BenchBUD Electric Height Adjustable Workbench User manual

Instruction #54469 • Dated: 5/24/2021

Warranty: benchbud.com/pages/warranty

1 of 12

Electric Height Adjustable Workbench Instructions

(Base & Worksurface)

K&A Manufacturing • 800.298.4351 • www.benchbud.com 2 of 12

READ ALL INSTRUCTIONS BEFORE USING THIS PRODUCT.

USE THIS PRODUCT ONLY AS INSTRUCTED.

FAILURE TO COMPLY WITH ALL INSTRUCTIONS AND WARNINGS

MAY RESULT IN SERIOUS PROPERTY DAMAGE OR BODILY INJURY.

Basic Safety Instructions

1. Intended Use. This Product is exclusively designed for use as indoor oice furniture in compliance with all instructions and safety warnings

in the user manual. Any dierent use, or use extending beyond the intended use, may result in property damage or bodily injury and is

prohibited. This Product should not be used, operated or maintained with additional components not authorized by K&A Manufacturing, Inc.

BY USING THIS PRODUCT OR ANY FEATURE OF THIS PRODUCT, YOU AGREE TO COMPLY WITH ALL PRODUCT TERMS

AND POLICIES, INCLUDING WITHOUT LIMITATION ANY SAFETY WARNINGS AND INSTRUCTIONS, PROVIDED BY

K&A MANUFACTURING, INC. AND ITS AFFILIATES. K&A MANUFACTURING, INC. SHALL ASSUME NO LIABILITY FOR ANY

DAMAGE OR INJURY CAUSED BY USE OF THE PRODUCT A) IN VIOLATION OF ANY SAFETY WARNINGS OR INSTRUCTIONS;

B) NOT AUTHORIZED BY K&A MANUFACTURING, INC.; OR C) BY EVENTS BEYOND K&A MANUFACTURING, INC.’S CONTROL.

DO NOT SIT, STAND OR CRAWL ON OR UNDER THE PRODUCT.

MAKE SURE NO OBSTACLES ARE IN THE PRODUCT’S PATH.

MAKE SURE ALL CORDS ARE LONG ENOUGH TO ACCOMMODATE ANY CHANGE IN HEIGHT.

DO NOT USE ATTACHMENTS NOT RECOMMENDED BY THE MANUFACTURER.

2. Electrical Height Adjustment. The height of this Product may be adjusted electronically. Contact with electrical voltage may cause serious injury

and death. Only use the Product in compliance with these instructions. This Product should not be used in environments with high levels of humidity

or moisture.

KEEP CORDS AND ELECTRICAL COMPONENTS AWAY FROM HEAT AND LIQUIDS.

DO NOT OPEN ANY OF THE COMPONENTS: CONTROL BOX OR KEYPAD.

DO NOT USE WITH A DAMAGED PLUG OR CORD.

DO NOT INSERT ANYTHING INTO ANY SEAM OR OPENING.

3. Setup and Use. This Product should only be used and operated in good condition. When in use, no one should sit, stand or crawl on or under the

Product. There is a danger of crushing, shearing, injury or damage. Keep the entire range of motion of the Product clear of all obstacles. Devices and

object on the Product can tip over, fall or be crushed by the Product.

KEEP HANDS AND FINGERS CLEAR.

KEEP ALL OBSTACLES CLEAR OF THE PRODUCT’S PATH.

4. Users. This Product is not intended for use with children, individuals with restricted physical, sensory or mental capabilities, or individuals who lack

experience or knowledge, unless they are supervised by a person who is responsible for their safety or they have received

instructions from a person who is responsible for their safety concerning how the Product must be used. Children should be closely

supervised to ensure that they do not play with the Product and its height adjustment mechanism to avoid risk of physical injury or

electric shock.

KEEP CHILDREN AWAY FROM THE PRODUCT, ITS CONTROL UNITS, AND KEYPADS.

