Benchmark 1282 309 User manual

WEAR CSA APPROVED

EYE PROTECTION

WEAR EAR

PROTECTION

WEAR A

FACE MASK

READ ALL INSTRUCTIONS BEFORE FIRST USE.

KEEP THIS MANUAL FOR FUTURE REFERENCE.

KEEP AWAY FROM CHILDREN.

5 Year Limited Warranty

PNEUMATIC COIL

ROOFING NAILER

1

PRODUCT SPECIFICATIONS

PNEUMATIC COIL ROOFING NAILER

Maximum working pressure 120 PSI

Air inlet size 1/4" NPT

Activation mode contact actuation

15°

Magazine angle

120pcs

Magazine Capacity

70-110 PSI

1/4" (6.35mm) or 3/8" (9.5mm)

Working pressure

Recommended hose

¼” NPT

Air Inlet

white mineral oil 16#

2 CFM @ 90 PSI

Recommended lubricant

Average Air Consumption

6.1lb (2.8kg)

Weight (without fasteners)

Fastener Type Round Head Roofing Nails 3/4” to 1-3/4”

Long, flat wire welded

NEED ASSISTANCE?

Call us on our toll- free customer support line:

1-866-349-8665 (Monday through Friday 9am – 5pm Eastern Standard Time)

• Technical questions

• Replacement parts

• Parts missing from package

Note these instructions pertain to the tool only. Please refer to your

compressors operator’s manual and follow the manufacturers instructions.

*Please note (where the ¼” NPT connecter is not already installed on the tool) your

tool may be shipped with a black plastic cap installed in the air inlet. Pry the cap

out prior to installing the ¼” NPT connector.

1282 309

PNEUMATIC COIL ROOFING NAILER

2

TABLE OF CONTENTS

Product Specifications................................................................................... 1

Table of Contents........................................................................................... 2

Safety Guidelines ..................................................................................... 3-6

Symbols ....................................................................................................... 7

Tool Specific Warnings .................................................................................. 8

..................................................... 9

Know Your Pneumatic Coil Roofing Nailer

....................................................................... 10-14

Assembly and Operating

Maintenance

Troubleshooting

Exploded View

........................................................................................... 15

Parts List .............................................................................................

............................................................................................

.................................................................................... 15-16

Warranty......................................................................................................

17

18-21

22

3

SAFETY GUIDELINES

DANGER! Potential hazard that will result in serious injury or loss of life.

WARNING:

WARNING! Potential hazard that could result in serious injury or loss of life.

CAUTION! Potential hazard that may result in moderate injury or damage to

equipment.

Note - The word " Note " is used to inform the reader of something he / she needs to

know about the tool.

This manual contains information that relates to PROTECTING PERSONAL SAFETY

and PREVENTING EQUIPMENT PROBLEMS. It is very important to read this manual

carefully and understand it thoroughly before using the product. The symbols listed

below are used to indicate this information.

These precautions are intended for the personal safety of the user and others working

with the user. Please take time to read and understand them.

PERSONAL SAFETY

Do not use oxygen or any other combustible or

bottled gas to power air-powered tools. Failure

to observe this warning can cause explosion

and serious personal injury or death.

Use only the compressed air to power the

air-powered tools. Use a minimum of 25’

(7.6 m) of hose to connect the tool to the

compressor. Failure to comply will result in

serious injury or loss of life.

•

Risk of electric shock: Do not expose a compressor to rain.

Store it indoors. Disconnect the compressor from power

source before servicing. Compressor must be grounded. Do

not use grounding adaptors.

•

Risk of personal injury: Do not direct compressed air from the

air hose towards the user or other personnel.

•

Oxygen

Hydrogen

Explosive

Combustible

SYMBOL MEANING

1282 309

PNEUMATIC COIL ROOFING NAILER

4

DANGER!

Keep children away from the work area. Do not allow children to handle

power tools.

Do not use this tool in the presence of flammable liquids or gases. Sparks

that are created during use may ignite gases.

Keep air hose away from heat, oil, and sharp edges. Check air hose for wear

before each use and ensure that all connections are proper.

