Benchmark 1282 208 User manual

WEAR CSA APPROVED

EYE PROTECTION

WEAR EAR

PROTECTION

WEAR A

FACE MASK

READ ALL INSTRUCTIONS BEFORE FIRST USE.

KEEP THIS MANUAL FOR FUTURE REFERENCE.

KEEP AWAY FROM CHILDREN.

5 Year Limited Warranty

PNEUMATIC

PALM NAILER

1

PRODUCT SPECIFICATIONS

PNEUMATIC PALM NAILER

Nail length 3”-3 1/2” (50-90mm)

Nail size 3 1/2” (90mm)

Recommended operating pressure 70-100 psi (4.8-7 bar)

Air inlet 1/4” (6.4mm) 18 NPT

Weight 0.8 lbs. oz (0.37KG)

Average air consumption 0.2 CFM /cycle @ 90 psi

NEED ASSISTANCE?

Call us on our toll- free customer support line:

1-866-349-8665 (Monday through Friday 9am – 5pm Eastern Standard Time)

Note these instructions pertain to the tool only. Please refer to your

compressors operators manual and follow the manufacturers instructions.

• Technical questions

• Replacement parts

• Parts missing from package

*Please note (where the ¼” NPT connecter is not already installed on the tool) your

tool may be shipped with a black plastic cap installed in the air inlet. Pry the cap

out prior to installing the ¼” NPT connector.

1282 208

PNEUMATIC PALM NAILER

2

TABLE OF CONTENTS

Product Specifications................................................................................... 1

Table of Contents........................................................................................... 2

Safety Guidelines ..................................................................................... 3-6

Symbols ....................................................................................................... 7

Tool Specific Warnings .................................................................................. 8

............................................................ 9

Know Your Pneumatic Palm Nailer

.......................................................................... 10-12

Important Information

.......................................................................... 13-14

Operating Instructions

Maintenance

Troubleshooting

Exploded View

............................................................................................. 15

Parts List .....................................................................................................

............................................................................................

.......................................................................................... 16

Warranty......................................................................................................

17

18

19

3

SAFETY GUIDELINES

DANGER! Potential hazard that will result in serious injury or loss of life.

WARNING:

WARNING! Potential hazard that could result in serious injury or loss of life.

CAUTION! Potential hazard that may result in moderate injury or damage to

equipment.

Note - The word " Note " is used to inform the reader of something he / she needs to

know about the tool.

This manual contains information that relates to PROTECTING PERSONAL SAFETY

and PREVENTING EQUIPMENT PROBLEMS. It is very important to read this manual

carefully and understand it thoroughly before using the product. The symbols listed

below are used to indicate this information.

These precautions are intended for the personal safety of the user and others working

with the user. Please take time to read and understand them.

PERSONAL SAFETY

Do not use oxygen or any other combustible or

bottled gas to power air-powered tools. Failure

to observe this warning can cause explosion

and serious personal injury or death.

Use only the compressed air to power the

air-powered tools. Use a minimum of 25’

(7.6 m) of hose to connect the tool to the

compressor. Failure to comply will result in

serious injury or loss of life.

•

Risk of electric shock: Do not expose a compressor to rain.

Store it indoors. Disconnect the compressor from power

source before servicing. Compressor must be grounded. Do

not use grounding adaptors.

•

Risk of personal injury: Do not direct compressed air from the

air hose towards the user or other personnel.

•

Oxygen

Hydrogen

Explosive

Combustible

SYMBOL MEANING

1282 208

PNEUMATIC PALM NAILER

4

DANGER!

Keep children away from the work area. Do not allow children to handle

power tools.

Do not use this tool in the presence of flammable liquids or gases. Sparks

that are created during use may ignite gases.

Keep air hose away from heat, oil, and sharp edges. Check air hose for wear

before each use and ensure that all connections are proper.

Always ensure that the workpiece is firmly secured leaving both hands free

to control the tool.

Always ensure that the tool has stopped before putting it down after use, for

safety purposes and to prevent possible damage to the tool/user.

Keep proper footing at all times in order to ensure correct balance.

