Benchmark 1282-204 User manual

18 GAUG E PNEUMATI C BRAD NAILER

5YearLimitedWarranty

WEARCSAAPPROVEDEYEPROTECTION

WEAREARPROTECTIO

N

WEARAFACEMASK

1

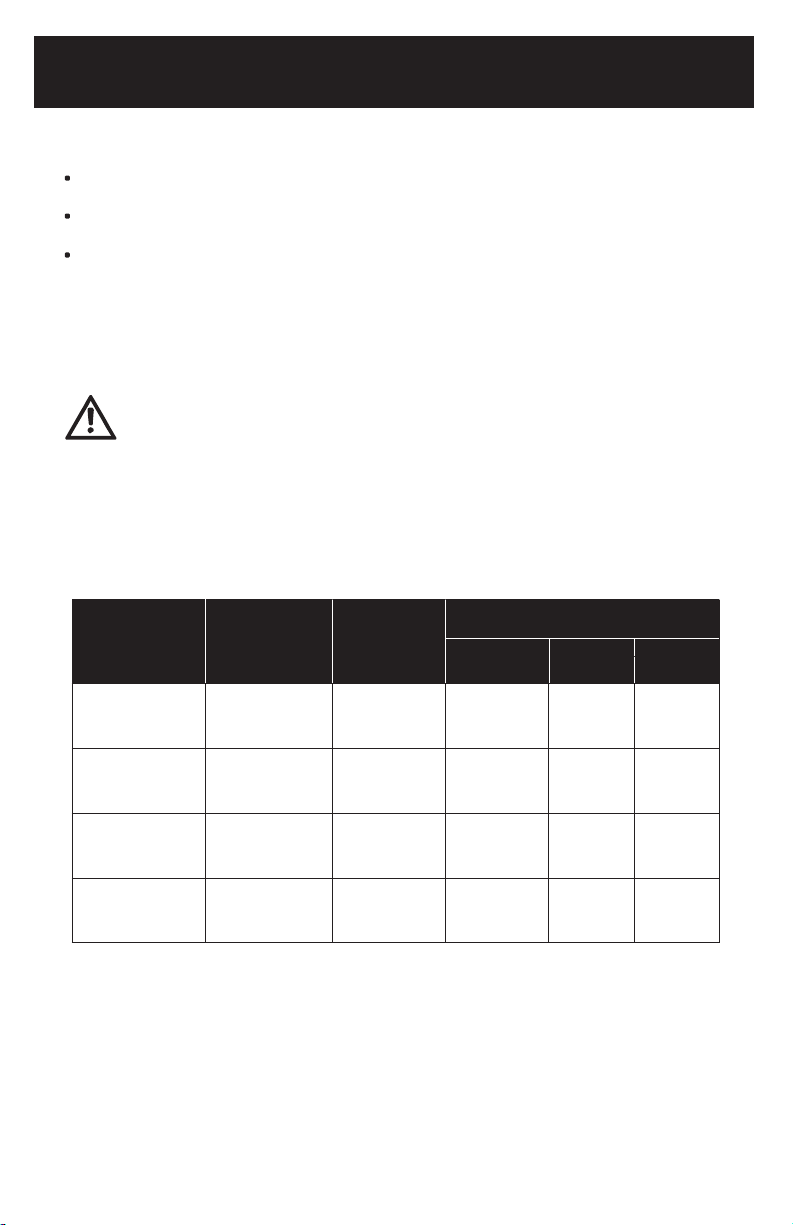

PRODUCTSPECIFICATIONS

18GaugePneumaticBradNailer

MagazineCapacity

100Nails

FastenerCapacity

18Gauge5/8”to2”Long

MaxPressure

120PSI

AverageAirConsumption

0.3CFM@90PSI

Workingpressure

70-110PSI

MAGAZINEANGLE

90°

Airinlet

1/4”NPT

Recommendedhose

1/4"OR3/8"

Weight

3.2lb(1.5kg)

•Pleasenote(wherethe¼”NPTconnecterisnotalreadyinstalledonthetool)yourtoolmaybeshippedwithablackplasticcapinstalledintheairinlet.Prythecapoutpriortoinstallingthe¼”NPTconnector.NEEDASSISTANCE?Callusonourtoll-freecustomersupportline:1-866-349-8665(MondaythroughFriday9am–5pmEasternStandardTime)•Technicalquestions•Replacementparts•PartsmissingfrompackageNOTEtheseinstructionspertaintothetoolonly.Pleaserefertoyourcompressorsoperator’smanualandfollowthemanufacturesinstructions.

1282-204

18GAUGEPNEUMATICBRADNAILER

2

TABLEOFCONTENTSProductSpecifications.............................................................................................. 1TableofContents....................................................................................................... 2SafetyGuidelines....................................................................................................3-6Symbols...................................................................................................................... 6ToolSpecificWarnings.............................................................................................. 7KnowyourPneumaticBradNailer........................................................................... 8AssemblyandOperating..................................................................................... 9-16Maintenance...................................................................................................... 16-19ExplodedView..........................................................................................................20PartsList.............................................................................................................20-23Warranty................................................................................................................... 24

3

SAFETYGUIDELINESWARNING:ThismanualcontainsinformationthatrelatestoPROTECTINGPERSONALSAFETYandPREVENTINGEQUIPMENTPROBLEMS.Itisveryimportanttoreadthismanualcarefullyandunderstanditthoroughlybeforeusingtheproduct.Thesymbolslistedbelowareusedtoindicatethisinformation.DANGER!Potentialhazardthatwillresultinseriousinjuryorlossoflife.WARNING!Potentialhazardthatcouldresultinseriousinjuryorlossoflife.CAUTION!Potentialhazardthatmayresultinmoderateinjuryordamagetoequipment.Note-Theword"Note"isusedtoinformthereaderofsomethinghe/sheneedstoknowaboutthetool.PERSONALSAFETYTheseprecautionsareintendedforthepersonalsafetyoftheuserandothersworkingwiththeuser.Pleasetaketimetoreadandunderstandthem.

