Bend-Pak 1000-BL Operation manual

1 Bender Operation Manual Revision 90196

BendPak®

INCORPORATED

Bend-Pak®

INCORPORATED

FORWARD THIS MANUAL TO ALL

OPERATORS. FAILURE TO OPERATE

THIS EQUIPMENT AS DIRECTED HEREIN

MAY CAUSE INJURY

OPERATION AND SERVICE MANUAL

“America’s Most Popular

Tubing Bender”

Models:

1000-BL 1302-BL (“Blue Bullet”)

1000-BAS 1302-BAS

1000-BA 1302-BA

1502-BL

1502-BAS

1502-BA

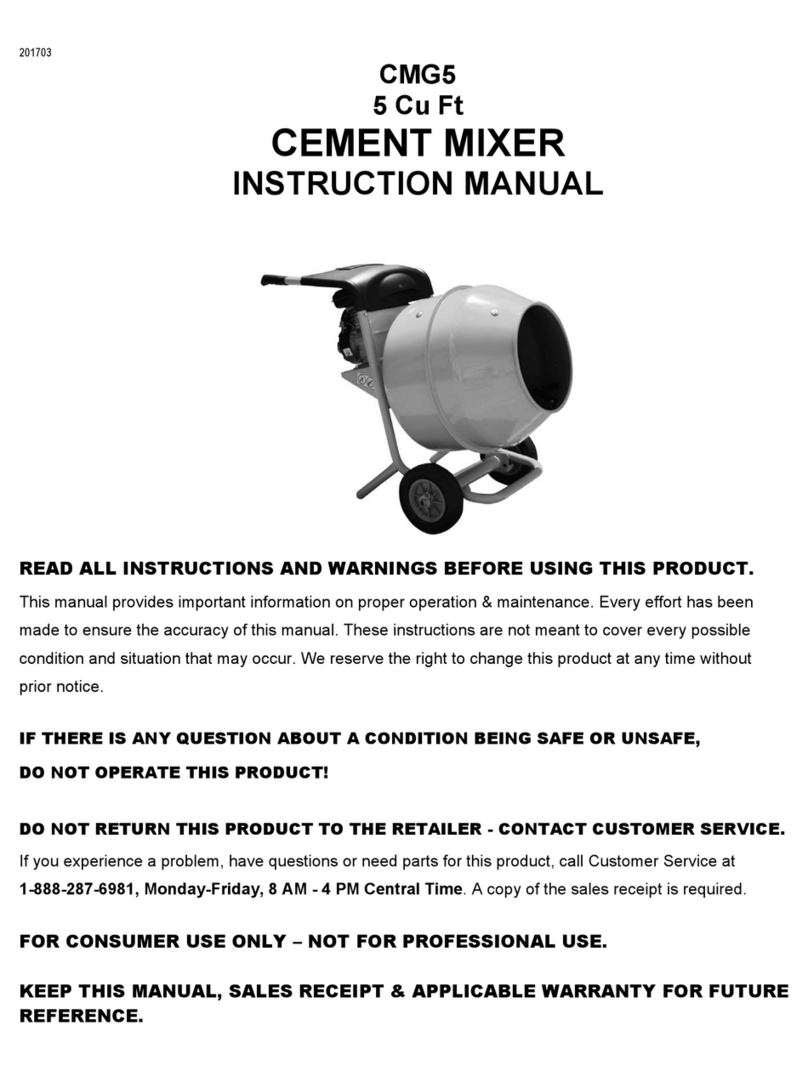

Model 1502-BA

shown with typical

tooling package.

SHIPPING DAMAGE CLAIMS

When this equipment is shipped, title passes to the pur-

chaser upon receipt from the carrier. Consequently, claims

for material damaged in shipment must be made by the

purchaser against the transportation company at the time

shipment is received.

BE SAFE

Bend-Pak, Inc. benders are designed and built with safety

in mind. However, your overall safety can be increased by

proper training and thoughtful operation on the part of the

operator. DO NOT operate or repair this equipment without

reading this manual and the important safety instructions

shown inside.

1645 Lemonwood Drive

Santa Paula, CA 93060 U.S.A.

Tel: 805-529-3675

Fax: 805-529-2909

TABLE OF CONTENTS

Identification Data / Warranty.....................................................................................................................................3

Specifications .............................................................................................................................................................4

Important Safety Instructions......................................................................................................................................5

Definition Of Terms / Model Identification ..................................................................................................................6

Installing The Electrical Plug ......................................................................................................................................7

Turning Your New Bender On ....................................................................................................................................8

Introduction Of Tooling Identification ..........................................................................................................................8

Segment Identification Chart..................................................................................................................................... 11

Typical End Finishing Illustrations .............................................................................................................................12

Description Of Digital Controls (BA Models) .............................................................................................................12

Operating The Digital Control Board (BA Models) ....................................................................................................13

Description Of Three-Button Control ((BAS Models) ................................................................................................14

Operating The Manual Knee Control (BL / Bullet Models)........................................................................................15

Introduction Of Bending Operations..........................................................................................................................15

Using The Program Cards ........................................................................................................................................15

Pattern Bending.........................................................................................................................................................19

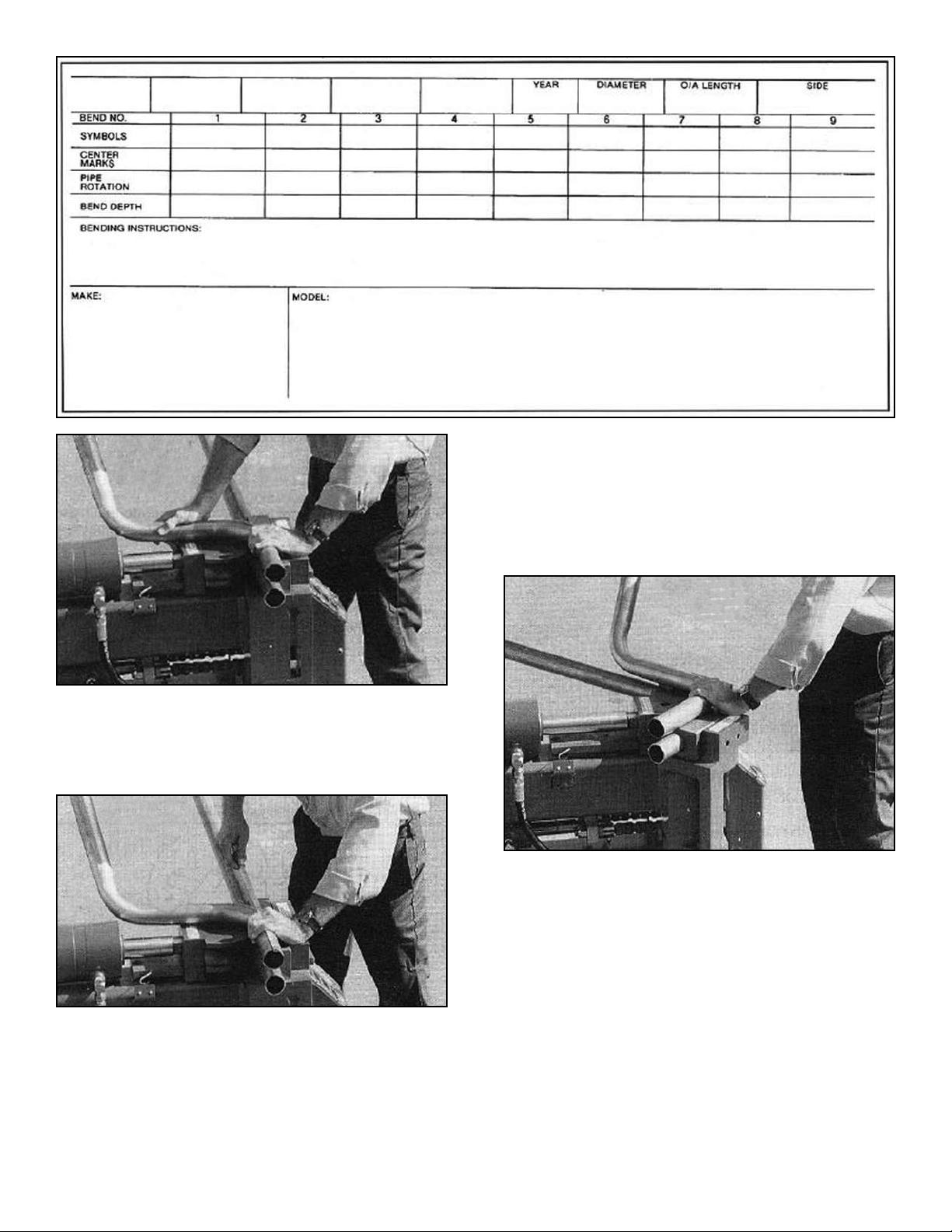

Blank Program Card..................................................................................................................................................20

Three Inch Tube Bending Procedure ........................................................................................................................21

Stainless Tube Bending Procedure...........................................................................................................................22

Using The Standard Segment Expanders.................................................................................................................23

Using The Ball-Joint Segment Expanders ................................................................................................................24

Using The Flare Segment Expanders.......................................................................................................................24

Using The Manifold Flange Segment Expanders .....................................................................................................25

Introduction Of The Swager Assembly......................................................................................................................25

Using The STED Expander Dies...............................................................................................................................25

Making Male Ball Expansions ...................................................................................................................................26

Making Female Ball Expansions ...............................................................................................................................27

Making 45 Degree Flares..........................................................................................................................................27

Making A Manifold Flange Using The HPF-300 Tool ................................................................................................28

Making A Manifold Flange Using The CFT Tool........................................................................................................30

Using the Reducing Tool ...........................................................................................................................................30

Using The Doming Die To Finish Tailpipe Ends ........................................................................................................31

Making Header Collectors Using the HCT-2I4/2I2 Tool ............................................................................................ 3I

Maintenance Introduction ..........................................................................................................................................32

Hydraulic Oil Service.................................................................................................................................................32

Recommended Weekly / Monthly Maintenance........................................................................................................32

Pressure Settings ......................................................................................................................................................33

Chain Adjusting Procedure........................................................................................................................................34

Aligning The Guide Plate ..........................................................................................................................................35

Barrel Bushing Maintenance .....................................................................................................................................36

Aligning The Swager Box Cylinder............................................................................................................................37

Pusher Block Maintenance........................................................................................................................................38

Calibrating The Depth-Of-Bend Plate Manual Models..............................................................................................39

Calibrating The Depth-Of-Bend Switch (BAS Models).............................................................................................. 39

Calibrating The Digital Readout Display (BA Models)...............................................................................................40

Using The Jumper Board BA Models........................................................................................................................41

Operating The Machine Manually Using The Solenoid Valve...................................................................................42

Solenoid Valve Maintenance .....................................................................................................................................43

Checking The Micro Switches (Automatic Models)..................................................................................................43

Motor Lead Connections ...........................................................................................................................................43

Checking Motor Rotation...........................................................................................................................................44

Manual Electric Starter..............................................................................................................................................44

Trouble Shooting Procedures................................................................................................................................. 45-47

Bending Problems .....................................................................................................................................................48

Electrical Wiring Diagrams (Models BA & BAS)..................................................................................................... 49,50

Service Parts .............................................................................................................................................................51

Deluxe 302 Die Package...........................................................................................................................................52

Economy 202 Die Package.......................................................................................................................................53

BB-1 Die Package For Blue Bullet ............................................................................................................................54

BB-2 Die Package For Blue Bullet ............................................................................................................................55

2 Bender Operation Manual

3 Bender Operation Manual

YOUR NEW BENDER

This instruction manual has been prepared especially for you.

Your new bender is the product of over 25 years of continuous research, testing and

development and is the most technically advanced bender on the market today.

READ THIS ENTIRE MANUAL BEFORE OPERATION BEGINS.

The manner in which you care for and maintain your bender will have a direct effect on

it's overall performance and longevity.

RECORD HERE THE FOLLOWING INFORMATION WHICH IS LOCATED AT THE

FRONT END OF YOUR MACHINE.

Serial No. _________________

Model No. _________________

Manufacturing date __________

Bender Operation Manual 3

WARRANTY

Your new bender is warranted for two years on equipment structure; one year on

all operating components and tooling to the original purchaser, to be free of defects

in material and workmanship. The manufacturer shall repair or replace at their

option for this period those parts returned to the factory freight prepaid which prove

upon inspection to be defective. The manufacturer will pay labor costs for the first

l2 months only on parts returned as previously described.

This warranty does not extend to defects caused by ordinary wear, abuse,

misuse, shipping damage, or lack of required maintenance.

This warranty is exclusive and in lieu of all other warranties expressed or implied.

