Benchmark 1150-002 User manual

READ ALL INSTRUCTIONS BEFORE FIRST USE.

KEEP THIS MANUAL FOR FUTURE REFERENCE.

KEEP AWAY FROM CHILDREN.

WEAR CSA APPROVED

EYE PROTECTION

WEAR EAR

PROTECTION

WEAR A

FACE MASK

229683

Inverter FC 125

120V 60Hz

5 year limited warranty on tool

INVERTER FLUX-CORE

WELDER KIT

1

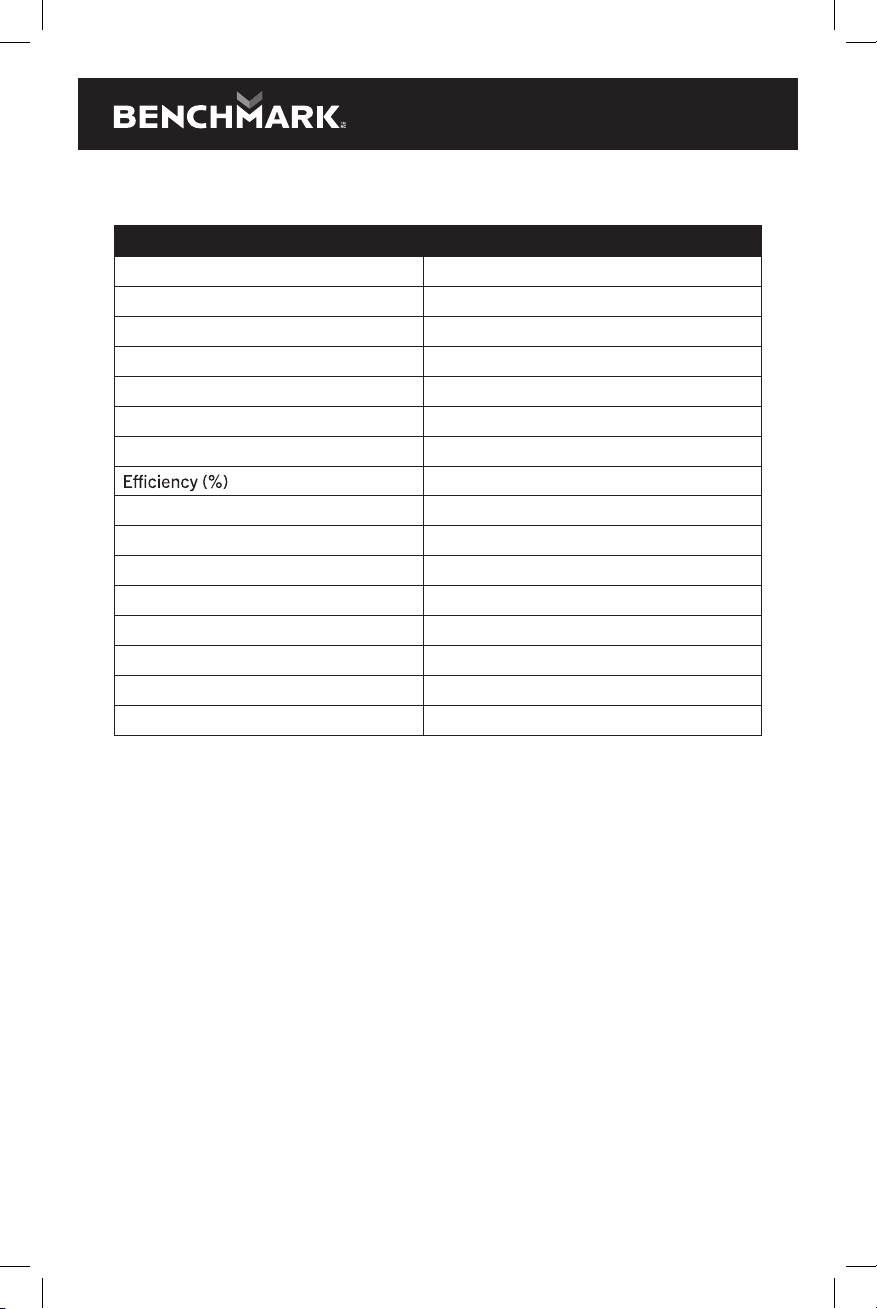

PRODUCT SPECIFICATIONS

BENCHMARK FLUX CORE WELDER

Input Voltage 1ph 120V

Input Power (KVA) 2.76

Input Current (A) 23

Output Current Range (A) 30-125A

Max. Output Current 125A/20.3V

No-load Voltage (V) 42

Rated Duty Cycle 30% at 90A

85

Power Factor 0.67

Protection Class IP21S

Insulation Class H

Welder Dimensions 12.5"x5.6"x10.2" (31.6x14.1x26cm)

Net Weight 16.5Lb (7.5 Kg)

Input Power Cord Length 3m/10ft

MIG Torch Length 1.8m/5.9ft

Earth Clamp Length 1.8m/5.9ft

NEED ASSISTANCE?

Call us on our toll- free customer support line:

1-866-349-8665 (Monday through Friday 9am – 5pm Eastern Standard Time)

• Technical questions

• Replacement parts

• Parts missing from package

1150-002

INVERTER FLUX-CORE WELDER KIT

2

TABLE OF CONTENTS

Product Specifications .................................................................................. 1

Table of Contents .......................................................................................... 2

General Safety Warnings ............................................................................... 3

Specific Safety Rules for Flux Core Welder ..................................................... 7

Safety Symbols ............................................................................................. 9

Know Your Benchmark Flux Core Welder ...................................................... 10

Assembly..................................................................................................... 12

Operation .................................................................................................... 17

Troubleshooting .......................................................................................... 22

Exploded View ............................................................................................ 23

Parts List .................................................................................................... 24

Warranty ..................................................................................................... 25

3

GENERAL SAFETY WARNINGS

IMPORTANT SAFETY INSTRUCTIONS

Read and understand all safety and operational instructions. failure to follow the

safety rules listed below and other basic safety precautions may result in serious

personal injury. Keep this manual, sales receipts and applicable warranty forms

for future reference.

SAFETY SYMBOLS

The purpose of safety symbols is to alert you of the potential safety RISKS.

Recognize and understand them. Follow the instructions provided.

SYMBOL MEANING

Failure to obey a DANGER safety alert WILL result in serious personal

injury or death to you or to others. Always obey all messages following

this symbol to reduce the risk of serious personal injury or death.

Failure to obey a WARNING safety alert MAY result in serious personal

injury or death to you or to others. Always obey all messages following

this symbol to reduce the risk of potential serious personal injury or

death.

Failure to obey a CAUTION safety alert MAY result in personal injury

or property damage to you or to others. Always obey all messages

following this symbol to reduce the risk of personal injury or

property damage.

Failure to obey a NOTICE or a CAUTION (without a safety alert)

MAY result in property damage to you or to others. Always obey all

messages following this symbol to reduce the risk of property damage.

ALWAYS WEAR EYE PROTECTION THAT CONFORMS WITH CSA

Z94.3 or ANSI SAFETY STANDARD Z87.1

FLYING DEBRIS can cause permanent eye damage. Prescription

eyeglasses ARE NOT a replacement for proper eye protection. The

usage of a safety standard compliant face shield placed over proper

safety glasses or goggles can reduce the risk of facial injury.