1282-204

18GAUGEPNEUMATICBRADNAILER

4

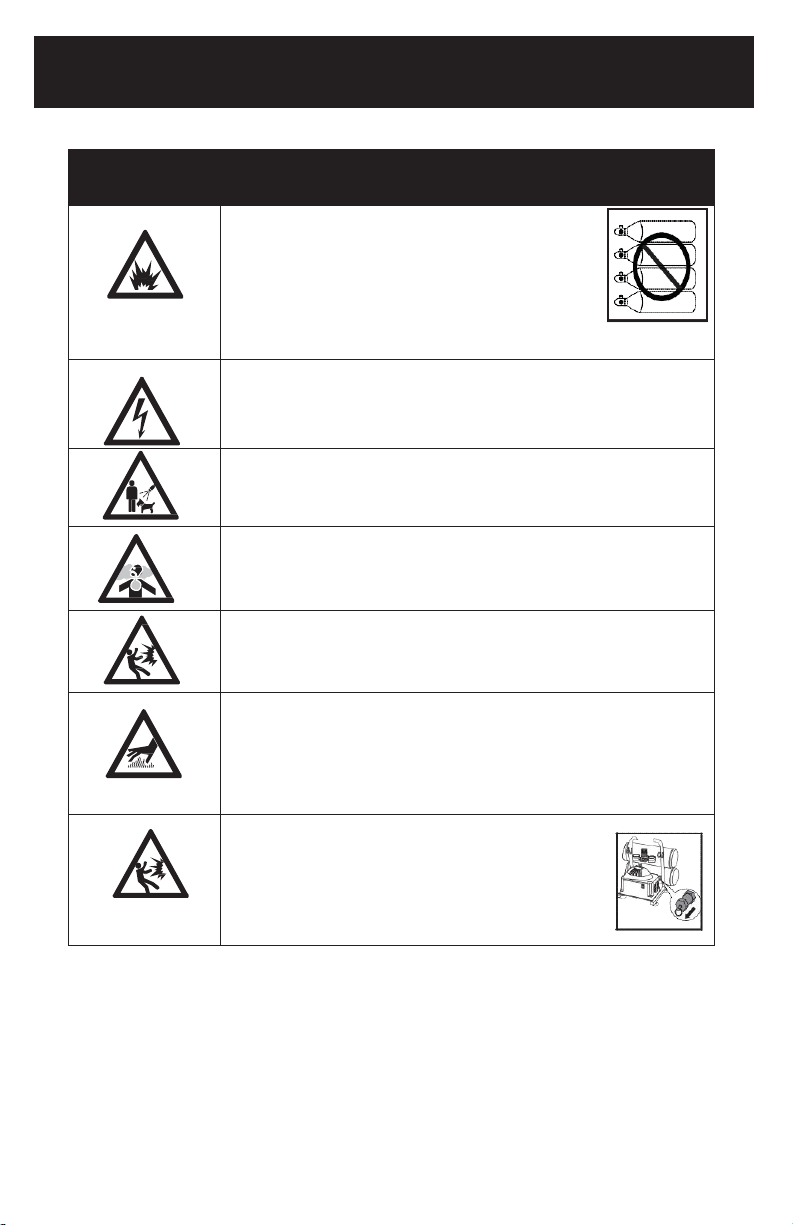

Donotuseoxygenoranyothercombustibleorbottledgastopowerair-poweredtools.Failuretoobservethiswarningcancauseexplosionandseriouspersonalinjuryordeath.Useonlythecompressedairtopowertheair-poweredtools.Useaminimumof25’(7.6m)ofhosetoconnectthetooltothecompressor.Failuretocomplywillresultinseriousinjuryorlossoflife.

Riskofelectricshock:Donotexposeacompressortorain.Storeitindoors.Disconnectthecompressorfrompowersourcebeforeservicing.Compressormustbegrounded.Donotusegroundingadaptors.

Riskofpersonalinjury:Donotdirectcompressedairfromtheairhosetowardstheuserorotherpersonnel.

Riskforinhalation:Neverdirectlyinhaletheairproducedbythecompressor.

Riskofbursting:Donotadjustthepressureswitchorsafetyvalveforanyreason.Theyhavebeenpresetatthefactoryforthiscompressor’smaximumpressureTamperingwiththepressureswitchorthesafetyvalvemaycausepersonalinjuryorpropertydamage.

Riskofburns.Thepumpandthemanifoldgeneratehightemperatures.Inordertoavoidburnsorotherinjuries,donottouchthepump,themanifold,orthetransfertubewhilethecompressorisrunning.Allowthepartstocooldownbeforehandlingorservicing.Keepchildrenawayfromthecompressoratalltimes.

Riskofbursting:Makesuretheregulatorisadjustedsothatthecompressoroutletpressureissetlowerthanthemaximumoperatingpressureofthetool.Beforestartingthecompressor,pulltheringonthesafetyvalvetomakesurethevalvemovesfreely.Drainwaterfromtankaftereachuse.Donotweldorrepairtank.Relieveallpressureinthehosebeforeremovingorattachingaccessories.

Oxygen

nydrogen

Combustible

explosive

SYMBOLMEANING

5

DANGER!Keepchildrenawayfromtheworkarea.Donotallowchildrentohandlepowertools.Keepairhoseawayfromheat,oil,andsharpedges.Checkairhoseforwearbeforeeachuseandensurethatallconnectionsareproper.Alwaysensurethattheworkpieceisfirmlysecuredleavingbothhandsfreetocontrolthetool.Alwaysensurethatthetoolhasstoppedbeforeputtingitdownafteruse,forsafetypurposesandtopreventpossibledamagetothetool/user.Keepproperfootingatalltimesinordertoensurecorrectbalance.WARNING!Donotallowunskilledoruntrainedindividualstooperatethetool.Donotusethetoolforanytaskotherthanthatitisdesignedtoperform.Keephandsandotherpartsofthebodyawayfromthefiringheadduringuse.Keephands,feet,andallotherpartsofthebodyatleast8"(20cm)awayfromthefiringhead.Nailsorobjectsintheworkpiececancauseseriousinjuryiftheyaredeflectedbytheworkpieceoriftheyaredrivenawayfromthepointofentry.Donotoverloadthetoo.Allowthetooltooperateatitsoptimumspeedformaximumefficiency.Locatethecompressorinawell-ventilatedareaforcooling,andaminimumof12”(31cm)awayfromthenearestwall.Protecttheairhoseandthepowercordfromdamageandpuncture.Inspectthemforweakorwornspotseveryweekandreplacethemifnecessary.Alwayswearhearingprotectionwhenusingtheaircompressor.Failuretodosomayresultinhearingloss.Donotcarrythecompressorwhileitisrunning.Donotoperatethecompressorifitisnotinastableposition.Donotoperatethecompressoronarooftoporanelevatedpositionthatcouldallowtheunittofallorbetippedover.Alwaysreplaceadamagedgaugebeforeoperatingtheunitagain.Donotconnectthetooltoacompressedairsourcewithapressureoutputthatishigherthan120PSICAUTION!Alwaysensurethatthetoolhasstoppedbeforeconnectingtotheairsupply.Donotwearwatches,rings,bracelets,orlooseclothingwhenusinganyair-poweredtool.Donotoverloadthetool

.Allowthetooltooperateatitsoptimumspeedformaximumefficiency.

Donotuseatoolthatisleakingair,thathasmissingordamagedparts,orthatrequiresrepairs.Verifythatallscrewsaresecurelytightened.Foroptimalsafetyandtoolperformance,inspectthetooldailyinordertoensurefreemovementofthetrigger,safetymechanisms,andsprings.Alwayskeepyourairtoolcleanandlubricated.Dailylubricationisessentialtoavoidinternalcorrosionandpossiblefailures.Ensurethefloorisnotslipperyandwearnon-slipshoes.Floorsshouldbekeptcleanandclear.Alwaysfollowallworkshopsafetyrules,regulations,andconditionswhenusingthetool.Carrythetoolbythehandleonly,keepingfingersawayfromthetrigger.Donotcarrythetoolbythehose,magazine,oranyotherparts.Donotusethetoolnearorbelowfreezingpoint,asdoingsomaycausetoolfailure.Donotstorethetoolinafreezingenvironmenttopreventiceformationonthetoolsoperatingvalves,asdoingsomaycausetoolfailure.Handlingandstorageofoil:Usewithadequateventilation.Avoidcontactofoilwitheyes,skin,andclothing.Avoidbreathingsprayormist.Storeinatightlyclosedcontainerinacool,dry,well-ventilatedareafreefromIncompatiblesubstances.

1282-204

18GAUGEPNEUMATICBRADNAILER

6

CAUTION!Disconnecttoolfromtheairsupplyandturnoffthecompressorbeforeperforminganymaintenanceorchangingaccessories,whenclearingajammedfastener,whenthetoolisnotinuse,whenitisbeinghandedtoanotherperson,andwhenitisleftunattended.Failuretocomplymayresultinmoderateinjuryordamagetoequipment.Usesafetygogglesandearprotection:Wearsafetyglasseswithsideshieldswhenoperatingthetool/compressorandverifythatothersintheworkareaarealsowearingsafetyglasses.SafetyglassesmustconformtoAmericanNationalStandardsInstitute(ANSIZ87.1)requirementsandmustprovideprotectionfromflyingparticlesfromthefrontandthesides.Air-poweredtoolsareloud,andthesoundcancausehearingdamage.Alwayswearearprotectiontopreventhearingdamageandloss.Failuretocomplymayresultinmoderateinjury.Note:Recycle unwanted materials rather than disposing of them as waste. Sort the tools,

hoses, and packaging in specific categories and take to the local recycling center or

dispose of in an environmentally safe way.

SYMBOLSWARNING:Someofthefollowingsymbolsmayappearonthetool.Studythesesymbolsandlearntheirmeaning.Properinterpretationofthesesymbolswillallowformoreefficientandsaferoperationofthistool.

SYMBOLS

Read operator s manual: To reduce the risk of injury ,

user must read and understand operator s manual

before using this product.

Eye protection: Always wear safety goggles, safety

glasses with side shields, or a full-face shield when

operating this product.