In no event shall the manufacturer be liable for special, consequential or incidental

damages for the breach or delay in performance of the warranty. The manufacturer

reserves the right to make design changes or add improvements to its product line

without incurring any obligation to make such changes on product sold previously.

Warranty adjustments within the above stated policies are based on the model

and serial number of the equipment. This data must be furnished with all

warranty claims.

WARRANTY IS NOT VALID UNLESS

WARRANTY CARD IS RETURNED

4 Bender Operation Manual

Bending Capacity .............................Tubing from 1/2” OD - 3” OD

Maximum Capacity/Tube Thickness

....See Chart Below

Maximum Bending Radius ...............5”

Minimum Bending Radius ................3-1/2”

Swaging Capability*..........................Expansion / Reduction / Forming

Swaging Capacity.............................1” O.D. Tubing - 3” O.D. Tubing

Motor.................................................5 H.P / Single or Three Phase /

220-380-440 VAC

Pump Output ....................................3 GPM / 4200 psi (max. output)

Operation Modes ..............................Full Automatic or Manual Foot Switch

Hydraulic Filter..................................Canister type

Bending Force ..................................55,000 Pounds Maximum

Bend-Depth Control..........................

Degree Plate With Adjustable Pointer /

Automatic Stop and Return

Overall Length ..................................62” I302-BAS / 64” 1502-BAS

Overall Width ....................................30” I302-BAS / 26” 1502-BAS

Overall Height...................................41”

* Special radius dies are available.

** Reduction tools do not come standard

DESIGN FEATURES

MODELS 1302-BAS / 1502 BAS

Bending Capacity .............................Tubing from 1/2” OD - 3” OD

Maximum Capacity/Tube Thickness

....See Chart Below

Maximum Bending Radius ...............5”

Minimum Bending Radius ................3-1/2”

Swaging Capability*..........................Expansion / Reduction / Forming

Swaging Capacity.............................1” O.D. Tubing - 3” O.D. Tubing

Motor.................................................5 H.P / Single or Three Phase /

220-380-440 VAC

Pump Output ....................................3 GPM / 4200 psi (max. output)

Operation Modes ..............................Manual Control Valve

Hydraulic Filter..................................Canister type

Bending Force ..................................55,000 Pounds Maximum

Bend-Depth Control..........................

Manual / No

Automatic Stop

Overall Length ..................................68” I302-BL / 65” 1502-BL

Overall Width ....................................30” I302-BL / 26” 1502-BL

Overall Height...................................41”

* Special radius dies are available.

** Reduction tools do not come standard

DESIGN FEATURES

MODELS 1302BL (BLUE BULLET) / 1502 BL

GAUGE / WALL DECIMAL BENDER CAPACITY

THICKNESS EQUIVALENT

RADIUS MAXIMUM

SIZE BEND DEPTH

Bending Capacity .............................Tubing from 1/2” OD - 3” OD

Maximum Capacity/Tube Thickness

....See Chart Below

Maximum Bending Radius ...............5”

Minimum Bending Radius ................3-1/2”

Motor.................................................5 H.P / Single or Three Phase /

220-380-440 VAC

Pump Output ....................................3 GPM / 4200 psi (max. output)

Operation Modes ..............................Automatic / BA or BAS Manual / BL

Hydraulic Filter..................................Canister type

Bending Force ..................................55,000 Pounds Maximum

Bend-Depth Control..........................

BA / Digital Readout / Automatic

BAS / Depth-of-Bend Plate / Automatic

BL / Manual

Overall Length ..................................52” 1000-BA/1000 BAS 55” 1000-BL

Overall Width ....................................39”

Overall Height...................................41”

* Special radius dies are available.

DESIGN FEATURES

MODELS 1000BL / 1000 BAS

Bending Capacity .............................Tubing from 1/2” OD - 3” OD

Maximum Capacity/Tube Thickness

....See Chart Below

Maximum Bending Radius ...............5”

Minimum Bending Radius ................3-1/2”

Swaging Capability*..........................Expansion / Reduction / Forming

Swaging Capacity.............................1” O.D. Tubing - 3” O.D. Tubing

Motor.................................................5 H.P / Single or Three Phase /

220-380-440 VAC

Pump Output ....................................3 GPM / 4200 psi (max. output)

Operation Modes ..............................Full Automatic or Manual Foot Switch

Hydraulic Filter..................................Canister type

Bending Force ..................................55,000 Pounds Maximum

Bend-Depth Control..........................

Digital Readout

Automatic Stop and Return

Overall Length ..................................62” I302-BA / 64” 1502-BA

Overall Width ....................................30” I302-BA / 26” 1502-BA

Overall Height...................................41”

* Special radius dies are available.

** Reduction tools do not come standard

DESIGN FEATURES

MODELS 1302-BA / 1502 BA

SPECIFICATIONS

4 .238 1”- 1-3/4 O.D. Tubing / Pipe

5 .220 1” - 7/8” O.D. Tubing / Pipe

6 .203 1” - 2” O.D. Tubing / Pipe

7 .180 1”- 2-1/8” O.D. Tubing / Pipe

8 .165 1”- 2-1/4” O.D. Tubing / Pipe

9 .148 1”- 2-1/4” O.D. Tubing / Pipe

10 .134 1”- 2-1/2” O.D. Tubing / Pipe

11 .120 1”- 2-1/2” O.D. Tubing / Pipe

12 .109 1”- 2-1/2” O.D. Tubing / Pipe

13 .095 1”- 3” O.D. Tubing / Pipe

14 .083 1”- 2-1/2” O.D. Tubing / Pipe

15 .072 1”- 2-1/2” O.D. Tubing / Pipe

16 .065 1”- 2-1/2” O.D. Tubing / Pipe

17 .058 1”- 2” O.D. Tubing / Pipe

18 .049 1”- 1-3/4” O.D. Tubing / Pipe

3-1/2” 135°

4” 145°

5” 172°

4” 150°

180° Style*

5” 180°

180° Style*

NOTE

180° STYLE DIES ARE NOT

INCLUDED IN STANDARD

TOOLING PACKAGES.

Special size dies not listed in this manual may be manufactured to your specifications.

Call factory for details. Special manufactured items require a 60-day minimum lead time.

5 Bender Operation Manual

1. Read and understand all safety warning proce-

dures before operating machine.

2. Keep hands clear. Remove hands prior to bending,

forming, swaging or expanding tubing. Avoid pinch

points.

3. Keep work area clean. Cluttered work areas invite

injuries.

4. Consider work area environment. Do not expose

equipment to rain. Do not use in damp or wet locations.

Keep area well lighted.

5. Only trained operators should operate this

machine. All non-trained personnel should be kept away

from work area. Never let non-trained personnel come in

contact with, or operate machine.

6. Use tooling correctly. Use all tooling in the proper

manner. Never try to use a tool for something that it was

not designed for. See manual for proper use.

7. Dress properly. Never wear loose gloves, clothing

or jewelry. They can be caught in moving parts. Non-

skid steel - toe footwear is recommended when operat-

ing machine. Wear protective hair covering to contain

long hair.

8. Always wear safety goggles when operating this

machine.

9. Do not overreach. Keep proper footing and balance

at all times.

10. Guard against electric shock. This machine must

be grounded while in use to protect the operator

from electric shock. Never connect the green power

cord wire to a live terminal. This is for ground only.

11. Always unplug machine before servicing. Never

yank cord to disconnect it from the receptacle. Make

sure electrical connections are good. Never use an

extension cord longer than 15 feet. If the power cord

becomes frayed, replace it. Never alter electrical

components on this machine. Never operate

machine in or around water or damp environments.

12. Warning! Risk of explosion. This equipment has

internal arcing or sparking parts which should not be

exposed to flammable vapors. This machine should

not be located in a recessed area or below floor level.

13. Maintain with care. Keep machine clean for better

and safe performance. Follow manual for proper

lubrication and maintenance instructions. Keep control

handles and/or buttons dry, clean and free from grease

and oil.

14. Stay alert. Watch what you are doing. Use common

sense. Be aware.

15. Check for damaged parts. Check for alignment of

moving parts, breakage of parts or any condition that

may affect its operation. Do not use machine if any

component is broken or damaged.

16. Never remove electric foot switches from their

protective safety housing. Always remove foot from

pedal enclosure between bends.

17. Always allow for the “Safety Circle Of Swing”

around the bender. There should be at least 10 feet

of space on both sides of the bender so that the tubing

will not come in contact with persons and/or objects.

Bender Operation Manual 5

THESE SAFETY INSTRUCTIONS MUST BE GIVEN TO ALL OPERATORS TO READ.

IF THE INDIVIDUAL CANNOT READ, INSTRUCTIONS MUST BE READ TO THEM.

UPON DELIVERY

IMPORTANT SAFETY INSTRUCTIONS

Read these safety instructions entirely!

1. Carefully remove the crating and packing materials.

2. Inspect the bender for any signs of concealed

shipment damage or shortages. Remember to report any

shipping damage to the carrier and make a notation

on the delivery receipt.

3. Check the voltage, phase and proper amperage

requirements for the motor shown on the motor plate.

Wiring should be performed by a certified

electrician only.

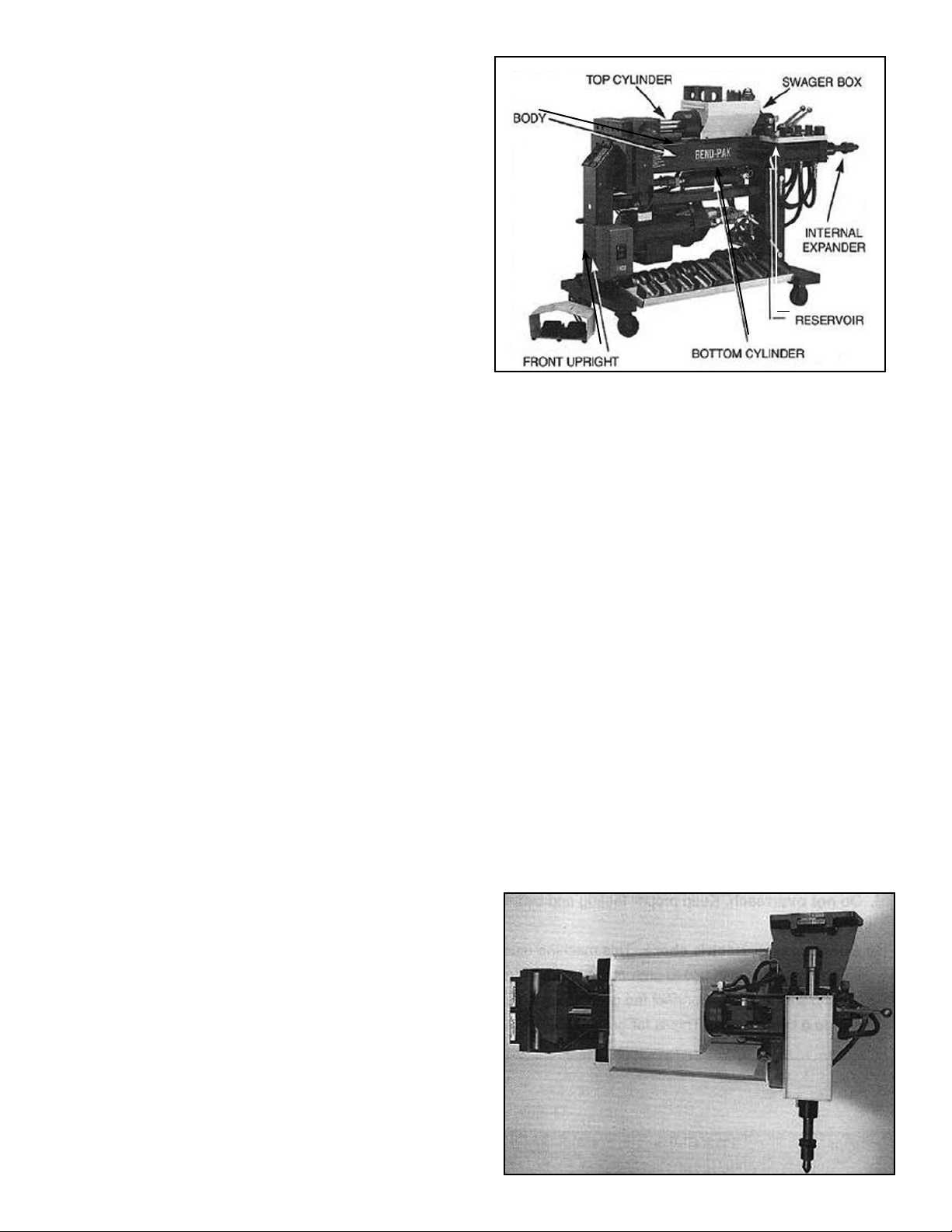

INTRODUCTION

Your new bender is a “press-style” bender that is capable

of bending, flaring and swaging tubing up to 3 inches in

diameter. The thickness of the tubing plays an important

part. (See previous chart for recommended tubing

allowances.) The front of the bender is where all the bend-

ing is performed. The top cylinder activates the bending or

radius die which moves forward through the back shoes.

