Bender iso685 User manual

T M

Document NAE1018021 • 09.2014 • © Bender Inc. • Page 1/1 • Side 1/2Bender Inc. • USA: 800.356.4266 / 610.383.9200 / info@bender.org • Canada: 800.243.2438 / 905.602.9990 / [email protected] • www.bender.org

iso685

Installation Bulletin / Reference Guide

This document is intended as a reference guide for installing and using a BENDER iso685 ground fault

detector. This document includes installation, setup, and usage instructions. For complete details,

including installation, setup, settings, and troubleshooting, refer to the complete iso685 user manual.

This document is intended as a supplement and not a replacement to the complete user manual.

Only qualied maintenance personnel shall operate or service this equipment. These instructions

should not be viewed as sucient for those who are not otherwise qualied to operate or service this

equipment. This document is intended to provide accurate information only. No responsibility is as-

sumed by BENDER for any consequences arising from use of this document.

Installation

Mounting

The iso685 is a DIN-rail mounted device. See reverse side for dimensions.

!DANGER

• Disconnect all power before servicing.

• Observe all local, state, and national

codes, standards, and regulations.

HAZARD OF ELECTRIC SHOCK,

EXPLOSION, OR ARC FLASH

Wiring - General

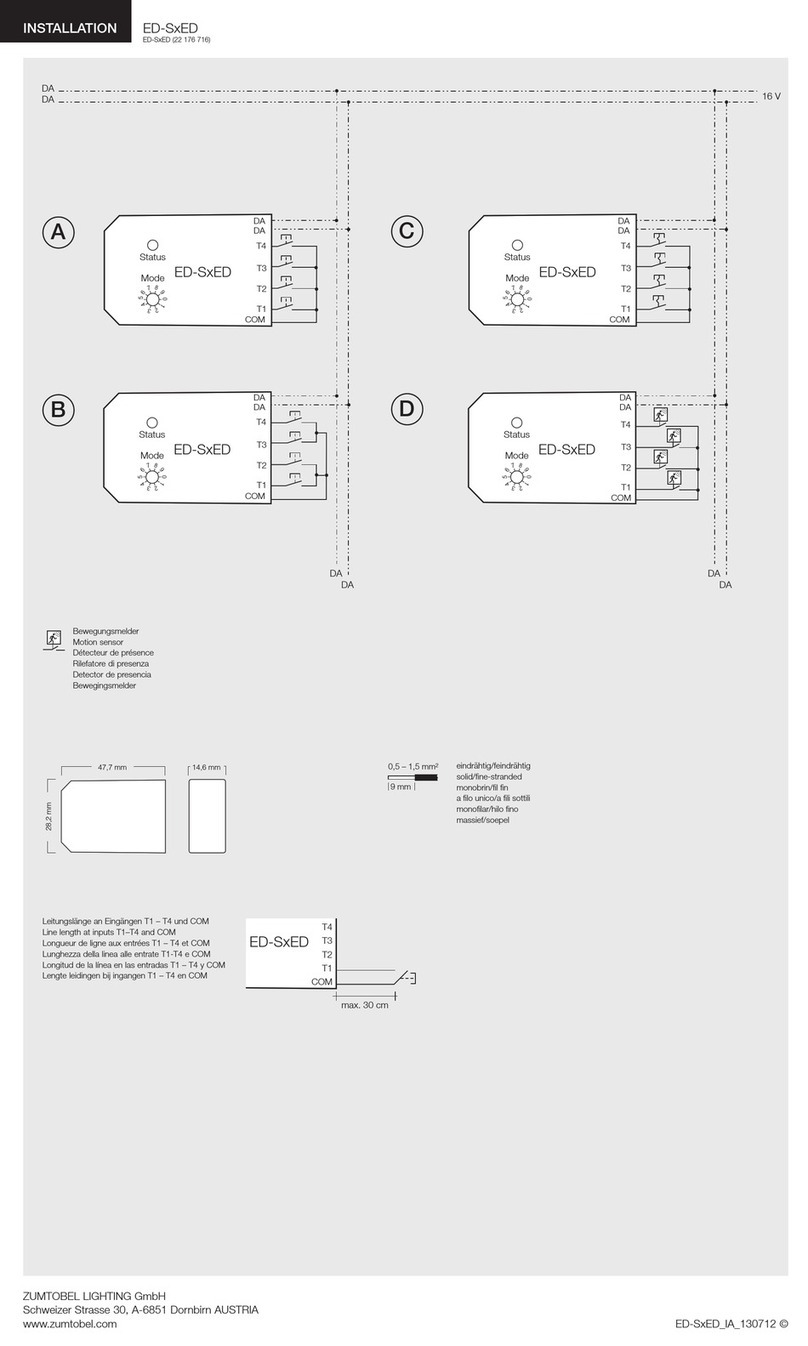

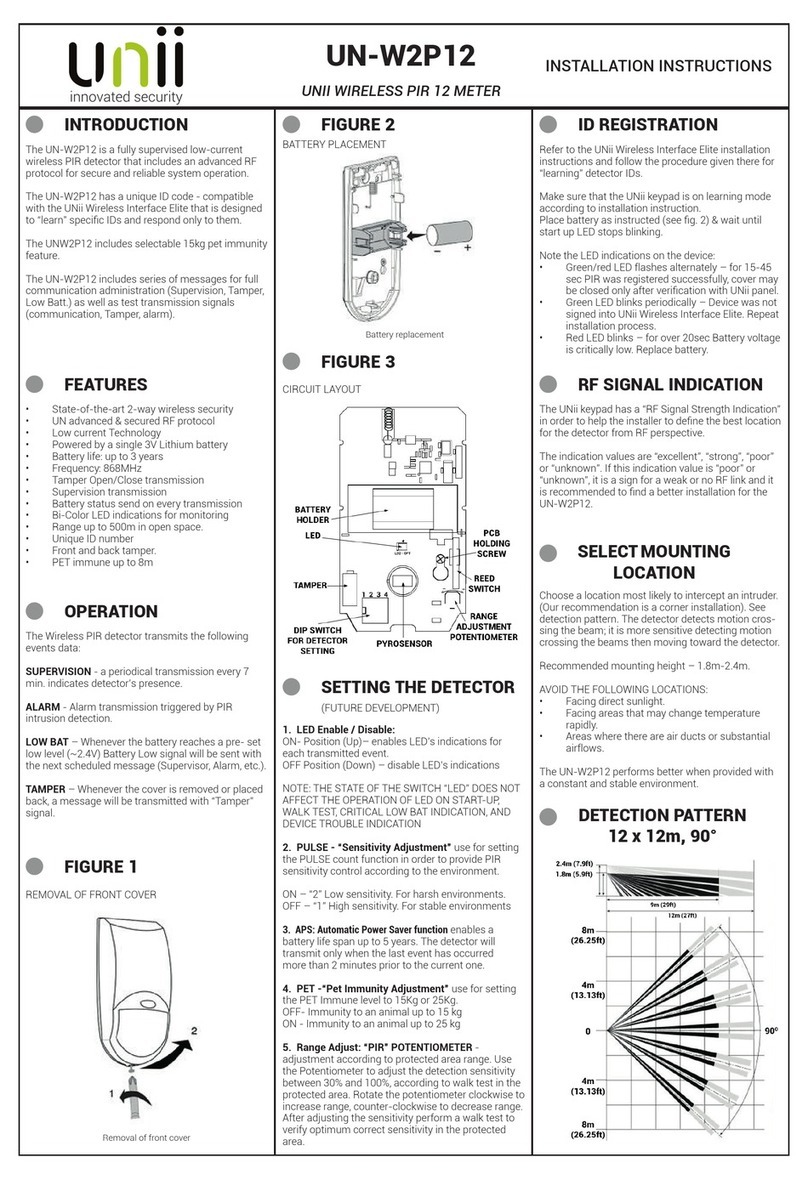

See gure 1 for basic wiring schematic. Line connections

(L1 and L2) may use the schematic below for systems be-

low 793 VAC or 1000 VDC. If a voltage coupler is used

to connect to the system, refer to the complete user

manual for the specic wiring diagram. Use minimum

AWG 24, maximum AWG 12 wire. When wiring is com-

plete, replace the terminal cover, making sure it clicks.

For more information, refer to the iso685 user manual.

In addition to the AC/DC 100-240 V supply voltage via

A1/A2 terminals, the device may also be powered by 24

VDC connected to the X1 connector. Refer to “Wiring -

Connector X1” for more information. Do not connect

both simultaneously.

Initial setup

Initial steps

• Select the language.

• Set the date and time.

• Set the system type - choose “DC” for DC systems, “AC” for single-phase AC systems, and

“3AC”for three-phase AC systems. In systems with power conversion, the system type that

should be selected should be the type at the point that the iso685 is connected.

• If a voltage coupler is used, select the correct one. Otherwise, select “None.”