Non-compliant eyewear can cause serious injury if broken during

the operation of a power tool.

Use hearing protection, particularly during extended periods of

operation of the tool, or if the operation is noisy.

WEAR A DUST MASK THAT IS DESIGNED TO BE USED WHEN

OPERATING A POWER TOOL IN A DUSTY ENVIRONMENT.

1150-002

INVERTER FLUX-CORE WELDER KIT

4

SYMBOL MEANING

Always wear non-slip gloves that fit properly to protect your hands

and to help you grip the tool.

Always wear sturdy clothing with long sleeves and long pants.

Never operate the tool while wearing shorts, short sleeve shirt or

while shirtless.

Always wear non-slip safety boots to prevent foot injuries and slipping

that could cause loss of control of the tool.

To avoid electrical hazards, fire hazards or damage to the tool,

use proper circuit protection.

WARNING: Ventilation openings in batteries and chargers must

always be open to allow cooling air to circulate freely. Air vents that

are blocked, restricted or covered may result in the battery or charger

overheating. Overheating may lead to damage to the tool or cause a

fire, resulting in possible serious injury.

ELECTRIC SHOCK CAN KILL

FUMES AND GASES

FIRE HAZARDS

ARC RAYS

HOT MATERIALS

MAGNETIC FIELDS

This machine is wired at the factory for 120V AC operations.

Plug the power cord into a properly grounded, GFCI protected 120VAC

receptacle that matches the plug. The circuit must be equipped with

delayed action-type circuit breaker or fuses. To avoid shock or fire,

replace power cord immediately if it is worn, cut or damaged in any way.

5

GENERAL SAFETY INSTRUCTIONS

WARNING: OWNER’S MANUAL.

Read and understand this owner’s manual BEFORE using machine.

TRAINED OPERATORS ONLY. Untrained operators have a higher risk of being

hurt or killed. Only allow trained/supervised people to use this machine. When

machine is not being used, dis- connect power, remove switch keys, or lock-out

machine to prevent unauthorized use - especially around children. Make your

workshop kid proof!

DANGEROUS ENVIRONMENTS. Do not use machinery in areas that are wet,

cluttered, or have poor lighting. Operating machinery in these areas greatly

increases the risk of accidents and injury.

MENTAL ALERTNESS REQUIRED. Full mental alertness is required for safe

operation of machinery. Never operate under the influence of drugs or alcohol,

when tired, or when distracted.

ELECTRICAL EQUIPMENT INJURY RISKS. You can be shocked, burned, or

killed by touching live electrical components or improperly grounded machinery.

To reduce this risk, only allow qualified service personnel to do electrical

installation or repair work, and always disconnect power before accessing or

exposing electrical equipment.

DISCONNECT POWER FIRST. Always disconnect machine from power supply

before making adjustments, changing tooling, or servicing machine. This prevents

an injury risk from unintended startup or contact with live electrical components.

EYE PROTECTION. Always wear ANSI-approved safety glasses or a face shield

when operating or observing machinery to reduce the risk of eye injury or blindness

from flying particles. Everyday eyeglasses are NOT approved safety glasses.

WEARING PROPER APPAREL. Do not wear clothing, apparel or jewellery that

can become entangled in moving parts. Always tie back or cover long hair. Wear

non-slip footwear to reduce risk of slipping and losing control or accidentally

contacting cutting tool or moving parts.

HAZARDOUS DUST. Dust created by machinery operations may cause cancer,

birth defects, or long-term respiratory damage. Be aware of dust hazards

associated with each workpiece material. Always wear a NIOSH-approved

respirator to reduce your risk.

HEARING PROTECTION. Always wear hearing protection when operating or

observing loud machinery. Extended exposure to this noise without hearing

protection can cause permanent hearing loss.

REMOVE ADJUSTING TOOLS. Tools left on machinery can become dangerous

projectiles upon startup. Never leave chuck keys, wrenches, or any other tools on

machine. Always verify removal before starting!

USE CORRECT TOOL FOR THE JOB. Only use this tool for its intended purpose

- do not force it or an attachment to do a job for which it was not designed. Never

intended may result in malfunction or mechanical failure that can lead to personal

injury or death!

1150-002

INVERTER FLUX-CORE WELDER KIT

6

AWKWARD POSITIONS. Keep proper footing and balance at all times when

operating machine. Do not overreach! Avoid awkward hand positions that make

workpiece control dicult or increase the risk of accidental injury.

CHILDREN & BYSTANDERS. Keep children and bystanders at a safe distance

from the work area. Stop using machine if they become a distraction.

GUARDS & COVERS. Guards and covers reduce accidental contact with moving

parts or flying debris. Make sure they are properly installed, undamaged, and

working correctly before operating machine.

FORCING MACHINERY. Do not force machine. It will do the job safer and better at

the rate for which it was designed.

NEVER STAND ON MACHINE. Serious injury may occur if machine is tipped or if

the cutting tool is unintentionally contacted.

STABLE MACHINE. Unexpected movement during operation greatly increases risk

of injury or loss of control. Before starting, verify machine is stable and mobile base

(if used) is locked.

USE RECOMMENDED ACCESSORIES. Consult this owner’s manual or the

manufacturer for recommended accessories. Using improper accessories will

increase the risk of serious injury.

UNATTENDED OPERATION. To reduce the risk of accidental injury, turn machine

OFF and ensure all moving parts completely stop before walking away. Never leave

machine running while unattended.

MAINTAIN WITH CARE. Follow all maintenance instructions and lubrication

schedules to keep machine in good working condition. A machine that is improperly

maintained could malfunction, leading to serious personal injury or death.

DAMAGED PARTS. Regularly inspect machine for damaged, loose, or misaligned

parts - or any condition that could aect safe operation. Immediately repair/replace

before operating machine. For your own safety, DO NOT operate machine with

damaged parts!

MAINTAIN POWER CORDS. When disconnecting cord-connected machines

from power, grab and pull the plug—NOT the cord. Pulling the cord may damage

the wires inside. Do not handle cord/plug with wet hands. Avoid cord damage by

keeping it away from heated surfaces, high trac areas, harsh chemicals, and wet/

damp locations.

SERVICE

• Have your machinery serviced by a qualified repair person using only identical

replacement parts. This will ensure that the safety of the machinery is

maintained.

7

SPECIFIC SAFETY RULES FOR FLUX CORE WELDER

WARNING: In order to avoid mistakes that could cause serious injury, read the

following steps carefully and understand them thoroughly before using this welder.

WELDING FUMES. Breathing welding fumes can cause suocation or poisoning

without warning. Keep your head out of welding fumes. Use adequate ventilation at

the arc to safely remove the fumes from your breathing zone and the general area.

Use ANSI approved respirators for the type of welding operation. Protect others

from these fumes.

WELDING IN A CONFINED SPACE CAN BE HAZARDOUS. Always open all

covers, sustain forced ventilation, remove toxic and hazardous materials, and

provide a power disconnect to the welder inside the workspace. Always work with

someone who can give you help from outside the space. Welding can displace

oxygen. Always check for safe breathing atmosphere and provide air-supplied

respirators if necessary. Keep in mind that all normal welding hazards are intensified

in a confined space.