Always ensure that the workpiece is firmly secured leaving both hands free

to control the tool.

Always ensure that the tool has stopped before putting it down after use, for

safety purposes and to prevent possible damage to the tool/user.

Keep proper footing at all times in order to ensure correct balance.

Always assume that the tool contains fasteners.

Do not point the tool toward yourself or anyone else.

•

•

•

•

•

•

•

•

Risk of inhalation: Never directly inhale the air produced by the

compressor.

•

Risk of bursting: Do not adjust the pressure switch or safety

valve for any reason. They have been pre-set at the factory for

this compressor’s maximum pressure Tampering with the

pressure switch or the safety valve may cause personal injury

or property damage.

•

Risk of burns. The pump and the manifold generate high

temperatures. In order to avoid burns or other injuries, do not

touch the pump, the manifold, or the transfer tube while the

compressor is running. Allow the parts to cool down before

handling or servicing. Keep children away from the compressor

at all times.

•

Risk of bursting: Make sure the regulator is

adjusted so that the compressor outlet

pressure is set lower than the maximum

operating pressure of the tool. Before

starting the compressor, pull the ring on

the safety valve to make sure the valve

moves freely. Drain water from tank after

each use. Do not weld or repair tank.

Relieve all pressure in the hose before removing or attaching

accessories.

•

SYMBOL MEANING

5

WARNING!

Do not allow unskilled or untrained individuals to operate the air tool.

Do not use the tool for any task other than that it is designed to perform.

Locate the compressor in a well-ventilated area for cooling, and a minimum

of 12” (31 cm) away from the nearest wall.

Protect the air hose and the power cord from damage and puncture. Inspect

them for weak or worn spots every week and replace them if necessary.

Always wear hearing protection when using the air compressor. Failure to do

so may result in hearing loss.

Do not carry the compressor while it is running.

Do not operate the compressor if it is not in a stable position.

Do not operate the compressor on a rooftop or an elevated position that

could allow the unit to fall or be tipped over.

Always replace a damaged gauge before operating the unit again.

Do not connect the tool to a compressed air source with a pressure output

that is higher than 120psi.

•

•

•

•

•

•

•

•

•

•

CAUTION!

Always ensure that the tool has stopped before disconnecting the air supply.

Do not wear watches, rings, bracelets, or loose clothing when using any

air- powered tool.

Do not overload the tool. Allow the tool to operate at its optimum speed for

maximum eciency.

Do not use a tool that is leaking air, that has missing or damaged parts, or

that requires repairs. Verify that all screws are securely tightened.

For optimal safety and tool performance, inspect the tool before every usage,

in order to ensure free movement of the trigger, safety mechanisms, and

springs. Always keep your air tool clean and lubricated. Daily lubrication is

essential to avoid internal corrosion and possible failures.

Ensure the floor is not slippery and wear non-slip shoes. Floors should be

kept clean and clear.

Always follow all workshop safety rules, regulations, and conditions when

using the tool and keep the work area clean.

Carry the tool by the handle only, keeping fingers away from the trigger. Do

not carry the tool by the hose, magazine, or any other parts.

Do not use the tool near or below freezing point, as doing so may cause tool

failure. Do not store the tool in a freezing environment to prevent ice

formation on the tools operating valves, as doing so may cause tool failure.

Handling and storage of oil: Use with adequate ventilation. Avoid contact of

oil with eyes, skin, and clothing. Avoid breathing spray or mist. Store in a

tightly closed container in a cool, dry, well-ventilated area free from

Incompatible substances.

Tripping hazard. The air hose may become a tripping hazard when it is

placed in the work area. Use care when walking in the work area.

•

•

•

•

•

•

•

•

•

•

•

1282 309

PNEUMATIC COIL ROOFING NAILER

6

CAUTION!

Disconnect tool from the air supply and turn o the

compressor before performing any maintenance or

changing accessories, when clearing a jammed

fastener, when the tool is not in use, when it is being

handed to another person, and when it is left

unattended. Failure to comply may result in

moderate injury or damage to equipment.