WARNING

DANGER

K&A Manufacturing • 800.298.4351 • www.benchbud.com 3 of 12

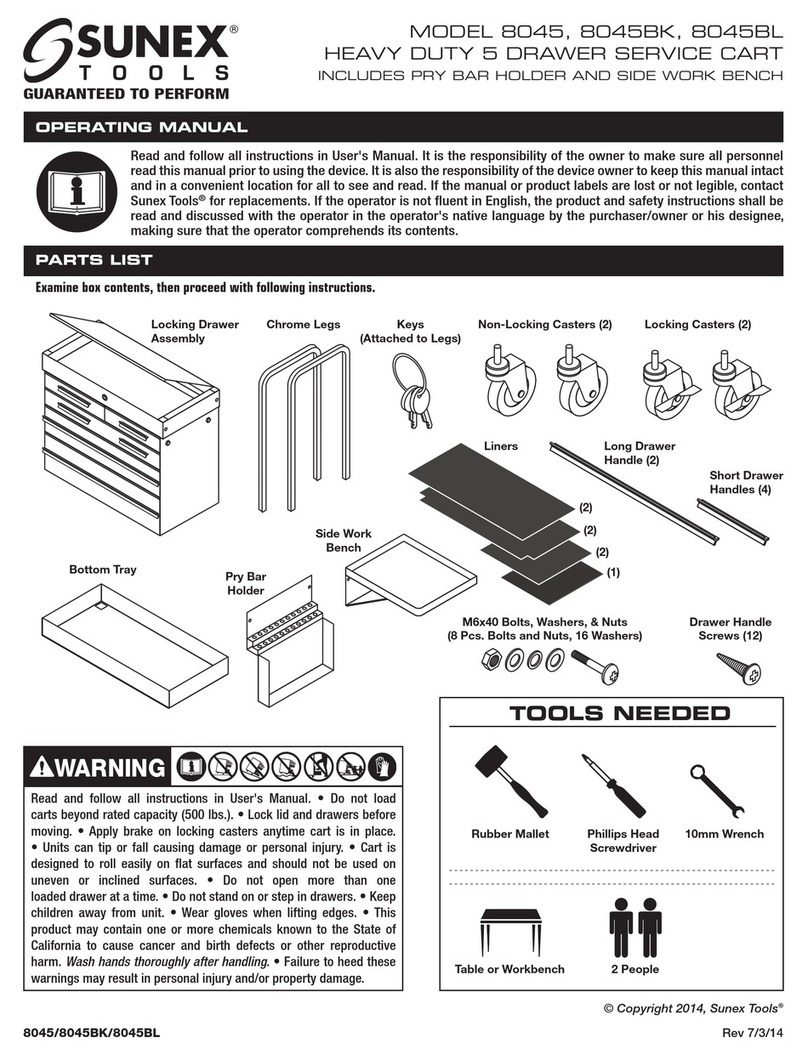

E. 5/8” Washer Head Wood Screw x52

F. 1/4”x 5/8” Bolt x4

G. Lock Washer x4

H. 5/8” Wood Screw x4

I. Cord Clip x1

J. M6 x 10mm Bolt x8

K. Star Washer x8

L. Wire Management Channel x1

M. 3/16” Allen Wrench x1

N. 4mm Allen Wrench x1

O. 6mm Hex Rod Wrench x1

Note

location

of drive

input hole.

Tools Required for Assembly

A. Power Driver with Adjustable Torque

B. Tape Measure

C. #2 Phillips Head Driver Bit

D. #2 Square Head Drive Bit (Recommended)

A B C D

Hardware and Tools Included for Assembly (may have extra)

E F G H I

J K

M N O

BenchBUD Parts

P. Cross Support x2

Q. U-Channel x2

R. Short Hex Rod x2

S. Switch x1

T. Control Box x1

U. Power Cord x1

V. Le Motor x1

W. Right Motor x1

X. Le Leg x1

Y. Right Leg x1

Z. Worksurface x1

(not pictured)

P Q

V

X

R

S

T

L

U

Y

Le Leg Right Leg

Legs must be in their lowest

position before installation.

W

K&A Manufacturing • 800.298.4351 • www.benchbud.com 4 of 12

Step 1

• Place the le leg column (X) onto the

worksurface and align with predrilled pilot holes.

Make sure leg is in its lowest position.

• Insert the short hex rod (R) through the le motor

assembly (V)(insert starting at bracket side of the

motor).

• Slide hex rod into le leg drive input hole. Hex rod

should slide all the way into leg.

• If hex rod is not properly aligned with drive input,

slightly rotate the motor 1/6th or

1/3rd of a turn.

Lay the worksurface on a protected

surface with pilot holes facing up.