ELECTRIC SHOCK. DO NOT touch live electrical parts. Connect welder to power

source with approved earth ground. Make sure all electrical connections are tight,

clean, and dry. Connect workpiece to approved earth ground. The work lead is NOT

a ground connection and is to be used only to complete the working welding circuit.

PREVENT FIRES. Welding work zones must be kept clear of flammable liquids,

such as gasoline and solvents; combustible solids, such as paper and wood; and

flammable gases, such as acetylene and hydrogen. Provide approved fire barriers

and fire extinguishing equipment for the welding zone. Stay alert for sparks and

spatter thrown into cracks and crevices that can start a smoldering fire. Inspect the

work area again one hour after welding for any potential fire hazards.

WORKING AREA. Keep working area clear of any material not involved in the

welding operation. Keep all equipment, workpieces, and work surfaces clean, dry,

and free of entanglements. Keep lead cables organized and away from your body.

PROTECT BODY FROM ARC BURNS, SPARKS, AND SPATTER. Wear correct

and approved eye, ear, and body protection. Wear complete body protection, such

as clean and oil-free protective clothing, leather gloves, protective cap, heavy long-

sleeve shirt, cuess pants, and high leather boots. DO NOT wear jewellery or frayed

clothing. Use a welding helmet with the correct shade of filter for the operation.

Protect other people and property in your working zone from exposure to arc

radiation, sparks, and spatter.

HANDLING GAS CYLINDERS. Regardless of content, pressurized gas cylinders

can explode. Always secure a protector cap in place over the outlet valve assembly

when moving the cylinder. A broken o valve could release the pressurized contents

and cause the cylinder to be hurled about at dangerously high speeds, causing

serious property damage, personal injury, or death. Always use safe methods when

moving gas cylinders. Always secure a gas cylinder to a wall or approved cylinder

cart with a chain before using or storing.

PROTECT GAS CYLINDERS FROM HEAT OR DAMAGE. An excess of heat can

cause the pressurized gas to expand and explode the cylinder. Never weld on the

gas cylinder. Damaging the outside of the cylinder can cause the cylinder to crack

1150-002

INVERTER FLUX-CORE WELDER KIT

8

and explode. Exploding pressurized gas cylinders can cause serious property

damage, personal injury, or death.

ELECTRIC AND MAGNETIC FIELDS (EMF). Welding operations create EMF

around the welding equipment and workpieces. Workers who have pacemakers

must consult with their physician before using this equipment or being within 50

feet of welding operations.

EXPERIENCING DIFFICULTIES. If you are experiencing diculties performing the

intended operation, stop using the equipment.

Keep the environment you will be welding in free from flammable materials.

Always keep a fire extinguisher accessible to your welding environment.

Always have a qualified person install and operate this equipment.

Make sure the area is clean, dry and ventilated. Do not operate the welder in humid,

wet or poorly ventilated areas.

Always have your welder maintained by a qualified technician in accordance with

local, provincial and national codes.

Always be aware of your work environment. Be sure to keep other people, especially

children, away from you while welding.

Check all components to ensure they are clean and in good operating condition

before use.

Do not operate the welder if the output cable, wire, or any part of the system is wet.

Do not immerse them in water.

Do not allow any body part to come in contact with the wire if you are in contact with

the material being welded, ground or wire from another welder.

Do not weld if you are in an awkward position. Always have a secure stance while

welding to prevent accidents. Wear a safety harness if working above ground.

Do not drape cables over or around your body.

Wear a full-coverage helmet with shade (see ANSI Z87.1 safety standard)

and safety glasses while welding.

Wear proper gloves and protective clothing to prevent your skin from being exposed

to hot metals, UV and IR rays.

Do not overuse or overheat your welder.

Allow proper cooling time between duty cycles.

Always use this welder in the rated duty cycle to prevent excessive heat and failure.

Do not attempt to repair or maintain the welder while the power is on.

Do not touch the electrode and the ground or grounded work piece at

the same time.

Do not use a welder to thaw frozen pipes.

SAVE THIS USER MANUAL

WARNING:

MISUSE or failure to follow the safety rules stated in this instruction manual

may cause serious personal injury.

9

SAFETY SYMBOLS

The rating plate on your tool may show symbols. These represent important

information about the product or instructions on its use.

WARNING: Please read all of the safety and operating instructions

carefully before using this tool. Please pay particular attention to all

sections of this User Guide that carry warning symbols and notices. Some

of the following symbols may be used on this tool.

Observe caution and safety notes.

To reduce the risk of injury, user must read and understand User Guide

before using this tool.

Wear ear protection.

Wear protective helmet and eye protection.

maintenance.

Do not use in the rain or leave outdoors while it is raining.

Keep bystanders away.

Don’t touch the inlet and outlet when the vacuum cover is opened or the

tube is removed.

Double insulation.

Remove plug from the power source immediately if the power cord is

damaged or cut.

This symbol designates that this tool is listed with Canadian and U.S.

requirements by CSA Group conforms to CAN/CSA C22.2 No. 0; CAN/CSA C22.2

No. 0.4; CSA-C22.2 No. 60-M1990; UL551(8th Edition)