Risk to hearing Always wear ear protection using this

tool. when Failure to do so may result In hearing loss.

7

TOOLSPECIFICWARNINGS

Keep hands and other parts of the body away from the firing

head during use. Keep hands, feet, and all other parts of the

body at least 8"(20 cm) away from the firing head. Nails or

objects in the workpiece can cause serious injury if they are

deflected by the workpiece or if they are driven away from the

point of entry.

Do not overload the too. Allow the tool to operate at its

optimum speed for maximum efficiency.

Disconnect the tool from the air supply and turn off the

compressor before performing any maintenance, loading, or

changing nails. when the tool is not in use, when it is being

handed to another person, when it is left unattended.

Failure to comply may result in injury or damage to the

equipment.

Do not keep the tool pressed while loading fasteners.

Do not disconnect or reconnect the air hose with the tool

pressed or with a fastener in the guide. The tool may fire when

it is reconnected to the air supply.

Do not drive a fastener on top of a fastener. The fastener

may ricochet, causing serious personal injury.

Use only fasteners of the proper size and gauge as specified

in this manual.

Do not drive fasteners close to the edge of the workpiece.

The workpiece may split which could allow the fastener to fly

free or ricochet.

1282-204

18GAUGEPNEUMATICBRADNAILER

8

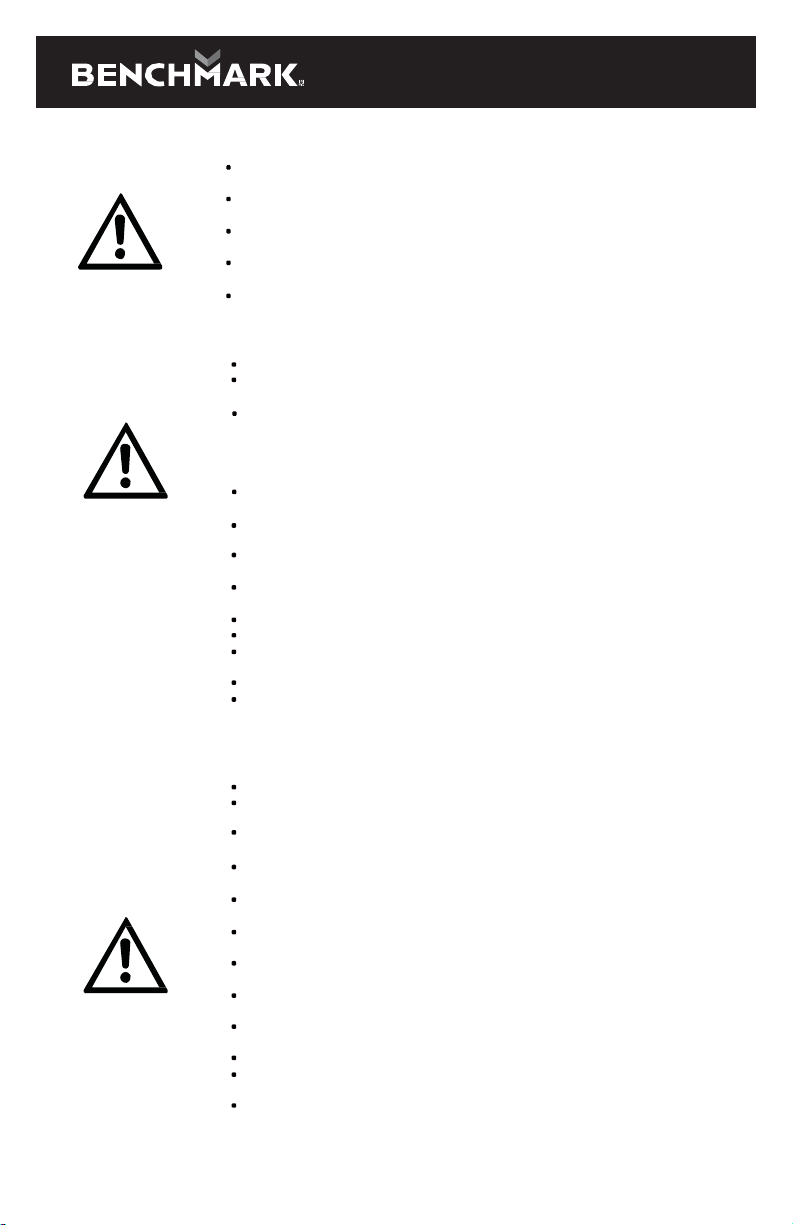

KNOWYOUR18GAUGEBRADNAILER8

1

2

7

6

5

3

4

No.

Description

No.

Description

1

Airinletplug

6

Depthadjustmentdial

2

Magazinelatch

7

Trigger

3

Magazine

8

Airexhaustdeflector

4

Safetytip

9

ModeSelectionSwitch

5

QuickNailExtractionlever

9

9

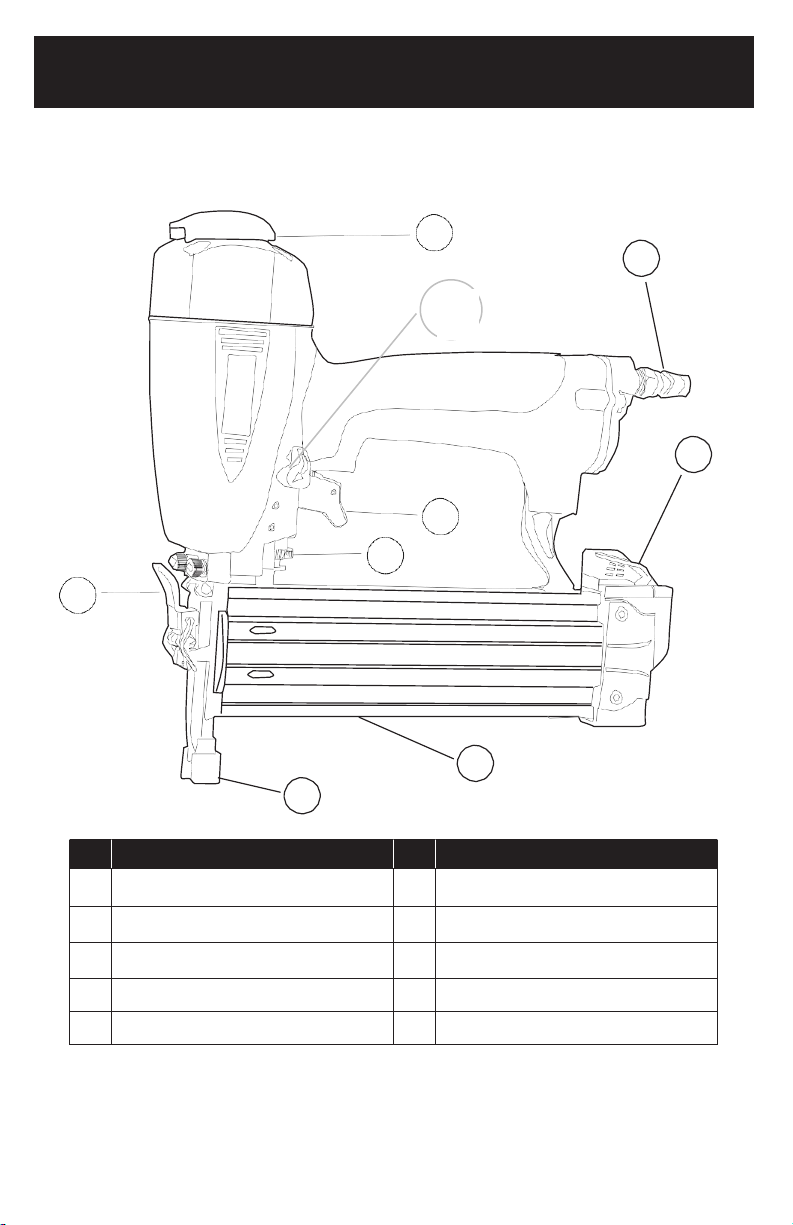

ASSEMBLYANDOPERATINGThe18GaugePneumaticBradNailerdeliverssuperiorpower-easilydriving2“bradnailsthroughsolidoak.Tool-freedepthadjustmentmakesiteasytoworkwithvariousdimensionsoftrimandmolding.Thesuper-narrowtoolbodyandnosemakeiteasytogetprecisepositioningincornersandtightspots.Handlesfastenersfrom5/8”to2”long.COMPATIBLECOMPRESSORSGUIDELINESFORPROPERUSEANDOPERATIONBesuretouseaproperaircompressorwithair-poweredtools.Thecompressorshouldbeabletosupplyaminimalairdeliveryof0.3CFM@90PSItoensurethecompressorcanruncontinuouslywiththetool.