•

Use safety goggles and ear protection: Wear safety

glasses with side shields when operating the tool/

compressor and verify that others in the work area

are also wearing safety glasses. Safety glasses must

conform to American National Standards Institute

(ANSI Z87. 1) requirements and must provide

protection from flying particles from the front and

the sides.

Air-powered tools are loud, and the sound can cause hearing damage.

Always wear ear protection to prevent hearing damage and loss. Failure to

comply may result in moderate injury.

Note: Recycle unwanted materials rather than disposing of them as waste. Sort the

tools, hoses, and packaging in specific categories and take to the local recycling

centre or dispose of in an environmentally safe way.

•

7

1282 309

PNEUMATIC COIL ROOFING NAILER

8

Do not disconnect or reconnect the air hose with the tool pressed or with a

fastener in the guide. The tool may fire when it is reconnected to the air

supply.

•

TOOL SPECIFIC WARNINGS

DANGER Potential hazard that will result in serious injury or death.

Keep hands and other parts of the body away from the nail guide during use.

Keep hands and feet and all other parts of the body at least 8” (20cm) away

from the firing head.

Objects in the workpiece can cause serious injury if they cause the fasteners

to be deflected or to be driven away from the point of entry.

Do not drive fasteners on top of a fastener. The fastener may ricochet,

causing serious personal injury.

Do not drive fasteners on scaoldings, ladders, or such similar construction.

Use only fasteners of the proper size and gauge, as specified in this manual.

Do not drive fasteners close to the edge of the workpiece.The workpiece may

split which could allow the fastener to fly free or ricochet and cause serious

personal injury.

•

•

•

•

•

•

WARNING Potential hazard that could result in serious injury or death.

9

KNOW YOUR

PNEUMATIC COIL ROOFING NAILER

Coil Magazine

Guide base

Canister latch

Depth

adjustment

wheel

Trigger

Air quick coupler

Exhaust vent

ASSEMBLY AND OPERATING

1282 309

PNEUMATIC COIL ROOFING NAILER

10

Be sure to use a proper air compressor with air powered tools. The compressor

should be able to supply a minimal air deliver of 2 CFM @ 90 PSI to ensure the

compressor can run continuously with the tool.

GUIDELINES FOR PROPER USE AND OPERATION

COMPATIBLE COMPRESSORS

Nail length: ¾-1-3/4”; Magazine capacity: 120pcs

Acceptable Fasteners

• Uses 15-degree 19mm (3/4”) to 45mm (1-3/4”) wire collated roofing nails.

• Has steel contact safety with dual carbide inserts for less wear.

• Features soft grip for comfort and control.

• Delivers the power to consistently drive nails in the toughest applications.

• Big loading capacity magazine will fasten a full bundle of shingles without reloading.

Description / Features

The Nailer has two firing modes: Single-Sequential actuation for single firing, or

Contact / bump actuation for repetitive, fast firing of nails.

Each mode requires a dierent method of operation:

Single Firing: To operate the tool in this manner, first position the Workpiece

Contact (nose of tool) on the work surface, WITHOUT PULLING THE TRIGGER.

Depress the Workpiece Contact until the Workpiece contact (nose of tool) touches

the work surface and then pull the trigger to drive a fastener. Do not press the tool

against the work with extra force. Instead allow the tool to recoil o the work

surface to avoid a second, unwanted fastener. Remove your finger from the trigger.

Contact or Bumping actuation mechanism: To operate the tool in this manner, hold

the tool with the Workpiece Contact (nose of tool) pointing towards but not touching

the work surface. Pull the trigger and then tap (bump) the Workpiece Contact

against the work surface using a bouncing motion. Each depression of the

Workpiece Contact will cause a fastener to be driven.

FIRING MODES

WARNING: The use of any other types of fasteners will cause the tool to jam.

Failure to comply could lead to serious injury or loss of life.

11

Always use clean, dry, regulated, compressed air at 5 to 7.5 bar (70 To 110 PSI).

Do not exceed the maximum or minimum pressures. Operating the tool at the wrong

pressure (too low or too high) will cause excessive noise or rapid wear of tool.

