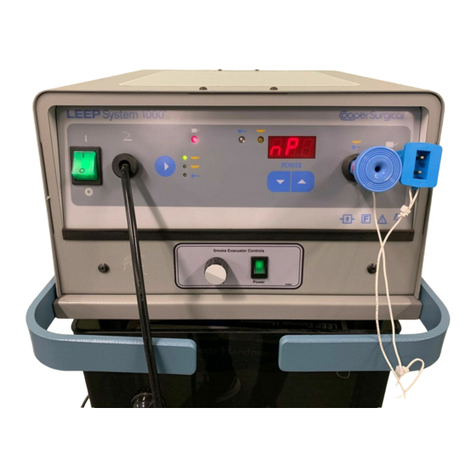

WSA-100 Utility Station QSG 2of 4P/N 5900095 – Rev. B – September 2021

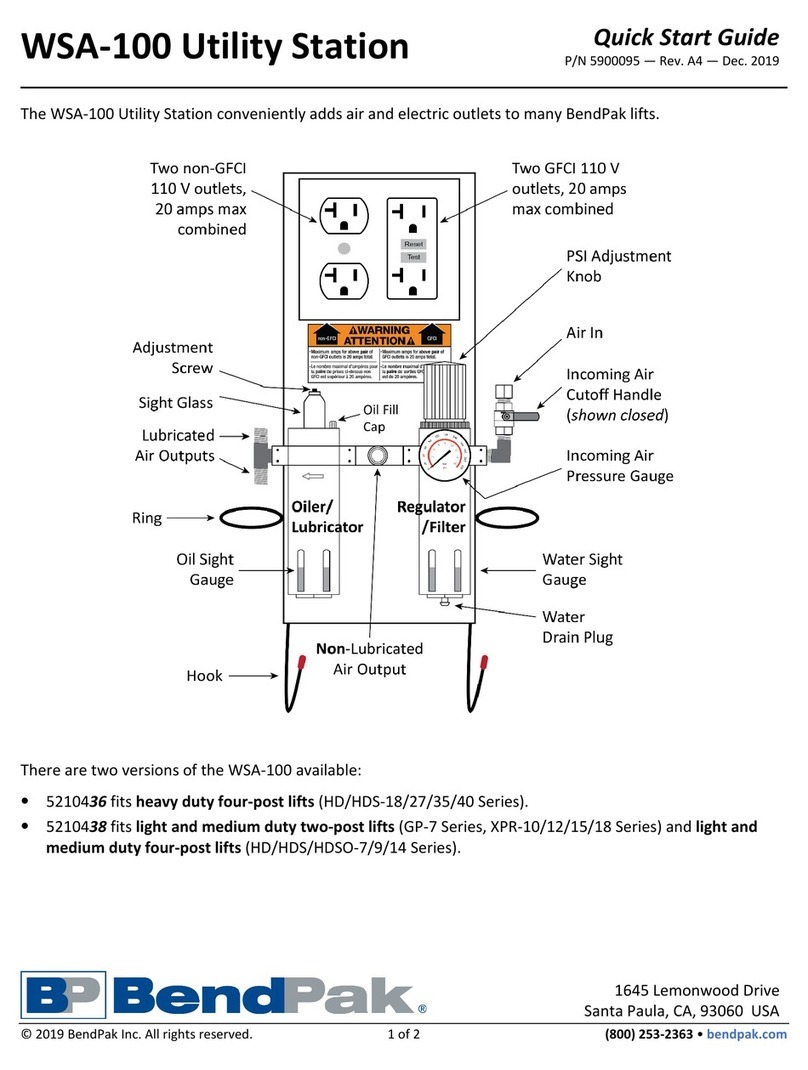

The main components of the WSA-100 are:

•Four 110 VAC outlets. Two have GFCI, two do not. Maximum current 20 Amps. Have a licensed,

electrician connect outlets to 1 phase, 60 Hz, 110 VAC using suitable conduit (not supplied). Duplex receptacle

must be connected through the GFCI with the input line to the box connected to a circuit breaker or time delay fuse

rated at 20 amps. Both receptacles

be grounded to the box. Note that the maximum amperage for one outlet

in use is 20 amps total;

when using all four outlets, the combined total cannot exceed 20 amps

.

⚠DANGER All wiring

must

be performed by a licensed, certified Electrician in accordance with local and national

electrical codes.

•Two rings and two hooks. For holding tools and hoses, for example. The large hooks ensure that the electrical

cords can be stowed away neatly and out of the way.

•Air source. Brings pressurized air to your lift. There are three parts to the air source:

–Incoming air. Connect an incoming air supply to the Air In connector. You need to supply an appropriate

1/4" NPT fitting for the Air In connector.

–Regulator / Filter

Removes contaminants from incoming air. Includes a gauge that shows the pressure of

the incoming air. Non-lubricated air can be used to put air into tires or for instrument calibration. To adjust air

pressure, lift the PSI Adjustment Knob to unlock and turn clockwise to increase pressure and

turn

counterclockwise to decrease pressure

. Push Knob back down to lock in new pressure setting.

–Oiler / Lubricator. Puts pneumatic oil, for tool lubrication, into the incoming air. Pressurized air, saturated

with oil, provides lubrication to pneumatic tools, which reduces friction and helps them last longer. Only use

lubricated air with pneumatic products that require it.

To drain water from the Regulator/Filter Reservoir:

Check the Water Sight Gauge to see how much water

is currently in the Reservoir.

CAUTION If the Reservoir is one quarter (~25%) or

more filled with water, you need to drain it.

Disconnect the air source at the Air In connector.

Press upwards on the Water Drain Plug at the bottom

of the Reservoir. The water drains out.

Release the Water Drain Plug and re-connect the air

source.

To add pneumatic oil to the Oiler/Lubricator:

Check the Oil Sight Gauge to see how much

pneumatic oil is currently in the reservoir.

CAUTION If the reservoir is less than one half (~50%)

filled with pneumatic oil, you need to add

oil to it.

Disconnect the air source at the Air In connector.

Turn the oil reservoir Oil Fill Cap counter-clockwise with

a slot screwdriver and pull it off.

Add SAE 10W Air Tool Oil or generic pneumatic oil to

the reservoir.

Put the oil reservoir back in place, turning it clockwise

until tight, then re-connect the air source.