229683

Inverter FC 125

1150-002

INVERTER FLUX-CORE WELDER KIT

10

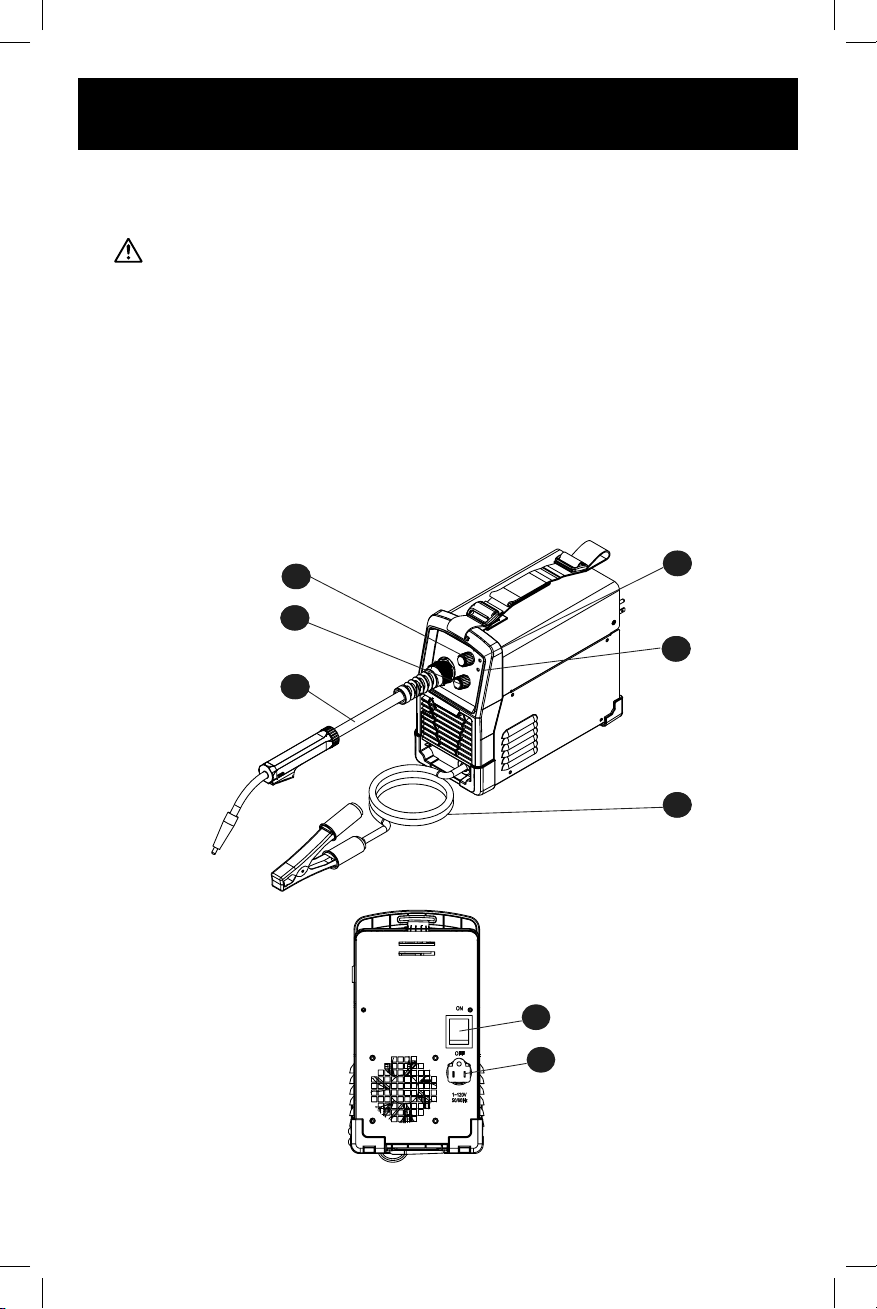

KNOW YOUR BENCHMARK FLUX CORE WELDER

Attention

Always be sure that the machinery is switched o and unplugged before adjusting

or checking function on the machinery.

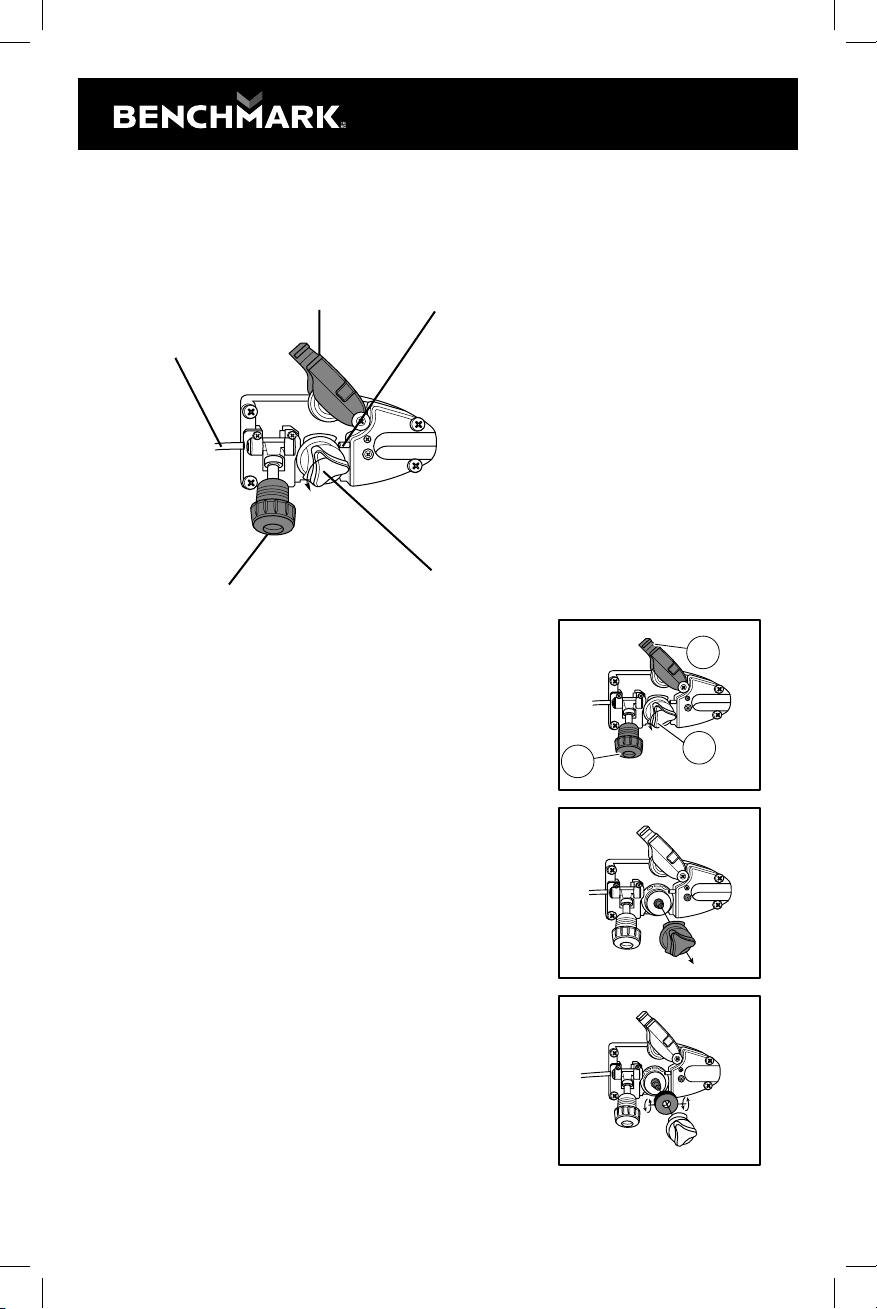

FUNCTIONS

1. POWER INDICATOR

2. OVERLOAD INDICATOR

3. WELDING CURRENT

4. VOLTAGE

5. WELDING CABLE AND FLUX-CORE GUN

6. GROUND CABLE AND CLAMP

7. ON/OFF SWITCH

8. POWER CORD

7

8

��

�

�

�

�

1

2

6

3

4

5

11

POWER INDICATOR

When the machine is turned on, the power indicator will be on.

Overload Indicator

When this indicator is on, it shows the machine is overloaded and the internal

temperature is too high. Weld output will turn o automatically but the fan will

still be working. When the internal temperature is decreased, the overload light

will turn o and the machine will be ready to weld.

Welding Voltage

Set output voltage and wire speed. Refer to the “set up” chart inside the

wire feed compartment.

Welding cable and Flux-Core Gun

The welding wire is driven through the welding cable and Flux-Core gun to

the work piece. It is fixed to the drive system.

Ground Cable and Clamp

The ground cable and clamp is attached to the work piece to complete

the flow of current needed to weld.

ON/OFF Switch

In the “o” position, no power is being supplied to the welder. In the “ON” position,

power is supplied to the main transformer and control circuit.

Power Cord

The power cord connects the welder to the 120-V power supply.