Always assume that the tool contains fasteners.

Do not point the tool toward yourself or anyone else.

•

•

•

•

•

•

•

•

Risk of inhalation: Never directly inhale the air produced by the

compressor.

•

Risk of bursting: Do not adjust the pressure switch or safety

valve for any reason. They have been preset at the factory for

this compressor’s maximum pressure Tampering with the

pressure switch or the safety valve may cause personal injury

or property damage.

•

Risk of burns. The pump and the manifold generate high

temperatures. In order to avoid burns or other injuries, do not

touch the pump, the manifold, or the transfer tube while the

compressor is running. Allow the parts to cool down before

handling or servicing. Keep children away from the compressor

at all times.

•

Risk of bursting: Make sure the regulator is

adjusted so that the compressor outlet

pressure is set lower than the maximum

operating pressure of the tool. Before

starting the compressor, pull the ring on the

safety valve to make sure the valve moves

freely. Drain water from tank after each use.

Do not weld or repair tank. Relieve all

pressure in the hose before removing or

attaching accessories.

•

SYMBOL MEANING

5

WARNING!

Do not allow unskilled or untrained individuals to operate the air tool.

Do not use the tool for any task other than that it is designed to perform.

Locate the compressor in a well-ventilated area for cooling, and a minimum

of 12” (31 cm) away from the nearest wall.

Protect the air hose and the power cord from damage and puncture. Inspect

them for weak or worn spots every week and replace them if necessary.

Always wear hearing protection when using the air compressor. Failure to do

so may result in hearing loss.

Do not carry the compressor while it is running.

Do not operate the compressor if it is not in a stable position.

Do not operate the compressor on a rooftop or an elevated position that

could allow the unit to fall or be tipped over.

Always replace a damaged gauge before operating the unit again.

Do not connect the tool to a compressed air source with a pressure output

that is higher than 120psi.

•

•

•

•

•

•

•

•

•

•

CAUTION!

Always ensure that the tool has stopped before disconnecting the air supply.

Do not wear watches, rings, bracelets, or loose clothing when using any

air- powered tool.

Do not overload the tool. Allow the tool to operate at its optimum speed for

maximum eciency.

Do not use a tool that is leaking air, that has missing or damaged parts, or

that requires repairs. Verify that all screws are securely tightened.

For optimal safety and tool performance, inspect the tool before every usage,

in order to ensure free movement of the trigger, safety mechanisms, and

springs. Always keep your air tool clean and lubricated. Daily lubrication is

essential to avoid internal corrosion and possible failures.

Ensure the floor is not slippery and wear non-slip shoes. Floors should be

kept clean and clear.

Always follow all workshop safety rules, regulations, and conditions when

using the tool and keep the work area clean.

Carry the tool by the handle only, keeping fingers away from the trigger. Do

not carry the tool by the hose, magazine, or any other parts.

Do not use the tool near or below freezing point, as doing so may cause tool

failure. Do not store the tool in a freezing environment to prevent ice

formation on the tools operating valves, as doing so may cause tool failure.

Handling and storage of oil: Use with adequate ventilation. Avoid contact of

oil with eyes, skin, and clothing. Avoid breathing spray or mist. Store in a

tightly closed container in a cool, dry, well-ventilated area free from

Incompatible substances.

Tripping hazard. The air hose may become a tripping hazard when it is

placed in the work area. Use care when walking in the work area.

•

•

•

•

•

•

•

•

•

•

•

1282 208

PNEUMATIC PALM NAILER

6

CAUTION!

Disconnect tool from the air supply and turn o the

compressor before performing any maintenance or

changing accessories, when clearing a jammed

fastener, when the tool is not in use, when it is being

handed to another person, and when it is left

unattended. Failure to comply may result in moderate

injury or damage to equipment.

•

Use safety goggles and ear protection: Wear safety

glasses with side shields when operating the

tool/compressor and verify that others in the work

area are also wearing safety glasses. Safety glasses

must conform to American National Standards

Institute (ANSI Z87. 1) requirements and must

provide protection from flying particles from the front

and the sides.

Air-powered tools are loud, and the sound can cause hearing damage.