Prole selection

Selecting a prole allows for an automatic setup of key system parameters required for opera-

tion. Select the prole that closest matches your application. Detailed descriptions of proles

are listed below. As a general guideline:

• For standard AC/DC power distribution with no power conversion, select“Power circuits.”

• For low voltage AC/DC control systems, select “Control circuits.”

• For systems with small- to mid-size inverters / VFDs, select “Inverter > 10 Hz.”

Select “High capacitance”if your system meets one or more of the following requirements:

• Very large distribution network (i.e. rated for 2000 A or more)

• System contains a high quantity of power conversion equipment (inverters / VFDs)

• The application typically includes high leakage capacitance, such as ships and solar arrays

Refer to the table below. NOTE: “Power conversion” refers to AC/DC or frequency conversion

equipment, including but not limited to rectiers, inverters, and variable frequency drives

(VFD/ASD).

1. Connection to 1Ø AC system

2. Connection to DC system

3. Connection to 3Ø AC system

4. Supply voltage connections (100 - 240

VAC) - 5 A fuses required

5. Line connections to monitored system

6. Connections to equipment / protective

ground

7. Alarm relay K1 - SPDT dry contact

8. Alarm relay K2 - SPDT dry contact

9. Switchable termination resistor - used

when connecting to Bender RS-485 bus

10. Ethernet port (currently inactive)

11. Connector X1 for digital inputs, RS-485,

analog output - see below

Wiring - Contacts

Using a normally closed or normally open contact utilizes two factors: wiring out of the proper

terminal, and setting the respective contact to normally energized or deenergized operation.

Refer to the chart below for relay conditions. Changing the energized state of the contact is

done via the “Relay 1”and “Relay 2” options (option“Mode”) found in the main menu. Prole name System specs (voltage,

frequency, leak. capacitance) Application

Power circuits

Up to 690VAC (15 - 460 Hz)

Up to 1000VDC

0 - 150 μF

Standard AC and DC power distribution systems with no power

conversion equipment. Suitable for general applications.

Control circuits

Up to 230VAC (15 - 460 Hz)

Up to 230VDC

0 - 150 μF

Designed for low-voltage AC/DC control systems with no power

conversion equipment.

Generator

Up to 690VAC (15 - 460 Hz)

Up to 1000VDC

0 - 5 μF

Designed for generator monitoring applications with no power

conversion equipment, as well as systems with an extremely low

leakage capacitance.

High capacitance

Up to 690VAC (15 - 460 Hz)

Up to 1000VDC

0 - 1000 μF

Designed for applications with high leakage capacitances, inlcuding:

very large systems, ships, and solar applications.

Inverter > 10 Hz

Up to 690VAC (10 - 460 Hz)

Up to 1000VDC

0 - 20 μF

Use this prole when using standard power conversion equipment. If

the system contains a high amount of power conversion equipment,

select“High capacitance”prole.

Inverter < 10 Hz

Up to 690VAC (1 - 460 Hz)

Up to 1000VDC

0 - 20 μF

Use this prole when power conversion equipment is used that

continuously runs at an extremely low frequency.

GND

US

6A

A1/+ A2/-

11RX2X1 12 14 21 22 24

L1/+ L2 L3/- KE E

L1/+ L3/- KE E

L1

L2

GND

L1/+ L3/- KE E

L+

L-

GND

3Ø AC System

L1

L2

L3

1Ø AC System

DC System

1

2

3

45 6

7 8

91011

Digital interface Terminal Description

I1 I2 I3 AB

Q1

+

Q2 M+

X1

I1 Input 1

I2 Input 2

I3 Input 3

A RS-485 A

B RS-485 B

++24 V

Q1 Output 1

Q2 Output 2

M+ Analog output

Ground

I1

I2

I3

A

B

M+

Q2

Q1

+

Reset

Test

Standby

Installation (continued)