AirCompressorSizeandPower

1/3–11/3HP

11/2–2HP

2+HP

2–6Gallons

Light-dutyandIntermittentuse

Light-dutyandIntermittentuse

Light-dutyandIntermittentuse

8-11Gallons

Light-dutyandIntermittentuse

Medium-dutyandIntermittentuse

Medium-dutyandIntermittentuse

15+Gallons

Medium-dutyandIntermittentuse

Heavy-dutyandContinuoususe

Heavy-dutyandContinuoususe

WoodDensity

NailSize

CompressorAirPressure

0.6g/cm3

<11/4”(32mm)bradnails

90PSI(6.3bar)

<11/4”(32mm)bradnails

100PSI(7bar)

0.6g/cm3

<11/4”(32mm)bradnails

70PSI(4.8bar)

<11/4”(32mm)bradnails

90PSI(6.3bar)

1282-204

18GAUGEPNEUMATICBRADNAILER

10

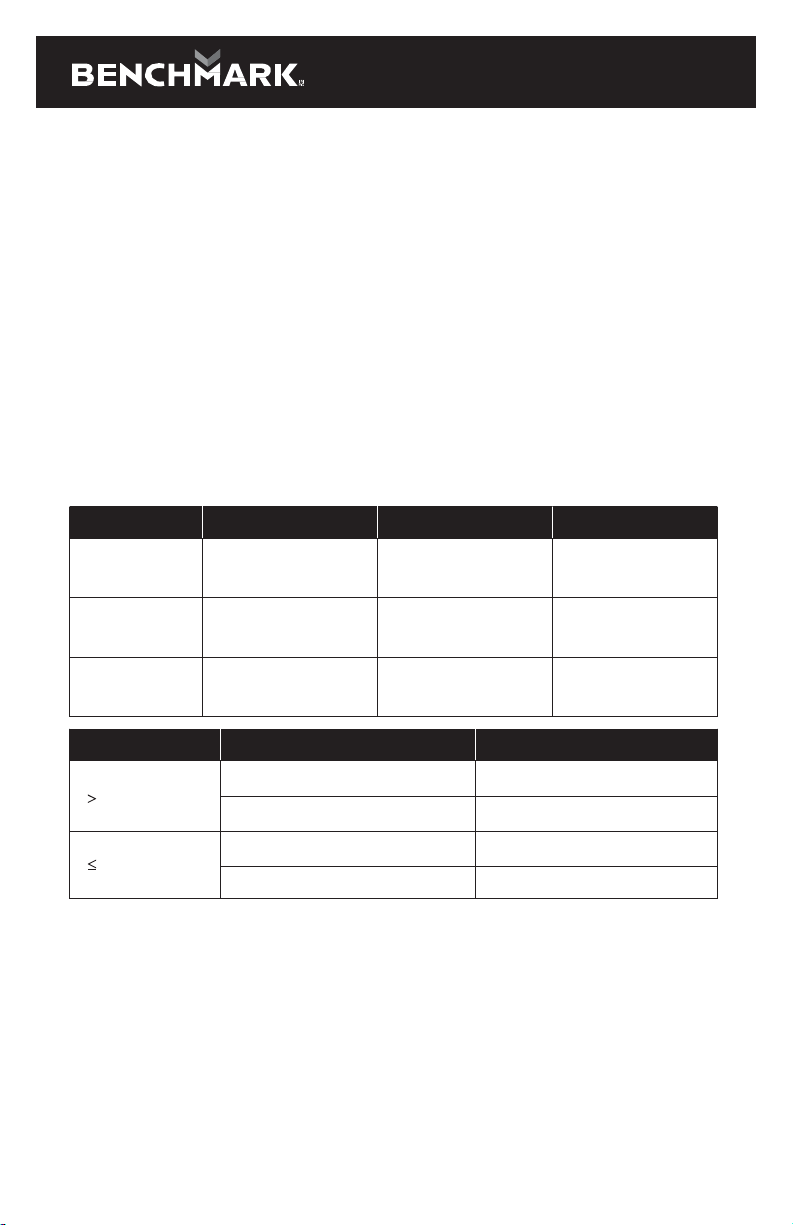

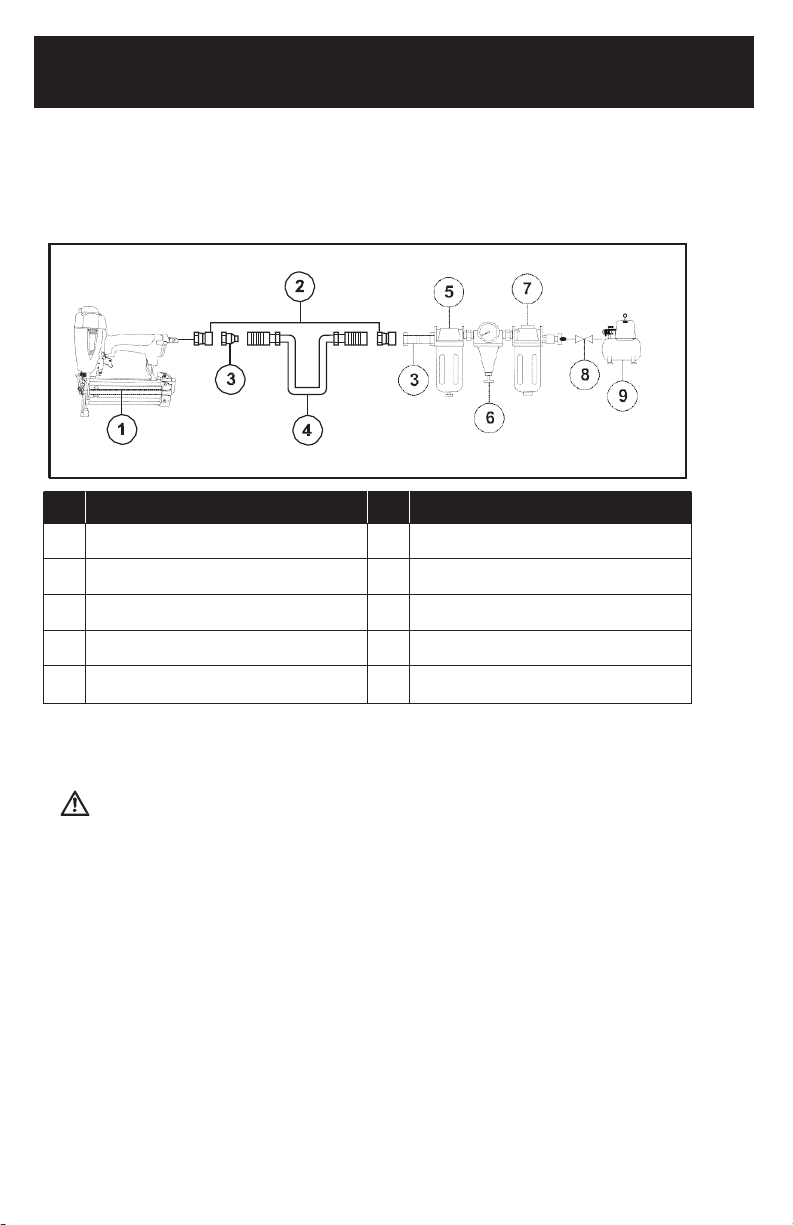

AIRSYSTEMAlwaysuseclean,dry,regulated,compressedairat4.8to7.5bar(70to110PSI)Donotexceedthemaximumorminimumpressures.Operatingthetoolatthewrongpressure(toolowortoohigh)willcauseexcessivenoiseorrapidwearoftool.