Always wear ear protection to prevent hearing damage and loss. Failure to

comply may result in moderate injury.

Note: Recycle unwanted materials rather than disposing of them as waste. Sort the

tools, hoses, and packaging in specific categories and take to the local recycling

centre or dispose of in an environmentally safe way.

•

7

1282-208

PNEUMATIC PALM NAILER

8

Do not disconnect or reconnect the air hose with the tool pressed or with a

fastener in the guide. The tool may fire when it is reconnected to the air

supply.

•

TOOL SPECIFIC WARNINGS

DANGER Potential hazard that will result in serious injury or death.

Keep hands and other parts of the body away from the nail guide during use.

Keep hands and feet and all other parts of the body at least 8” (20cm) away

from the firing head.

Objects in the workpiece can cause serious injury if they cause the fasteners

to be deflected or to be driven away from the point of entry.

Do not drive fasteners on top of a fastener. The fastener may ricochet,

causing serious personal injury.

Do not drive fasteners on scaoldings, ladders, or such similar construction.

Use only fasteners of the proper size and gauge, as specified in this manual.

Do not drive fasteners close to the edge of the workpiece. The workpiece may

split which could allow the fastener to fly free or ricochet and cause serious

personal injury.

•

•

•

•

•

•

WARNING Potential hazard that could result in serious injury or death.