Wiring - Connector X1

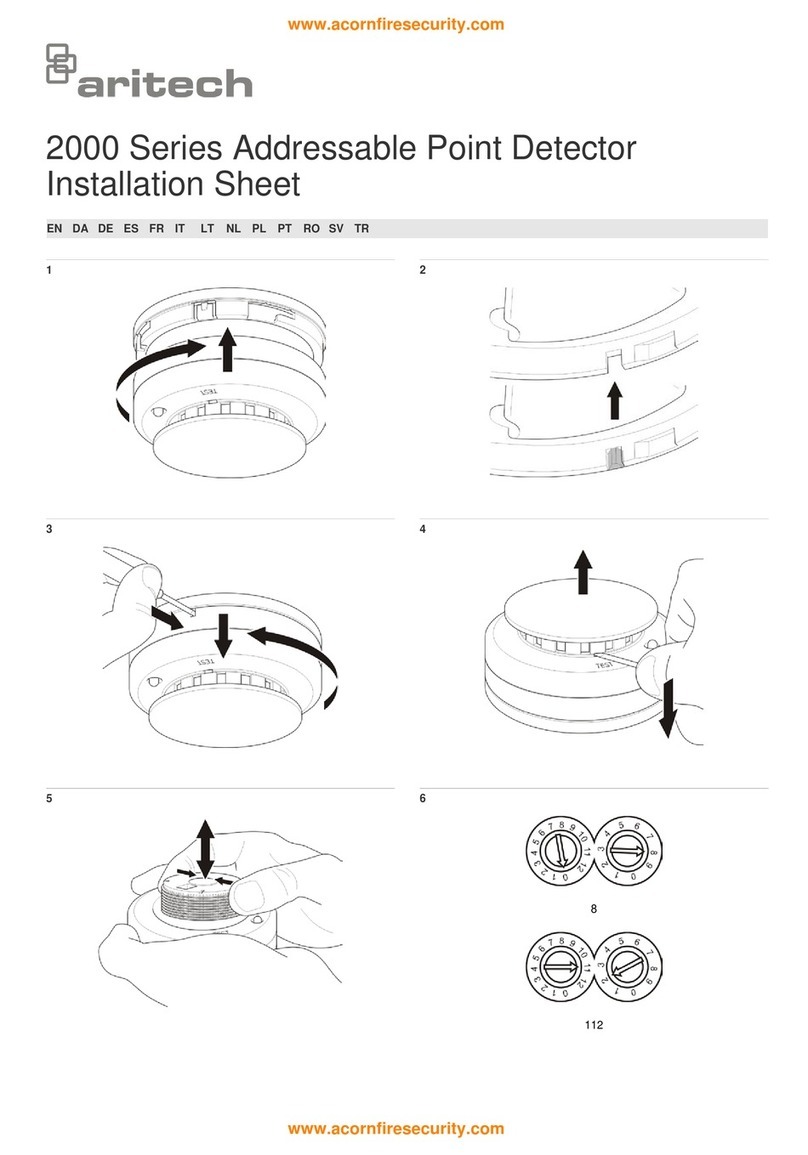

The X1 connector provides a series of low-voltage inputs, including digital inputs, connections

to Bender RS-485 bus, and the analog output. Typically, these functions are used for remote

test, remote reset, analog output, and RS-485. The function that these inputs utilize must be

set in the menu. Refer to the menu ow chart on the reverse side for more information. Do not

connect the 24 VDC supply voltage and supply via A1/A2 simultaneously.

Relay operation setting Device alarm state Relay K1 State Relay K2 State

Normally de-energized mode

(N/D)

Non-failsafe mode

“N/O”in device settings menu

Energized in the alarm state

Relay will switch when the

alarm is activated.

Power ON, normal state

(no alarms)

11-12 CLOSED

11-14 OPEN

21-22 CLOSED

21-24 OPEN

Power OFF 11-12 CLOSED

11-14 OPEN

21-22 CLOSED

21-24 OPEN

Power ON, alarm state 11-12 OPEN

11-14 CLOSED

21-22 OPEN

21-24 CLOSED

Normally energized mode

(N/E)

Failsafe mode

“N/C”in device settings menu

Energized in the normal state

Relay will switch when the

alarm is activated, on device

startup, or when power to the

device is lost.

Power ON, normal state

(no alarms)

11-12 OPEN

11-14 CLOSED

21-22 OPEN

21-24 CLOSED

Power OFF 11-12 CLOSED

11-14 OPEN

21-22 CLOSED

21-24 OPEN

Power ON, alarm state 11-12 CLOSED

11-14 OPEN

21-22 CLOSED

21-24 OPEN

Example wiring for external

test, reset, and standby is

shown to the right. Note that

the correct option must be

set in the menu under “Func-

tion” for each digital input.