AIR SYSTEM

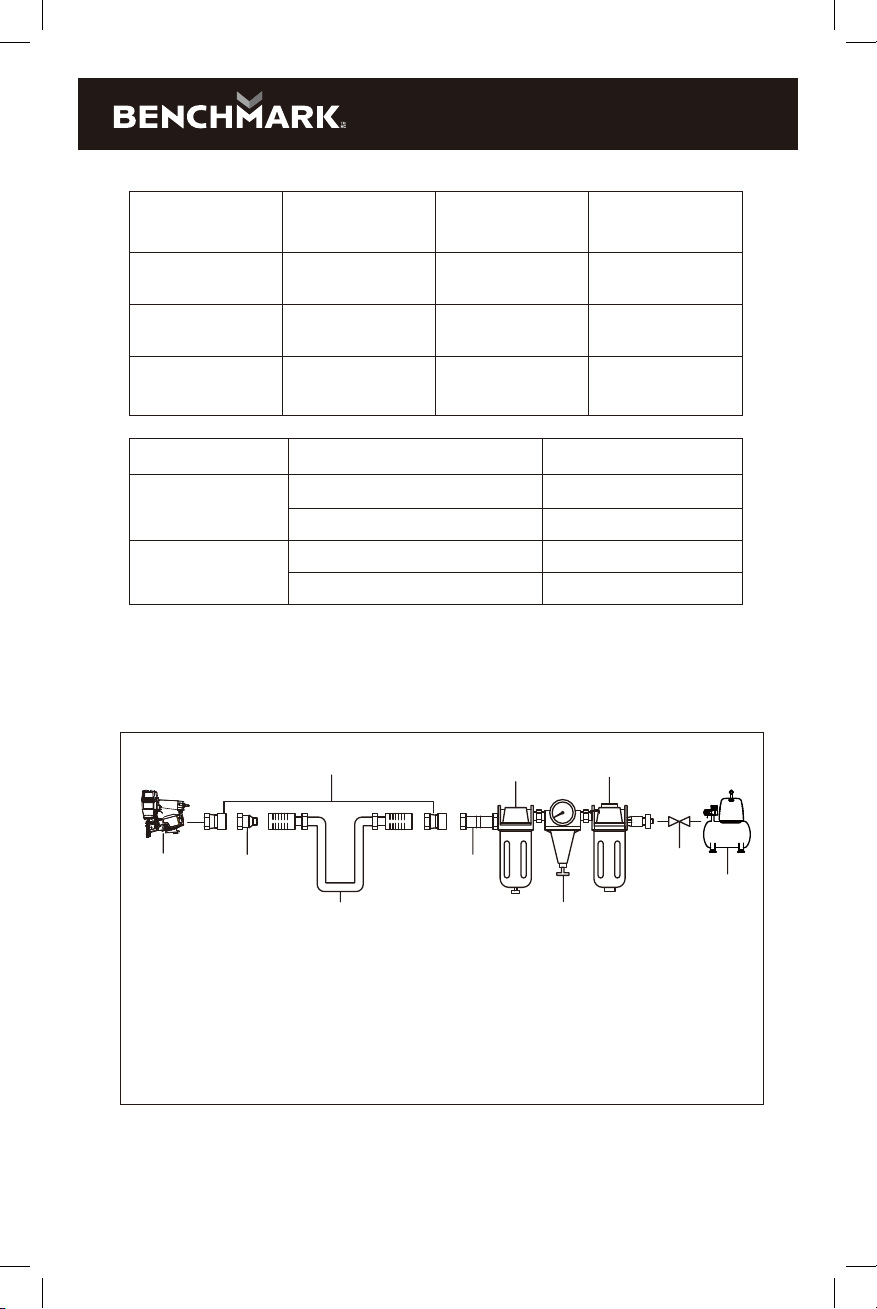

No. Description No. Description

Pneumatic coil roofing nailer

Quick connector

Quick coupler

Air hose

Lubricator

Regulator (0 to 8.5 bar)