9

KNOW YOUR

PNEUMATIC PALM NAILER

Air inlet plug

Cylinder cover

Turn buckle

Magnet

IMPORTANT INFORMATION

1282 208

PNEUMATIC PALM NAILER

10

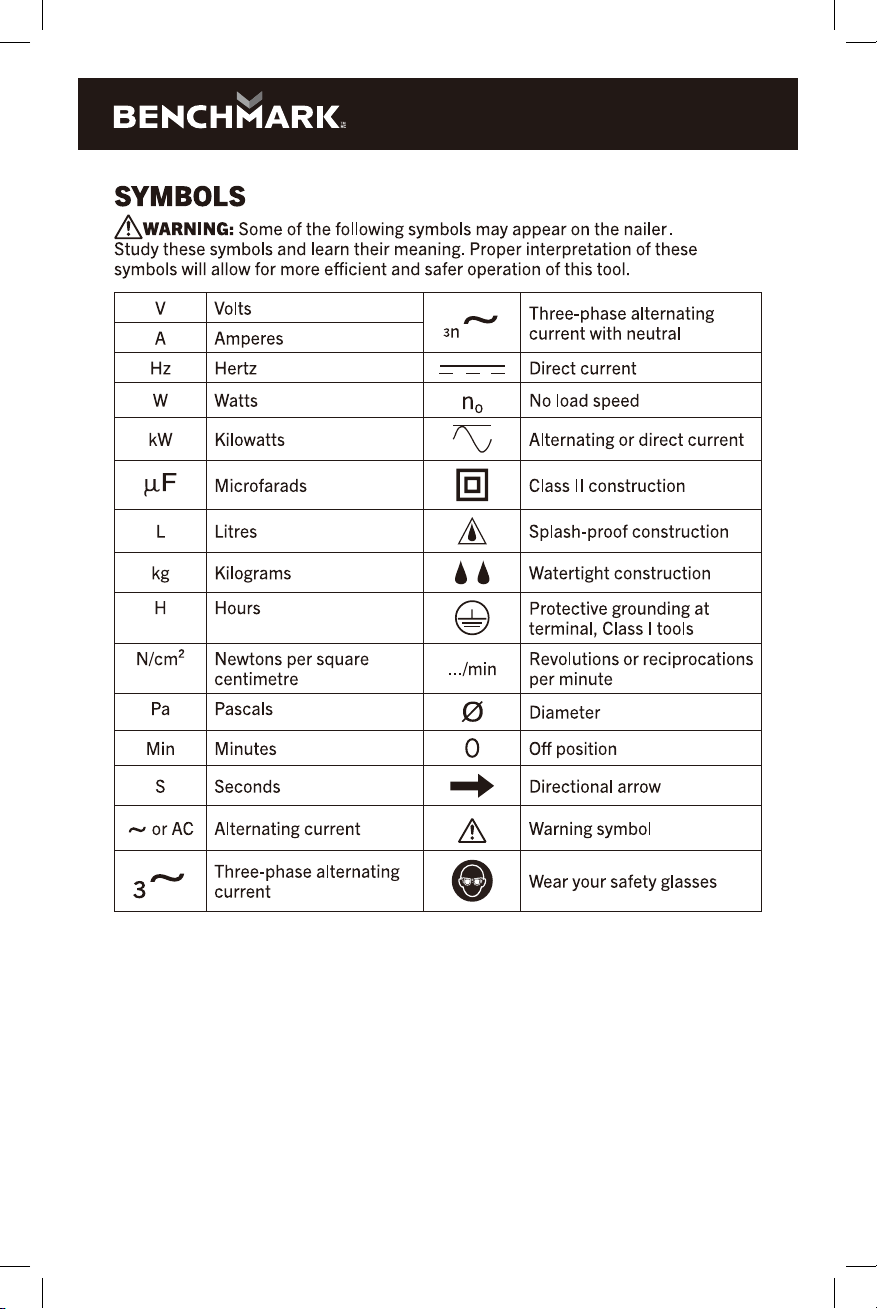

Be sure to use a proper air compressor with air-powered tools. The compressor

should be able to supply a minimal air delivery of 4.0 SCFM @ 90 psi to ensure the

compressor can run continuously with the Pneumatic Palm nailer.

COMPATIBLE COMPRESSORS

GUIDELINES FOR PROPER USE AND OPERATION

Air Compressor

Size & Power

>0.6g/cm3<21/2" (63 mm) brad nails

≥21/2" (63 mm) brad nails

<21/2" (63 mm) brad nails

≥21/2" (63 mm) brad nails

90 psi

100 psi

80 psi

90 psi

≤0.6g/cm3

Wood density Nail size Compressor air pressure

4 – 5 Gallons Light-duty and

intermittent use

Light-duty and

intermittent use

Light-duty and

intermittent use

6 – 11 Gallons Light-duty and

intermittent use

Heavy-duty and

continuous use

Heavy-duty and

continuous use

15+ Gallons Medium-duty and

intermittent use

Heavy-duty and

continuous use

Heavy-duty and

continuous use

1 1/2 – 2 HP 2 1/2 HP 3 HP and more

Air system

Always use clean, dry, regulated, compressed air at 70 to 100 psi (5 to 7 bar).

Do not exceed the maximum or minimum pressures. Operating the tool at the

wrong pressure (too low or too high) will cause excessive noise or rapid wear.

•

11

WARNING! Potential hazard that could result in serious injury or loss of life.

• Do not use the tool if it is not in proper working order.

• Do not use oxygen or any other combustible or bottled gas to power this tool.

• Do not use this tool in the presence of any flammable liquids or gases.

• Keep hands and other parts of the body away from the firing head during use.

• Do not point the tool towards the operator or other people.

• Do not attempt to clear a jammed nail when the air hose is connected.

• Do not drive a nail on top of an existing nail. Failure to comply could lead to

serious injury or loss of life.

No. Description No. Description

Pneumatic Palm nailer

Quick connector

Quick coupler

Air hose

Lubricator

Regulator

Filter

Cut-o valve

Air compressor

1

2

3

4

5

6

7

8

9

Read this Instruction Manual carefully before using the Pneumatic Palm nailer

Read and follow all the safety instructions at the beginning of this manual. Inspect

the Pneumatic Palm nailer prior to each use in order to

– ensure that the proper power source is being used.

– verify that the tool is in proper working order.

•

It is recommended that a filter-regulator-lubricator be used and be located as

close to the tool as possible.

If a filter-regulator-lubricator is not installed, place up to 6 drops of compressor oil

into the air inlet plug before each use.

•

•

257

1

33

6

8

9

4

WARNING! Potential hazard that could result in serious injury or loss of life.

Keep hands and other parts of the body away from the tool’s discharge and

working areas when connecting the air supply. Failure to comply could lead

to serious injury or loss of life.

