Bender UNIMET 800ST User manual

Manual

EN

UNIMET8xxST_D00008_01_M_XXEN/02.2016

UNIMET® 800ST/UNIMET® 810ST

Test system for electrical safety

Software version: from 3.1.9

Bender GmbH & Co. KG

P.O. Box 1161 • 35301 Gruenberg • Germany

Londorfer Straße 65 • 35305 Gruenberg • Germany

Tel.: +49 6401 807-0 • Fax: +49 6401 807-259

© Bender GmbH & Co. KG

All rights reserved.

Reprinting only with permission

of the publisher.

Subject to change!

Photos: Bender archives.

3

Table of Contents

UNIMET8xxST_D00008_01_M_XXEN/02.2016

1. How to get the most out of this manual ............................................................. 7

1.1 About this operating manual .............................................................................................. 7

1.2 Technical support .................................................................................................................... 7

1.3 Explanation of symbols and notes ..................................................................................... 8

2. Safety instructions .................................................................................................. 9

2.1 Delivery ........................................................................................................................................ 9

2.2 Intended use .............................................................................................................................. 9

2.3 Qualified personnel ................................................................................................................. 9

2.4 General safety instructions ................................................................................................ 10

2.5 Delivery conditions, warranty and liability .................................................................. 10

3. System description .............................................................................................. 11

3.1 Areas of application ............................................................................................................. 11

3.2 Versions UNIMET® 800ST and UNIMET® 810ST ........................................................... 11

3.3 Functional description ........................................................................................................ 12

3.4 Standard-compliant tests .................................................................................................. 13

3.5 System components ............................................................................................................15

3.6 Operating elements ............................................................................................................. 16

4. Quick reference guide ......................................................................................... 17

5. Operation and setting ......................................................................................... 21

5.1 Commissioning ...................................................................................................................... 21

5.1.1 The touchscreen .................................................................................................................... 22

5.1.2 Connecting a printer ............................................................................................................ 22

5.1.3 Print setup in PDF file .......................................................................................................... 22

5.1.4 Connecting an external keyboard .................................................................................. 23

5.1.5 Connecting barcode scanner ........................................................................................... 23

5.1.6 Connecting USB stick ........................................................................................................... 23

5.1.7 TP1010 for tests according to DIN EN 61010-1 (VDE0411-1):2011-07 ............... 23

5.1.8 Other device settings .......................................................................................................... 24

5.2 Principle of operation .......................................................................................................... 24

5.2.1 Menu bar .................................................................................................................................. 24

Table of Contents

4UNIMET8xxST_D00008_01_M_XXEN/02.2016

5.2.1.1 The "Action" menu ......................................................................................................... 24

5.2.1.2 The "View" menu ............................................................................................................. 25

5.2.1.3 The "?" menu ..................................................................................................................... 25

5.2.2 Main window ........................................................................................................................... 25

5.2.3 The software keyboard ........................................................................................................ 26

5.2.3.1 Entries via the keyboard ............................................................................................... 26

5.2.3.2 Selection from a list ........................................................................................................ 26

5.2.4 Saving settings or cancelling ............................................................................................. 27

5.2.5 Toolbar ...................................................................................................................................... 28

5.2.5.1 How to use the context menu when only one entry is activated ................. 28

5.2.5.2 How to use the context menu if more than one entry is activated .............. 29

5.2.5.3 How to use the query filter .......................................................................................... 30

5.3 Main folder ............................................................................................................................... 31

5.4 Test engineer names ............................................................................................................ 32

5.4.1 Log in test engineer .............................................................................................................. 32

5.4.2 Test engineer names administration .............................................................................. 32

5.4.2.1 Other options for "Log in test engineer" ................................................................ 32

5.4.2.2 Logging in, changing or deleting test engineers ................................................ 33

5.4.2.3 Creating a new test engineer ..................................................................................... 33

5.5 Device settings ....................................................................................................................... 34

5.5.1 Windows system control .....................................................................................................34

5.5.1.1 Saving settings ................................................................................................................. 34

5.5.1.2 Display ................................................................................................................................ 34

5.5.1.3 Printer .................................................................................................................................. 34

5.5.1.4 Date/time ........................................................................................................................... 35

5.5.1.5 Regional settings ............................................................................................................ 35

5.5.1.6 Stylus ................................................................................................................................... 35

5.5.1.7 Input panel ........................................................................................................................ 35

5.5.1.8 Keyboard ............................................................................................................................ 35