LEGS MUST BE IN LOWEST POSITION

BEFORE INSTALLING HEX RODS.

Hex Rod Wrench

(O) can also be used

to rotate hex rod

O

R

Motor Assembly (V)

Reference below

images for proper

positioning of each

motor.

Step 2

Faces Front

Faces Leg

• Place the right leg column (Y) onto the

worksurface and align with predrilled pilot holes.

Make sure leg is in its lowest position.

• Insert the short hex rod (R) through the right

motor assembly (W) (insert starting at bracket

side of the motor).

• Slide hex rod into le leg drive input hole. Hex rod

should slide all the way into leg.

• If hex rod is not properly aligned with drive input,

slightly rotate the motor 1/6th or

1/3rd of a turn.

FRONT EDGE

FRONT EDGE

Le Motor

V

Le Leg

X

Le Leg

X

Y

Right Leg W

Right Motor

(ID#802136) V

Le Motor

(ID#801064)

Hex Rod Wrench

(O) can also be used

to rotate hex rod

O

K&A Manufacturing • 800.298.4351 • www.benchbud.com 5 of 12

Step 4

Step 3

For proper alignment of pre-drilled

holes, first insert screws at the four

corners of the U-channel. Then,

install the remaining screws.

• Align the U-channel (Q) with the pre-

drilled pilot holes*.

• Make sure the end with the holes closest

the edge faces towards the le leg.

• Attach U-channel to worksurface with

washer head wood screws (E).

• Do NOT fully tighten until all screws are

installed.

A ED

*Hole placement may vary depending on table width.

F

G

F

G

Le Leg

Le Leg

Important:

Please be aware that 5/8” screws are

provided. If your worksurface is 5/8” or thinner, you

will need to supply your own hardware.

• Aer hex rods are installed, align le motor

bracket and corresponding mounting holes on le

leg column (X).

• Position lock washers (G) and tighten motor

mounting bolts (F).

• Repeat to attach right motor bracket to right leg

column (Y).

F G M

E

Holes closest to end of

U-channel face le leg.

Le Motor

Le Leg

Q

Q

K&A Manufacturing • 800.298.4351 • www.benchbud.com 6 of 12

Step 5

• Slide cross supports (P) over leg

cross support brackets.

Step 6

P

• Install bolts and washers (8 sets).

Do NOT fully tighten.

P

J K

M

K

J

Le Leg

Le Leg

K&A Manufacturing • 800.298.4351 • www.benchbud.com 7 of 12

Step 7

Step 8

• Fully tighten bolts in both cross supports.

Tighten bolts

• Align assembled base with the pre-

drilled pilot holes.

• Secure the base to the worksurface

with washer head wood screws (E).

• Do NOT fully tighten until all wood

screws are inserted.

For proper alignment,

first insert screws at the

four corners of each leg

mounting bracket. Then,

install remaining screws.

A ED

E

Le Leg

K&A Manufacturing • 800.298.4351 • www.benchbud.com 8 of 12

Step 10

Step 9

• Mount control switch (S) to worksurface

using two wood screws (H).

• For standard install location, align switch

with pre-drilled pilot holes.

ACH

NOTE:

Please refer to the installation instructions included with switch.

• Mount control box (T) to worksurface

using two wood screws (H).

• For standard install location, align

control box with pre-drilled pilot holes.

However, it can be installed in any

location, wire lengths permitting.

NOTE:

Table will

NOT

operate unless the control box (T) is

screwed tight into the table without any play.

Required Orientation:

Long side of control box must

run parallel to the long side of

the worksurface.

ACH

Le Leg

H

Control

Box

Required Orientation

S

K&A Manufacturing • 800.298.4351 • www.benchbud.com 9 of 12

Step 11

Step 12

• Plug the control switch (S), motors (V & W), and power

cables (U) into the control box (T).

• Plug power cable into outlet.

• With the desk still upside down, test your BenchBUD to

check if assembly was successful.

• Hold the down arrow on the control switch until

table no longer moves to complete “reset mode.”

• Once table is in lowest position, push up arrow.

• If the table legs move properly, installation was a

success. Now, you can flip table right-side up and

begin use.

Control Box End View

• Install wire management channel (L) and cord

clip (I) to organize the cords and cables with

washer head wood screws (E).

• Pilot holes are not provided.