•

1282 208

PNEUMATIC PALM NAILER

12

WARNING! Potential hazard that could result in serious injury or loss of life.

• The use of any other types of nails will cause the nailer to jam and could lead

to serious injury or loss of life.

This nailer can be used with a variety of shank types (e.g., ring, smooth, spiral) and

a variety of coatings or nail compositions (e.g., Electro, mechanical, hot-dipped

galvanized or stainless steel, etc.).

Nails (14 gauge)

ACCEPTABLE FASTENERS

This Pneumatic Palm nailer drives 90 mm (3 1/2").

If a filter-regulator-lubricator is installed, keep the air filter clean. A dirty filter will

reduce the air pressure to the tool, which will cause a reduction in power,

eciency, and general performance.

For optimal performance, install a quick connector to the tool and a quick coupler

on the hose, if applicable.

Verify that all of the connections in the air supply system are sealed in order to

prevent air leakage.

•

•

•

up to

3 1/2”

13

DANGER! Potential hazard that will result in serious injury or loss of life.

• Do not point the tool towards the operator or other people while changing

the nails or after loading the nail.

• Do not hold the tool with the nail guide pressed while changing nails.

Failure to comply will lead to serious injury or loss of life.

Plug in compressor, turn it on, set the pressure regulator to 40 psi, attach one

end of the air hose to the compressor and the other end of the air hose (1) to the

tool (2) (fig A). page 7 (wood density chart)

OPERATING INSTRUCTIONS

Loading nails

fig A fig B

1.

Grip the base of the tool in one hand. Hold a nail by the shaft (1), and place the

flat head into the nail guide (2). The nail will be held in place by the magnet (fig B).

2.

Place the pointed end of the nail (1) on the workpiece (2). Keep your free hand

away from the tool and the nail (fig C).

3.

This Pneumatic Palm nailer is an air-powered tool with a new and advanced design,

compact structure, and superior technology which enables the tool to drive nails into

the workpiece without a trigger. The tool is dexterous, safe, and reliable to operate.

The tool is ideal for nailing at tight corners, toe-nailing, joist hanger installations, etc.

1

21

2

1282 208

PNEUMATIC PALM NAILER

14

CAUTION! Potential hazard that may result in moderate injury or damage to

equipment.

Add some drops of pneumatic tool oil into the air inlet for lubrication before

use. Failure to comply may result in moderate injury or damage to equipment.

fig C fig D

Press the tool straight down. This will trigger the tool and cause it to hammer

the nail. Continue pressing down until the nail is driven all the way in (fig D).

4.

•

WARNING! Potential hazard that could result in serious injury or loss of life.

Do not operate the tool if the nails are not loaded, as doing so may damage

the tool.

Load the correct type of nails only. Failure to comply could lead to serious

injury or loss of life.

•

•

When operating any air-powered tool below freezing temperature. Do not use below

14°F(-10°C) freezing temperature.

Cold weather operation

Verify the compressor tanks have properly drained prior to use.

Keep tools as warm as possible using any safe,convenient method.

Place up to 6 drops of pneumatic tool oil into the tool’s air inlet.

Adjust the air pressure to 80 psi or lower.

Actuate the tool 5 to 6 times into a scrap wooden piece in order to lubricate the

O-rings.

Adjust the air pressure to the operating level (do not exceed 120 psi) and use the

tool normally.

Relubricate the tool, as described in the maintenance section.

Drain the compressor tanks at least once per day.

Do not store tools in a cold weather environment to prevent frost or ice formation on

the tools operating valves and mechanisms that could cause tool failure. Store in a

dry place.

•

•

•

•

•

•

•

•

1

2

1

15

DANGER!

Disconnect the tool from the air compressor before maintenance/service,

adjusting, cleaning jams, reloading, and when it is not in use. Repairs must be

performed by a qualified service technician only. Failure to comply will lead to

serious injury or loss of life.

MAINTENANCE

Lubrication: If the Pneumatic Palm nailer and the compressor are not equipped

with an in-line lubrication system, place 2 to 6 drops of pneumatic tool oil into

the air inlet before each work day or after every 2 hours of continuous use,

depending on the characteristics of the workpiece and type of nails used.