No.

Description

No.

Description

1

18GaugeAirBradNailer

6

Regulator0-110PSI(0to7.5bar)

2

Quickconnector

7

Filter

3

Quickcoupler

8

Cut-offvalve

4

Airhose

9

Aircompressor

5

Lubricator

WARNINGThe use of any other types of fasteners will cause the tool to jam. Failure

to comply could lead to serious injury or loss of life.

It is recommended that a filter-regulator-lubricator is used and located as close to the tool as

possible.

If a filter-regulator-lubricator is not installed, place up to 6 drops of compressor oil into the

NPT inlet plug before each use.

If a filter-regulator-lubricator is installed, keep the air filter clean. A dirty filter will reduce the

air pressure to the tool, which will cause reduction in power, efficiency, and general

performance.

For optimal performance, install a quick coupler in the hose, if applicable.

Verify that all of the connections in the air supply system are sealed in order to prevent air

from leaking.

11

Airtools

ReadthisInstructionManualcarefullybeforeusingthetoolRead and follow all the safety instructions at the beginning of this manual. Inspect the air-

powered tool prior to each use in order to:

-Ensure that the proper power source is being used.

-Verify that the tool is in proper working order.

-Verify that the air pressure level (s) are properly set on the air compressor. Do

not use the tool if it is not in proper working order.

Do not use oxygen, CO2(carbon dioxide) or any other combustible, or bottled gas to power this

tool.

Do not use this tool in the presence of any flammable liquids or gases.

Keep hands and other parts of the body away from the firing head during use.

Do not point the tool towards the operator or other people.

Never attempt to clear a jammed fastener while the air hose is connected.

Do not drive a fastener on top of an existing fastener. Failure to comply could lead to serious

injury or death.

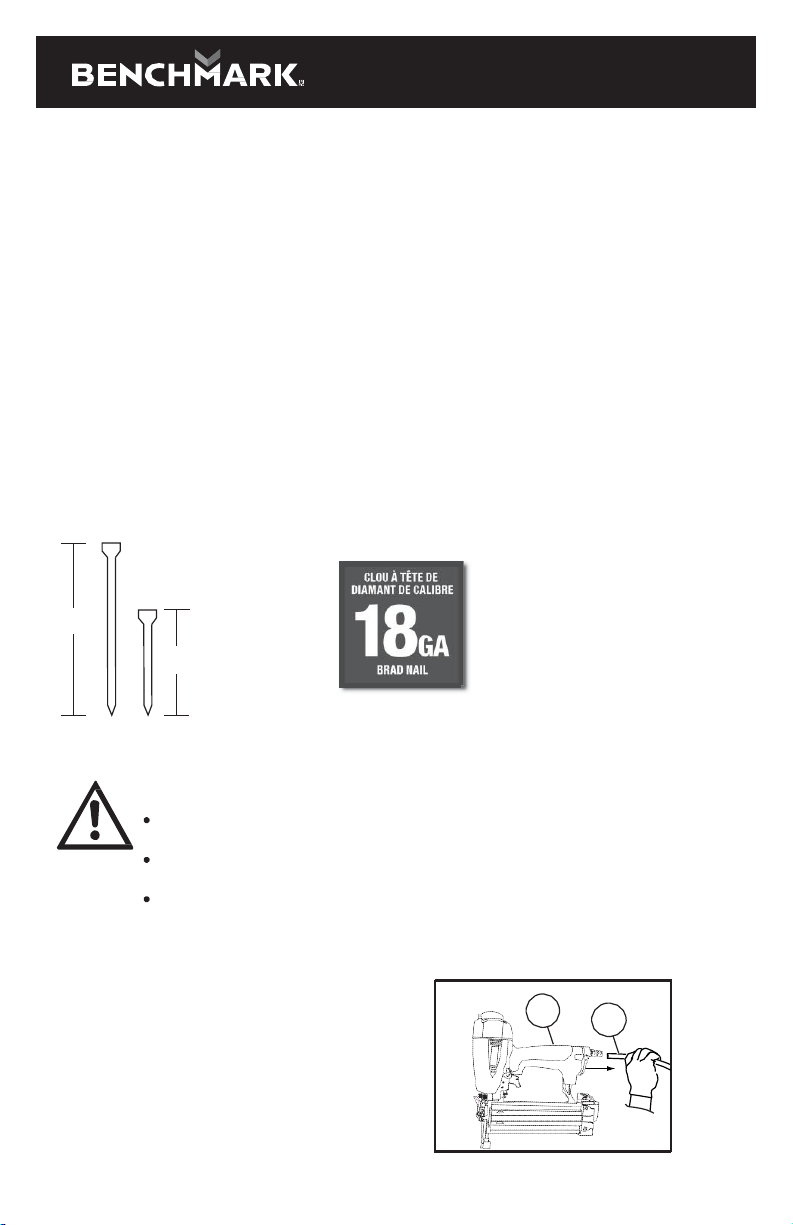

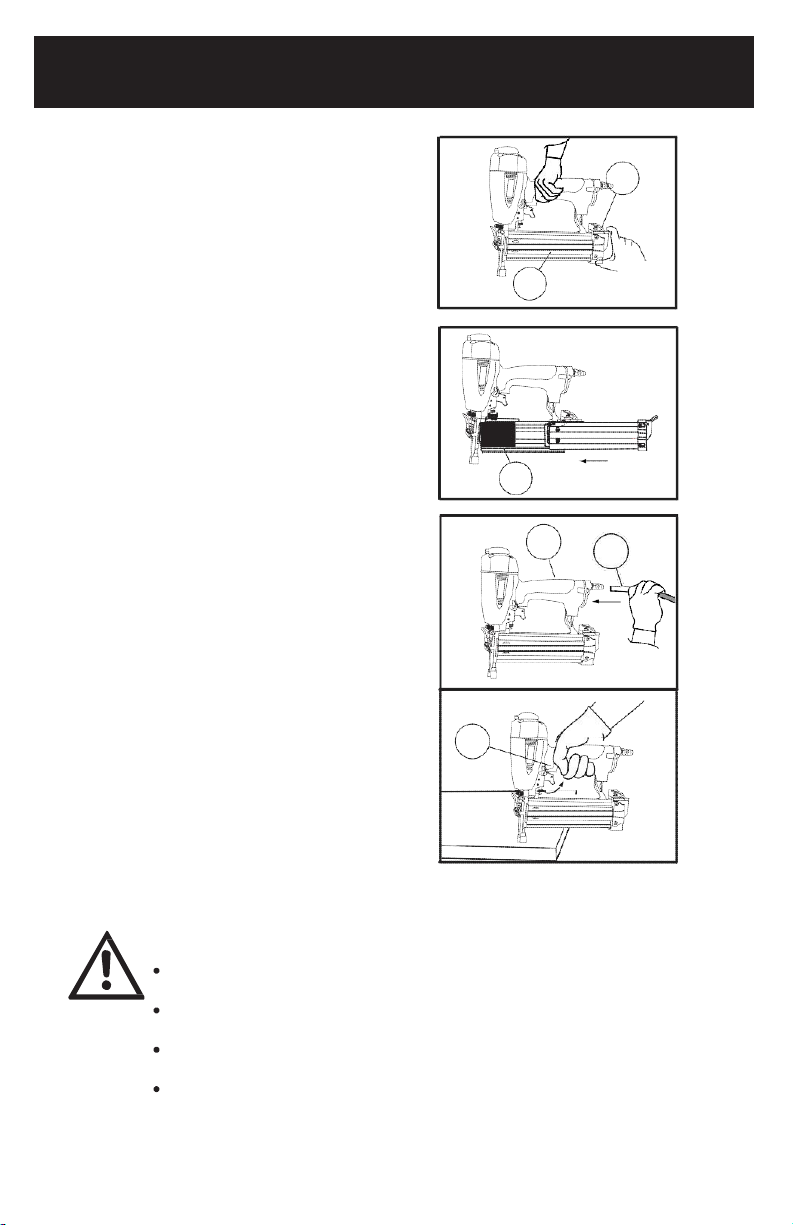

ACCEPTABLENAILSNAILTYPEICONLength:5/8-2"(15to50mm)TheseIconsareusedtoselectthepropernailsforthisspecificnailer.2”5/8”LoadingnailsWARNING!Disconnectthetoolfromthecompressedairsourcebeforeloadingnails.Donotpointthetooltowardstheoperatororotherpeoplewhilechangingnails.Donotholdthetoolwiththetriggerpressedwhilechangingnails.Failuretocomplywillleadtoseriousinjuryordeath.

