3

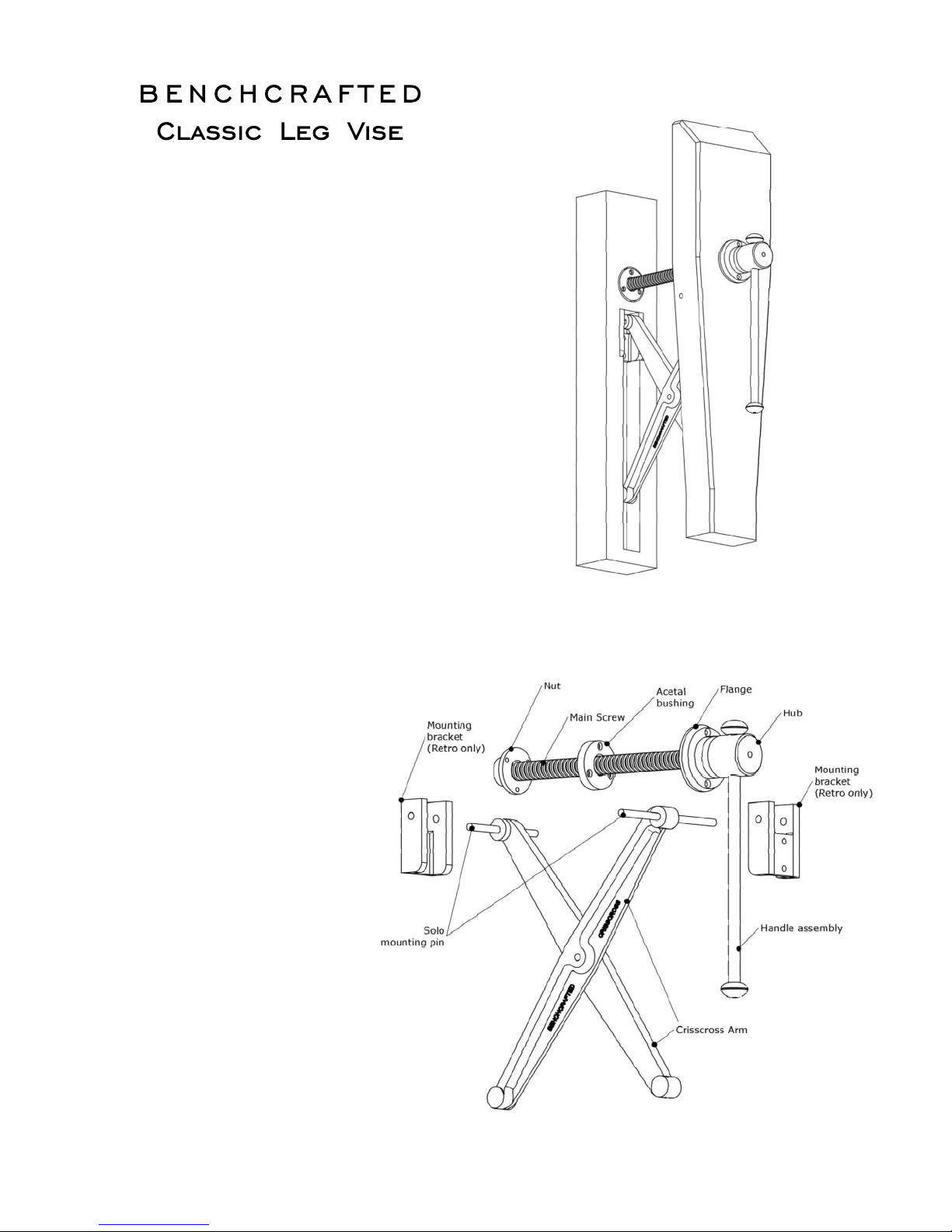

The Benchcrafted Classic Leg Vise

We developed the Classic Leg Vise for woodworkers who prefer the traditional look and function of

classic bench hardware from the 19th century and earlier. Unlike American examples, which use a T-

shaped casting and sliding wooden handle, we patterned our vise after extant French examples. The

classic look and function pairs excellently with the Benchcrafted Crisscross and maintains our ideal of

effortless workholding.