5.5.1.9 Keyboard layout .............................................................................................................. 35

5.5.1.10 Volume & sound .............................................................................................................. 35

5.5.2 Zero balance PE resistance (test probe/measuring lead) ....................................... 36

5.5.3 Nominal voltage ..................................................................................................................... 36

5.5.4 Database ................................................................................................................................... 37

5.5.5 Backup (USB) ........................................................................................................................... 37

5.5.6 Remote control RS-232 ........................................................................................................ 37

5.5.7 Diagnostic ................................................................................................................................ 38

6. Testing and measuring ....................................................................................... 39

6.1 Test concept ............................................................................................................................ 39

Table of Contents

5

UNIMET8xxST_D00008_01_M_XXEN/02.2016

6.2 Classification ........................................................................................................................... 40

6.2.1 General ...................................................................................................................................... 40

6.2.2 Method of measurement ................................................................................................... 41

6.2.3 Applied part ............................................................................................................................ 41

6.2.4 Equipment type ..................................................................................................................... 42

6.2.5 Extras ......................................................................................................................................... 42

6.2.6 Test sequence ......................................................................................................................... 43

6.2.7 Visual inspection ................................................................................................................... 44

6.2.8 Functional test ....................................................................................................................... 45

6.2.9 Exiting classification ............................................................................................................. 47

6.3 Device test ............................................................................................................................... 48

6.3.1 Connecting the DUT ............................................................................................................ 50

6.3.2 Carrying out the visual inspection .................................................................................. 51

6.3.3 Carrying out the electrical test steps ............................................................................. 51

6.3.3.1 PE conductor test ........................................................................................................... 52

6.3.3.2 Switching on the DUT ................................................................................................... 53

6.3.4 Carrying out the functional test ...................................................................................... 54

6.3.5 Evaluating and documenting the test result .............................................................. 55

6.3.5.1 Client administration ....................................................................................................56

6.4 Importing test data .............................................................................................................. 57

6.5 The "Test specifications" folder ........................................................................................ 58

6.5.1 How to access the "Test specifications" folder ........................................................... 58

6.5.2 How to start a device test from the "Test specifications" folder .......................... 58

6.5.3 Editing, printing, exporting and deleting a test specification .............................. 58

6.5.3.1 Test step editor ............................................................................................................... 60

6.6 The "Device protocols" folder ........................................................................................... 62

6.6.1 How to access the "Device protocols" folder" ............................................................ 62

6.6.2 How to start a device test from the "Device protocols" folder ............................. 62

6.6.3 Editing, printing, exporting and deleting a device protocol ................................. 62

6.7 Single test ................................................................................................................................ 64

6.7.1 How to access the "Single test" folder ........................................................................... 64

6.7.2 How to start a single test .................................................................................................... 64

6.7.3 Using the query filter ........................................................................................................... 64

6.7.4 Protective earth resistance measurement ................................................................... 64

6.7.4.1 Differentiating between the types of protective earth resistance

measurement .................................................................................................................. 65

7. Maintenance and calibration ............................................................................. 67

7.1 Calibration ............................................................................................................................... 67

7.2 Changing the battery .......................................................................................................... 67

7.3 Maintenance ........................................................................................................................... 67

Table of Contents

6UNIMET8xxST_D00008_01_M_XXEN/02.2016

7.4 Cleaning and care .................................................................................................................. 67

7.5 Device error ............................................................................................................................. 67

8. Data ......................................................................................................................... 69

8.1 Standards .................................................................................................................................. 69

8.1.1 Application standards .......................................................................................................... 69

8.1.2 Design standards ................................................................................................................... 69

8.2 Terms and abbreviations .................................................................................................... 70

8.2.1 Terms used ............................................................................................................................... 70

8.2.2 Abbreviations used ............................................................................................................... 71

8.3 Test steps .................................................................................................................................. 73

8.4 Technical data ......................................................................................................................... 90

8.5 Ordering information ........................................................................................................... 92

INDEX ...........................................................................................................................95

7

UNIMET8xxST_D00008_01_M_XXEN/02.2016

1. How to get the most out of this manual

1.1 About this operating manual

This operating manual describes the test systems UNIMET® 800ST and UNIMET® 810ST with the soft-

ware version indicated on the cover page. The functions and processes described may vary from

those featured in other versions. It is designed for electrically skilled persons working in electrical en-

gineering and electronics.

Please read this operating manual before using the devices. This documentation must be kept in an

easily accessible location near to the device.