1.Disconnectthetool(1)fromtheairsupply(2).

1

2

1282-204

18GAUGEPNEUMATICBRADNAILER

12

2.HoldtheBradNailerfirmlywithonehand,andusetheotherhandtopressthelatch(1)onthemagazine1(2)andslideitback.23.Insertastripofnails(1)intothemagazine.Afterensuringthatthepointsofthenailsarefacingdown,closethemagazine.1

4.Plugincompressor,turniton,setthe1

pressure regulator to 90 PSI, attach oneend of the air hose to the compressorand the other end of the air hose (2) to the tool (1). Use plumber’s tape to prevent air leaks.5.Testthedrivingdepthofthetoolagainstasamplepieceofwoodbypressingthetrigger(1)beforeworkingonthe1workpiece.Ifthenailsarebeingdriventoodeepornotdeepenough,adjusttheregulatorintheairsupplyinordertoprovidemoreorlessairpressure,asrequired.FastenersdepthadjustmentWARNING!Thesafetytipmustbeincontactwiththeworkpiecebeforeactivatingthetool.Donotoperatethetoolifthenailsarenotloaded,asdoingsomaydamagethetool.Donotfirenailsintotheair,asdoingsomaycauseinjurytotheoperatorsorothers,apartfromdamagingthetool.Loadthecorrecttypeofnailsonly.Failuretocomplycouldleadtoseriousinjuryorlossoflife.

2

13

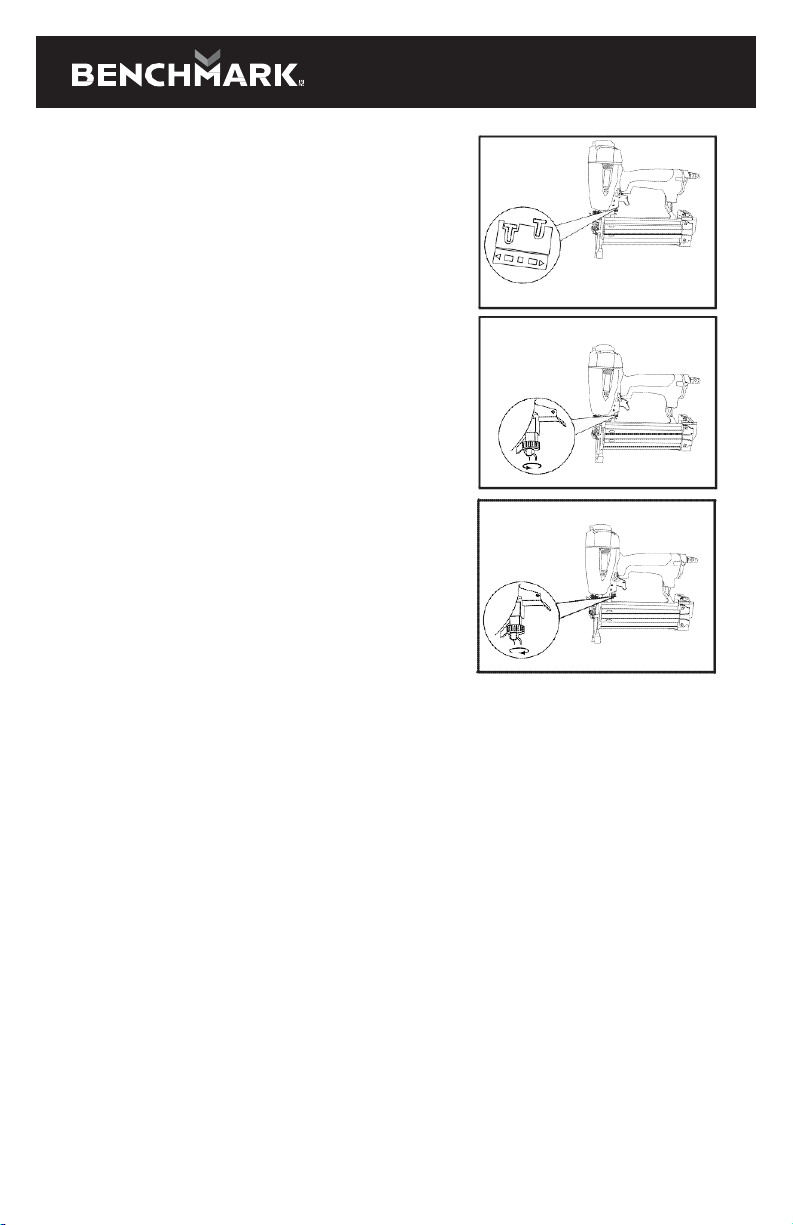

TheBradNailerhasadepthadjustmentdialbelowthetriggertoadjustthefiringdepthofthefasteners.Note:Refertothegraphicimprintedbelowthetriggerandadjustthefiringdepthaccordingly.DECREASINGFASTENERDEPTHTurnthedepthadjustmentdialcounterclockwise(withthedischargeareaofthetoolfacingawayfromtheoperator).INCREASINGFASTENERDEPTHTurnthedepthadjustmentdialclockwise(withthedischargeareaofthetoolfacingawayfromtheoperator).MODESELECTIONSWITCHFiringmodesTheBradNailerhastwofiringmodes:Single-Sequentialactuationforsinglefiring,orContact/bumpactuationforrepetitive,fastfiringofnails.YoumayswitchbetweenthesetwomodessimplybyadjustingtheModeSelectionSwitchonthetool.Forsinglesequentialactuationmode,theselectorswitchmustbepositionedtowardthebackofthetool(towardthesinglenailicononthetool.Forrepetitivefiring,alsoknownascontactorbumpmode,themodeselectorswitchmustbepositionedtowardthefrontofthetool(towardthemultiplenailicononthetool).Ensuretheswitchispositionedeitherfullyinsinglesequentialorcontact/bumpmode,otherwise,ifswitchisin-betweenthetoolwillnotfunctionproperly.

1282-204

18GAUGEPNEUMATICBRADNAILER

14

SINGLESEQUENTIALACTUATIONMODEThesinglesequentialactuationmechanismisforusewhereprecisefastenerplacementisdesired.Thesinglesequentialactuationmechanismmayreducethepossibilityofbodilyinjurytoyouorothersintheworkareacomparedtothecontact/bumpactuationmechanism.Thisisbecauseitislesslikelytodriveanunwantednailifyoukeepthetriggerpulledandaccidentallybumpthepushleveragainstyourselforothers.Thesinglesequentialactuationmechanismmayalsoreducethespeedofoperationcomparedtothecontact/bumpactuationmechanism.Thesinglesequentialactuationmechanismisrecommendedtoinexperiencedusers.1.Setswitchontool(towardbackoftool)tosinglesequentialactuationmode.2.Positionthenoseofthetoolontheworkpiecewithyourfingeroffthetrigger.3.Depressthepushleveronthefiringheadofthetoolfirmlyagainsttheworkpieceuntilitiscompletelydepressed.4.Pullthetriggertodriveanail.5.Removefingerfromthetrigger.6.Tocontinuenailinginaseparatelocation,movethenaileralongthewood,repeatingsteps2-5asrequired.CONTACTORBUMPMODE*Thismodeissuitablewhenlessprecisenailplacementisrequired.Itallowstheusertoworkmorequickly.Sincenailscanbeactuatedwithoutremovingthefingerfromthetrigger,thisisalesscontrolledmode,suitableformoreexperiencedusers.1.Setswitchontool(towardthefrontoftool)tocontactorbumpmode.2.Pressandholdthetriggerwhileoperatinginthismode.Eachtimethefiringheadcontactsaworkpiece,anailisactuated(fired).Liftthenailerandlocateitatthesiteforthenextnail.Movethenaileralongtheworkpiecewithabouncingmotion.Eachdepressionofthepushleveronthefiringheadofthetoolwilldriveanail.Assoonasthedesirednumberofnailshavebeendriven,removefingerfromthetrigger.3.Thisprocesscanberepeateduntilthetriggerisreleased.Extremecareshouldbetakenbecauseanailwillbedrivenwhenthefiringheadcontactsanysurface.