Plug into a 120-V/20-A receptacle to supply power to the welder

1150-002

INVERTER FLUX-CORE WELDER KIT

12

ASSEMBLY

INSTRUCTIONS FOR SHOULDER STRAP INSTALLATION

Step 1

Get the strap through

the buckle

Step 2

Step 4

Pull the strap tight enough until it is

locked in place by the buckle

Step 3

Pull the two ends through the buckle

Install the strap onto the machine

Leave 165 mm

on each end

Put the shoulder pad in

the middle of the strap

ASSEMBLY INSTRUCTIONS

1. Power requirement

AC single-phase 120 V (110-130 V), 60 Hz fused with a 20-A time-delayed fuse

or circuit breaker is required. DO NOT OPERATE THIS UNIT if the ACTUAL power

source voltage is less than 105 V AC or greater than 132 V AC.

BEFORE YOU START—DESCRIPTION

Connect your welder’s power cord to a properly grounded 120-V AC, 60-Hz, single-

phase, 20-A power source.

2. Extension cord

During normal use an extension cord is not necessary. It is strongly recommended

that an extension cord should not be used because of the voltage drop they

produce. This drop in voltage can aect the performance of the welder. If you need

to use an extension cord it must be a #12 gauge cord at the least. Do not use an

extension cord over 25' (7.6 m) in length.

13

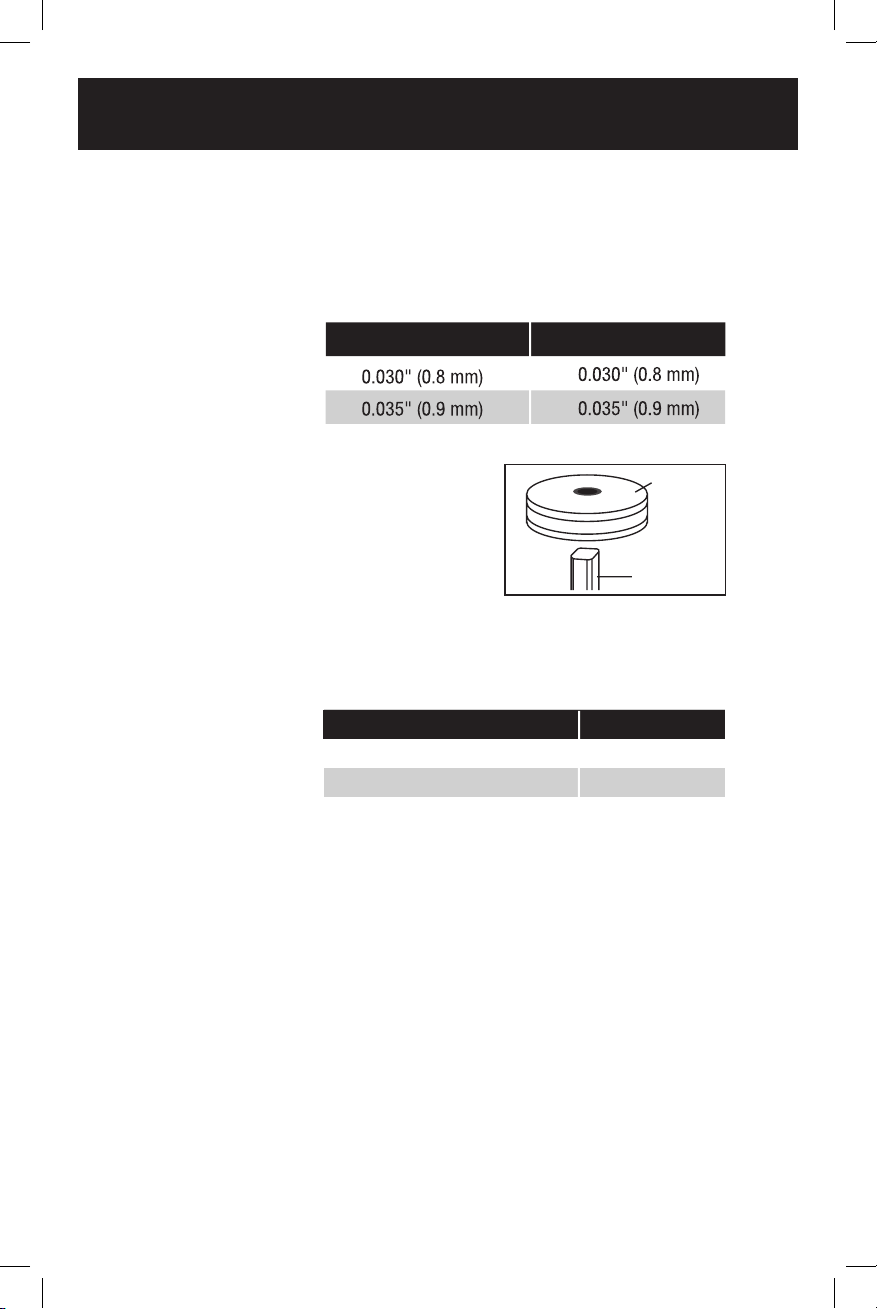

3. Install the wire roller

Before installing any welding wire into the unit, the properly-sized groove must be

positioned on the wire drive mechanism. Adjust the drive roller according to the

following steps, see following picture about the wire feeder structure:

3.1. Open the door to the welder drive compartment.

3.2. Remove the drive tension (see 1) by loosening

the tension adjusting knob and lifting the drive

tension adjustor away from the drive tension arm

(see 2).

Pull the drive tension arm away from the drive

roller (see 3). See following images for reference.

3.3. If a wire is already installed in the welder, roll it

back onto the wire spool by hand-turning the

spool counter-clockwise. Be careful not to allow

the wire to come out of the rear end of the inlet

guide tube without holding onto it or it will unspool

itself. Put the end of the wire into the hole on the

outside edge of the wire spool and bend it over to

hold the wire in place. Remove the spool of wire

from the drive compartment of the welder.

3.4. Rotate the drive roller cap counter-clockwise and

remove it from the drive roller.

3.5. Pull the drive roller o of the drive roller shaft.

Drive tension arm Gun liner

Drive roller

Drive tension arm

Inlet guide tube

6.