This manual has been compiled with great care. It may nevertheless contain errors and mistakes. The

Bender Group cannot accept any liability for injury to persons or damage to property resulting from

errors or mistakes in this manual.

Each of the registered trademarks which appears in this document remains the property of its owner.

For improved readability, the test systems UNIMET® 800ST and UNIMET® 810ST will also be referred

to as "UNIMET®".

1.2 Technical support

As a Bender customer, you will receive technical support and assistance in the event of queries relat-

ing to equipment you have purchased. Please contact the Technical Sales Department or our Service

Department:

Service hotline: 0700-BenderHelp (telephone and fax)

Carl-Benz-Straße 8 • 35305 Gruenberg • Germany

Tel: +49 6401 807-760 • Fax: +49 6401 807-629

E-mail: info@bender-service.com • www.bender.de

How to get the most out of this manual

8UNIMET8xxST_D00008_01_M_XXEN/02.2016

1.3 Explanation of symbols and notes

The following terms and symbols are used to denote hazards and instructions in Bender documen-

tation:

The signal word indicates that there is a high risk of danger, that will result in

death or serious injury if not avoided.

This signal word indicates a medium risk of danger that can lead to death or se-

rious injury, if not avoided.

This signal word indicates a low-level risk, that can result in minor or moder-

ate injury or damage to property, if not avoided.

This symbol denotes information intended to assist the user in making optimum

use of the product.

DANGER

WARNING

CAUTION

9

UNIMET8xxST_D00008_01_M_XXEN/02.2016

2. Safety instructions

2.1 Delivery

Inspect the dispatch and equipment packaging for damage, and compare the contents of the pack-

age with the delivery documents. Devices damaged in transit must not be used. In the event of dam-

age in transit, please contact Bender immediately.

Equipment may only be stored in areas where it is protected against dust, damp, spray water and

dripping water and where the specified storage temperatures can be assured.

The selling company's "General conditions of sale and delivery" always apply.

2.2 Intended use

The test systems are exclusively intended for the area of use stipulated in the chapter "System de-

scription" on page 11.

Intended use also implies:

Observance of all instructions in this operating manual and

compliance with any test intervals.

Any other use than that described in this manual is regarded as improper. The Bender Group cannot

accept any liability for damage resulting from such use.

2.3 Qualified personnel

Only appropriately qualified personnel may work with the Bender devices. Personnel who are famil-

iar with the installation, commissioning and operation of the equipment and have undergone ap-

propriate training are considered qualified. The personnel must have read this manual and

understood all instructions relating to safety.

Bender would be happy to provide training in respect of the use of test equipment. Training for two

people is included in the purchase price of the test system. You can find the current dates on our

homepage http://www.bender.de -> Know-how-> Seminars.

Risk of destruction due to incorrect mains voltage

The UNIMET® 800ST or 810ST must always be connected to the supply voltage

(AC 100…120 V, AC 220…240 V) indicated on the nameplate. Only these two

voltage ranges are permissible. Voltages between these two voltage ranges are

not permissible!

Failure to observe this requirement may damage the test system and any device

under test connected to it.

CAUTION

Safety instructions

10 UNIMET8xxST_D00008_01_M_XXEN/02.2016

2.4 General safety instructions

Bender devices are designed and built in accordance with the state of the art and accepted rules in

respect of technical safety. However, the use of such devices may introduce risks to life and limb of

the user or third parties and/or result in damage to Bender devices or other property.

Use Bender devices only:

–Asintended

– In perfect working order

– In compliance with the relevant safety regulations and safety standards applicable at the

location.

Eliminate all faults immediately which may endanger safety.

Do not make any unauthorised changes.

Use only accessories (e.g. measuring cables, adapters, etc.) or replacement parts purchased

from or recommended by the manufacturer of the devices. Failure to observe this requirement

can result in fire, electric shock and injury.

Reference signs must always be clearly legible. Replace damaged or illegible signs immediately.

2.5 Delivery conditions, warranty and liability

The conditions of sale and delivery set out by Bender apply.

For software products, the "Softwareklausel zur Überlassung von Standard-Software als Teil von

Lieferungen, Ergänzung und Änderung der Allgemeinen Lieferbedingungen für Erzeugnisse und

Leistungen der Elektroindustrie" (software clause in respect of the licensing of standard software as

part of deliveries, modifications and changes to general delivery conditions for products and servic-

es in the electrical industry) set out by the ZVEI (Zentralverband Elektrotechnik- und Elektronikindus-

trie e.V., the German Electrical and Electronic Manufacturers' association) also applies.