T M

Document NAE1018021 • 09.2014 • © Bender Inc. • Page 1/1 • Side 2/2Bender Inc. • USA: 800.356.4266 / 610.383.9200 / info@bender.org • Canada: 800.243.2438 / 905.602.9990 / [email protected] • www.bender.org

iso685

Installation Bulletin / Reference Guide

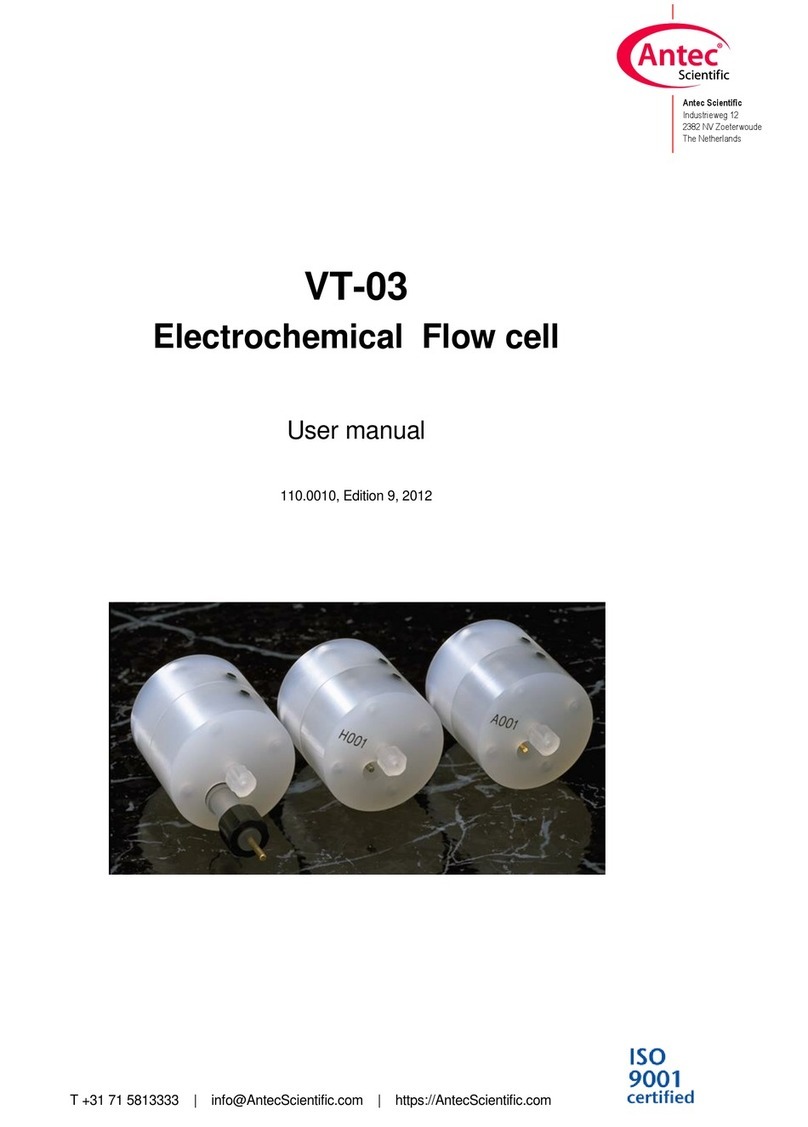

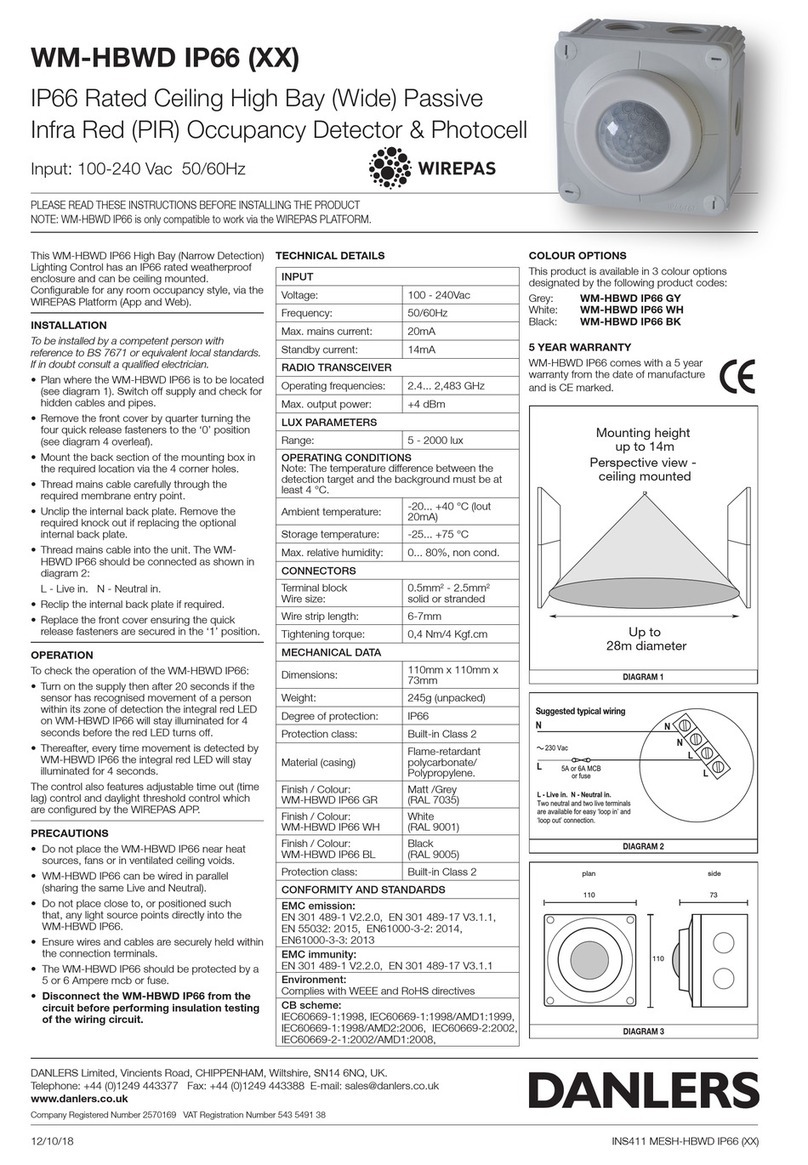

Menu structure flow chart

Figure 5 shows the structure of the menu built into the iso685. The menu is used for viewing

alarms, viewing the status of the system, and making any necessary settings changes.

Use the supplied gray boxes to take note of applied settings for future reference. For detailed

descriptions of each menu option, refer to the complete iso685 user manual.