0

Fig 2

Fig 3

2

13

Fig 1

1150-002

INVERTER FLUX-CORE WELDER KIT

14

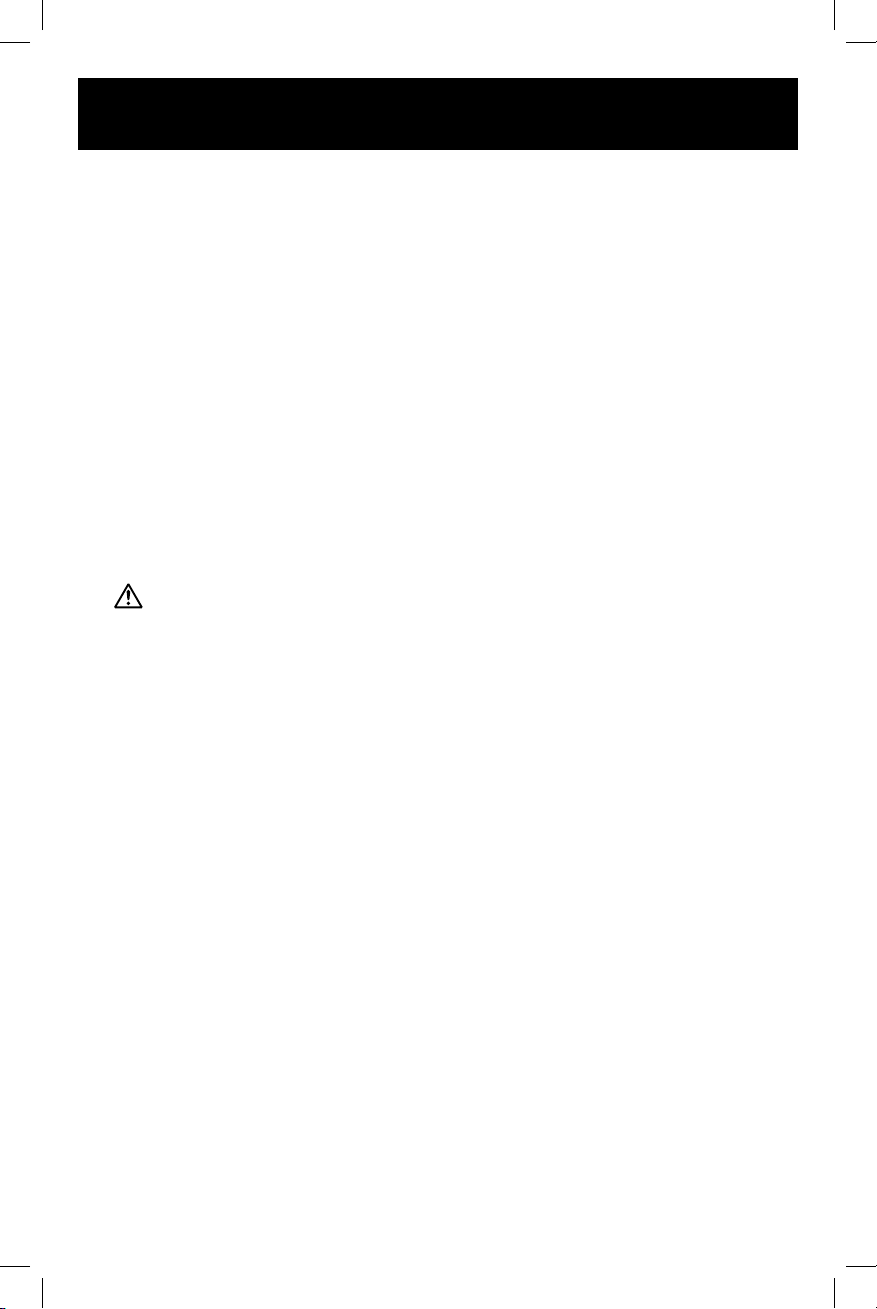

RECOMMENDED WIRE

3.6 Depending on the wire diameter, select the correct groove according to the

following table about the relationship between wire diameter and wire roller

groove size.

The drive roller has two wire-size grooves built

into it. When installing the drive roller, the number

stamped on the drive roller for the wire size you

are using should be facing you. Push the drive

roller onto the drive roller shaft.

3.7. Reinstall the drive roller cap and lock in place by turning it clockwise.

3.8. Close the door to the welder drive compartment.

4. Install the wire

4.1 Select the wire.

4" (10 cm) wire spools of 0.030" (0.8 mm) or 0.035" (0.9 mm).

Self-shielding flux-core wire can be used on this welder.

Steel from 18 gauge up to 3/16” thick can be welded with this wire.

NOTE:

- Metal thinner than 18 gauge cannot be welded with this machine. Attempting

to do so will cause burn-through in the metal you are intending to weld.

- Remove any wire that is rusty; if the whole spool is rusty, discard it.

This welder uses both 4" (10 cm) spools of 0.030 or 0.035"

(0.8 or 0.9 mm) thick wire.

4.2 Install the wire.

4.2.1 Remove the nozzle and contact tip from the end of the torch assembly.

4.2. 2 Make sure the proper groove on the drive roller is in place for

the wire installed.

Wire Diameter Roller Groove

Motor shaft

Drive

roller

0.035

MIG wire No

Flux-core wire 0.030" (0.8 mm)

Flux-core wire 0.035" (0.9 mm) Yes

Wire Type Available or not

Yes

FLUX CORED WIRE SELECTION---- E71T-GS

15

If not, change the drive roller as described above.

4.2.3 Unwrap the spool of wire and then find the leading end of the wire. The wire

goes through a hole in the outer edge of the spool and is bent over the spool edge to

prevent the wire from unspooling BUT DO NOT UNHOOK IT at this point.

4.2.4 Place the spool on the spool holder in such a manner that the welding wire

comes o the bottom of the spool into the drive mechanism. See following diagram.

WARNING!

Electric shock can kill! Always turn the POWER switch OFF and unplug the power

cord from the AC power source before installing wire.

• Metal thinner than 18 gauge cannot be welded with this machine. Attempting to

do so will cause burn through in the metal you are intending to weld.

•

If the wire is rusty, remove any wire with rust. If the whole spool is rusty, discard it.

• Before installing, make sure that you have removed any old wire from the torch

assembly. This will help to prevent the possibility of the wire jamming inside the

torch liner.

• Be very careful when removing the welding nozzle. The contact tip on this welder

is live whenever the torch trigger is pulled. Make sure the POWER is turned OFF.

4.2.5 The welder can use 4" (10 cm) spool, please see the following chart. The

adjustment knob is designed to adjust the pressure tension of the wire spool.

4.2.6. Once adjustment knob is installed, set the spool tension.

a) With one hand, turn the wire spool and continue turning it while adjusting

the tension on the spool.

b) With your free hand, tighten the drive tension adjustment knob.

c) Stop tightening when drag is felt on the wire spool that you are turning,

then stop hand-turning the wire spool.

Wire installation

Right way Wrong way

4" (10 cm)

spool

4.2.7. After checking to make sure that your welder is disconnected from the AC

power source, free the leading end of the wire from the spool, but do not let go of it

until told to do so, or the wire will unspool itself.

4.2.8. Using a wire cutter, cut the bent end o the leading end of the wire so that

only a straight leading end remains.

4.2.9. Loosen the tension adjusting knob holding the drive tension arm in place

and lift the tension arm up o the drive roller.

4.2.10. Insert the leading end of the wire into the inlet guide tube.

Then push it across the drive roller and into the torch assembly about 6" (15 cm).

4.2.11. Line the wire up to place in the groove of drive roller, then allow the drive

tension arm to drop onto the drive roller.

4.2.12. Flip the quick-release drive tension back up into position on the

drive tension arm.

4.2.13. Tighten (turn clockwise) the drive tension adjusting knob until the

tension roller is applying enough force on the wire to prevent it from slipping

out of the drive assembly.

4.2.14. Let go of the wire.

CAUTION

If TOO MUCH tension is applied to the wire spool, the wire will slip on the drive roller

or will not be able to feed at all. If TOO LITTLE tension is applied, the spool of wire

will want to unspool itself. Readjust the drive brake tension as necessary to correct

for either problem.