The bottom cylinder keeps pressure applied to the back

shoes by a chain assembly and integrated hydraulic

sequence valve. In addition to the contoured shape of the

radius dies, resistance pressure is applied to help the tub-

ing maintain it's shape.

DEFINITION OF TERMS

The following definitions explain the major components

and operating features of your machine. The RIGHT,

LEFT, and REAR sides of the bender are relative to the

FRONT of the machine where all bending is performed.

BENDER- The whole machine including all end

finishing components.

BODY- The main 6” x 6” tubular structure that sits

horizontal to the floor and is located just below the top

cylinder.

SWAGER OR SWAGER BOX- The expanding/flaring

unit located to the rear of the bender which utilizes

pipe collars in conjunction with bullet shaped expander/

forming dies to perform a variety of tube end finishing.

INTERNAL EXPANDER- The expanding/flaring unit

located to the rear of the machine that utilizes seg-

mented expander dies. These “segment sets” are expand-

ed by the means of a tapered arbor pulled through their

center. This style of end finishing is usually required with

shorter pieces of tubing such as muffler nipples which do

not allow the use of a collar.

TOP CYLINDER- The main hydraulic bending cylinder

located at the top of the bender. It's primary function is to

activate movement of the radius dies.

BOTTOM CYLINDER- The hydraulic cylinder located

just below the body of the bender. It's primary function is

to apply resistance pressure to the back shoes as the

radius die pushes through.

RESERVOIR-The rear vertical leg that contains the

hydraulic oil.

FRONT UPRIGHT- The front vertical leg.

BENDER MODELS

There are nine different bender models available.

1000-BL 1000-BAS 1000-BA

1302-BL (Blue-Bullet) 1302-BAS 1302-BA

1502-BL 1502-BAS 1502-BA

The following is a brief description of their controls and

operating features. The model nomenclature consists of a

number (1302) followed by letters BA. The numbers des-

ignate what style frame assembly is used while the letters

signify the control features.

FRAME CONFIGURATION

1000 Series- A machine capable of bending only. Does

not come with any end finishing capabilities.

1302 Series- A machine capable of bending and end

finishing. Equipped with both swager and internal

expander. A double-ended hydraulic cylinder is used for

both end finishing functions. The end finishing assembly,

(the swager and internal expander) is positioned

“cross-wised” on the rear of the machine.

6 Bender Operation Manual

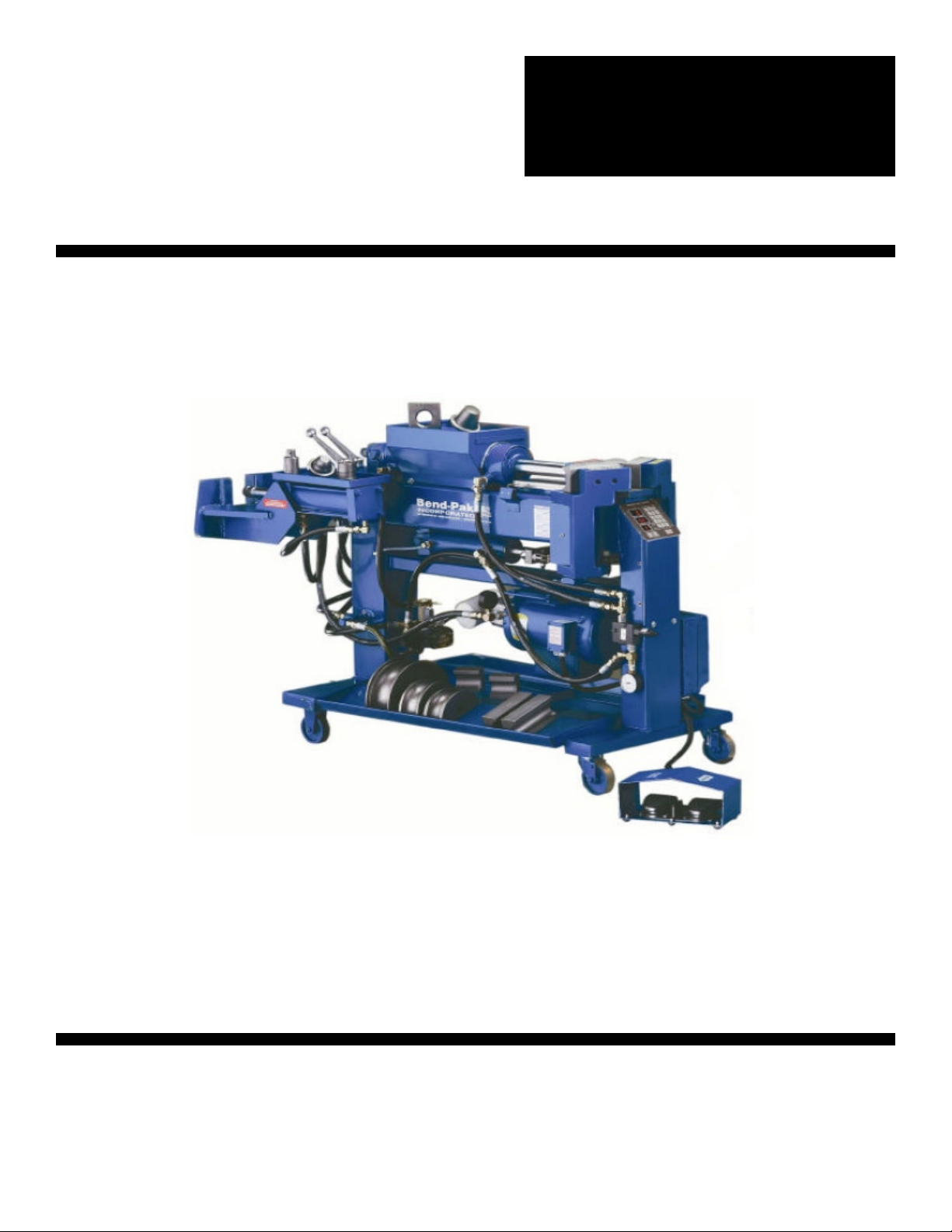

Overhead view of Model 1302

Side view of Bender showing major components.

7 Bender Operation Manual Bender Operation Manual 7

1502 Series- A machine capable of bending and end fin-

ishing. Equipped with both swager and internal expander.

Individual hydraulic cylinders are utilized for both end fin-

ishing functions. The swager and internal expander are

positioned at the rear of the machine, one on each side

and are positioned parallel with the main body.

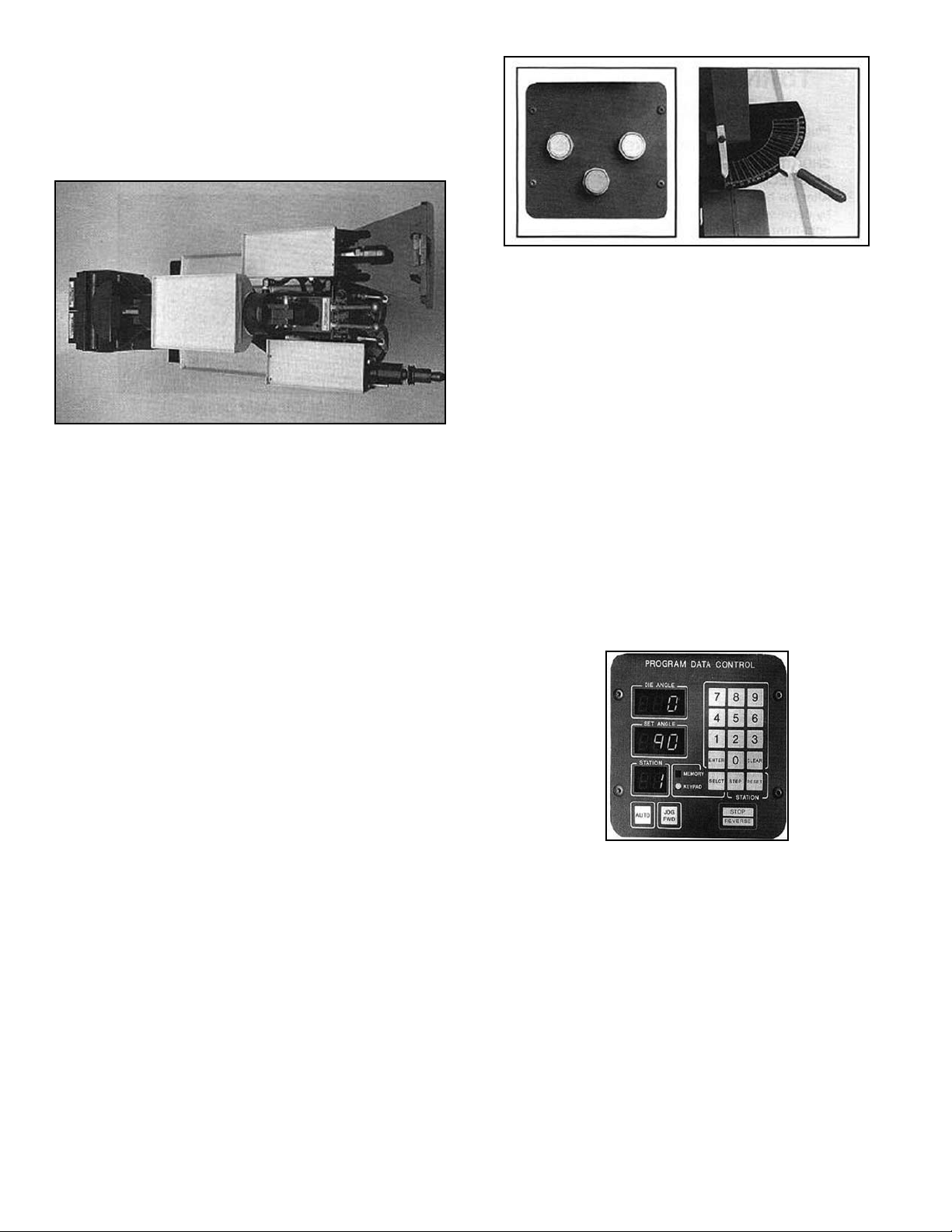

CONTROL FEATURES

BL or BLUE-BULLET Models- A hydraulic control valve

is located at the front of the machine at knee height that

allows the operators to manually control the machine with

their leg. A degree plate is mounted up front that shows

proper bend depths. This model does not

incorporate any automatic bending features.

BAS Models- These models have two different control

modes. An electric foot switch assembly for manual bend-

ing operations and a three-button control board for auto-

matic functions. The degrees of bends are shown on a

degree plate mounted near the front of the machine which

also incorporates an adjustable slide pointer that can be

set to any desired bend depth. The control board consists

of three colored buttons; GREEN, BLUE and RED; each

with its own operating functions. If you choose to use the

machine in the automatic mode, you would simply set the

pointer to 90 degrees for example, then press the GREEN

button. At this time the bending head would activate and

the radius die would begin to move forward. After the

desired bend depth has been reached, the machine would

automatically initiate the retract sequence that returns the

die to the original

starting position. The BLUE button is for automatically

returning the die to the original starting position while the

RED button is an emergency stop control. The electric foot

switches will override the three button controls.

BA Models - These models have two different control

modes; an electric foot switch assembly for manual bend-

ing operations and a digital control board for automatic

functions. The digital control board eliminates the depth of

bend scale and replaces it with a digital readout labeled

“DIE ANGLE”. It also offers the user the capability to “pro-

gram” certain bend depths in a desired sequence. When

the power is turned off, all memory is erased. Once a bend

depth is programmed into memory the number appears in

a L.E.D. window labeled “SET ANGLE.” The bend

sequence is initiated by pressing the “AUTO” button. At

this time the die moves forward and upon reaching the

desired bend depth immediately retracts to the original

starting position. An emergency “STOP” button pauses

the machine at any time, and an additional auto “REVERSE”

button activates the return sequence. The electric foot

switches will override the digital controls.

INSTALLING THE

ELECTRICAL PLUG

Before installing a plug on the end of the power cord it is

important to check for proper voltage, phase, and amp

requirements. The tag attached to the end of the power

cord, or the motor identification plate will show this

necessary information. Due to the high amps and voltage

required to operate this machine at long durations, it is

recommended that you DO NOT USE AN EXTENSION

CORD LONGER THAN 15 FEET. This motor must be

grounded. The GREEN wire is for ground only. All wiring

should be done by a certified electrician only. Damage

to the motor caused by improper wiring is not covered

under warranty.