The Benchcrafted Crisscross

A popular mechanism for maintaining parallelism in vise jaws began to surface in the American patent

record in the mid 19th century. There are also documented sources of this mechanism in the La Forge

Royale catalog, Paris, late 19th to early 20th c. This device is basically two pieces or "arms" of metal or

wood, equal in length, joined in the middle to create a pivot. The upper ends of the arms (also on pivots)

are joined to the bench's leg and the chop. The resulting mechanism not only maintains a parallel open-

ing, but also supports the weight of itself, the vise screw, and the chop. The beauty of the mechanism is

its simplicity. In modern times this mechanism has become known as the "St. Peter's Cross", taken from

an early 20th c. publication describing it as such. To our knowledge, this is the only reference to this

device by name. There has been some discussion about the history of this moniker, and the possible

misnomer, since it was the Apostle Andrew that was crucified on an "X"-shaped cross, St. Peter being

crucified on a "T"-shaped cross, albeit upside down. We eventually acquired a 19th century version of the

St. Peter's Cross, and used it to prototype our version, the Benchcrafted Crisscross.

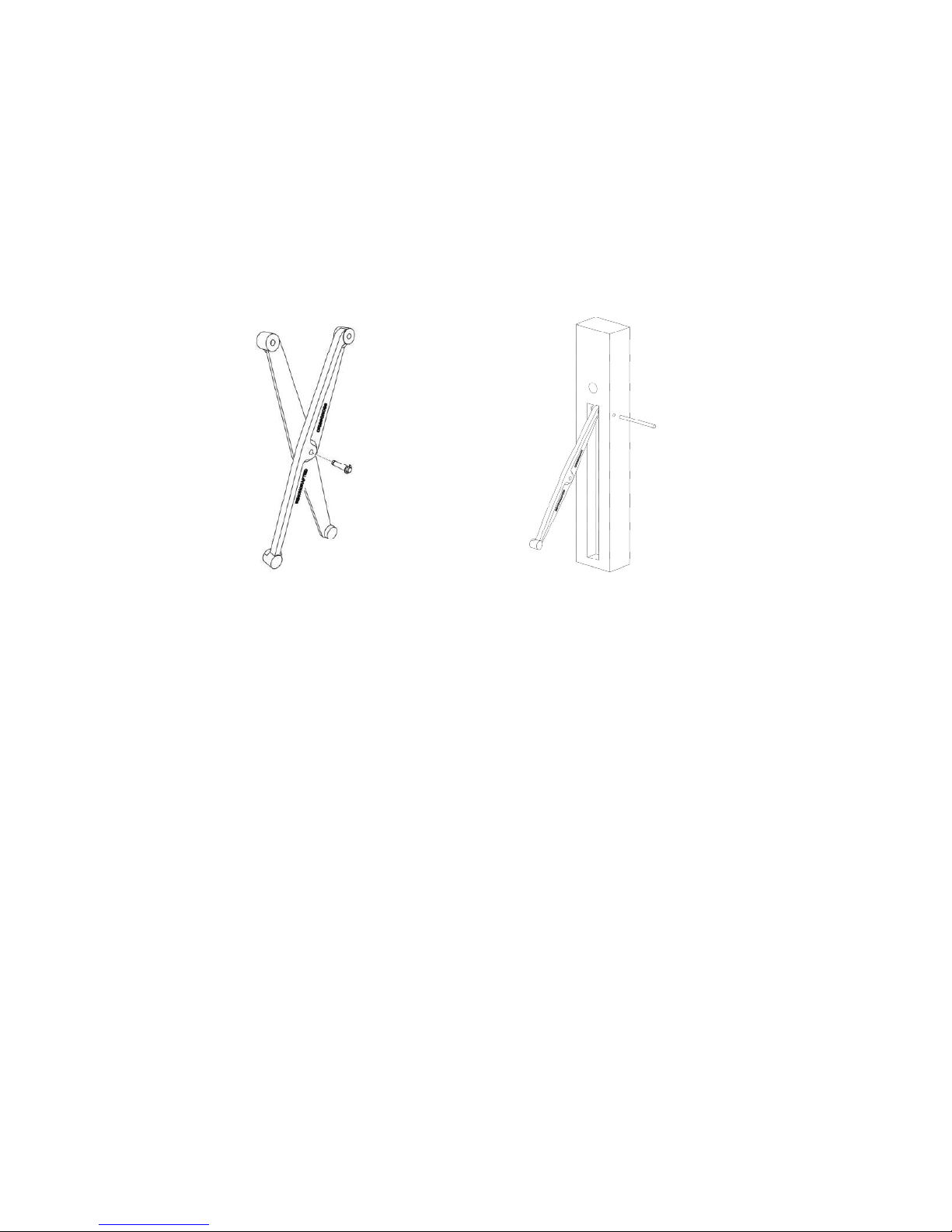

The Crisscross is built with a small amount of toe-in. In other words, the chop will contact the bench top at

the upper end of the vise slightly before it contacts the bottom. This helps hold thin or irregular stock. You

will need to follow the specific installation sequence in order to install the Crisscross to best effect.

About these instructions

We don't like to be wordy, and we don't like complexity. The length of these instructions is such as to

convey the information you need to install the vise intelligently. If it's superfluous, we won't include it, if its

useful for the installation, you bet we're going to include it. We know you don't want any surprises, and we

know this vise is going into some beautiful benches. This is the info you need to get it right straightway.

It's an easy install, but you can screw it up if you dive in without reading this.