Delivery and payment conditions along with a copy of the software clause can be obtained from

Bender in printed or electronic format.

.

11

UNIMET8xxST_D00008_01_M_XXEN/02.2016

3. System description

3.1 Areas of application

The UNIMET® is used to test electrical safety. It has been designed for following areas of application:

Testing medical electrical equipment in accordance with DIN EN 60601-1 (VDE 0750-1):2013-12

(optional software licence required for IEC 60601-1).

Recurrent tests and testing prior to first use of medical electrical equipment or systems in

accordance with DIN EN 62353 (VDE 0751-1).

Testing electrical equipment for measurement, control and laboratory use in accordance with

DIN EN 61010-1 (VDE 0411-1):2011-07 (optional software licence for IEC 61010-1 as well as test

probe TP1010 required).

Recurrent tests of hospital and care beds.

Single-phase electrical equipment: "Prüfung nach Instandsetzung, Änderung elektrischer

Geräte - Wiederholungsprüfung elektrischer Geräte" (Inspection after repair, modification of

electrical appliances and periodic inspection on electrical appliances) acc. to DIN VDE 0701-

0702; VDE 0701-0702:2008-06.

In conjunction with a DS32A adapter, the electrical safety of three-phase devices with a current

input of up to 32 A can be tested acc. to IEC 62353 (VDE 0751-1) and DIN VDE 0701-0702 . Tests

are always carried out during operation using the differential measurement method.

3.2 Versions UNIMET® 800ST and UNIMET® 810ST

The difference between the hardware of the UNIMET® 810ST and its predecessor UNIMET® 800ST is

an even more efficient PC module.

If the corresponding software licence has been purchased, the operating software enables addition-

al tests according to IEC 60601-1 (med. electrical equipment) or DIN EN 61010-1 (electrical equip-

ment for laboratory use).

The operating software indicated on the cover page can be used with the UNIMET® 810ST, but also

with the existing UNIMET® 800ST. In this case, the following restrictions apply:

UNIMET® has been designed solely for use with earthed systems. If the test system

is used other than as intended, i.e. on an IT system, the measured values of any

leakage currents will not be reproducible. The test result cannot be used.

Art. no. of the

UNIMET® 800ST Restrictions

B 9602 8010

B 9602 8014, B 9602 8016

B 9602 8017, B 9602 8018

No restriction of the range of functions. Software licences for DIN EN

60601-1 and DIN EN 61010-1 can be installed.

B 9602 8000

B 9602 8004, B 9602 8006

B 9602 8007, B 9602 8008

Software licences for DIN EN 60601-1 and DIN EN 61010-1 cannot be

installed.

System description

12 UNIMET8xxST_D00008_01_M_XXEN/02.2016

3.3 Functional description

The test system supplies measurement results and evaluates them immediately in order to classify

the test as "PASSED" or "FAILED". In addition to the electrical test steps, the test specification, which

follows classification, contains a visual inspection and a functional test. The test specification is saved

in the "Test specifications" folder. The test sequence can be completed automatically, semi-automat-

ically or manually dependent upon the DUT.

The test results can be displayed on the screen, saved or printed out using an external printer. The

test results can be stored as PDF file and saved to a USB drive (USB stick) for any subsequent print-

outs.

In the event of unexpected results, the DUT can be inspected in more detail by carrying out a single

test. Tested devices can be saved under their device IDs in the "Device protocols" folder. The data

memory provides space for up to 10000 data records. Device IDs may only appear more than once if

they are assigned to different clients.

The date of the last test and the test interval are saved. If a device passes the test, the test date is up-

dated by the set test interval. Filter and sort functions (query filter) make selecting test data easy.

Test specifications and device protocols can be transferred to a PC software program (e.g.

UNIMET® 800ST Control Center) via the RS-232 interface or using a USB drive (USB stick). For recur-

rent tests, the data stored in the PC software are transferred back to the UNIMET®.

The RS-232 interface is also used for any subsequent updates of the internal operating software on

the test system.

The "Test engineer catalogue" folder can be beneficial if more than one person is working with the test

system. Test engineers already registered on the system are simply selected from this folder. There is

no need to re-enter the name of the test engineer. The "Test engineer names", "Test specifications" and

"Device protocols" folders share the same data memory. Accordingly, the number of test engineer

names is limited only by the size of the available memory.