•

Air-operated tools must be inspected periodically and worn or broken parts must

be replaced in order to keep tools operating safely and eciently.

Inspect and replace worn or damaged O-rings, seals, etc. Tighten all screws and

caps frequently in order to help prevent personal injury.

Inspect the spring and safety mechanism for free movement on a regular basis in

order to ensure that the safely system is fully functional. Verify that no parts are

loose or missing and no parts are sticking or jammed.

Keep the nail guide clean and free of any dirt or abrasive particles.

•

•

•

•

MAINTENANCE

REQUIRED

TOOLS OR

MATERIALS

REQUIRED

Each Use or

every 2 Hrs. Monthly As

Needed

DESCRIPTION

MAXIMUM SERVICE INTERVAL

General inspection –

free movement

Trigger, spring,

safety mechanism

In-depth inspection Worn or broken

parts

Replace worn or

broken parts

Lubrication See below Pneumatic tool

oil

None X

X X

X

X

Note: Do not store the tool anywhere temperatures will fall below freezing.

1282 208

PNEUMATIC PALM NAILER

16

PROBLEM POSSIBLE CAUSES SOLUTIONS

Air leakage. 1. O-rings are worn or damaged.

2. Screws are loose.

1. Inspect and replace the O-rings.

2. Tighten the screws.

Attack strength

is not enough.

1. Air pressure is not in specified

range.

2. The O-ring beside slip set is

worn.

1. Adjust the air pressure to specified

range.

2. Replace the O-ring.

The tool does not

drive out the nails

when connected to

air supply.

1. Insucient air supply.

2. O-rings are worn or damaged.

1. Adjust the air pressure.

2. Inspect and replace the O-rings.

DANGER! If any of the following symptoms appear while the tool is in use, turn

it o and disconnect it from the air supply immediately. Failure to comply will

lead to serious injury or loss of life.

Disconnect the tool from the air supply before making any adjustments.

Repairs must be performed by a qualified service technician only.

When replacing O-rings or cylinder, lubricate the tool with pneumatic tool oil

before assembly.