Overhead view of Model 1502

Three button control

Digital

control

board

D.O.B. Plate

TURNING YOUR NEW

BENDER ON

1. Plug the power cord into a receptacle closest to the

available circuit panel. IF SMOKE APPEARS OR

SHORTlNG OCCURS, DlSCONNECT

IMMEDIATELY! RE-CHECK ALL CONNECTIONS.

2. After the bender is plugged in, turn the machine on

by depressing the “ON” button located on the lower

right-front side of the machine. IF SMOKE

APPEARS OR SHORTlNG OCCURS,

DlSCONNECT IMMEDIATELY! RECHECK ALL

CONNECTIONS.

3. Let the bender run for approximately five minutes

without operating the controls.

4. At this time, it is necessary to install all control han-

dles by properly connecting the linkages as shown.

5. After the bender is warmed up, retract the radius

die that contains the sample tube. On automatic

models do this by depressing the left foot switch.

On Blue-Bullet or manual models activate the knee

control valve by moving the handle to the right.

6. IF THE RADIUS DIE DOES NOT MOVE,

CONSULT THE FACTORY.

7. After the radius die has completely retracted,

remove the sample tubing that is in place.

8. Bring the radius die forward by depressing the right

foot switch or by moving the manual control valve

handle to the left.

9. Advance the radius die to l00 degrees then retract

fully. Repeat this sequence for at least five times.

The bending die may move erratically for the fIrst

few cycles due to air trapped in the lines. This is

normal. The air will dissipate after use. Do not try to

“crack” a line to help the air escape.

10. At this time check for any possible leaks that could

have developed during shipment. Tighten any

hoses that may have loosened.

11. Check the oil level by observing the sight gauge

located near the right-rear side of the machine. If

the oil level appears low, add oil now. (See page 32

for recommended hydraulic oils.)

12. Activate the swaging and internal expander cylinders

by depressing the control handles located at the rear

of the machine. Cycle the cylinders to their full extent

at least fIve times. Again, these cylinders may act

erratically until the air dissipates.

TOOLING

Find the packing list that accompanied your bender, item-

izing each tool that was to be included in your tooling

package. Double check the pieces you received with

those that were checked off. ALL THE TOOLS THAT

ARE CHECKED OFF IN THE “SHIPPED” COLUMN DID

SHIP WITH YOUR BENDER. If you cannot fInd a certain

piece that you feel should be with the shipment, check

with the freight carrier or observe the packing list and

check the back ordered column. If a certain item is back

ordered it will be automatically forwarded to you. A

description of tooling is listed below.

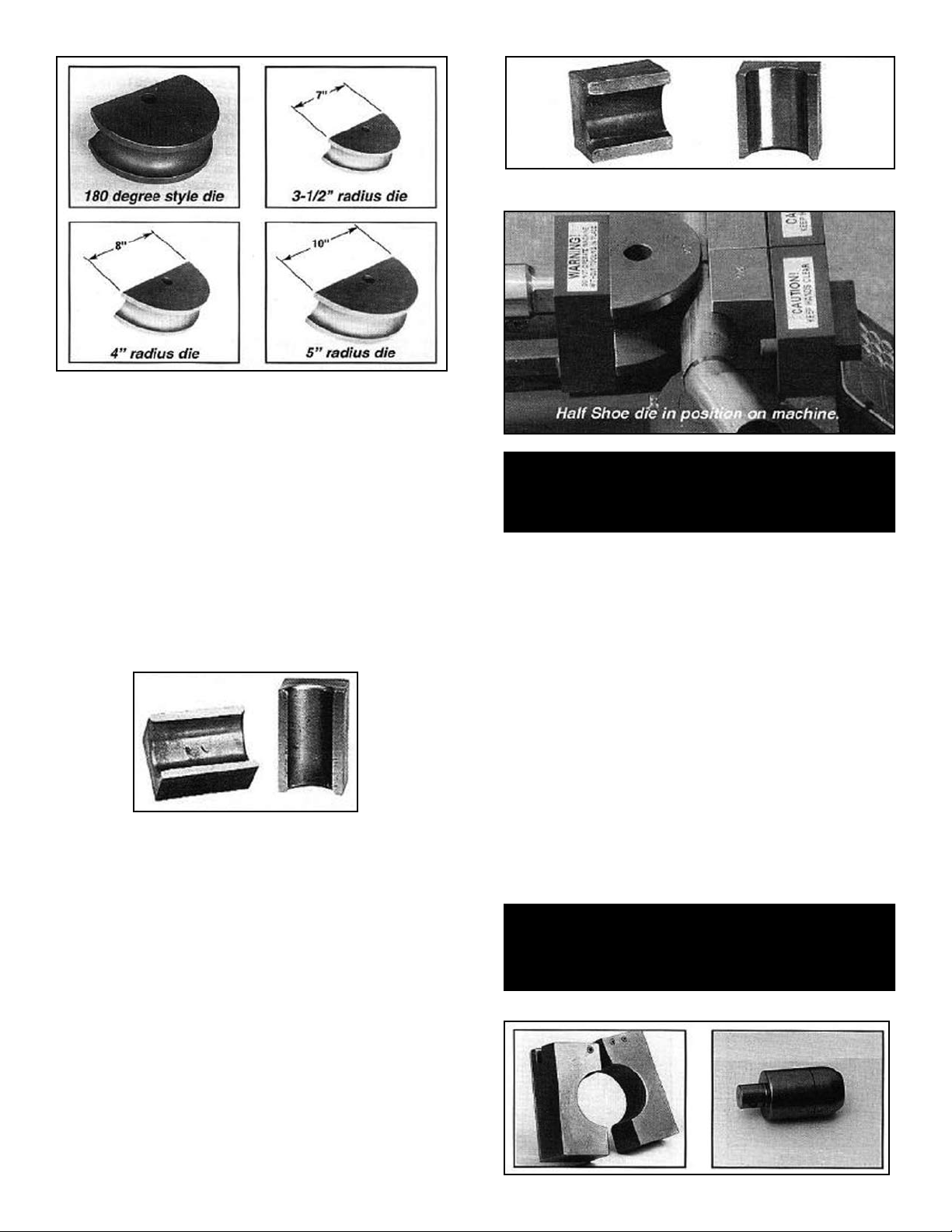

RADlUS DIES- These dies which are commonly referred

to as the “bending dies” come in different radii and tubing

sizes. Each die is machined and sized according to tubing

diameters. The proper tube size is stamped on the top of

each die. 112 represents 1-1/2” tubing, 134 represents

1-3/4” tubing etc. The radius dies are available in three

standard radii, 5”, 4” and 3-1/2”. Each standard radius die

represents half of a circle or diameter. 180 degree dies

are also available which represent three quarters of a

circle and allow the tubing to “wrap” around farther

although the radii are the same.

8 Bender Operation Manual

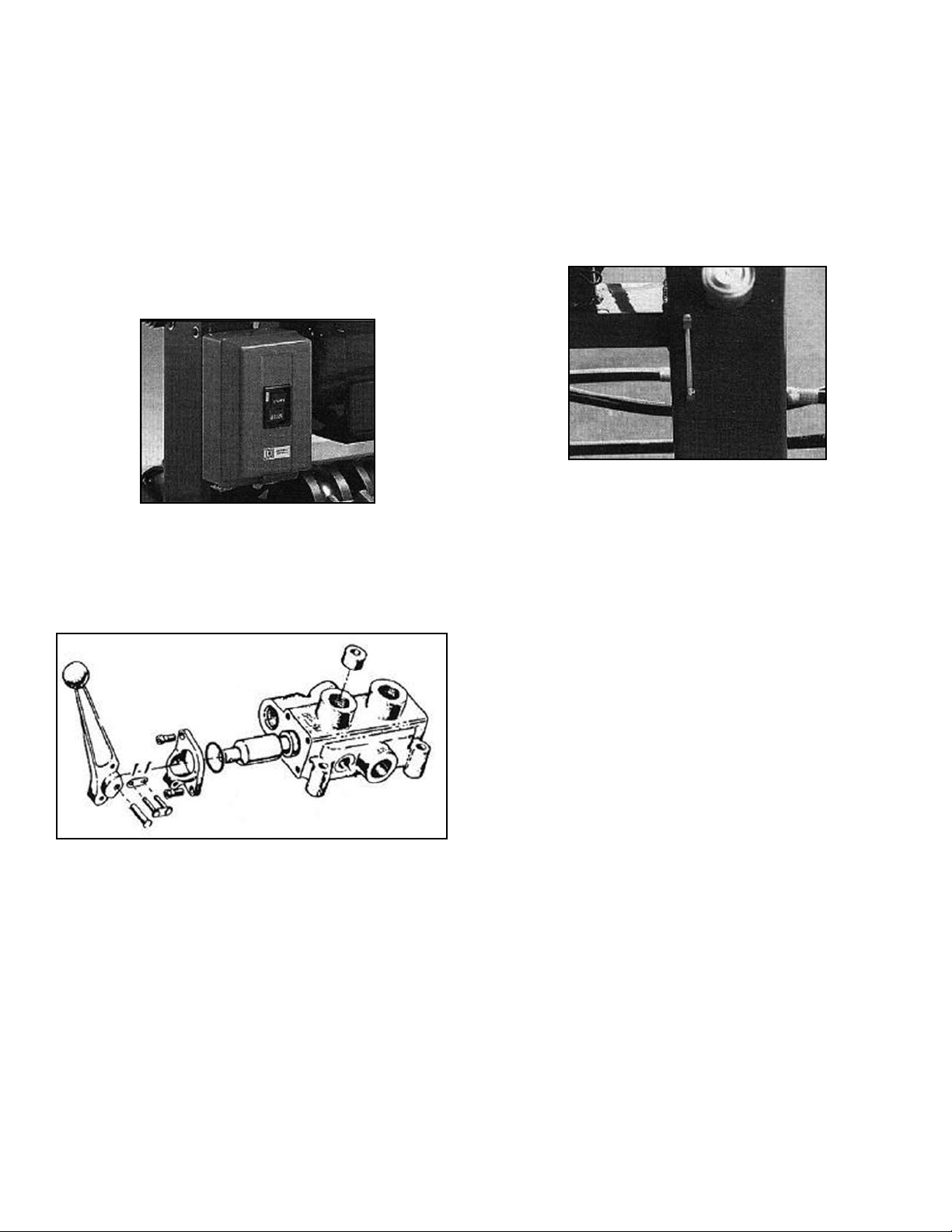

Control handle linkage assembly

Oil sight gauge

Electrical On / Off switch box

9 Bender Operation Manual

BACK SHOES- Back shoes, which are commonly referred

to as wiper dies come in pairs and are used together with

the radius dies during the bending process. These dies

play an important part as their primary

purpose is to form the outside radius of the bend. These

dies are used to clamp or retain the pipe as it is wrapped

around the radius die. Each back shoe is machined and

sized according to tubing diameter. The proper tubing size

is stamped on the top of each back shoe.

NOTE:

Back shoes should be kept clean and lightly oiled.

Never use the bender without back shoes in

place. Never use the bender as a vice or a press.

HALF SHOES AND THREE QUARTER SHOES Half

shoes and three quarter shoes do not come in pairs. Only

one is required. Half shoes are exactly half the length of a

standard back shoe and three quarter shoes are three

quarters the length. These smaller shoes are required

when an upcoming bend is less than ten inches from an

existing bend. The half/three quarter shoe will be used in

conjunction with the back shoe and placed only on the

side where the full back shoe may interfere with the

upcoming bend. (Details for the proper use of these tools

are explained in the BENDING section.)

NOTE:

Half shoes and three quarter shoes must be used

with radius dies and back shoes of the same

corresponding size.

HAC's & STED's- HAC's are Commonly referred to as

“adapter collars” while the STED's are referred to as “solid

expander dies”. HAC's are used to hold or clamp the tub-

ing in place when performing end-finishing Operations or

when using the STED's. These “adapter collars” are heat

treated which causes the inside threads or “teeth” to

become brittle. Because of this, these “teeth” have the

tendency to chip during normal use. This is normal and will

have no effect on their performance. The STED's or “solid

expander dies” are used to expand the tubing to exact

inside diameters and are also used to create male ball

expansions. Both tools are stamped and marked with their

appropriate tubing sizes. (Details on the proper use of

both tools is explained in the END FINISHING section.)

NOTE:

Keep collars free of debris and build up. Use a

wire brush periodically to clean the inside

threaded area. Keep all tooling lightly oiled.

Bender Operation Manual 9

Back shoe dies

CAUTION!

KEEP HANDS CLEAR when using all the tools

described in this manual. Improper use of these

tools may result in serious bodily harm

CAUTION!

All tooling described in this manual is heavy!