4.2.15. Connect the welder power cord to the AC power source. Turn the welder

ON. Set the VOLTAGE switch to the voltage (heat) setting recommended for the

gauge metal that is to be welded. Refer to the label mounted on the cover, inside

the drive compartment.

4.2.16. Set the WIRE SPEED control to the middle of the wire speed range.

4.2.17. Straighten the torch cable and pull the trigger on the welding torch to feed

the wire through the torch assembly. When at least 1" (2.5 cm) of the wire sticks

out past the end of the torch, release the trigger.

4.2.18. Turn the power switch to the OFF position.

4..2.19. Select a contact tip stamped with the same diameter as the wire being used.

NOTE: Due to inherent variances in flux-cored welding wire, it may be necessary

to use a contact tip one size larger than your flux core wire if wire jams occur.

4.2.20. Slide the contact tip over the wire (protruding from the end of the torch).

Thread the contact tip into the end of the torch and hand-tighten securely.

4.2.21. Install the nozzle on the torch assembly. For best results, coat the insid

of the nozzle with antistick spray or gel.

4.2.22. Cut o the excess wire that extends past the end of the nozzle.

4.2.23. Turn the welder ON.

5. Setting the wire tension

5.1. Press the trigger on the torch.

1150-002

INVERTER FLUX-CORE WELDER KIT

16

17

5.2. Turn the drive tension adjustment knob clockwise, increasing the drive tension

until the wire seems to feed smoothly without slipping.

WARNING:

Arc flash can injure eyes! To reduce the risk of arc flash, make sure that the wire

coming out of the end of the torch does not come into contact with work piece,

ground clamp or any grounded material during the drive tension setting process, or

arcing will occur.

OPERATION

1. Main control component

Power switch - The power switch supplies electrical current to the welder. Whenever

the power switch is in the ON position, the welding circuit is activated. ALWAYS turn

the power switch to the OFF position and unplug the welder before performing any

maintenance.

Voltage selector - The voltage selector controls the welding heat. This unit has two-

step voltage control. Refer to the label inside the welder side door for recommended

voltage selector settings for your welding job.

Wire speed control - The wire speed control adjusts the speed at which the wire

is fed out of the welding torch. The wire speed needs to be closely matched

(tuned in) to the rate at which it is being melted o. Some things that aect wire

speed selection are the type and diameter of the wire being used, the heat setting

selected, and the welding position to be used.

Note: The wire will feed faster without an arc. When an arc is being drawn, the wire

speed will slow down.

2. Hold the torch

The best way to hold the welding torch is the way that feels most comfortable to you.

While practicing using your new welder, experiment holding the torch in dierent

positions until you find the one that seems to work best for you.

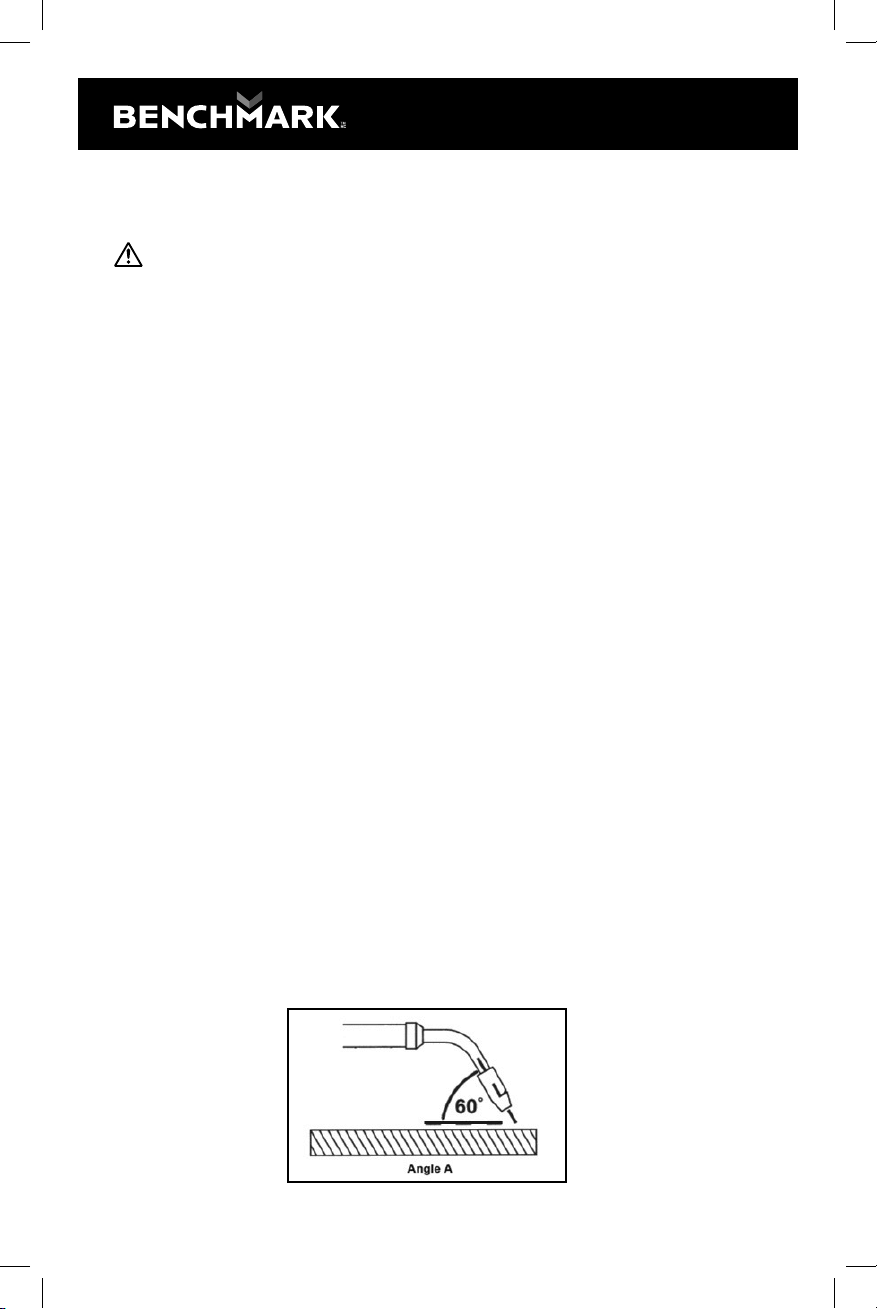

3. Position the torch to the work piece

There are two angles of the torch nozzle in relation to the work piece that must be

considered when welding.

3.1. Angle A can be varied, but in most cases the optimum angle will be 60

degrees, the point at which the torch handle is parallel to the work piece. If angle

A is increased, penetration will increase. If angle A is decreased, penetration will

decrease as well.