Filter

Cut-o valve

Air compressor

1

2

3

4

5

6

7

8

9

257

133

6

8

9

4

Air Compressor

Size & Power

>0.6g/cm3<1/2" (38 mm) T nails

≥1/2" (38 mm) T nails

<1/2" (38 mm) T nails

≥1/2" (38 mm) T nails

90 psi

110 psi

70 psi

100 psi

≤0.6g/cm3

Wood density Nail size Compressor air pressure

4 - 5 Gallons Light duty and

intermittent use

Light duty and

intermittent use

Light duty and

intermittent use

6 - 11 Gallons Light duty and

intermittent use

Medium duty and

intermittent use

Medium duty and

intermittent use

15+ Gallons Medium duty and

intermittent use

Heavy-duty and

continuous use

Heavy duty and

continuous use

1 1/2–2 HP 2 1/2 HP 3+ HP

1282 309

PNEUMATIC COIL ROOFING NAILER

12

Please read and observe these operating instruction before using the tool. Basic

safety measures should always be strictly followed to protect against damage to the

equipment and personal injury to the user or other people working in the vicinity of

operation.

Connection to the compressed air system

Ensure that the pressure supplied by the compressed air system does not exceed

the maximum allowable pressure of the tool. Set the air pressure initially to the

lower value of the recommended allowable pressure (see Product Specifications).

Empty the magazine to prevent a fastener from firing.

Connect the tool to the compressed air supply using a suitable pressure hose

equipped with quick-action connectors.

Check for proper functioning by applying the nose of the tool to a piece of wood

and actuating the trigger once or twice.

Load nails into tool.

PREPARING THE TOOL FOR USE

•

•

•

•

•

DANGER! Potential hazard that will result in serious injury or loss of life.

• Disconnect the tool from the compressed air source before loading nails.

• Do not point the tool towards the operator or other people while changing nails.

• Do not hold the tool with the trigger pressed while changing the nails. Failure

to comply will lead to serious injury or loss of life.