HANDLE WITH CARE. Always wear steel toe boots

when operating bender.

Adapter Collars STED Expander dies

Half Shoe Three Quarter Shoe

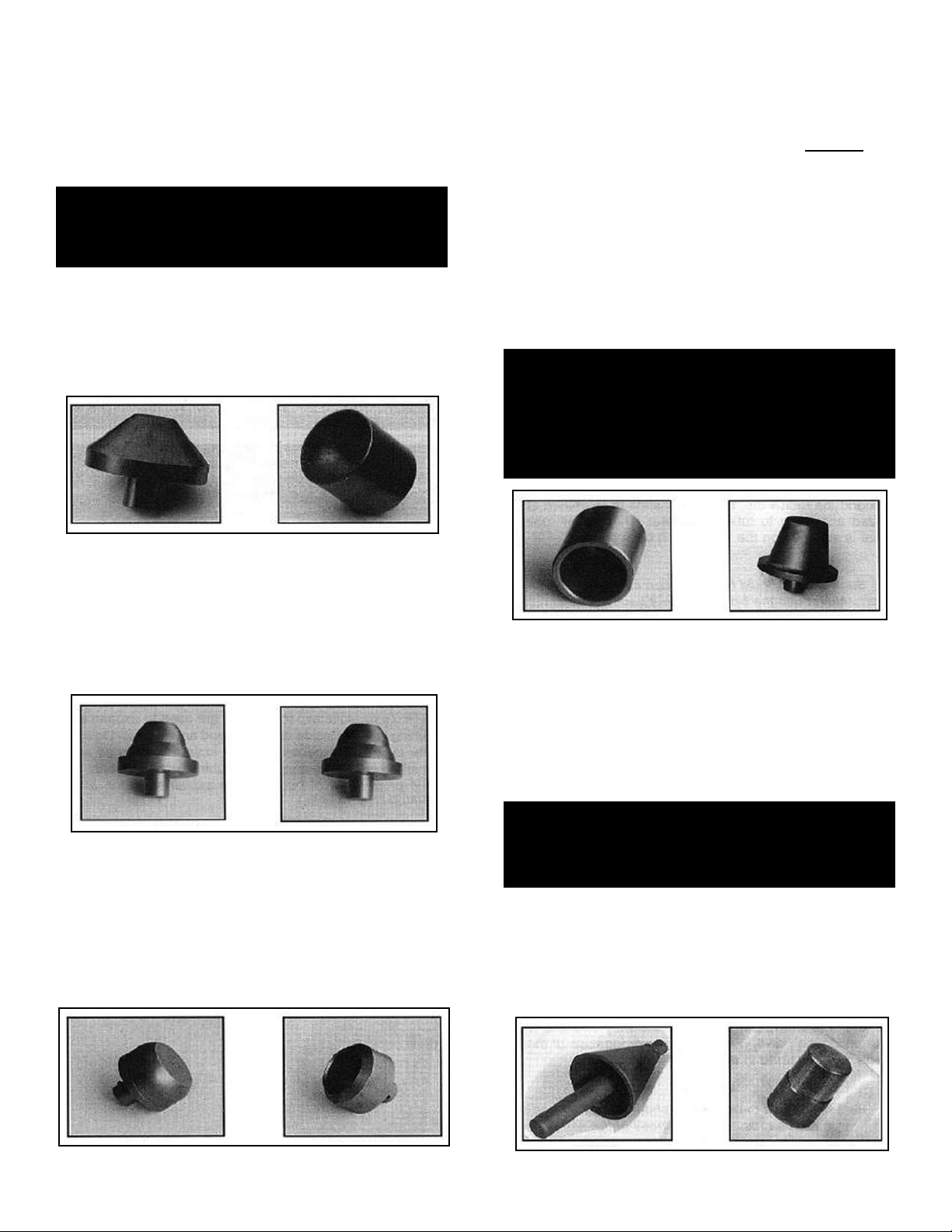

END-FINISHING TOOLS - A variety of end finishing tools

are available that perform different functions. Not every

tool is included with your tooling package. If you are

unsure as to what was included, please consult your dis-

tributor or review the delivery receipt and invoice. Each

tool is marked with the appropriate size.

HPF-300 - A tool for making 45 and 90 degree flanges on

pipe ends. Usually for manifold connections.

DD-134/212- A tool for doming pipe ends or making male

ball expansions when used in conjunction with the male

ball expanders.

DD-134/212 & BFED-200/214 - Tools for flaring pipe ends

to make female ball expansions. Each tool is “stepped”

and has the ability to flare two different sizes. The BFED-

134/214 is used for tubing sizes 1-3/4” and 2-1/4” while

the BFED-200/212 is used for tubing sizes 2” and 2-1/2”.

B-212- A tool used for making male ball expansions on

2-1/2” pipe ends.

CFT-200 & CFT-214 - Tools for making manifold flanges

on 2” and 2-1/4” pipe ends. Not included in standard

tooling packages.

REDUCING TOOLS - Reducing tools are used for

reducing or “shrinking” pipe ends to exact outside diame-

ters. Each tool is marked with the appropriate size. It is

important to understand that the size marked on the tool

will be the size that the tubing will be reduced down to. For

example, a tool marked 200 will reduce 2-1/4” tubing

down to 2” O.D. and a tool marked 214 will reduce

2-1/2” tubing down to 2-1/4” O.D. Not included in

standard tooling packages.

HCT-214/212 - This tool is for making header flanges or

“collectors” on 2-1/4” and 2-1/2” pipe ends. This

eliminates the need to purchase a collector when

installing header type manifolds.

Not included in standard tooling packages.

HSRO- A hand held pipe reshaping tool that is used for

reshaping pipe ends while the tubing remains on the

vehicle. By tapping the tool with a hammer or mallet the

tool can be used to reshape pipe ends. Can be used inter-

nally or externally by simply reversing the tool. Not avail-

able in standard tooling packages.

BENDING PLUGS - Bending plugs are used to contain

the shape of pipe ends during the bending process when

the radius die comes in close proximity to the pipe end.

Once the bend is completed, the bending plug is removed.

Not included in standard tooling packages.

10 Bender Operation Manual

CAUTION!

DO NOT attempt to use these tools unless you have

read and fully understand the

“Swaging and End Forming” section.

CAUTION!

ALWAYS wear protective safety glasses or goggles

when using this machine

IMPORTANT NOTICE

Installing headers on any motor vehicle is illegal in

most states and may violate the 1990 Clean Air Act.

Consult the EPA at (202) 260-7645 for questions

regarding the installation of any aftermarket perfor-

mance product that may alter vehicle emissions.

HPF-300 DD-134/212

Reducing Tool HCT-214/212

HSRO Bending Plug

BFED-134/214 BFED-200/212

B-212 CFT-200

11 Bender Operation Manual

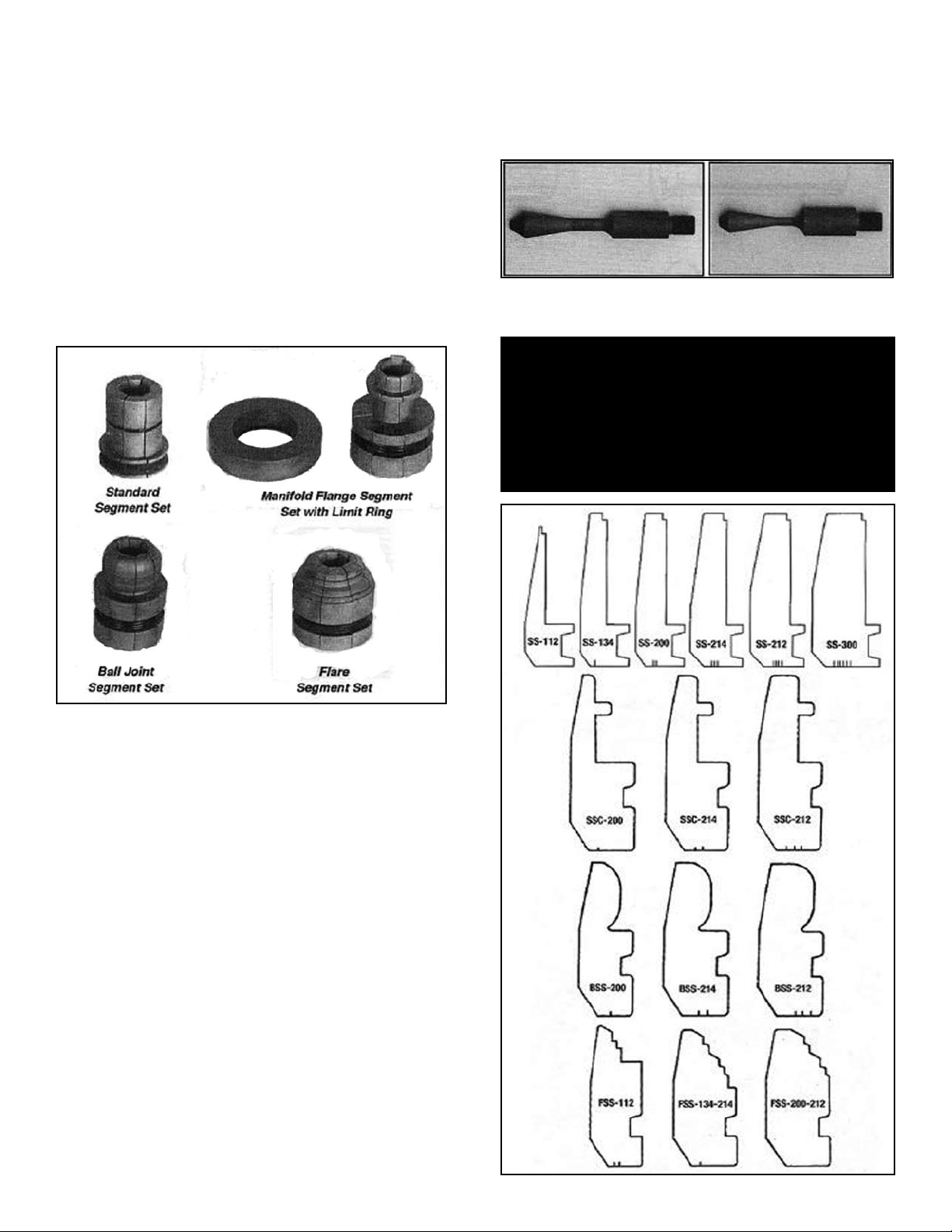

SEGMENT EXPANDERS - Segment expanders or “seg-

ment sets” come in a variety of sizes and shapes, each

performing it's own distinct function. Segment sets are

used for short pieces of tubing or when the tubing end is

minimized due to an existing bend. They can also be used

to expand tubing that is deformed in such a manner that

will not permit use of the swager expander. Segment sets

are used in conjunction with an arbor or mandrel. All seg-

ment sets are identified by grooved rings located at the

bottom as described on the following chart. There are

four different types of segment sets available; STANDARD

SEGMENT SETS, MANIFOLD FLANGE SEGMENT

SETS, BALL-JOINT SEGMENT SETS, and FLARE

SEGMENT SETS.

STANDARD SEGMENT SETS - These segment sets are

used to make straight expansions on tubing ends and are

found in all standard tooling packages.

MANIFOLD FLANGE SEGMENT SETS - These segment

sets are used to make donut-type manifold flanges on tub-

ing ends. They are available in five sizes; 1-1/4”, 1-1/2”,

2”, 2-1/4”, and 2-1/2”. All manifold segment sets are used

in conjunction with limit rings. Not included in standard

tooling packages.

BALL-JOlNT SEGMENT SETS - These segment sets are

used to make ball-joint expansions on tubing ends. They

are available in three sizes; 2”, 2-1/4” and 2-1/2”. Not

included in standard tooling packages.

FLARE SEGMENT SETS - These segment sets are used

to make 45 degree flares on tubing ends. Three different

sets are available that work on tubing sizes 1-1/2” -

2-1/2”.

Not included in standard tooling packages.

NOTE:

Keep segment sets and arbor well greased.

The ARBOR which is pulled through the center of the seg-

ment sets is available in two sizes. The HSA-114 is an

arbor used exclusively for 1-1/4” and 1-3/8” tubing while

the HSA-112 is used for tubing sizes 1-1/2” through 3”.

Bender Operation Manual 11

WARNING!

1. Always remove excess tooling from swager area

before using internal expander.

2. To avoid breaking tooling ALWAYS use proper

segment sets with appropriate tubing size.

3. NEVER stand in front of arbor when operating

internal expander.

HSA-112 Arbor HSA-114 Arbor

DIGITAL CONTROL

OPERATIONS.

“BA” MODELS.

Read each of the following sections carefully before

attempting any operation of this unit. All “BA” models are

equipped with a computer microprocessor that allows

minor storage and recall of certain bend data. It also gives

the user the ability to bend automatically or manually.