The large colour display is backlit. Graphics illustrate how to connect the DUT. Operation is quick and

easy via the touchscreen. A standard keyboard (PS/2 or USB) can also be connected.

System description

13

UNIMET8xxST_D00008_01_M_XXEN/02.2016

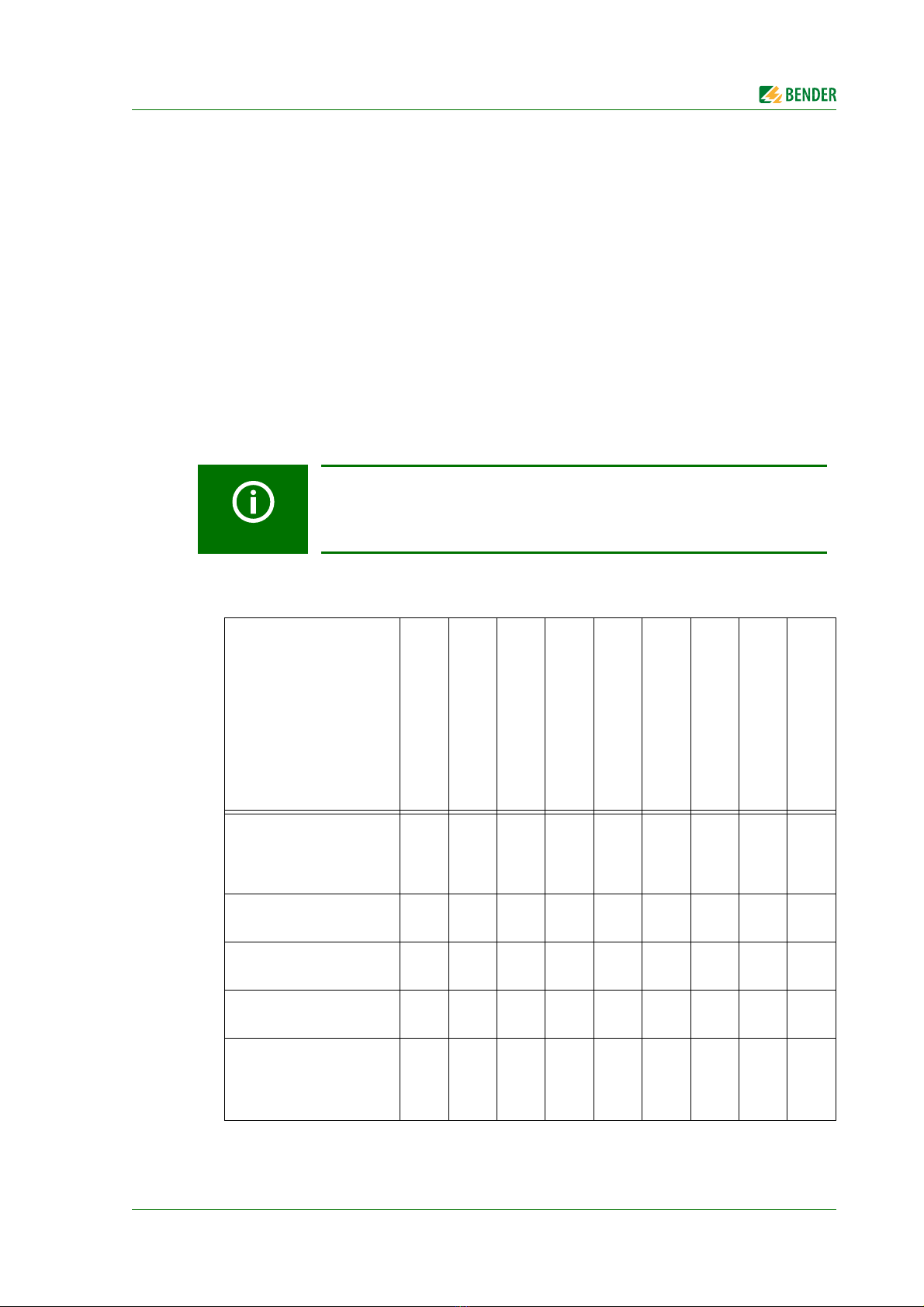

3.4 Standard-compliant tests

The UNIMET® carries out measurements and tests according to the following standards (see also

chapter "8.1 Standards"):

Medical electrical equipment -Part 1: General requirements for safety.