TROUBLESHOOTING

17

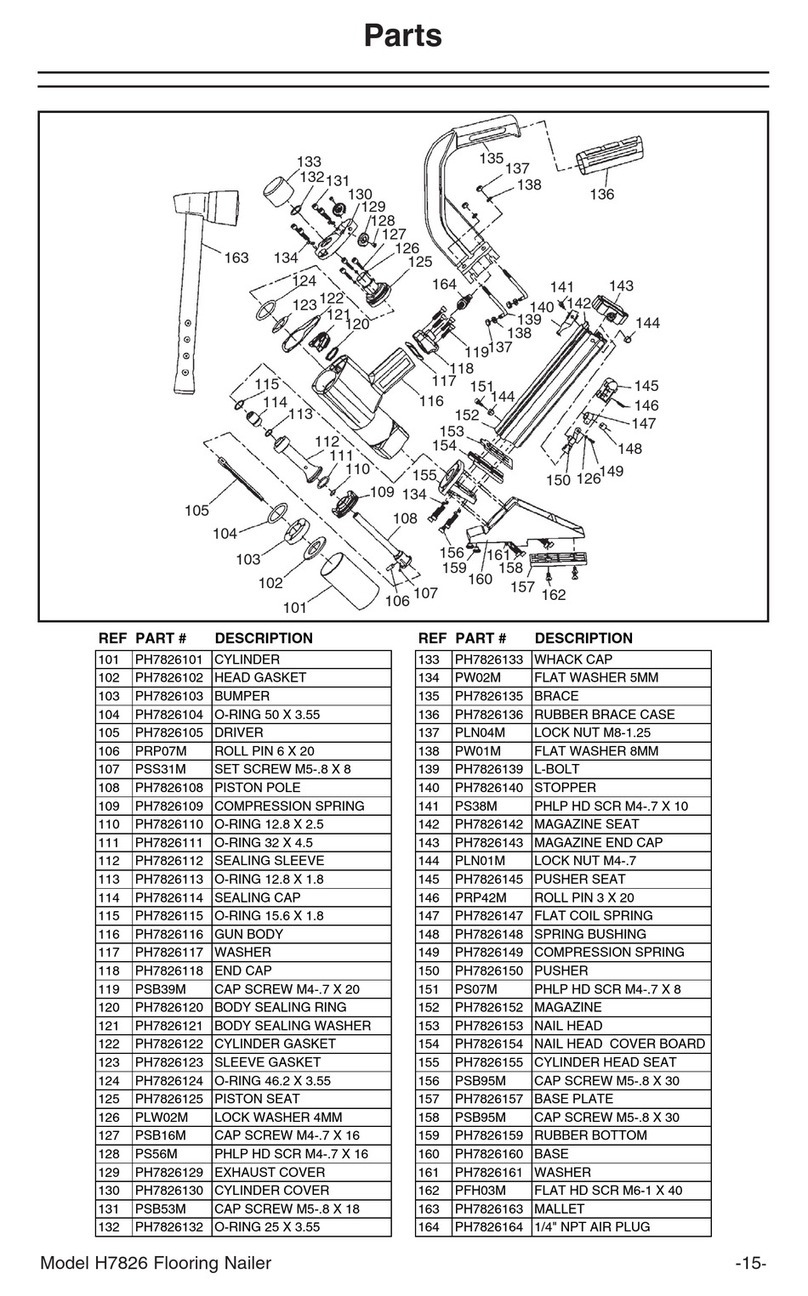

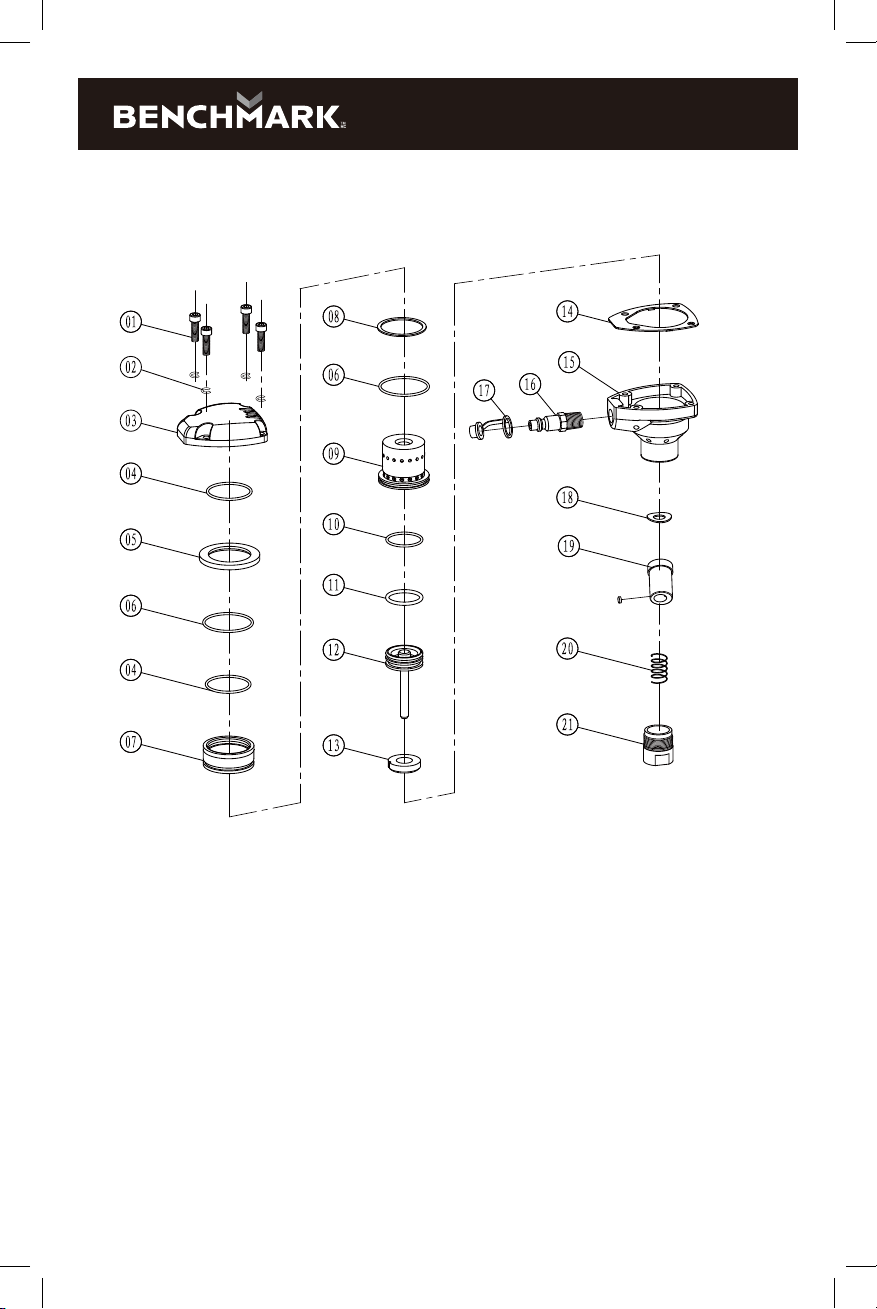

EXPLODED VIEW

1282 208

PNEUMATIC PALM NAILER

18

PARTS LIST

WARNING: When servicing, use only original equipment replacement parts.

The use of any other parts may create a safety hazard or cause damage to the tool.

Any attempt to repair or replace electrical parts on this tool may create a safety

hazard unless repairs are performed by a qualified technician. For more information,

call the Toll-free Helpline, at 1-866-349-8665.

Always order by part number.

Key # Part # Part Name Quantity

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

03.04.05.032

03.04.05.263-03

03.04.28.041-02

03.04.01.133

03.04.06.134

03.04.01.143

03.04.29.197

03.04.25.063

03.04.27.132

03.04.01.114

03.04.01.291

03.04.39.01.210

03.04.06.058

03.04.07.031

03.04.26.054

03.04.40.169

03.04.29.162

03.04.19.168

03.04.29.196

03.04.34.080

03.04.29.195

Bolt M5x20

Spring washer 5

Cylinder cover

O-ring 33.6x1.8

Cylinder washer

O-ring 37.5x1.8

Slip set

Sealing washer

Cylinder

O-ring 26.5x1.8

O-ring 25x2.4

Piston

Bumper

Washer

Gun body

Plug

Plug cover

Elasticity washer

Fix set

Spring

Screw cover

4

4

1

2

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

WARRANTY

BENCHMARK WARRANTY

If this Benchmark tool fails due to a defect in material or workmanship within five