DESCRIPTION OF

CONTROLS:

SELCT - Selects KEYPAD or MEMORY functions.

CLEAR - Clears the SET ANGLE.

ENTER - Enters the numbers displayed in SET ANGLE

into memory. (Only when KEYPAD is lighted.)

STEP - Advances station number display.

RESET - Resets station number back to one.

AUTO - Starts automatic cycle.

JOG/FWD - Press and hold to advance radius die manu-

ally. Release button and all forward motion will stop.

Overrides AUTO button.

STOP/REVERSE (Also, EMERGENCY STOP) -

Press to stop forward movement of radius die. Press

again to reverse, then again to stop.

SET ANGLE WINDOW - Displays depth-of-bend degrees

programmed for the next bend.

DIE ANGLE WINDOW - Continuously displays the degrees

of bend as the radius die moves forward.

STATION WINDOW - Shows the position or station num-

ber that a particular bend depth has been programmed

into.

REMOTE FOOT SWITCHES - Used for manual opera-

tion. The right foot switch advances the radius die while

the left foot switch retracts it. Either foot switch will also

serve as an emergency stop.

12 Bender Operation Manual

STOP!

Before any attempt is made to operate this machine

it is important that you have read and fully under-

stand all operating instructions described in this

manual.

13 Bender Operation Manual

NOTE:

Practice the following bending steps without

tubing and initiate a few “dry runs” until you

understand the operating features.

USING THE REMOTE FOOT SWITCHES OR AUTO

BUTTON - When using a card system or bending a pipe,

you are not required to use the “Memory” function. Some

operators will use the memory function only when multiple

pipes are to be bent. The most popular method will be

manual or semi-automatic. When KEYPAD is lighted, the

machine will operate manually using the remote foot

switches or JOG/FWD button or semi-automatically,

performing one bend at a time using the AUTO button.

The actual depth-of-bend degrees will continuously appear

in the DIE ANGLE window any time the machine is

running. To manually operate the bender, depress the

right foot switch to advance the radius die and the left one

to retract it. The foot switches will always override the

automatic controls. When using the foot switches, the

radius die will NOT stop at the SET ANGLE.

To bend one bend at a time using the AUTO button,

follow these step-by-step instructions.

1. Turn the bender on and depress the SELCT button

to illuminate the KEYPAD light.

2. Find out what degree of bend is required and enter it

by depressing the appropriate number keys.

This number will then appear in the SET ANGLE

window. If you make a mistake and improperly

enter the wrong number, simply clear the SET

ANGLE by depressing the CLEAR button then

re-enter the proper information.

3. With the KEYPAD light illuminated, disregard any

numbers that may appear in the STATION window.

4. After installing a matched die set, position the tubing

so that you can begin bending.

5. Check your “circle-of-swing” for allowable clearance.

6. Depress the AUTO button to initiate the semi-

automatic cycle.

7. At this time the radius die will begin to move forward

until it reaches the designated depth-of-bend dis-

played in the SET ANGLE window. The retract

sequence will then automatically initiate, reversing

the radius die until it is fully retracted.

8. For the remaining bends, move the pipe over until

the next bend position or “center mark” is centered

between the back shoes. Repeat steps 5-7.

9. After all bends are completed, cut off the tubing end

to match the existing pipe or master.

PROGRAMMING THE DIGITAL BOARD- Follow these

step-by-step instructions to properly utilize the MEMORY

feature. The PROGRAM DATA CONTROL board stores

bend depths only. All data will be cleared once power is

turned off. The memory feature can be used when bend-

ing multiple or individual pipes The following instructions

illustrate how to properly enter the data which is shown

on the program cards.

1. Press the SELCT button to illuminate the KEYPAD

light.

2. Press the RESET button to return the STATION

window to number one.

3. Using your program card, enter the first degree of

bend shown in the BEND-DEPTH column. Press the

appropriate number keys to display the recommended

bend depth in the SET ANGLE window. Now press

the ENTER key. You have just entered the first bend

depth in station number one.

4. Press the STEP button to change the station to display

the number “2”.

5. Using your program card, enter the second depth of

bend by pressing the appropriate number keys. The

number should appear in the SET ANGLE window. If

the information is correct press the ENTER key. You

have now entered the second bend depth in station

number two.

Bender Operation Manual 13

WARNING!

1. Either foot switch will act as an EMERGENCY

stop.

2. NEVER operate the remote electric foot switches

in or around water or damp areas.

3. If the foot switch cords become frayed or

damaged

in any way, discontinue use until they are properly

repaired.

4. ALWAYS disconnect power cord before making

any electrical repairs.

CAUTION!

KEEP HANDS CLEAR while dies are in motion.

Familiarize yourself with the EMERGENCY STOP

button and its operation. NEVER place hands near

bending area or any pinch points when motor is

running. ONLY TRAINED PERSONNEL should be

near machine when it is in operation.

CAUTION!

If operating controls are malfunctioning,

discontinue use immediately. DO NOT attempt to

operate machinery until controls have

been repaired.

6. Repeat these steps until all depth-of-bends have

been entered. Always remember to press the

ENTER key prior to advancing to the next station.

7. Now press the SELCT key to illuminate the MEMORY

light.

8. Press the RESET button. This will change the

STATION window to number “1”.

9. To double check the data that has been entered,

press the STEP key to advance the stations through

their appropriate sequence. Review the data that has

been entered. If you reach a particular station that is

incorrect, press the SELCT key to illuminate the

KEYPAD light, the SET ANGLE will show zero at this

time then press the appropriate number keys and

retain the data by depressing the ENTER key. After

correcting the improper data, press the SELCT button

to illuminate the MEMORY light and the RESET key

to reset the STATION window. Review the information

once again.

NOTE:

In order to store data into program memory

the KEYPAD light must be illuminated.

Entered data will not be shown in the SET

ANGLE window until the MEMORY light is

illuminated.

THREE-BUTTON

CONTROL OPERATIONS

“BAS” MODELS

Read each of the following sections carefully before

attempting any operation of this unit. All “BAS” models

are equipped with a three-button control board that con-

trols the semi-automatic bending function. In addition to

the three-button control board, all “BAS” models are

equipped with a remote foot switch for manual operation.

DESCRIPTION OF

CONTROLS:

NEVER HOLD IN COLORED CONTROL BUTTONS! -

To properly operate the colored control buttons, quickly

press and release. By holding the colored control buttons

in, damage to the machine and/or components may

result.

GREEN BUTTON - Activates the automatic bending

cycle. After pressing the GREEN button, the radius die

will move forward until the desired depth-of-bend is

reached then automatically retract until the die is

returned to the original starting position.

BLUE BUTTON - Automatically returns or retracts the

bending die to the original starting position. NEVER hold

the BLUE button in when retracting the bending ram.

RED BUTTON - Serves as an “Emergency Stop” button.

Automatically stops all movement of the bending die dur-

ing the automatic cycle.

REMOTE FOOT SWITCHES - Used for manual opera-

tion. The right foot switch advances the radius die to start

the bending process. The left foot switch retracts the

radius die. Either foot switch will also serve as an emer-

gency stop.

NOTE:

Practice the following bending steps without

tubing and initiate a few “dry runs” until you

understand the operating features.

USING THE “AUTO-STOP” DEPTH-OF-BEND FEATURE -

The “Auto-Stop” slide pointer is attached to the depth-of-

bend degree plate and stops the radius die at pre-set

bend depths. The “Auto-Stop” feature works with either

the GREEN automatic control button or the remote foot

switches.

14 Bender Operation Manual

WARNING!

1. Either foot switch will act as an EMERGENCY stop.

2. NEVER operate the remote electric foot switches

in or around water or damp areas.

3. If the foot switch cords become frayed or damaged

in any way, discontinue use until they are

properly repaired.

4. ALWAYS disconnect power cord before making

any electrical repairs.

5. If any operating controls are malfunctioning,

discontinue immediately.

15 Bender Operation Manual

To use the three-button automatic controls, follow these

simple instructions.

1. Position the “Auto-Stop” pointer at the desired depth

of bend.

2. Position the tubing at the appropriate bend mark.

3. Check your “circle-of-swing” and prepare to begin

bending.

4. Press the GREEN control button.

5. At this time the radius die will advance until the

desired depth-of-bend is reached, then, retract to the

original starting position.

6. Be prepared to support the tubing as it is released

from the dies.

USING THE REMOTE FOOT SWITCHES - The remote

foot switches are used for manual bending functions.

When using the foot switches for manual operation it is

best that you position the “Auto-Stop” pointer out of the

way or at 180 degrees so that it does not interfere. If you

want to use the foot pedals in conjunction with the “Auto-

Stop” pointer, position the pointer at the desired bend

depth and proceed by pressing the RIGHT foot switch

until the radius die stops at the pre-set bend angle.

Press the LEFT foot switch to retract the radius die.

Always be prepared to support the pipe as it is released

from the dies.

OPERATING THE MANUAL

KNEE CONTROL.

“BL” / BULLET MODELS

Read the following section completely before attempting

any operation of this unit. All “BL” models are equipped

with a hydraulic control valve mounted at knee height

that allows the user to operate the machine manually

with their leg. A degree plate with pointer is mounted

near the front of the machine that gives the user accu-

rate bend depths. “BL” models are not equipped with any

automatic features.

To operate the manual control valve, move the handle to

the left or the plunger down to advance the radius die.

The handle must be fully engaged to properly control

radius die movement.

To retract the radius die, move the handle to the right (or

plunger up) to return to the original starting position.

Always be prepared to support the pipe as it is released

from the dies.

OPERATION NOTE / BL MODELS:

If the operating control handle is pressed half way or par-

tially down during the bending operation, the radius die

may slow down or even retract slightly. To keep the

bending die at a controlled speed you must fully depress

the valve handle. If you wish to advance the radius die a

few degrees only, instead of easing the handle down, try

“tapping” the handle.

BENDING OPERATIONS

There are basically two styles of bending that can be per-

formed on your new bender. The first is PROGRAM CARD

BENDING which requires the use of PROGRAM CARDS

that contain instructional data for specific applications.

The second is PATTERN BENDING which is the most

popular method and duplicates pipes by using an existing

pipe or wire pattern as a master.

USING THE PROGRAM CARDS - The Program Card

System contains bending data for specific applications.

The following instructions define each section of the card.

It is important that you read the entire card carefully before

attempting to bend. Due to the many cards and applica-

tions covered, there may be some inaccuracies. No

responsibility is assumed by the manufacturer for any

consequences arising from inaccuracies found on the pro-

gram cards.

Look up the card number in the appropriate reference

catalog. Exhaust pipes numbers start with the letter “E”

and tail pipes numbers start with the letter “T”.

Bender Operation Manual 15

CAUTION!

Be alert at all times. NEVER place hands near

bending area or other pinch points

when motor is running.

Take down the number of the pipe to be bent, find and

remove it from the deck. Remember to place a marker of

some type in its place. The cards are filed in numerical

sequence by the number shown on the top left section of

the card. Only the last four digits shown are in sequential

order. Some cards start with a prefix such as T3 or T5 then

are followed by a four digit number. ALWAYS disregard the

prefix and follow the last four digits only.