Menu or settings option

Settings option essential for proper operation

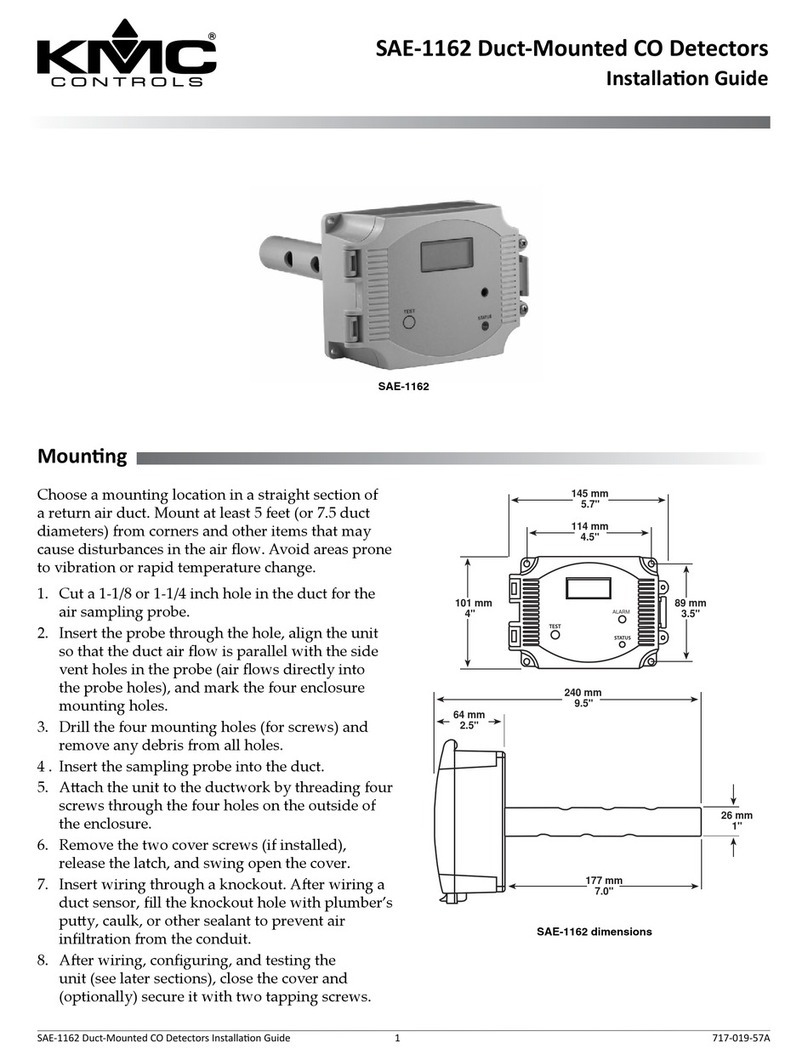

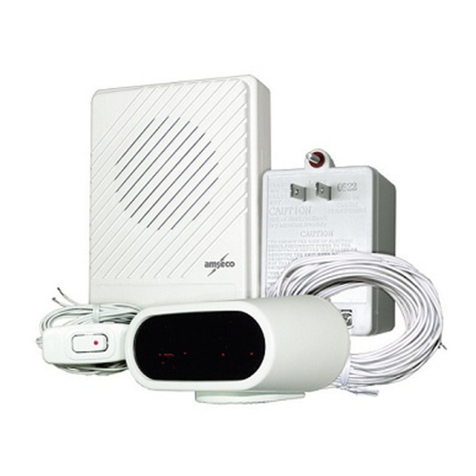

Displays and controls

1. “^” button: Up button, increase value in

menu

2. “RESET” button: Resets device in

latched mode; “<” button: Back button,

select parameter

3. “DATA” button: Displays data values; “v”

button: Down button, decrease value in

menu

4. “MENU” button: Enters main menu;

“ESC” button: Return to previous menu

level

5. “TEST” button: Activates self-test; “>”

button: Right / forward button, select

parameter

6. “INFO” button: Displays system infor-

mation; “OK” button: Confirms values

7. LED “ON”: Power applied to the device

8. Alarm LED indicators: SERVICE, 1, 2

9. Backlit LCD display

Dimensions

Dimensions in inches (mm).

4.25“ (108)

4.3“(110)

3.7“ (93)

1. Alarm settings 1. Insulation alarm

3. Memory

1. Alarm 1

2. Alarm 2

2. Profile

3. System type

4. Coupling

5. Device

6. t(start)

7. Coupler monitor.

8. Inputs 1/2/3. Digital 1/2/3 1. Mode

2. t(on)

3. t(off)

4. Function

9. Outputs 1/2. Relay 1/2 1. TEST

2. Relay mode

3/4/5. Function 1/2/3

3/4. Digital 1/2 1. TEST

2. Relay mode

3/4/5. Function 1/2/3

5. Buzzer 1. TEST

2/3/4. Function 1/2/3

6. Analog 1. Mode

2. Scale center

3. TEST

4. Function

2. Data meas. value

3. Control 1. TEST

2. RESET

3. Start initial

1 kΩ- 10 MΩ

active high / low

1 kΩ- 10 MΩ

on / off

See reverse page

AC / 3AC / DC

active / inactive

0 - 120 s

on / off

100 ms - 300 s

100 ms - 300 s

test / reset / standby

none / coupler

N/O / N/C

See reverse page

active / passive

See reverse page

See reverse page

0(4)-20 mA, 0-10V

linear / 28kΩ / 120kΩ

resistance / DC shift