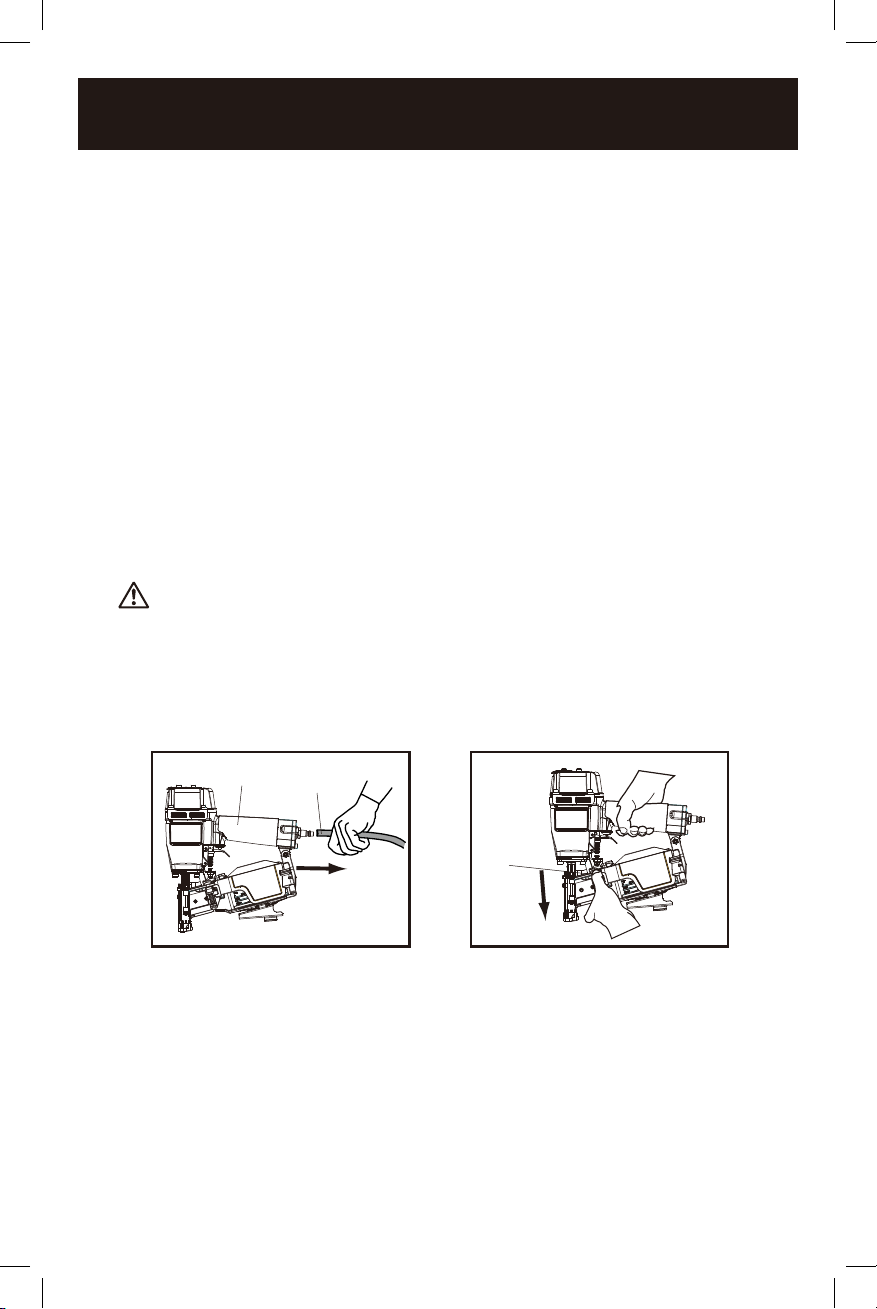

Disconnect the tool (1) from the air supply (2) (fig A).

Loading nails

1.

fig A fig B

12

1

Take hold of the nailer with one hand and use the other hand to press the

Canister latch (1) down (fig B), then open to the left and open the magazine to

the right (fig C).

2.

NOTE! Only those fasteners specified under specifications may be used. When

filling the magazine, hold the tool so that the nose is not pointing towards the

operator or any other person or animals.

Insert a strip of nails into the coil magazine. Ensure the points of the nails are

facing down. Be sure to insert the heads of the nails into the channel. Close the

coil magazine and push close the magazine latch (1) until it locks into place. The

tool is now ready for use (fig C).

3.

Plug in compressor, turn it on set the pressure regulator to 90 psi, attach one end

of the air hose to the compressor and the other end of the air hose (1) to the tool

(2). Use plumber’s tape to avoid air leak (fig D).

4.

Test the driving depth using a sample piece of wood before working on the

workpiece. If the nails are being driven too deep or not deep enough, adjust the

regulator in order to provide more or less air pressure, as required.

5.

fig C fig D

1

12

For varying materials, the nail depth can be tool- free adjusted with the depth

adjustment wheel.

Adjusting nail depth

Push the depth adjustment wheel down, while at the same time, turning the depth

adjustment wheel counter- clockwise (with the discharge area of the tool facing

away from the operator).

Increasing nail depth

Push the depth adjustment wheel down, while at the same time, turning the depth

adjustment wheel clockwise (with the discharge area of the tool facing away from

the operator).

Apply the tool to a work piece and actuate the trigger.

Check whether the fastener has been driven into the work piece in accordance with

the requirements, if it is not, then adjust the pressure of the regulator on the

compressor accordingly.

Decreasing nail depth

13

1282 309

PNEUMATIC COIL ROOFING NAILER

14

Any defective or improperly functioning fastener driving tool must immediately be

disconnected from the compressed air supply and passed to a specialist for

inspection.

NOTE:

WARNING: Avoid triggering the fastener driving tool if the magazine is empty.

WARNING: Potential hazard that could result in serious injury or loss of life.

• Always handle nails and package carefully. If nails are dropped, collating plastic

may be broken.

• After nailing:

1) Disconnect air hose from the nailer.

2) Remove all nails from the nailer.

3) Supply 5-10 drops of pneumatic tool lubricant into the air inlet plug on the nailer.