Test in compliance with DIN EN 60601-1 (VDE 0750-1); optional software licence required for

IEC 60601-1.

Medical electrical equipment, recurrent tests in accordance with DIN EN 62353 (VDE 0751-1).

Prüfung nach Instandsetzung, Änderung elektrischer Geräte - Wiederholungsprüfung elek-

trischer Geräte (Inspection after repair, modification of electrical appliances and periodic

inspection on electrical appliances) acc. to DIN VDE 0701-0702; VDE 0701-0702:2008-06.

Electrical equipment for measurement, control and laboratory use - Part 1: General require-

ments

Test according to DIN EN 61010-1 (VDE 0411-1): optional software licence for IEC 61010-1 as

well as test probe TP1010 required.

The UNIMET® carries out the following measurements and tests:

Depending on the national language selected for the user interface, the appro-

priate standard appears on the display and the device protocol. Example:

German: DIN EN 62353 (VDE 0751-1)

English or other languages: IEC 62353

Measurement

DIN EN 60601-1

(VDE 0750-1)

DIN EN 62353

(VDE 0751-1)

DIN VDE 0701-0702

DIN EN 61010-1

(VDE 0411-1)

Direct measurement method

Differential measurement

method

r.m.s.

(root mean square value)

AC

DC

PE resistance

(permanently installed

and transportable

equipment)

XXXX X

InsuIation resistance

(Class I and Class II) XXX X

InsuIation resistance

(applied part – PE) XX

InsuIation resistance

(applied part- LN) XX

Equipment leakage

current - alternative

method

(Class I and Class II)

XX X

System description

14 UNIMET8xxST_D00008_01_M_XXEN/02.2016

Applied part leakage

current - alternative

method

XX

Equipment leakage

current

(Class I and Class II)

X XXX

PE current X XXX

Earth leakage current XXX

Touch current X XXXXX

Touch voltage XXX

Applied part leakage

current XXX

Patient auxiliary current XXX

Total applied part leakage

current XXX

Applied part leakage

current with mains

voltage on applied part

XX X

Mains voltage XXXX X

Current consumption XXXX X

Apparent power XXXX X

Supply cable test X

Measurement

DIN EN 60601-1

(VDE 0750-1)

DIN EN 62353

(VDE 0751-1)

DIN VDE 0701-0702

DIN EN 61010-1

(VDE 0411-1)

Direct measurement method

Differential measurement

method

r.m.s.

(root mean square value)