4. History

5. Device settings 1. Language

2. Clock

3. Interface 1. BMS 1. Address 1 - 150

2. Ethernet

4. Display 1. Brightness

5. Password

6. Commissioning

7. Service

6. Info

Initial setup (continued)

Alarm value

Alarm values for insulation resistance vary by system due to the type of connected loads and

general system conditions. Adjust the alarm values to appropriate levels based on the system

that is connected to. As a general rule for setting initial alarms, values of 100 Ω/V for the pre-

warning and 50 Ω/V are recommended. These may be adjusted afterwards as prevailing sys-

tem comditions warrant.

Outputs

Two SPDT contacts are available for alarm outputs. The relays’energizing behavior is described

in the table “Device relay conditions.” Under the FUNCTION menu option for each relay, the

relay can be set to trip on individually assigned alarms. Each relay and digital output can trigger

on the following:

• Insulation resistance fault prewarning alarm

• Insulation resistance fault main alarm

• Connection error

• DC- alarm (when a sucient DC fault is detected on the negative line)

• DC+ alarm (when a sucient DC fault is detected on the positive line)

• Symmetrical alarm (when DC fault(s) are detected with no signicant pull on either line)

• Internal device error

• Common alarm (activates on any of the above alarms)

• Device inactive (iso685 is put into standby mode)

Each relay can trigger up to 3 types. The analog output and buzzer can trigger on insulation

resistance fault only. For the relays to trip on any alarm, set the function to“Common alarm.”For

more information, refer to Figure X (device relay conditions), Figure X (menu ow chart), and

the complete iso685 user manual.