DEFINITION OF CARD

SECTIONS:

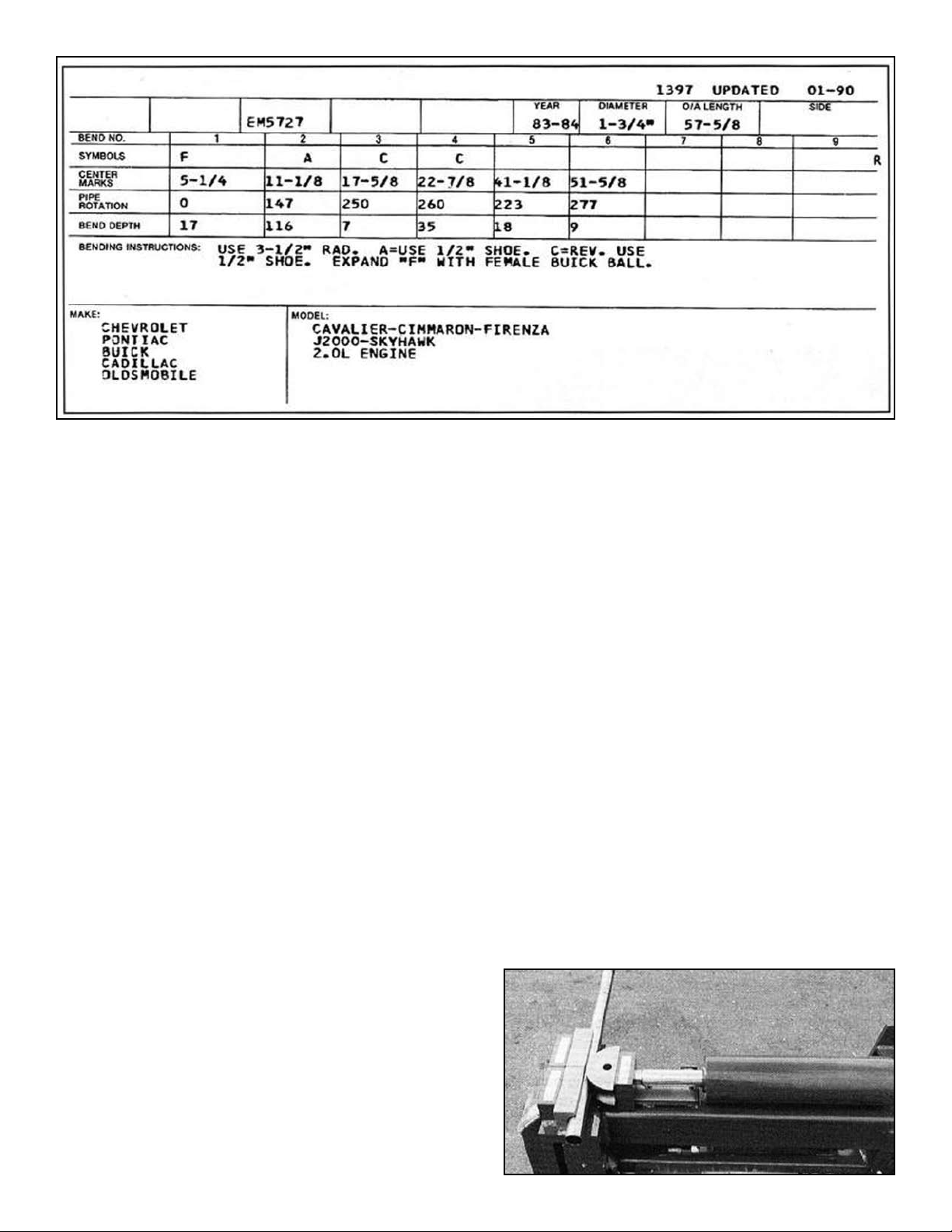

YEAR - Gives the year of the vehicle that the card pertains

to.

DIAMETER - The original equipment factory recommend-

ed tubing diameter for that particular vehicle,

O/A LENGTH - Overall length of tubing required for that

particular pipe. Also referred to as the cut-off point.

SIDE - When more than one section of tubing is required

for a particular card number, this section shows if it is the

front, rear, left or right side.

SYMBOLS - Shows certain symbols that pertain to indi-

vidual bending instructions that are explained in greater

detail in the BENDING INSTRUCTIONS section. The

symbol section also includes the descriptive “F” and “R”

symbols that indicate how the pipe fits on the vehicle. “F”

means front and “R” means rear.

CENTER MARKS - Refers to the actual locations or mea-

surements that the bends will be located.

PIPE ROTATION - Shows in degrees what the correct

pipe rotation (or plane) is for each bend.

BEND DEPTH - Shows in degrees what the correct bend

depth is for each bend.

MAKE - Gives the make of the vehicle. Chevrolet, Pontiac,

Ford, Chrysler, etc.MODEL - Gives descriptive factors

such as the model, engine and frame size.

BENDING INSTRUCTIONS - Shows what radius die will

be used in addition to other tooling such as half shoes

and three quarter shoes. Also gives instructions on

reversing and certain end-fInishing requirements. Not all

applications will be shown on the card.

Follow these step-by-step instructions to bend the pipe

for the card shown above.

1. Select the proper tubing size for the application as

called for in the DIAMETER SECTION of the card.

(See Recommended Tubing Chart on page 48) Wipe

tubing to remove excess oil.

2. Install the correct radius die as called for in the

BENDING INSTRUCTION section. Two back shoes

are required unless otherwise specifIed. Place tubing

in the bender between the back shoes and radius die

with the greater portion of the tubing extending out

the LEFT side of the bender. This is necessary so

that you can mark the tubing with the appropriate

CENTER MARKS shown on the card.

3. Engage the bending dies until the pusher

block springs are compressed and the tubing is held

fIrmly. Carefully control the advancement of the

radius die so as not to dent or bend the tubing at this

time. (See figure 1-A)

16 Bender Operation Manual

Sample card layout to be used in conjunction with bending instructions.

Figure 1-A

17 Bender Operation Manual

4. Using the program card, refer to the section marked

CENTER MARKS for the list of measurements in

inches where the different bends will be made. Each

CENTER MARK is measured from the left end of the

tubing. Mark and number the CENTER MARKS on

the tubing using a crayon or felt tip pen. The last

mark you make should be the cut off point shown in

the O/A LENGTH section. DO NOT CUT THE TUBING

at the last center mark until the final bend is

made. (See figure 1-B.)

5. Disengage the dies and reposition the tubing so that

the greater portion is now extending out the RIGHT

side of the bender and the first CENTER MARK is

lined up with the center of the two back shoes.

6. Engage the bending dies until the pusher block

springs are compressed and the tubing is held firmly.

(See figure 1-C)

7. Rotate the tubing so that the weld seam on the tubing

is facing up or at the 12 o-cIock position. The push-

er block springs are designed to hold the tubing

secure but still allow rotation of the pipe. Install the

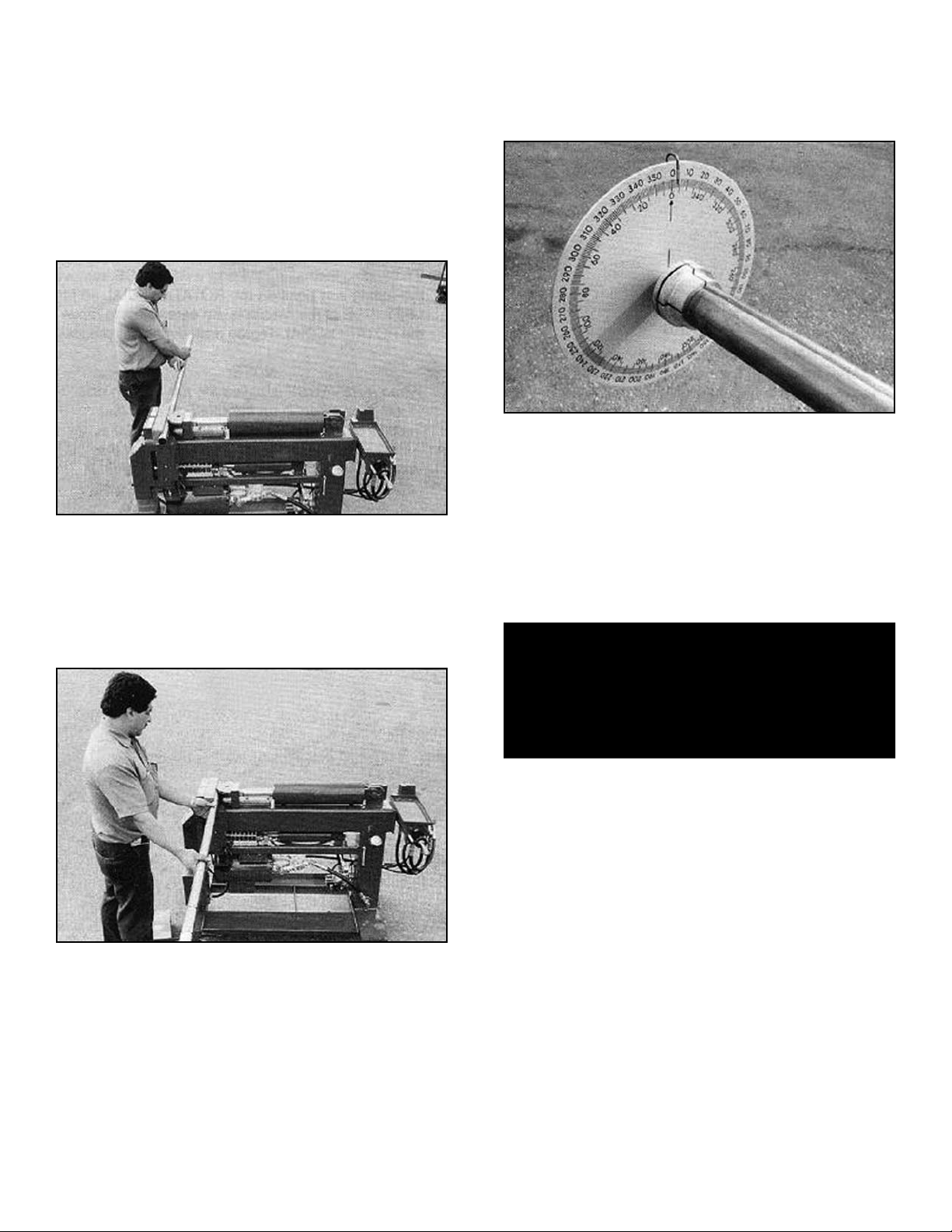

rotation dial on the RIGHT end of the tubing. Loosen

the butterfly nut if necessary and insert the segmented

expander inside the tubing end. Tighten the butterfly

nut until the rotation dial is secure.

9. With the rotation dial properly installed, rotate the

degree plate not the tubing so that the pendulum

pointer is showing ZERO. Make sure the butterfly nut

remains tight.

10. You are now ready to make your first bend. At this

time you may program your depth-of bends on the

digital board as described in the DIGITAL CONTROL

OPERATION section; position the depth-of bend

pointer on BAS models; or elect to use the electric

foot switches or manual knee control valve. For

beginning operators we suggest that manual controls

are used until you become more familiar with the

operating features of your machine

11. As described in the BEND DEPTH section of the

card, advance the radius die to 17 DEGREES then

retract the die to the original starting position. The

rotation dial should still show ZERO at this time.

12. Review the SYMBOLS section of the card and check

for any special instructions. On bend number two

you will notice that a HALF SHOE is called for. Install

the HALF SHOE now. Unless a special instruction is

given to change the radius size, you will continue to

use the 3-1/2” radius through the remaining bends.

NOTE:

Always position the HALF SHOE or THREE QUARTER

SHOE on the same side as the previous bend.

13. For the second bend, slide the tubing to the LEFT so

that the second CENTER MARK is lined up with the

center of the shoes.

(See figure 2-B.)

NOTE:

The weld seam on the tubing should be directly in line

with the ZERO mark at this time. (See figure 2-A)

Bender Operation Manual 17

CAUTION!

Before advancing the radius die check your

circle-of-swing for allowable bending clearances.

Figure 1-B

Figure 2-A

Figure 1-C

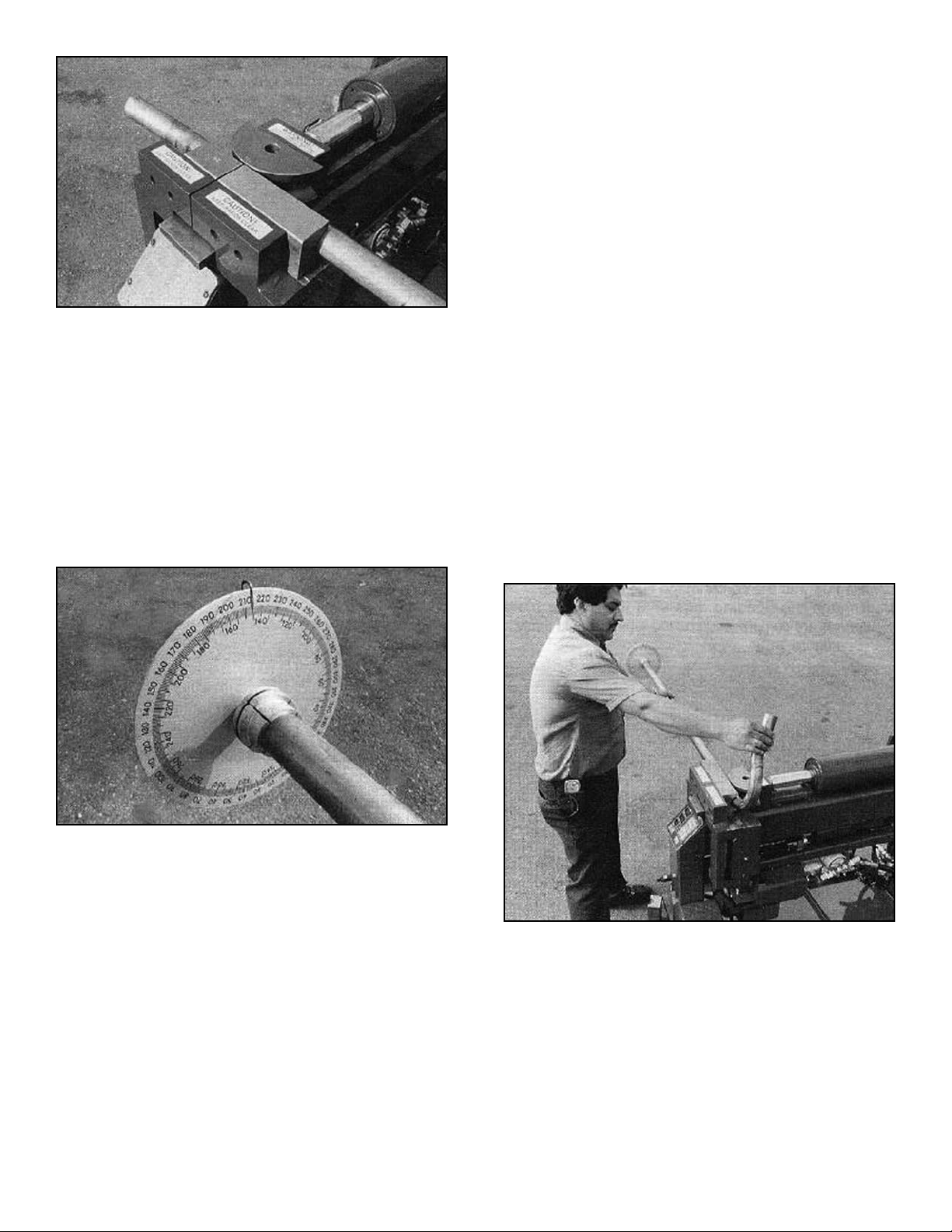

14. With the HALF SHOE in place and the secondCENTER

MARK lined up at the center of the shoes, advance

the radius die forward until the pusher block springs

are compressed and the tubing is held securely.

