remove melted film and waste from

knife area.

4. Problem: No film movement.

Cause: Film is not properly positioned in

machine.

Solution: Thread the film as per the thread-up

diagram label on the side of the

machine. Lightly pull the leading

edge of the film through the

machine, past the slitter and outfeed

nip, while jogging. The film must

be taut before pressing START.

Cause: Film or belts not being pulled.

Solution: Ensure the outfeed nips are closed

completely. The rubber nip rollers

should compress together resulting in

a 0.38" flat spot between them.

Ensure all seal belt idlers turn freely.

Cause: Film slipping.

Solution: Check nip wheels and sealing belts

for contamination and clean as

necessary.

Cause: Gap in film is too small for air

injector tube.

Solution: Replace roll of film.

Cause: Counter wheel not operating.

Solution: Check if counter wheel is against

air injection tube.

Check if wheel traction o-ring is

worn or missing.

Check if flat spring is holding wheel

firmly against air injection tube.

Check if air injection tube is bent,

not allowing counter wheel to make

proper contact.

Check if the proximity sensor is

close enough to the wheel to switch

on and off as the wheel turns.

5. Problem: Poor quality seal or no seals. Cause: Sealing wire broken.

Solution: Replace the sealing wire.

NOTE: Allow the seals to cool for approxi-

mately one minute before testing.

Cause: Sealing wire not hot enough.

Solution: Adjust the sealing temperature.

Cause: Air pressure blowing out seals.

Solution: Decrease the inflation air pressure

to prevent over inflating.

Check that the upper guard/clamp is

seated properly on lower block, iso-

lating the seal from inflation.

Check that the lower platen is

pivoting properly.

Check that the lower platen stiff,

outer plastic (DuritTM) sealing sur-

face is securely mounted to the

lower layer of soft silicone.

Ensure both nips are fully closed. It

is critical that the outfeed nip is pro-

viding the proper nip pressure on

the seal.

Cause: Film not held tight together between

sealing belts.

Solution: Check to ensure the upper

guard/clamp is lowered/closed.

Cause: Sealing belts are worn.

Solution: Replace sealing belts as necessary.

6. Problem: Main screen “Ready To Run” mes-

sage replaced with “Change Belts” message.

Cause: Belt Odometer screen has reached

the preset belt change interval

value.

Solution: Replace the sealing belt(s) and have

Management reset the Actual value

on the Belt Odometer screen to

zero (0) meters.

NOTE: Refer to the Sealing Belt Replacement

instruction for more information.

Table of contents

Other Pregis Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Kval

Kval Edge-SS Operation & service manual

ELRO

ELRO 2300 Series operating instructions

Spirotech

Spirotech SpiroVent Superior S6 Series user manual

Lillbacka Powerco

Lillbacka Powerco FINN-POWER P20 MS operating instructions

nord

nord MAXXDRIVE Customer's operating and assembly instructions

Balluff

Balluff BTL5-A11-M Series user guide