D150-01-00 1 I56-599-03R

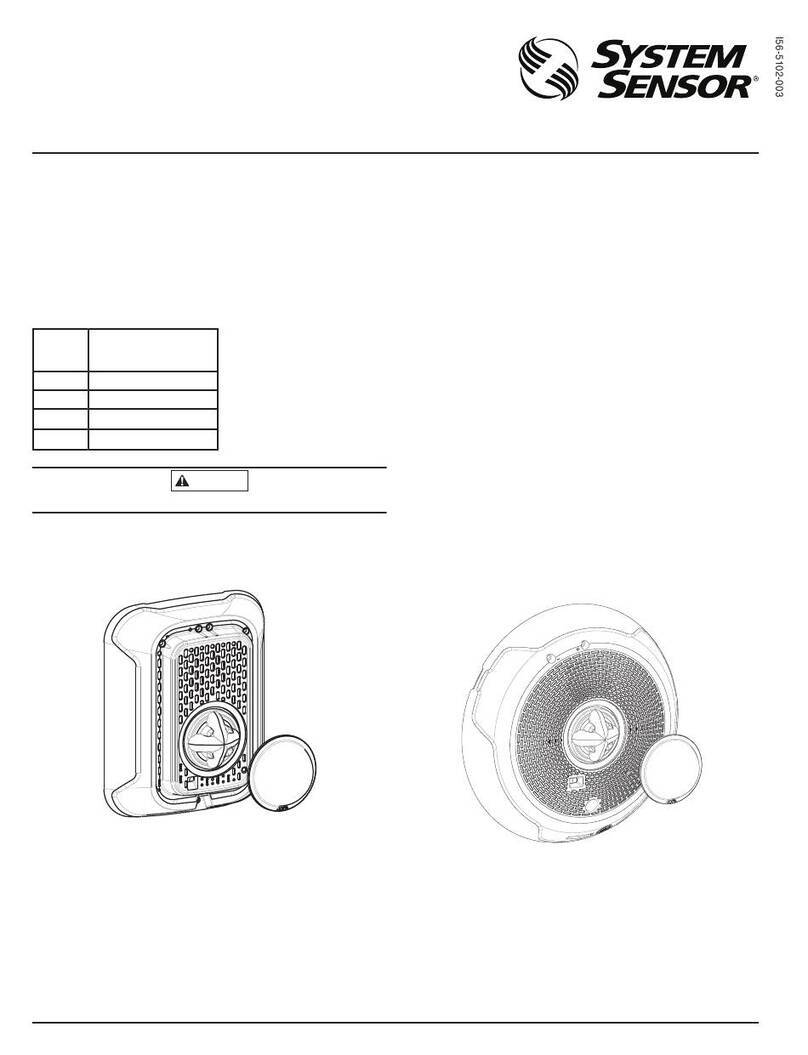

B116LP Plug-in Detector Base

For use with the following smoke detectors:

In US: 1151, 2151

In Canada: 1151A, 2151A

In Europe: 1151E, 2151E

INSTALLATION AND MAINTENANCE INSTRUCTIONS

3825 Ohio Avenue, St. Charles, Illinois 60174

1-800-SENSOR2, FAX: 630-377-6495

www.systemsensor.com

Before Installing

Please thoroughly read the System Sensor manual I56-407,

Guide for Proper Use of System Smoke Detectors, which

provides detailed information on detector spacing, place-

ment, zoning, wiring, and special applications. Copies of

this manual are available at no charge from System Sensor.

(For installation in Canada, please refer to CAN4-S524,

Standard for the Installation of Fire Alarm Systems and

CEC Part 1, Sec. 32.)

NOTICE: This manual should be left with the owner/user

of this equipment.

Specifications

Base Diameter: 6.2 inches (157 mm)

Base Height: 0.95 inches (24 mm)

Weight: 0.3 lb. (130 g)

Mounting: 4-inch square box with or without plaster ring. Min. Depth–1.5 inches

4-inch octagon box. Min. Depth–1.5 inches

3-1/2 inch-octagon box. Min. Depth–1.5 inches

50 mm box

60 mm box

70 mm box

Operating Temperature Range: 0° to +49°C (32° to 120°F) US and Canadian Installations

10° to 60°C (14° to 140°F) European Installations

Operating Humidity Range: 10% to 93% Relative Humidity

Electrical Ratings – includes base and detector

System Voltage: 24 VDC

Maximum Ripple Voltage: 4 Volts peak to peak

Start-up Capacitance: 0.02µF Maximum

Standby Ratings: 15 VDC Minimum

35 VDC Maximum

120 µA Maximum

Alarm Ratings: 8 V Minimum at 16 mA

12 V Maximum at 100 mA

(Alarm current MUST be limited to 100 mA maximum by the control panel.)

Relay Contact Ratings:

Resistive or Inductive (60% power factor) Load

Form C:* 2.0A @ 30 VAC/DC

0.6A @ 110 VDC

1.0A @ 125 VAC

Reset Voltage: 1.4 VDC Minimum

Reset Time: 0.3 Seconds Maximum

Start-up Time: 34.0 Seconds Maximum

*For Canadian installations relay contact ratings are 2.0A @ 30 VAC/DC.

IMPORTANT: The detector used with this base must be

tested and maintained regularly following NFPA 72 require-

ments. The detector used with this base should be cleaned

at least once a year.

General Description

The model B116LP plug-in detector base is used with

System Sensor model 1151, 1151A, and 1151E ionization

detector heads and model 2151, 2151A, and 2151E photo-

electronic detector heads. The capability of plugging these

detectors into a variety of special bases makes them more

versatile than equivalent direct-wired models. Refer to the

System Sensor catalog for other available plug-in detector

bases.

D150-01-00 4 I56-599-03R

© 2001 System Sensor

Three-Year Limited Warranty

System Sensor warrants its enclosed smoke detector base to be free from

defects in materials and workmanship under normal use and service for a

period of three years from date of manufacture. System Sensor makes no

other express warranty for this smoke detector base. No agent, represen-

tative, dealer, or employee of the Company has the authority to increase

or alter the obligations or limitations of this Warranty. The Company’s

obligation of this Warranty shall be limited to the repair or replacement

of any part of the smoke detector base which is found to be defective in

materials or workmanship under normal use and service during the three

year period commencing with the date of manufacture. After phoning

System Sensor’s toll free number 800-SENSOR2 (736-7672) for a Return

Authorization number, send defective units postage prepaid to: System

Sensor, Repair Department, RA #__________, 3825 Ohio Avenue, St.

Charles, IL 60174. Please include a note describing the malfunction and

suspected cause of failure. The Company shall not be obligated to repair

or replace units which are found to be defective because of damage,

unreasonable use, modifications, or alterations occurring after the date

of manufacture. In no case shall the Company be liable for any conse-

quential or incidental damages for breach of this or any other Warranty,

expressed or implied whatsoever, even if the loss or damage is caused by

the Company’s negligence or fault. Some states do not allow the exclu-

sion or limitation of incidental or consequential damages, so the above

limitation or exclusion may not apply to you. This Warranty gives you

specific legal rights, and you may also have other rights which vary from

state to state.

Please refer to insert for the Limitations of Fire Alarm Systems

I56-599-03R