15

ClearingajammednailToclearajammednailDisconnectthetoolfromtheairsupplyline.Removethenon-jammednailsthatarestoredinthetool’smagazine.Operatethemagazinelatchandslidethepusherbacktoopenthemagazineforcheckingthejammednails.Usepliersoranyappropriatetooltoremovethejammednails.Ifthenailisjammedinthe“firing”location,pulltheQuickNailExtractionleverawayfromthetooltoaccessandremovethejammednail.Closethemagazinecoverandslidethepushertoitsoriginalposition.Reloadthenailsintothetoolmagazine.Reconnecttheairsupplylinetothetool’sairinlet.Testfire3to5nailsintoapieceofscrapwoodinordertoensureaproperoperation.

1282-204

18GAUGEPNEUMATICBRADNAILER

16

StorageWhen the tool is stored for longer periods of time, apply an ample amount of lubrication

before storing.

Run the tool for approximately 30 seconds after lubricating, in order to ensure that the

lubrication is uniformly distributed throughout the tool.

Store the tool in a clean and dry environment.

MaintenanceNote:Donotstorethetoolanywheretemperatureswillfallbelowfreezing.

DANGER!Disconnectthetoolfromtheaircompressorbeforemaintenance/service,adjusting,cleaningjams,reloading,andwhenitisnotinuse.Repairsmustbeperformedbyaqualifiedservicetechnicianonly.Failuretocomplywillleadtoseriousinjuryorlossoflife.

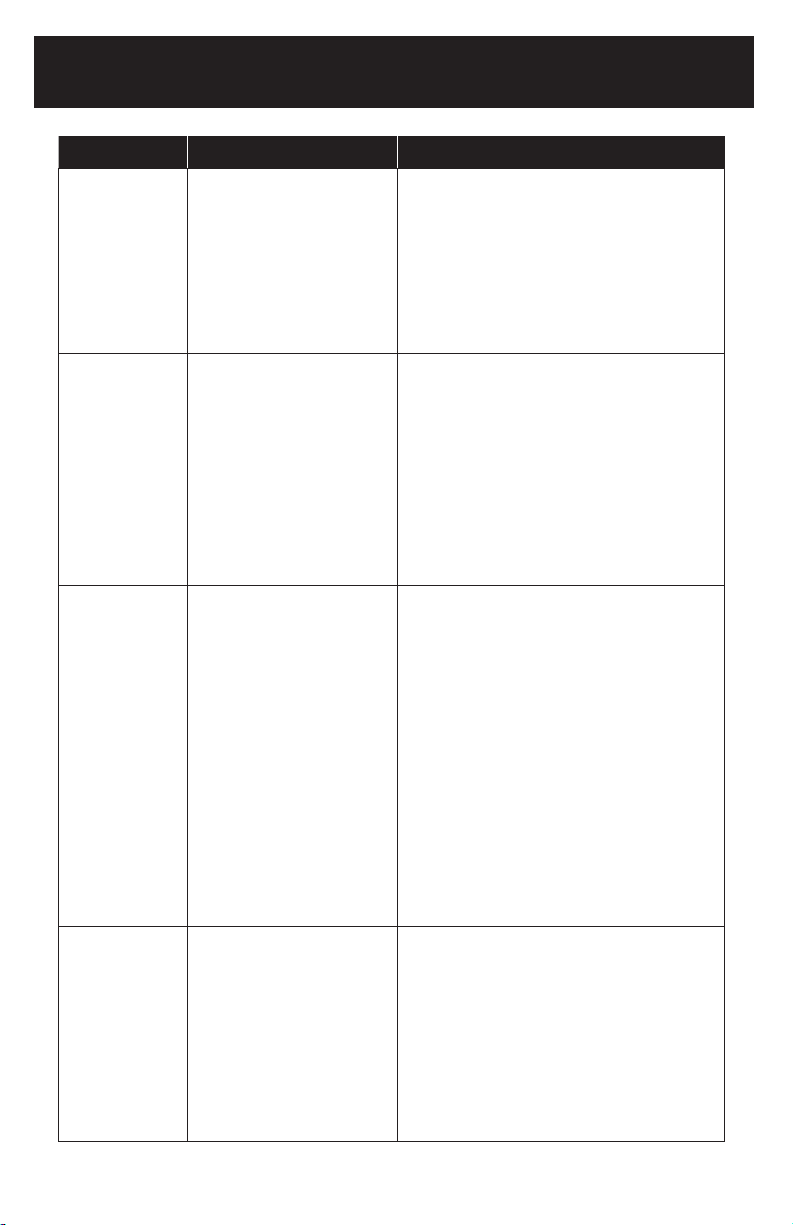

MAINTENANCEREQUIRED

DESCRIPTION

TOOLSORMATERIALSREQUIRED

MAXIMUMSERVICEINTERVAL

Eachuseorevery2hrs.

Monthly

Asneeded

Generalinspection-freemovement

Trigger,spring,

None

X

In-depthinspection

Wornorbrokenparts

X

X

Replacewornorbrokenparts

X

Lubrication

Seebelow

Pneumatic

tooloil

X

•

Lubrication: If tool and the compressor are not

equipped with an in-line lubrication system, place up

to 6 drops of pneumatic tool oil into the air inlet before

each use or after every 2 hours of continuous use,

depending on the characteristics of the workpiece.

17

Air-operatedtoolsmustbeinspectedperiodically,andwornorbrokenpartsmustbereplacedinordertokeeptoolsoperatingsafelyandefficiency.Inspectandreplacewornordamaged0-rings,seals,etc.Tightenallscrewsandcaps

frequentlyinordertohelppreventpersonalinjury.Inspectthetrigger,spring,andthesafetymechanismforfreemovementonaregularbasisinordertoensurethatthesafetysystemisfullyfunctional.Veritythatnopartislooseormissingandthatnopartsarestickingorjammed.Keepthemagazineandthesafetytipofthetoolcleanandfreeofanydirtorabrasiveparticles