1150-002

INVERTER FLUX-CORE WELDER KIT

18

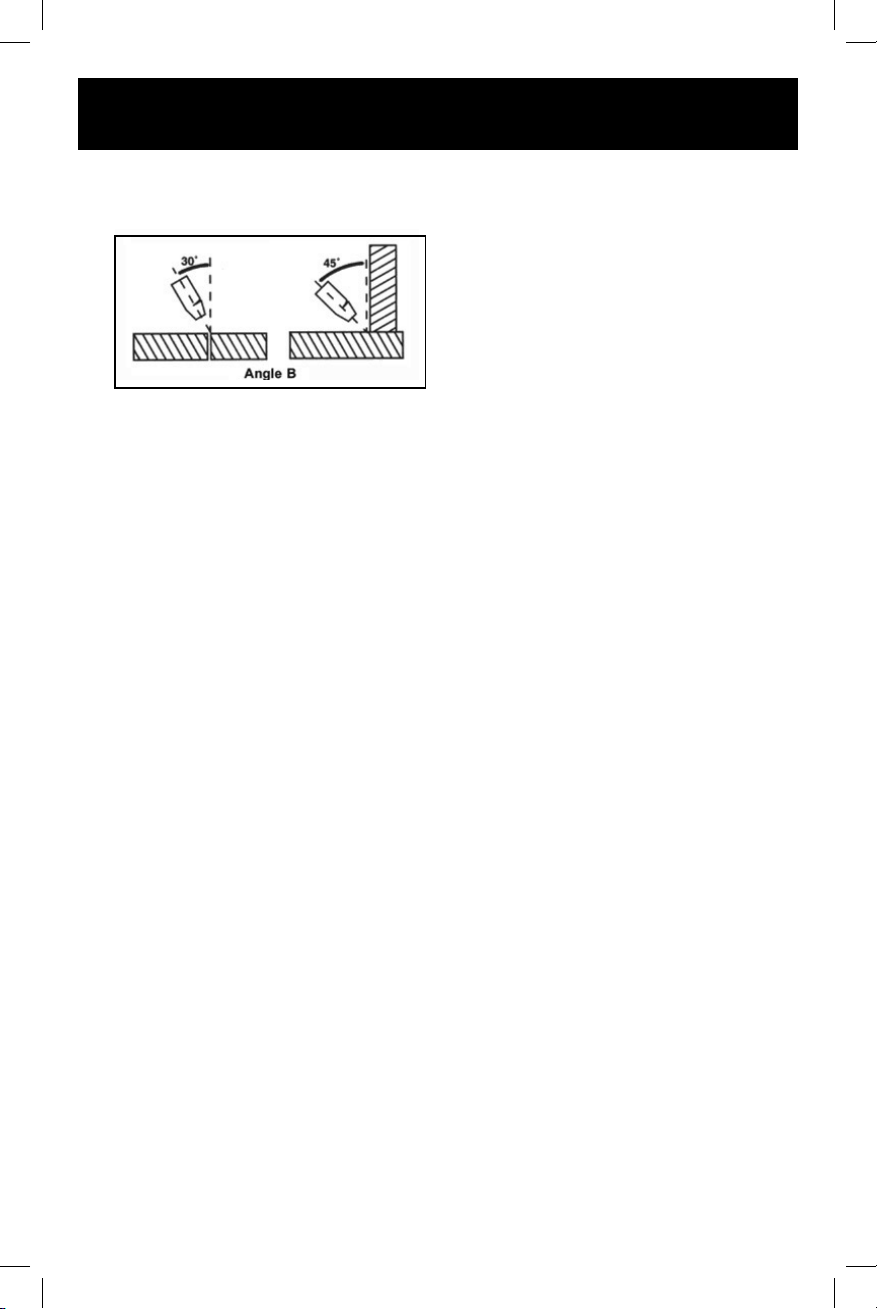

3.2. Angle B can be varied for two reasons: to improve the ability to see the arc in

relation to the weld puddle and to direct the force of the arc.

4. Distance from the work piece

If the nozzle is held o the work piece, the distance between the nozzle and the

work piece should be kept constant and should not exceed 1/4" (6 mm) or the arc

may begin sputtering, signaling a loss in welding performance.

5. Tuning in the wire speed

This is one of the most important parts of MIG welder operation and must be done

before starting each welding job or whenever any of the following variables are

changed: heat setting, wire diameter, or wire type.

5.1. Connect the ground clamp to a scrap piece of the same type of material which

you will be welding. It should be equal to or greater than the thickness of the actual

work piece, and free of oil, paint, rust, etc.

5.2. Select a heat setting.

5.3. Hold the torch in one hand, allowing the nozzle to rest on the edge of the

workpiece farthest away from you, and at an angle similar to that which will be used

when welding.

5.4. With your free hand, turn the wire speed dial to maximum and continue to hold

onto the knob.

5.5. Lower your welding helmet and pull the trigger on the torch to start an arc, then

begin to drag the torch toward you while simultaneously turning the wire speed dial

counter-clockwise.

5.6. LISTEN! As you decrease the wire speed, the sound that the arc makes will

change from a sputtering to a high-pitched buzzing sound and then will begin

sputtering again if you decrease the wire speed too much. The point on the wire

speed adjustment where the high-pitched buzzing sound is achieved is the correct

setting. You can use the wire speed control to slightly increase or decrease the heat

and penetration for a given heat setting by selecting higher or lower wire speed

settings. Repeat this tune-in procedure if you select a new heat setting, a dierent

diameter wire, or a dierent type of welding wire.

6. Welding Techniques

6.1 Moving the torch

Torch travel refers to the movement of the torch along the weld joint and is broken

into two elements: direction and speed. A solid weld bead requires that the welding

torch be moved steadily and at the right speed along the weld joint. Moving the

torch too fast, too slow, or erratically will prevent proper fusion or create a lumpy,

uneven bead.

19

Travel direction is the direction the torch is moved along the weld joint in relation to

the weld puddle. The torch is either PUSHED into the weld puddle or PULLED away

from the weld puddle.

For most welding jobs, you will pull the torch along the weld joint to take advantage

of the greater weld puddle visibility.

Travel speed is the rate at which the torch is being pushed or pulled along the weld

joint. For a fixed heat setting, the faster the travel speed, the lower the penetration

and the lower and narrower the finished weld bead. Likewise, the slower the travel

speed, the deeper the penetration and the higher and wider the finished weld bead.

6.2. Types of welding bead

As you become more familiar with your new

welder and better at laying some simple weld

beads, you can begin to try some dierent weld

bead types.

The stringer bead is formed by travelling with

the torch in a straight line while keeping the

wire and nozzle centered over the weld joint.

See following figure.

The weave bead is used when you want to

deposit metal over a wider space than would

be possible with a stringer bead. It is made by

weaving from side to side while moving with the

torch. It is best to pause momentarily at each

side before weaving back the other way.

6.3 Welding position

FLAT POSITION This is easiest of the welding

positions and is most commonly used. It is

best if you can weld in the flat position if at all

possible as good results are easier to achieve.

Push Pull

Weld

puddle

Table of contents

Popular Inverter manuals by other brands

Agilent Technologies

Agilent Technologies E8247C PSG CW user guide

Dometic

Dometic TEC60 operating manual

Duracell

Duracell Digital inverter 400 owner's guide

Terex

Terex T25 Service manual

Omnik New Energy

Omnik New Energy Omniksol-1k-TL2 user manual

Morningstar

Morningstar SureSine 150 Installation and operation manual