4) Open the petcock on the air compressor tank to drain any moisture.

Only those fasteners specified under product specification may be used when filling

the magazine, hold the tool so that the muzzle is not pointing towards the operator

or any other person or animals.

Filling the magazine

If it is necessary to store the tool for an extended period of time, apply a generous

amount of lubrication before storing. The tool should be allowed to run for

approximately 30 seconds after lubricating in order to ensure that the lubrication is

uniformly distributed throughout the tool.

STORAGE

• Disconnect the air hose from the tool and remove the non-jammed nails from the

tool before clearing a jammed nail.

• The nails are under pressure and failure to comply could cause them to be fired

out of the tool causing serious injury.

• Use pliers or any appropriate tool to remove the jammed nails.

• Reload the nails into the tool magazine.

• Reconnect the air hose to the tool’s air inlet.

• Test fire 3 to 5 nails into a piece of scrap wood in order to ensure a proper operation.

WARNING: Potential hazard that could result in serious injury or loss of life.

• Do not point the tool towards the operator or other people. Serious personal injury

could result if these instructions are not followed.

Clearing a jammed nail

DANGER!Potential hazard that will result in serious injury or loss of life.

MAINTENANCE

If any of the following symptoms appear while the tool is in use, turn it o and

disconnect it from the air supply immediately. Failure to comply will lead to serious

injury or loss of life.

Disconnect the tool from the air supply before making any adjustments. Repairs

must be performed by a qualified service technician only.

The following chart lists common issues and solutions. Please read it carefully and

follow all instructions carefully.

Lubrication: if the tool and the compressor are not equipped with an in-line

lubrication system, place up to 6 drops of pneumatic tool oil into the air inlet before

each use or after every 2 hours of continuous use, depending on the characteristics

of the workpiece and type of fastener used.

Air operated tools must be inspected periodically, and worn or broken parts must be

replaced to ensure that the tools are operating safely and eciently. Inspect and

replace worn or damaged O-rings, seals, etc. Tighten all screws and caps frequently

in order to help prevent personal injury. Keep the magazine of the tool clean and

free of any dirt or abrasive particles.

Note: Do not store the tool anywhere temperatures will fall below freezing.

TROUBLESHOOTING

DANGER!

Disconnect the tool from the air compressor before maintenance/service, adjusting,

cleaning jams, reloading, and when it is not in use. Repairs must be performed by a

qualified service technician only. Failure to comply will lead to serious injury or loss

of life.

15

SYMPTOM POSSIBLE SOLUTIONS

Air leak near top of

tool or in trigger

area

Air leak near

bottom of tool.

1. O-rings in trigger valve are

damaged.

2. Trigger valve heads are

damage.

3. Trigger valve stem, seal, or

O-rings are damaged.

1. Check and replace O-ring.

2. Check and replace.

3. Check and replace trigger valve stem,

seal, or O-ring

1. Loose screws.

2. Worn or damaged O-ring or

bumper.

1. Tighten screws.

2. Check and replace O-ring or bumper.

Air leak between

body and cylinder

cap.

1. Loose screws.

2. Worn or damaged O-ring or

seals.

1. Tighten screw.

2. Check and replace O-ring or bumper.

1282 309

PNEUMATIC COIL ROOFING NAILER

16

Tool skips

fasteners.

1. Worn bumper or damaged

spring.

2. Dirt in front plate.

3. Dirt or damage prevents

fasteners from moving freely in

magazine.

4. Worn or dry O-ring on piston

or lack of lubrication.

5. Cylinder cover seal leaking.

1. Replace bumper or pusher spring.

2. Clean drive channel on front plate.

3. Magazine needs to be cleaned.

4. O-ring need to be replaced. And

lubricate.

5. Replace sealing washer.

Tool jams. 1. Incorrect or damaged

fasteners.

2. Damaged or worn driver guide.

3. Magazine or nose screw loose.

4. Magazine is dirty.

1. Change and use correct fastener.

2. Check and replace the driver.

3. Tighten the magazine.

4. Clean the magazine.

SYMPTOM POSSIBLE SOLUTIONS

Blade driving

fastener too deep.