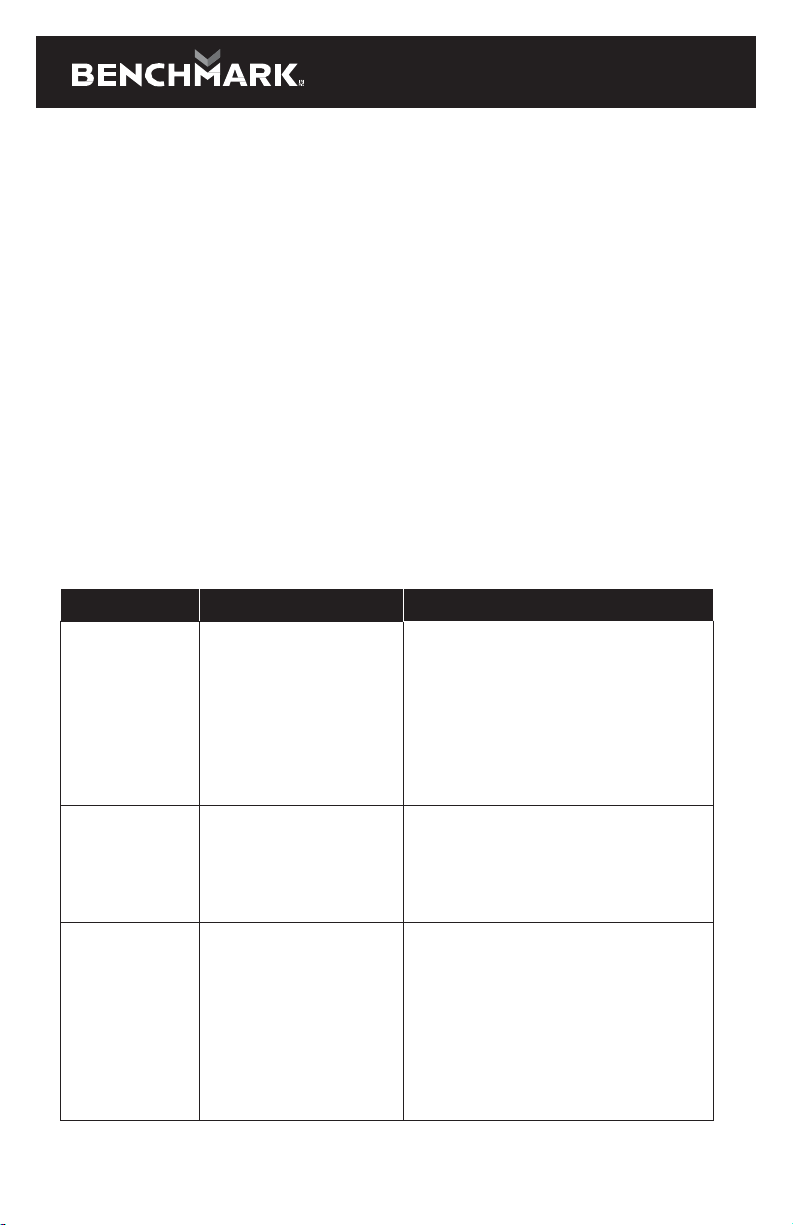

Troubleshooting

⚠

DANGER:

Ifanyofthefollowingsymptomsappearwhilethetoolisinuse,turnitoffanddisconnectitfromtheairsupplyimmediately.Failuretocomplywillleadtoseriousinjuryorlossoflife.Disconnectthetoolfromtheairsupplybeforemakinganyadjustments.Repairsmustbeperformedbyaqualifiedservicetechnicianonly.Thefollowingchartlistscommonoperatingsystemissuesandsolutions.Pleasereaditcarefullyandfollowallinstructionscarefully.

Problem

Possiblecauses

Solutions

Airleakageatthetopofthetoolorinthetriggerarea.

1.O-ringsinthetriggervalvearedamaged.2.Thetriggervalveheadsaredamaged.3.Triggervalvestem,seal,orO-ringsaredamaged.

1.InspectandreplacetheO-ring.2.Inspectandreplacetriggervalveheads.3.Inspectandreplacethetriggervalvestem,seal,orO-ring

Airleakagenearthebottomofthetool.

1.Thescrewsareloose.2.TheO-ringsorthebumperarewornordamaged.

1.Tightenthescrews.2.InspectandreplacetheO-ringsorthebumper.

Airleakagebetweenthebottomandthecylindercap.

1.Thescrewsareloose.2.TheO-ringsorthesealsarewornordamaged.

1.Tightenthescrews.2.InspectandreplacetheO-ringsortheseals.

1282-204

18GAUGEPNEUMATICBRADNAILER

18

Problem

Possiblecauses

Solutions

Thenailsarebeingdriventoodeep.

1.Thebumperisworn.2.Theairpressureistoohigh.3.Thedepthadjustmentknobisnotadjustedproperly.

1.Replacethebumper.2.Adjusttheairpressure.3.Adjustthedepthsettingbyturningthedepthadjustmentknobcounterclockwise(seesection“Adjustingnaildepth”formoredetailedinstructions).

Thetooldoesnotoperateproperly-itdoesnotdrivethenailsoroperatessluggishly.

1.Theairsupplyisinadequate.2.Lubricationisinadequate.3.TheO-ringsorsealsarewornordamaged.4.Theexhaustdeflectorinthecylinderheadisblocked.

1.Verifythattheairsupplyisadequate.2.Pourupto6dropsofoilintotheairinlet.3.InspectandreplaceO-ringsorseals.4.Replacethedamagedinternalparts.

Thetoolskipsnails.

1.Thebumperisworn,orthespringisdamaged.2.Thereisdirtinthefrontplate.3.Nailscannotmovefreelyinthemagazineduetodirtorwear.4.TheO-ringonthepistoniswornordryorlubricationisinsufficient.5.ThecylindercoversealIsleaking.

1.Replacethebumperorspring.2.Cleanthedrivechannelonthefrontplate.3.Cleanthemagazine.4.ReplacetheO-ring.5.Replacethesealingwasher.

Thetooljams.

1.Impropernailsareused,ornailsaredamaged.2.Thedriverguideisdamagedorworn.3.Themagazinescrewisloose.4.Thereisdirtinmagazine.

1.Usepropernails.(Seesection“Clearingajammednail.”)2.Inspectandreplacethedriver.3.Tightenthemagazine.4.Openandcleanthemagazine.

19

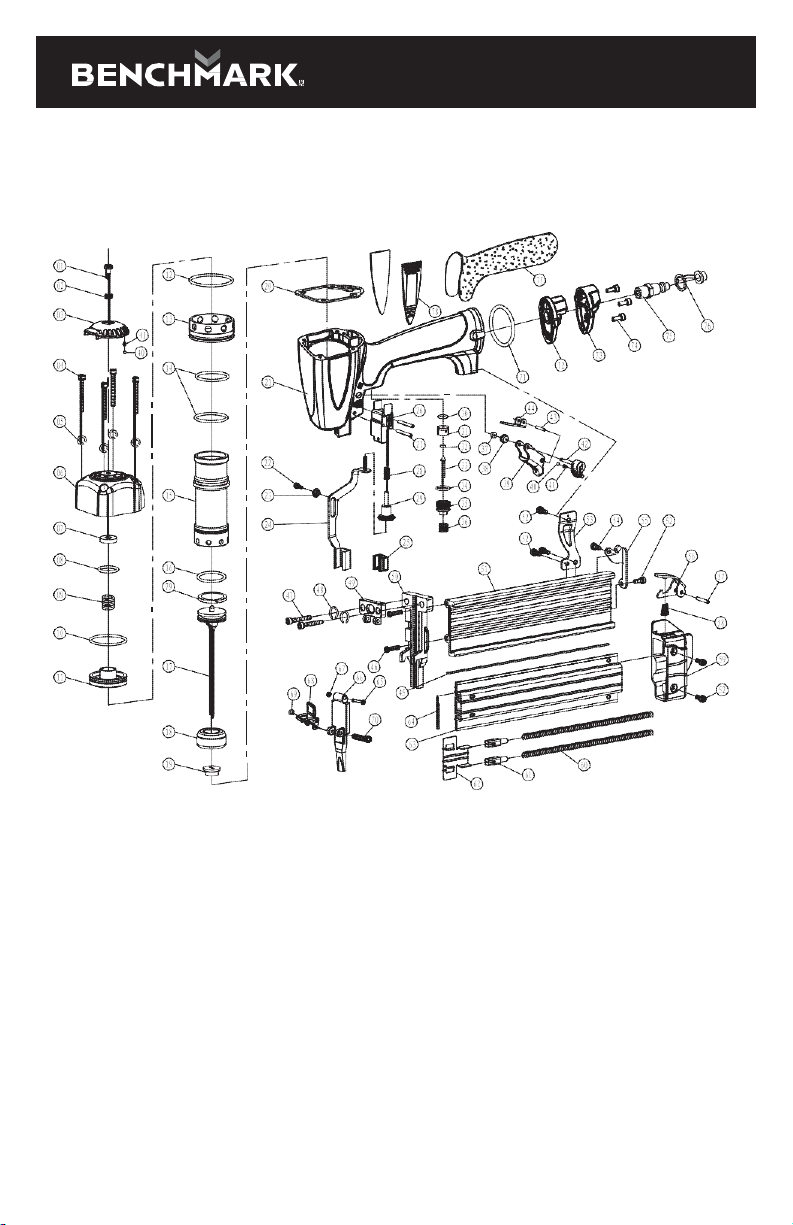

EXPLODEDVIEW

Table of contents

Other Benchmark Nail Gun manuals