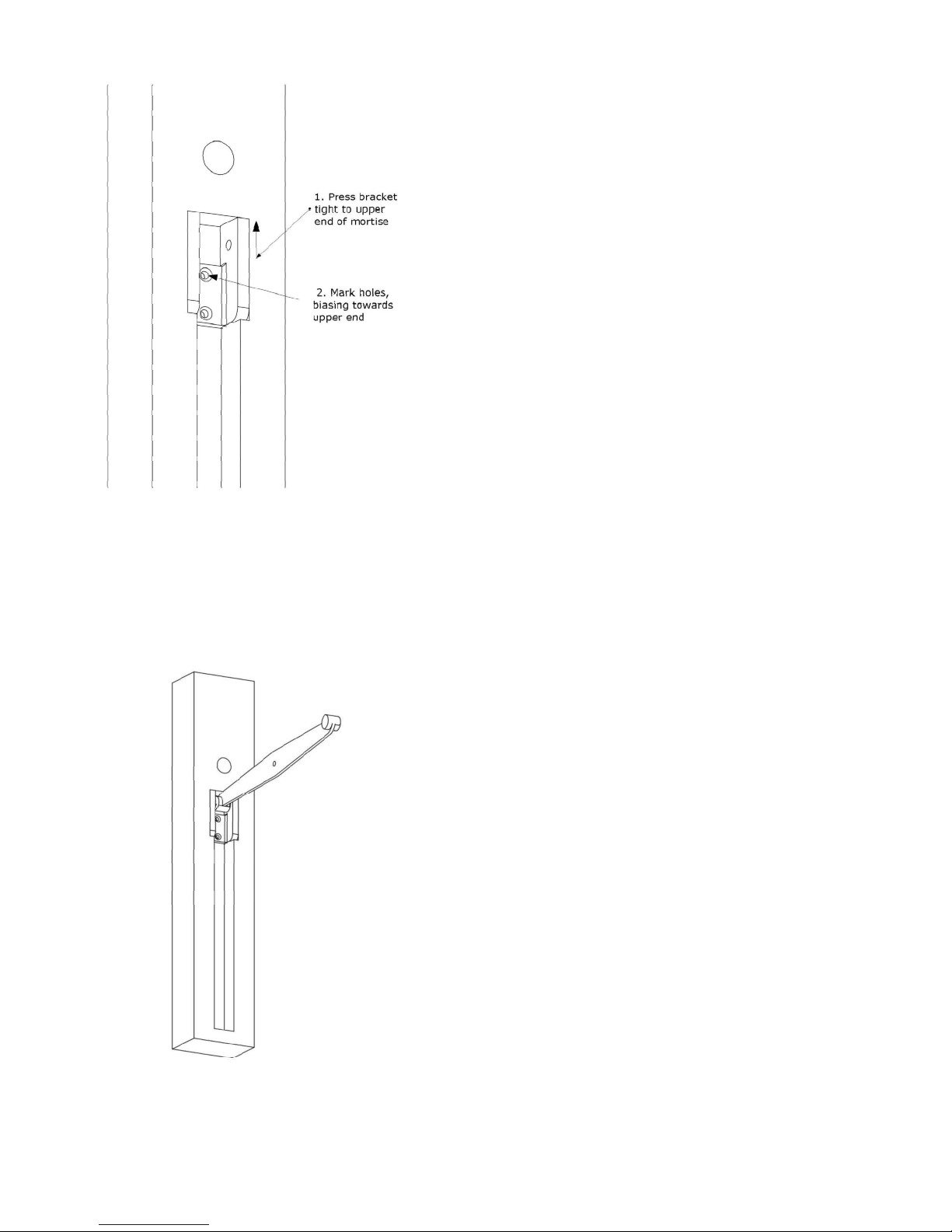

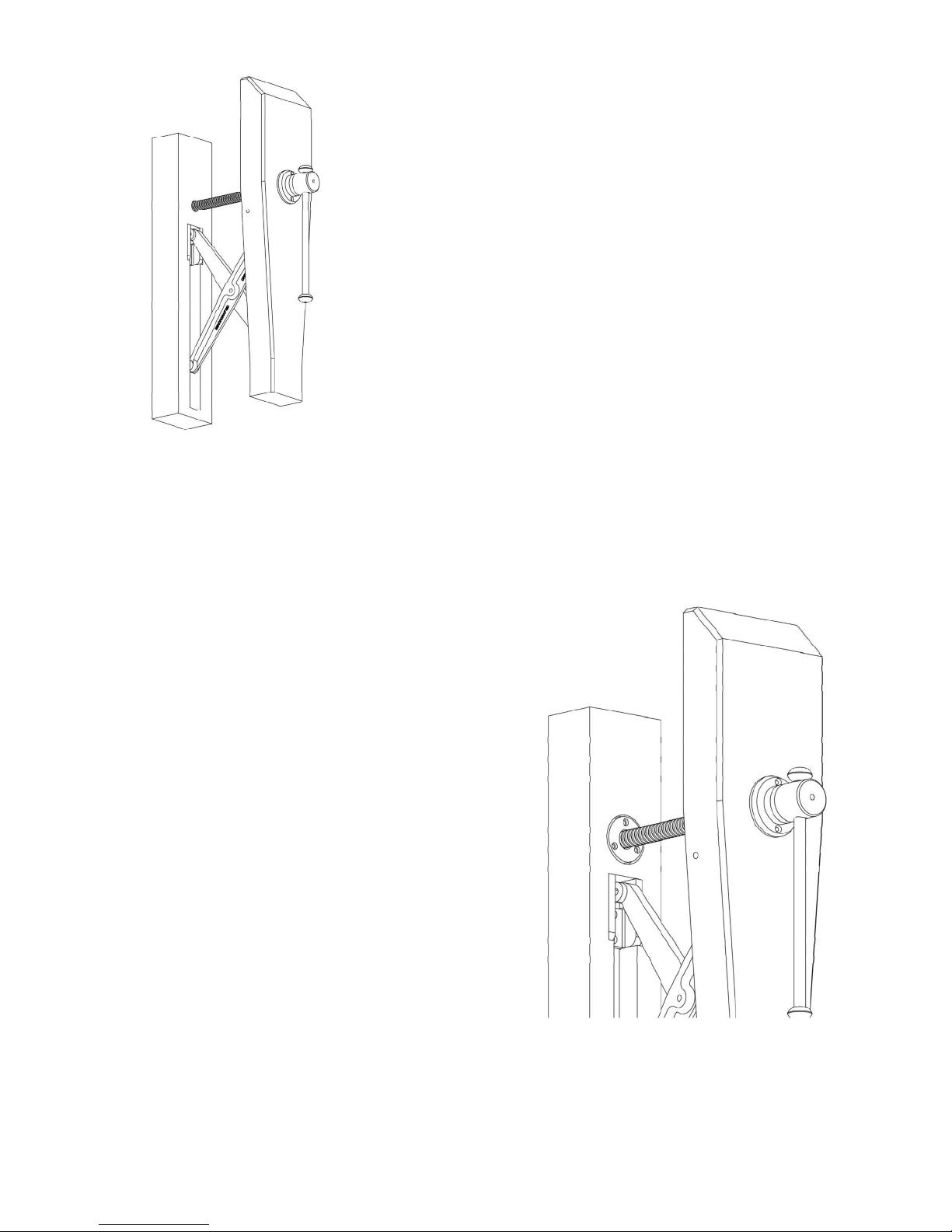