• See cable mounting diagram on next

page for help.

A E

L

I

Mount the wire management channel (L) with

adhesive strips AND two wood screws (E). Insert one

screw on flat edge of each side of the wire management

channel to penetrate plastic and worksurface.

L

E

I

Power

Cable

Motor

Cable

Switch

Cable

Le Leg

Have casters or accessories to

add? Install them while before

you flip your BenchBUD right-side

up to make the process easier.

Visit benchbud.com/pages/installation for instructions on

how to install BenchBUD casters and guidelines for

installation if using casters purchased elsewhere.

When providing your own worksurface, BenchBUD base-

only instructions are also available at the link above.

K&A Manufacturing • 800.298.4351 • www.benchbud.com 10 of 12

Cable Routing Diagram

For the safety of the user and the workstation; the control box contains an internal sensor that is

sensitive to movement, vibration, and collision. For faultless operation, ensure all cables, electronics,

and accessories are cable managed and secured. Excessive load or weight must be distributed evenly. Failure

to follow these guidelines may cause intermittent functionality.

Caution:

*For tables 48” or smaller, the wire management can be moved.

Switch

Switch Cable

Cord Clip

Motor Cable

Right Motor

Use Wire Management Channel to

hold extra lengths of cable*

Le Motor

Control Box

Power Cable

Motor Cable

Le Leg

FRONT EDGE

K&A Manufacturing • 800.298.4351 • www.benchbud.com 11 of 12

Start Up Procedure:

• Plug the power cord into a standard 110V receptacle. A power surge protector

is recommended.

• Press the down arrow until the worksurface reaches its lowest position.

• The workstation is ready for use.

• If the table is not functioning normally, or has lost power,

perform the reset procedure.

Reset Procedure:

• Unplug the unit from the wall for 10 seconds.

• Clear all obstructions from the travel path of the desk.

• Plug the unit back in the wall.

• Press and hold the down arrow key until the table reaches its lowest position

See Packaged Instructions for Programmable Options

Programmable Switch (full instructions packaged with switch)

If the leg assemblies are at uneven heights, it is usually caused by an improperly installed hex rod. Disassemble one of the leg

assemblies from the worksurface and make sure both ends of the hex rod are properly engaged in the hex drives near the top

of the leg assemblies.

Note

Troubleshooting:

If you are having any problems with the operation, contact BenchBUD at 715.903.3440

or [email protected]om.

The BenchBUD mobile app is currently in development!

Until its release, you can download and use the BenchBUD compatible NewHeights™ Mobile App from our sister

company.

This Bluetooth™ technology will allow mobile app users to control and manage their standing workstation directly

from their mobile device. Create voice commands that work with intelligent assistants, such as Siri and Google, for

hands-free desk positioning.

The app is free to download in both the App Store (Apple iOS) and Google Play Store (Android). No worries, there

are no additional in-app fees, it’s 100% free to use!

Learn more and find download links at www.raproducts.com/newheights/bluetooth-mobile-app.php.

K&A Manufacturing • 800.298.4351 • www.benchbud.com 12 of 12

If the table is unresponsive, uneven, or not functioning properly, perform a manual reset.

User settings are not reset in this process.

There are three methods to reset a workstation:

Reset Method A

1. Clear all obstructions from the travel path of the workstation

2. Disconnect the power to the control box for 30 seconds.

3. Reconnect the power

4. Press and hold the until the workstation has reached its lowest possible position.

Reset Method B (4 button programmable switch required)

1. Clear all obstructions from the travel path of the workstation

2. Quickly press UP + UP + UP + UP to enter the menu mode.

3. P01 is displayed and you will hear a musical tone.

4. Press the to navigate the menu.

5. Navigate to the P09 display

6. Press the button to enter or accept

7. Press and hold the until the workstation has reached its lowest possible position.

The workstation is now ready to operate

Reset Method C - 2 Button Switch

1. Clear all obstructions from the travel path of the workstation

2. Quickly press UP + UP + UP + UP to enter the menu mode.

3. You will hear a musical tone.

4. Press UP + UP + UP +

5. You will reach the limit adjustment menu and hear four musical tones.

6. Press and hold the until the workstation has reached its lowest possible position.

The reference is re-calibrated, the table should be leveled and the height indication should be correct.

Mechanical Reset Mode