AC

DC

System description

15

UNIMET8xxST_D00008_01_M_XXEN/02.2016

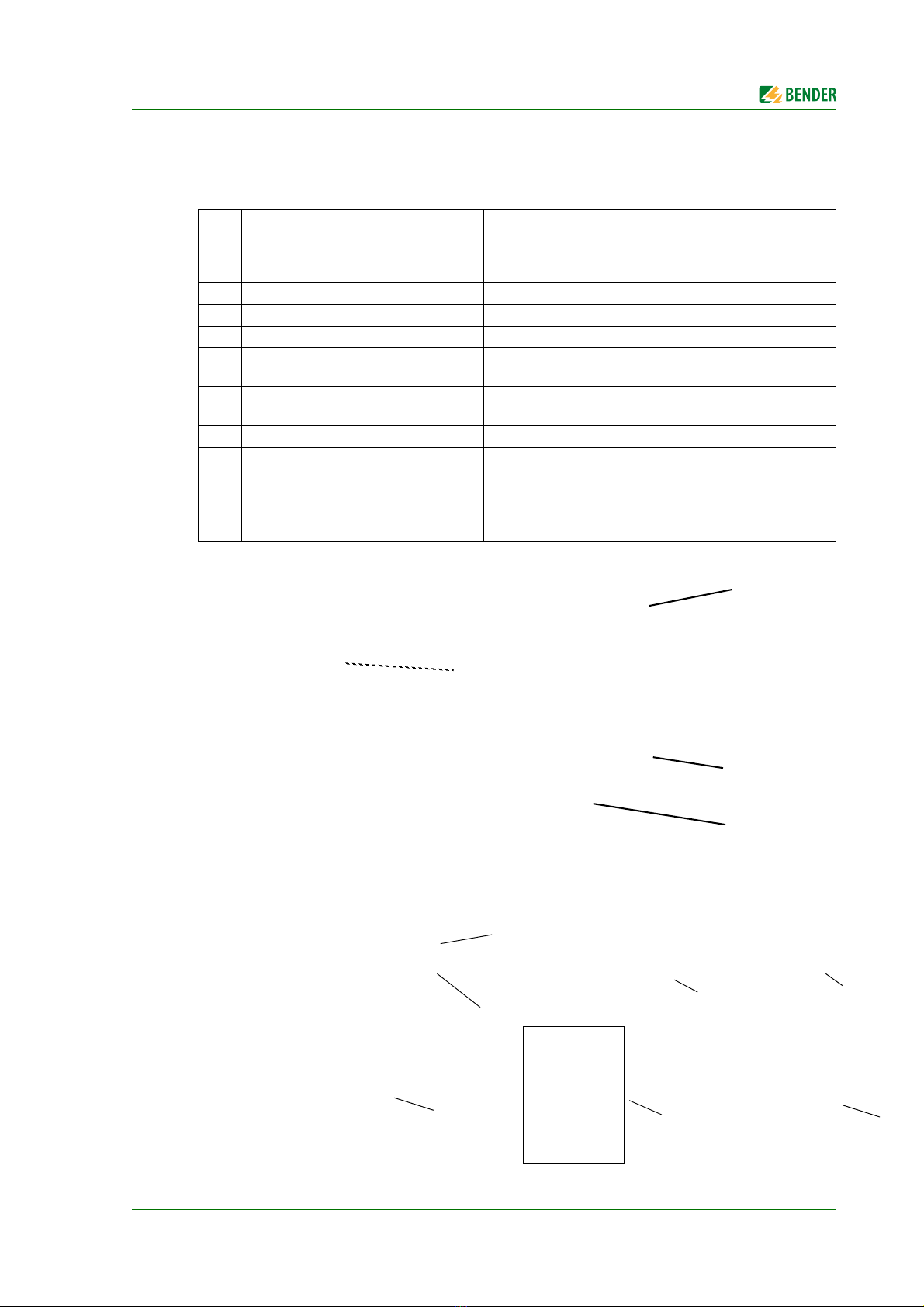

3.5 System components

The following accessories are supplied with the UNIMET® test system:

1 Carryingbag

For storage and transport of the test system and its accesso-

ries. Accessories are kept in the side pocket (1a) and the

inside pocket (1b). There is a loop to hold the stylus pen (1c)

supplied with the system for operating the touchscreen.

2 Test terminal (safety claw grip) For connection to accessible parts of the DUT

3 Test probe, single-pole For testing accessible parts of the DUT

4 Measuring lead, single-pole For testing permanently installed equipment

5 VK701-7 Adapter for non-heating

appliances

For testing device connecting cables

6 Interface cable (null modem cable) Enables data to be exchanged between the test system

and a PC (RS-232 interface)

7 Calibration certificate

Proof of the calibration work carried out in the factory

8 Technical manual and software tools

on CD. The CD is kept in the inside

pocket (1b).

- Manual of the test system

- Software for saving test specifications and device proto-

cols on a PC, software to transfer firmware updates to

the UNIMET

Power supply cord, detachable For connection to the supply voltage (no picture)

1

1B

1a

6

3

8

7

245

1c

System description

16 UNIMET8xxST_D00008_01_M_XXEN/02.2016

3.6 Operating elements

1 Touchscreen for operator control and indication. For this purpose, a stylus is included in the scope of

supply.

2 Durable plastic enclosure, with pushbuttons for safe storage in the carrying bag.

3 10 sockets (1…10) for the connection of patient electrodes.

4 Measuring terminals

- [B] (violet) for the connection of the single-pole test probe supplied with the product.

- [A] for active test probe TP800 with pushbutton (option).

- Socket [C] for equipotential bonding (e.g. connection for single-pole line extension with clip for the test-

ing of permanently installed equipment).

- Socket [D] for functional earth

5 Test socket: This is where the DUT's power supply cable is plugged in.

6 Connection to the supply voltage and power switch with thermo-magnetic circuit-breaker.

7 Connection for the external 25 A power source EPS800.

Note: The connector will lock into position and is protected against being pulled out unintentionally.

The plug can only be removed after pushing the movable grip back.