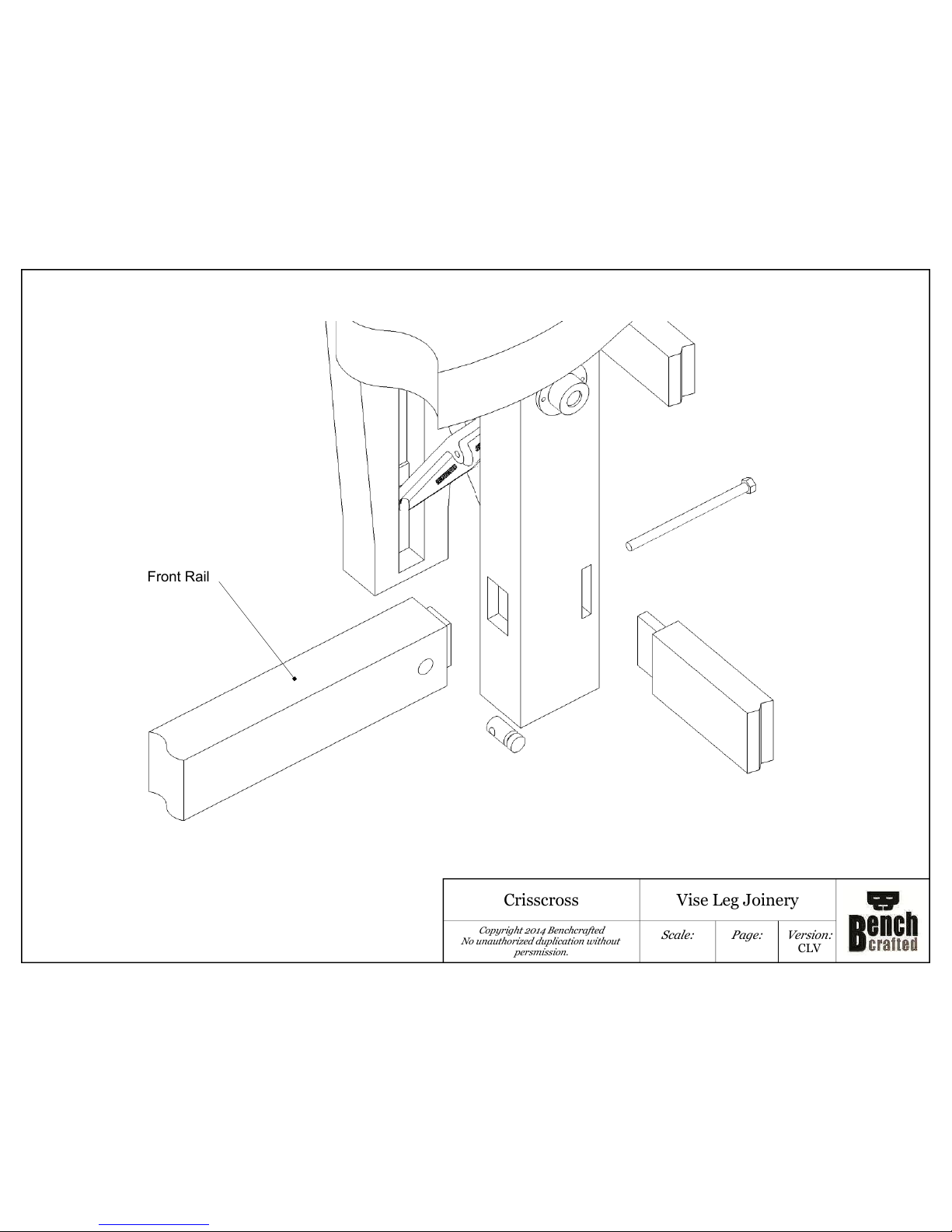

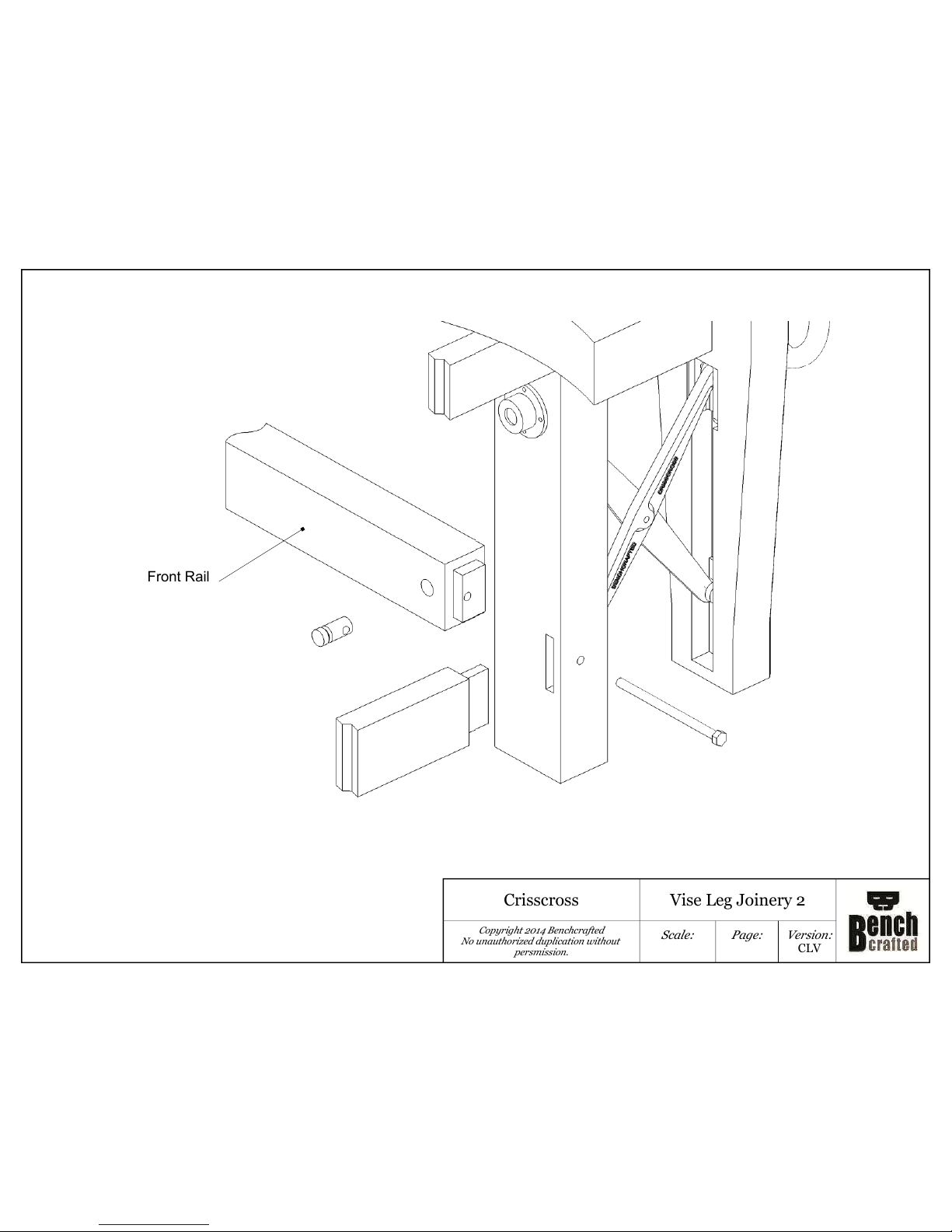

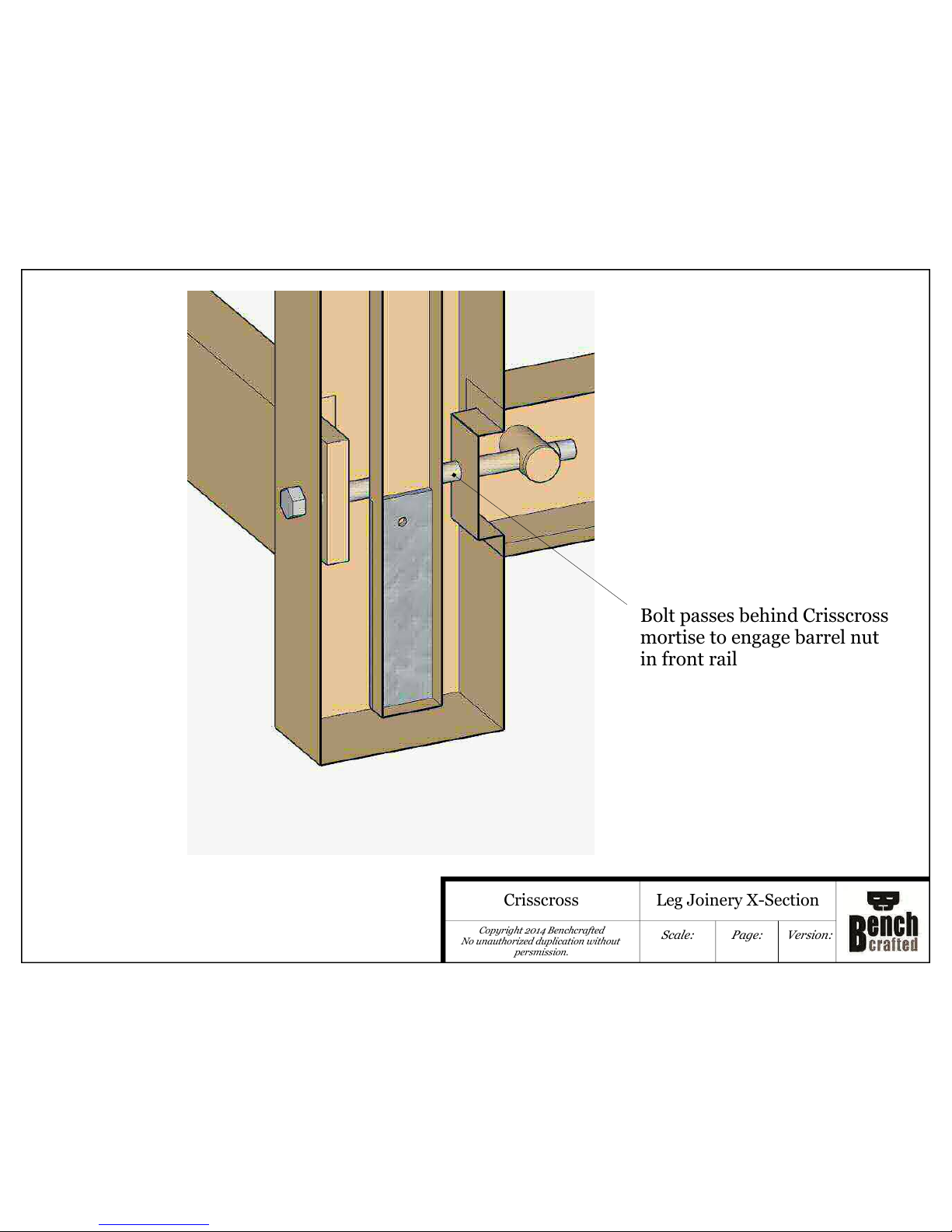

Illustrations are shown with a bench leg and chop only, without any joinery, for clarity.

1. Layout

First you’ll layout and install the Crisscross, then once that’s done, you’ll attach the flange, nut and acetal

bushing of the Classic Leg Vise. It’s important to install the Crisscross first.