years from the date of purchase, return it to any Home Hardware store with the

original bill of sale for exchange. 3-year warranty for the battery and charger. This

warranty does not include expendable parts including but not limited to blades,

brushes, belts, light bulbs. This warranty covers defects in material or workmanship

only. It does not cover normal wear and tear, failure due to abuse/misuse, or defects

caused by careless or accidental mishandling. If this Benchmark product is used for

commercial or rental purposes, this warranty does not apply.

19

Table of contents

Other Benchmark Nail Gun manuals

Popular Nail Gun manuals by other brands

Makita

Makita AF550H instruction manual

Makita

Makita XTP02 instruction manual

Porter-Cable

Porter-Cable DA250A instruction manual

Clarke

Clarke Contractor CFN34 Operating & maintenance instructions

Campbell Hausfeld

Campbell Hausfeld NB004200 operating instructions

Power Fist

Power Fist 8052409 owner's manual

Aircat

Aircat 6700-5-336 Operating instructions, parts list & warranty

Central Pneumatic

Central Pneumatic 93680 Assembly and operating instructions

Central Pneumatic

Central Pneumatic Contractor 97526 Assembly and operation instructions

Grizzly

Grizzly 1 1/4" Brad Nailer T20568 owner's manual

GreenWorks

GreenWorks NLG401 Operator's manual

Everwin

Everwin FSN130B Operation and maintenance manual