Carefully control the advancement of the radius die

to prevent denting or bending of the pipe at this time.

15. Now, rotate the tubing not the dial so that the pendulum

pointer or dial indicator points to the proper setting as

shown in the PIPE ROTATION section of the card. In

this case the PIPE ROTATION will be 147 degrees.

ALWAYS use the inside set of numbers. (See figure 2-C)

NOTE:

The rotation dial is equipped with two scales.

The standard scale which is used for all

regular bending operations is positioned to the

INSIDE of the dial. The OUTSIDE scale is

used for bending “mirror images” or opposite

side pipes.

16. With the rotation dial properly set at 147 degrees and

the center mark lined up, advance the radius die to

11 degrees as shown on the card. Retract the die to

the original starting position.

17. Review the SYMBOLS section of the card and check

for any special instructions. On bend number three

you will notice that a REVERSE / USE HALF SHOE

is called for.

The ROTATION DIAL degree plate MUST NEVER be

moved after bending has begun.

ALWAYS be prepared to support the tubing as it is released

from the dies to prevent it from hitting the ground. If the dial

is accidentally moved during the bending process,

re-position the dial so that the

ZERO mark is located at the weld seam of the tubing, or

return to the previous bend and position the pendulum point-

er to the degrees required for that particular bend.

18. lf a bending instruction calls for a REVERSE, remove

the tubing and position the ROTATION DIAL on the

LEFT SIDE of the machine. Be careful not to move

the ROTATION DIAL degree plate during this process.

NOTE:

When a REVERSE is called for, the rotation dial

will be positioned on the LEFT side for that

bend only. If the SYMBOL section shows a

REVERSE again for the following bend, the

rotation dial MUST remain on the LEFT side. If

no REVERSE is called for, the rotation dial

MUST be returned to the RIGHT side.

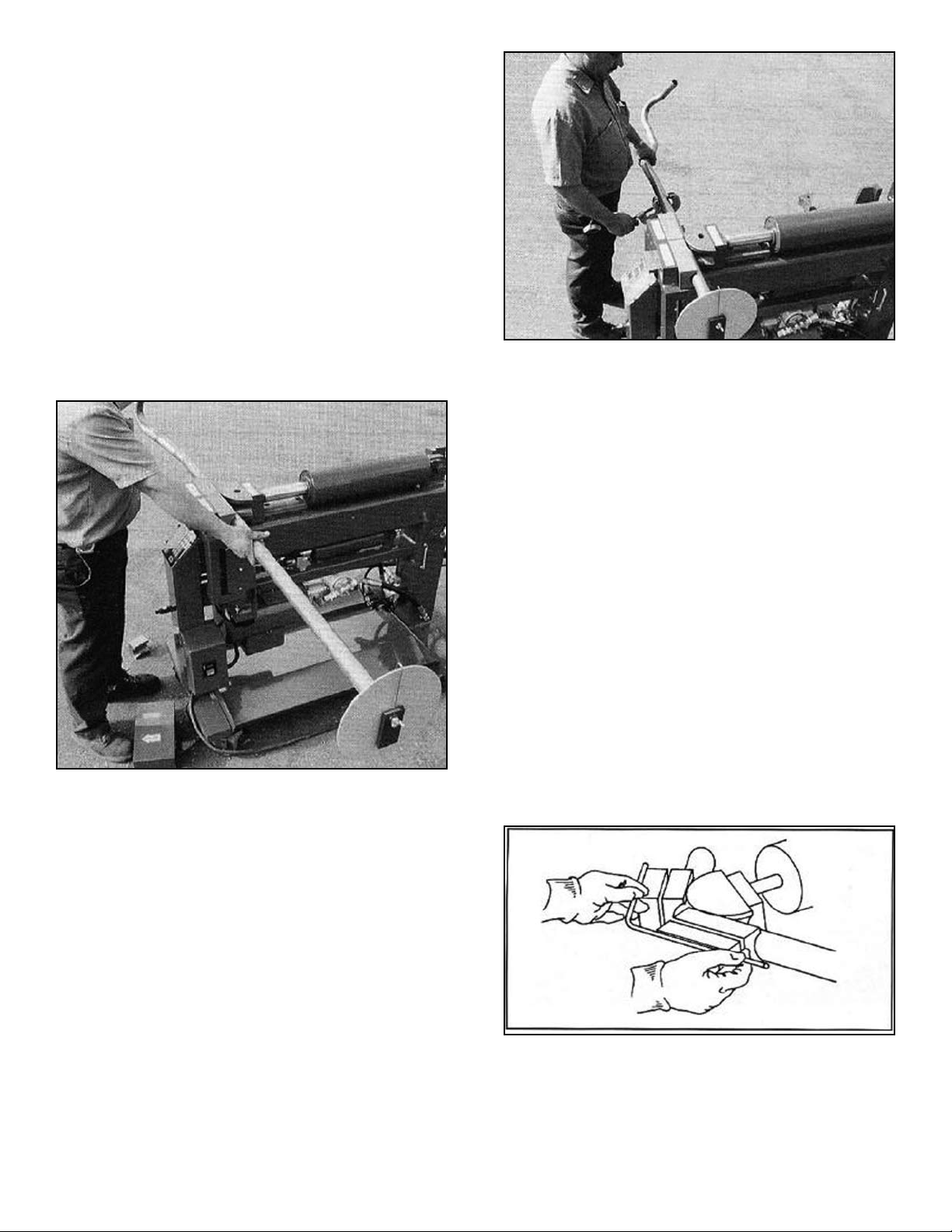

19. For bend number three, REVERSE the tubing and

install the HALF SHOE now. (See figure 3-A)

20. With the HALF SHOE in place and the third CENTER

MARK lined up at the center of the shoes, advance

the radius die forward until the pusher block springs

are compressed and the tubing is held securely.

21. Rotate the tubing not the dial so that the pendulum

pointer or dial indicator points to the proper setting as

shown in the PIPE ROTATION section of the card. In

this case the PIPE ROTATION will be 250 degrees.

USE THE INSIDE set of numbers. Advance the radius

die to 7 degrees.

18 Bender Operation Manual

Figure 2-C

Figure 2-B

Figure 3-A

19 Bender Operation Manual

22. Review the SYMBOLS section of the card and

check for any special instructions.

23. On bend number four you will notice that a

REVERSE USE HALF SHOE is again called for.

Keep the ROTATION DIAL on the LEFT side for this bend.

24. Advance the radius die forward until the pusher block

springs are compressed and the tubing is held securely.

25. Rotate the tubing so that the pendulum pointer or

dial indicator points to 260 degrees.

26. Advance the radius die to 35 degrees then retract

the die to the original starting position.

27. Review the SYMBOLS section of the card and check

for any special instructions for bend number five.

28. On bend number five no special instructions are

shown. In this case, return the ROTATION DIAL to

the right side and install the full BACK SHOE. A

HALF SHOE is not required for this bend.(See figure 3-B.)

29. Advance the radius die forward until the pusher block

springs are compressed and the tubing is held securely.

30. Rotate the tubing so that the pendulum pointer or

dial indicator points to 223 degrees.

31. Advance the radius die to 18 degrees then retract

the die to the original starting position.

32. Review the SYMBOLS section of the card and check

for any special instructions for bend number six.

33. On bend number six no special instructions are shown.

34. Advance the radius die forward until the pusher block

springs are compressed and the tubing is held securely.

35. Rotate the tubing so that the pendulum pointer or

dial indicator points to 277 degrees.

36. Advance the radius die to 9 degrees then retract the

die to the original starting position.

37.You are now finished bending the pipe. Remove the

ROTATION DIAL and cut the tubing end off at the

last O/A mark. (See figure 3-C.)

38. Now check the BENDING INSTRUCTIONS section

and check for any END FINISHING requirements.

On this particular card, it calls for a FEMALE BUICK

BALL on the FRONT or “F” side of the pipe. See

page 12 for TYPICAL END FINISHING illustrations.)

PATTERN BENDING

To pattern bend, proceed as follows. In order to retain the

information for later use, save the information as described

below.

NOTE:

Use the blank program card found on the next page

as a master to make additional

copies for later use.

1. Select the proper tubing size and die set to do the

job. Try to match the radius size with that of the existing

pipe.

2. Place the tubing in the bender with the greater portion

of the tubing protruding out the right side of the

bender.

3. Place the master pattern (existing pipe or bent wire

on the top of the back shoes so that the first bend is

centered between the back shoes.

4. Adjust the tubing out the left side of the bender so

that the tubing end matches the length with that of

the master. (See figure 1-A) Secure the straight pipe

by advancing the radius die until the pusher block

springs compress.

Bender Operation Manual 19

Figure 3-B

Wire pattern being used as a master.

Figure 3-C

5. Using a measuring tape, measure the distance from

the end of the tubing to the center of the back shoes.

This is the measurement to the first bend and should

be recorded in the CENTER MARKS section of a

blank card. (See figure 1B)

6. Place the ROTATION DIAL on the far right end of the

straight tubing and secure by tightening the wing nut.

Center the ROTATION DIAL degree plate so that the

indicator points to zero. ALWAYS USE THE

NUMBERS CLOSEST TO THE CENTER OF THE

ROTATION DIAL. THE OUTSIDE NUMBERS ARE

FOR SPECIAL APPLICATIONS ONLY. Record the

rotation degree as zero for your first PIPE ROTATION.

7. You are now ready to make your first bend. Place the

first bend of the master pipe or wire flat on top of

the back shoes. Hold in this position. Gradually

extend the radius die forward until the gates start to

open and the tubing begins to bend. Continue

bending until the bend depth is equal to that of the

master. (See figure 1-C)

8. Look at the Depth-of-Bend plate or observe the DIE

ANGLE window. This is the depth or degrees of the

first bend. Record this information in the BEND

DEPTH section.

9. Retract the bending dies and slide the straight tubing

to the left. Place the tubing or master on top of the

back shoes so that the centerline of the second bend

lines up with the centerline of the back gates. Be

sure that the master lies perfectly flat.

10. Line up the second bend of the new pipe with the

second bend of the master. Be sure that the master

remains flat on top of the back shoes. Advance the

radius die until the pusher block springs are

compressed and the tubing is held securely. Make

any adjustments at this time. Your second bend is

now correctly located. (See figure 2-A)

20 Bender Operation Manual

Figure 1-A

Figure 1-B

Figure 1-C

(This blank card may be used to make additional copies)

This manual suits for next models

8

Table of contents

Other Bend-Pak Construction Equipment manuals

Popular Construction Equipment manuals by other brands

Plymovent

Plymovent KUA-160/H Series Installation and user manual

MULTILIFT

MULTILIFT Ultima S Flex User and maintenance manual

Komatsu

Komatsu Super D155AX-3 Operation & maintenance manual

Dragon Wholesaling

Dragon Wholesaling LF1000 user manual

MULTIQUIP

MULTIQUIP Mikasa MVH408DE Operation manual

Case

Case 2050M Stage IIIB Service manual