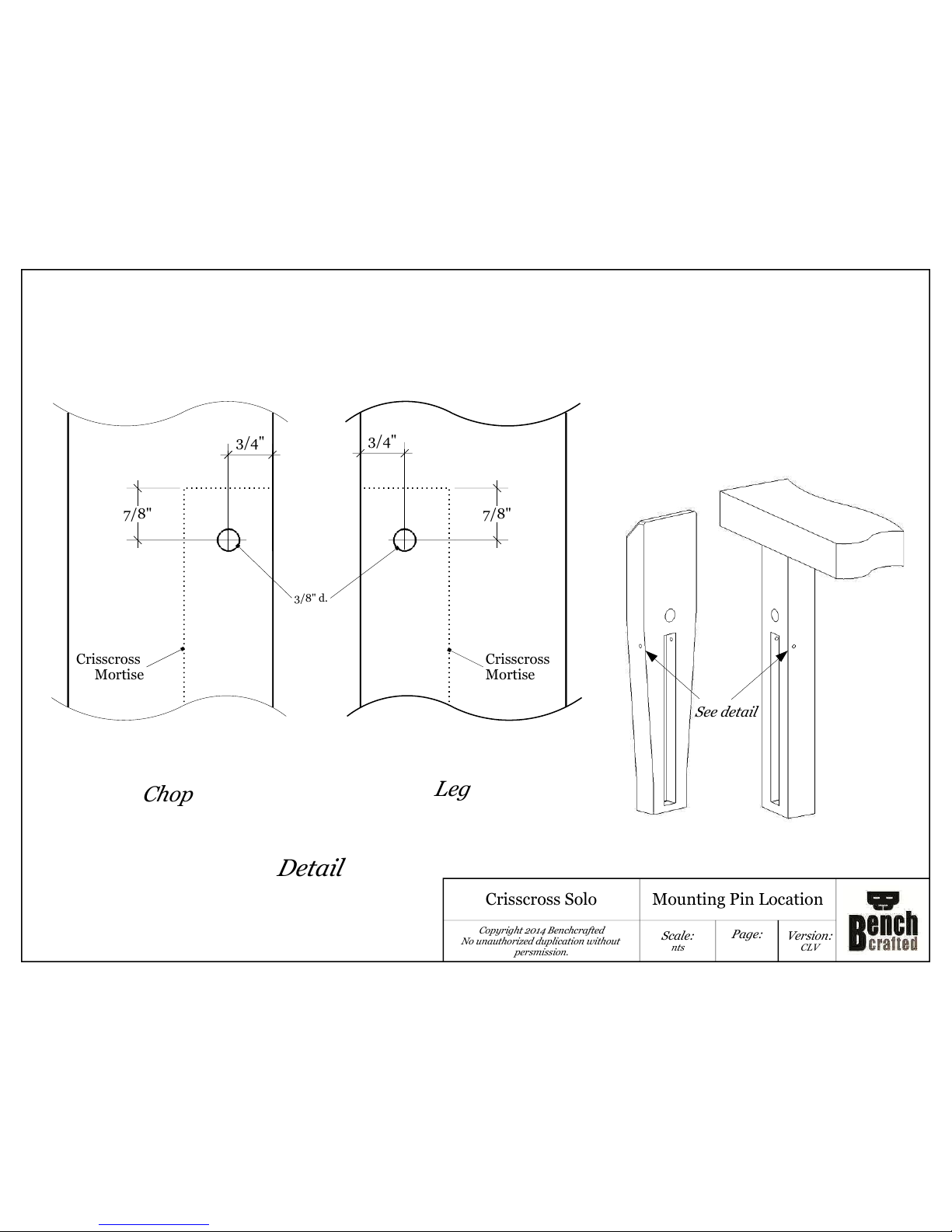

The Crisscross Solo and Retro occupies 19-1/2” of vertical space in your bench leg and chop. You can

position the Crisscross anywhere you like vertically (it should be centered left-to-right in the leg and chop)

even to the point of the mortise starting at the very bottom of the leg. If possible, try to keep some material

below the mortise (as pictured in the illustrations.) You should not mount the Crisscross Solo in a bench

leg that’s narrower than 3”, or the Retro in a leg narrower than 4”. Bench leg and chop each need to be at

least 2-1/2” thick. You don’t need solid stock, you can laminate 8/4 stock onto 4/4 stock to achieve that

thickness. Position the glue lines towards the inside face so the mortise floor falls within solid stock (not