8Interfaces:

- PS/2 Connection for external keyboard

- RS-485 Serial interface for Bender Service

- RS-232 interface, 9-pin, electrically isolated, for connection to a PC

- USB interface for connection to a printer, a USB stick, an external keyboard or a barcode scan-

ner (2 x host) and a PC (1 x device, for Bender Service only)

- Ethernet Network connection (optional)

543

18

7

6

2

17

UNIMET8xxST_D00008_01_M_XXEN/02.2016

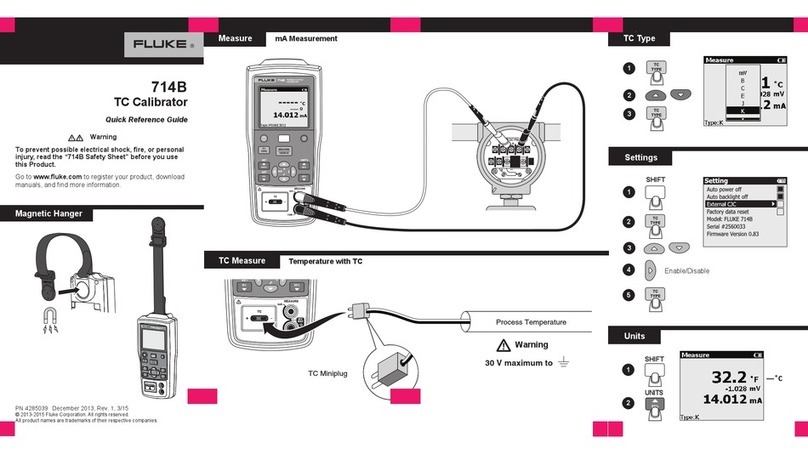

4. Quick reference guide

Switching on the test system

Selecting a test specification

There are three options, dependent upon the starting point:

The "Quick reference guide" chapter provides a brief overview of how the test sys-

tem works. We strongly recommend that you read the entire manual in order to

ensure that you can use all the functions of the test system.

Actions Details Page

1. Switch on the power switch 21

2. Select a test engineer 32

3. If you are switching the test system on

for the first time: Connect and configure

the accessories you need.

- Connect the printer

- Connect an external keyboard

- Connect barcode scanner

- Calibrate test probe or measuring lead if

necessary

22

23

23

36

Starting point Actions Page

The DUT is new:

Start the classification by selecting the appli-

cable test standard.

1. Select the applicable test standard.

2. Make the settings.

3.

Click to save (and test

)

18, 40

The DUT has previously been tested (recurrent

test):

The DUT is listed in the "Device protocol"

folder under its "Device ID.

1. Open the "Device protocols" folder.

2. Select the "Device ID".

3. Start the test with .

62

You know the type of the DUT:

The "Name" of the test specification" appears

in the "Test specifications" folder.

1. Open the "Test specifications" folder.

2. Select the "Name" of the test specifica-

tion.

3. Start the test with .

58

CAUTION

OK

Quick reference guide

18 UNIMET8xxST_D00008_01_M_XXEN/02.2016

Classification of a new DUT

There is not yet a test specification available for the DUT. The required test steps are identified by

means of classification.

Actions Details Page

1. Select the applicable test standard. 40

2. Select the applicable protection class. 40

3. Enter a name (type name) for the new

test specification.

Then open each tab in turn and make

the settings.

Click to complete the settings proc-

ess.

40

4. Click "Saving and testing" to save the

test specification and to start the test.

Click "Save" to save the test specifica-

tion without starting the test.

47

OK

Quick reference guide

19

UNIMET8xxST_D00008_01_M_XXEN/02.2016

Performing the test

To start a test (initial test), proceed as follows:

►After classification, select "Saving and testing",

►Select an existing test specification in the "Test specifications" folder and then click on the

"Measuring device" icon

►or call up "Start device test" from the context menu.

To start a recurrent test, proceed as follows:

►Select an existing device protocol in the "Device protocols" folder, then

– click on the "Measuring device" icon

– or call up "Start device test" from the context menu.

Actions Details Page

1. Connect the DUT, then click "Start". 48

2. Perform a visual inspection:

- Check that the information displayed

is applicable and check or uncheck

the boxes as appropriate.

- Click "Proceed" to carry out further

visual inspections.

- Click "Complete" to save and quit the

visual inspection process.

51

3. Perform the electrical test steps:

The test steps are carried out in

sequence with

- the DUT switched off

- the DUT switched on

- the DUT switched on and

the phase reversed.

51

4. Perform a functional test:

- answer the questions or

enter measured values as appropriate.

- Click "Proceed" to carry out further

functional tests.

- Click "Complete" to save and quit

the functional test process.

54

This manual suits for next models

11

Table of contents

Other Bender Test Equipment manuals