1 4

7

8

92 5

3 6

Using the iso685

Complete list of features

Consult the iso685 user manual for a complete list of features and instructions for use.

Navigating the device

Use the buttons to the right of the screen to navigate the information screens and the menu. All

button labels are backlit - depending on the current location in the menu, only the usable but-

tons will be backlit. Not all keypad labels may be visible at once. In the example shown below,

the device is in alarm. Only the usable button labels for that screen are lit.

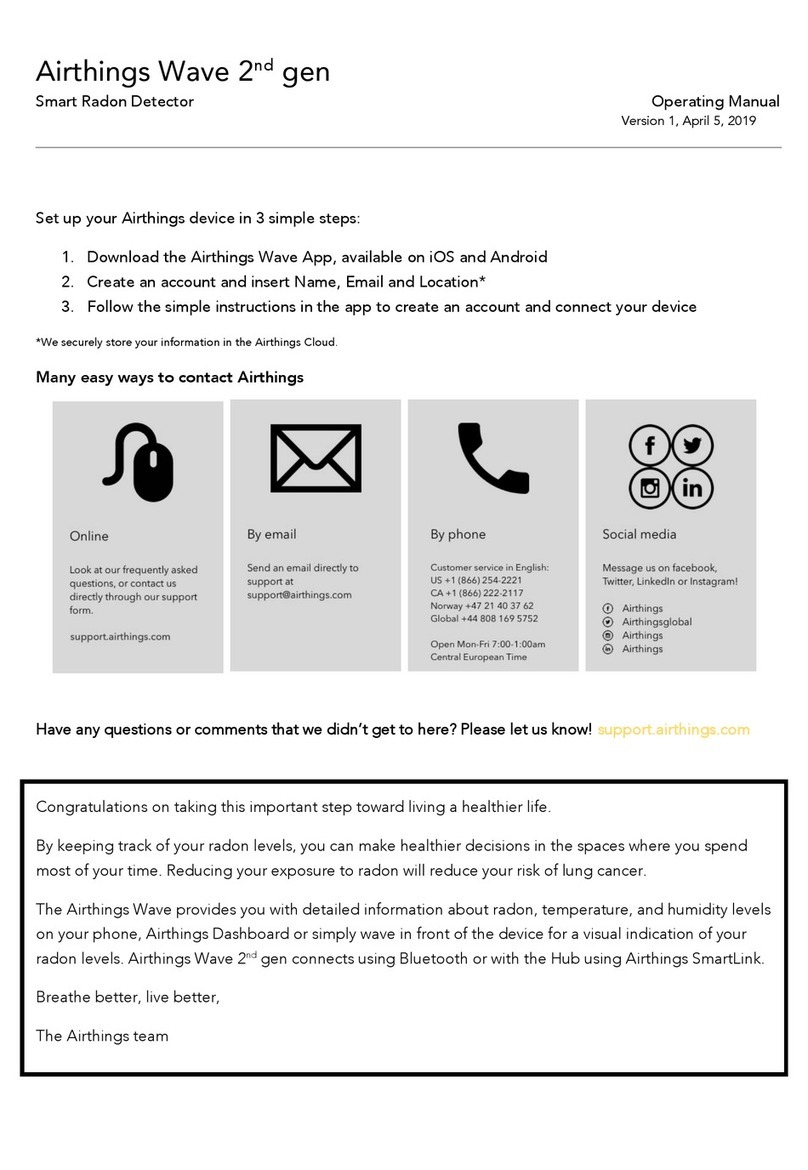

isoGraph - Data trending screen

The iso685 includes the isoGraph features, which provides onboard data trending of the sys-

tem insulation resistance over time. The isoGraph feature is particularly useful for trouble-

shooting ground faults into a time frame. To utilize this feature, access it through

1.0

.100

.010

.001

MΩ

Hour 12:26 12:52

Data-isoGraph 2

1/4

Analog Outputs

Linear option

If a linear analog output is selected, the insulation resistance is 10 kΩ at the high value, and 10

MΩ at the low value, and linerally proportional in between.

Nonlinear output

If the nonlinear output is selected, it is calculated using the following formula:

RF- Insulation resistance in kΩ

A1- Lower value, analog output (i.e. 0 for 0-20 mA)

A2- Upper value, analog output (i.e. 20 for 0-20 mA)

A3- measured analog output value

RSKM - selected midpoint value (28 / 120 kΩ)

Other manuals for iso685

2

Other Bender Security Sensor manuals