Tool does not

operate well: can

not drive fastener

or operate

sluggishly.

1. Worn bumper

2. Air pressure is too high.

1. Replace bumper

2. Adjust the air pressure.

1. Inadequate air supply.

2. Inadequate lubrication

3. Worn or damaged O-rings or

seals.

4. Exhaust port in cylinder head

is blocked.

1. Verify adequate air supply.

2. Place 2 or 6 drops of oil into air inlet.

3. Check and replace O-rings or seal.

4. Replace damaged internal parts.

EXPLODED VIEW

17

PARTS LIST

WARNING: When servicing, use only original equipment replacement parts.

The use of any other parts may create a safety hazard or cause damage to the tool.

Any attempt to repair or replace electrical parts on this tool may create a safety

hazard unless repairs are performed by a qualified technician. For more information,

call the Toll-free Helpline, at 1-866-349-8665.

Always order by part number.

Key # Part # Part Name Quantity

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

/

03.04.21.058-01

03.04.05.072

03.04.28.116

03.04.17.151

03.04.16.144

03.04.07.149

03.04.07.150

03.04.40.113

03.04.39.08.014

03.04.01.033

03.04.39.01.224

03.04.01.086

03.04.01.085

03.04.19.215

03.04.27.072

03.04.19.217

03.04.34.087

03.04.01.094

03.04.19.216

03.04.01.095

05.04.33.1126

03.04.26.249-01

/

03.04.01.096

03.04.06.092

03.04.19.218

03.04.07.151

03.04.05.402

/

Exhaust cover

Bolt M5x6

Cylinder cover

Protector

Body guard

Cylinder washer

Trigger valve wasner

Seal plug

Trigger valve assembly

O-ring 30.5x3.5

Piston

O-ring 65x2

O-ring 41.5x2.4

Upper collar

Cylinder

Cylinder sealing washer

Cylinder spring

O-ring 56x2.4

Lower collar

O-ring 47x2.4

Label

Gun body

/

O-ring 43.5x2.65

Bumper

Sealing washer

Gun body washer

Bolt M5x8

/

1

2

1

2

2

1

1

1

1

1

1

3

1

1

1

1

1

1

1

1

1

1

/

1

1

1

1

2

1282 309

PNEUMATIC COIL ROOFING NAILER

18

Key # Part # Part Name Quantity

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

03.04.02.155

03.04.08.199

03.04.17.144

03.04.05.023

03.04.36.295

03.04.05.372

03.04.05.738-01

03.04.39.04.058

03.04.19.236

03.04.29.230

03.04.07.152

03.04.11.097-03

03.04.05.405

03.04.40.170

03.04.29.158

03.04.05.197

03.04.34.088

03.04.01.115

03.04.15.110

03.04.32.115

03.04.01.301

03.04.19.059-01

03.04.40.112

03.04.25.146

03.04.32.059

03.04.15.046

03.04.01.035

03.04.03.018-03

03.04.15.112

03.04.29.144

03.04.01.059

03.04.40.422

03.04.40.413

03.04.01.298

03.04.19.220

03.04.04.170

03.04.29.164

Guard

Nose

Nose guard

Bolt M5x25

Safety shelf spring

Bolt M5x16

Nut M5

Safety shelf assembly

Washer d=5

Gun body grip

End cover washer

End cover

Bolt M5x20

Air inlet plug

Air inlet plug case

Pin 3x30

Plunger spring

O-ring 3.55x2

Plunger

Valve bushing

O-ring 11.8x1.5

Rectangle washe

Ball

Valve bushing fix plate

Trigger valve seat

Trigger valve pole

O-ring 2.8x1.8

Trigger

Pushing lever

Pushing lever case

O-ring 8.75x1.8

O-ring 14.2x1.9

Feed piston

O-ring 11.2x1.8

Feed piston sealing washer

Feed piston cover

Lockout bushing

1

1

2

3

1

1

1

1

1

1

1

1

3

1

1

2

1

1

1

1

3

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

19

Table of contents

Other Benchmark Nail Gun manuals