Bender UNIMET 300ST User manual

Operating Manual

UNIMET® 300ST

Testing system for

electrical safety

Software version: 3.2 and later

TGH1365en/10.2012

©Bender GmbH & Co. KG

All rights reserved.

Reprinting only with permission

of the publisher.

Subject to change!

Bender GmbH & Co. KG

Londorfer Str. 65 • 35305 Grünberg • Germany

Postfach 1161 • 35301 Grünberg • Germany

Tel.: +49 6401 807-0

Fax: +49 6401 807-259

E-mail: [email protected]

Web: http://www.bender-de.com

3

TGH1365en/10.2012

Table of Contents

1. How to get the most out of this manual ............................................................. 5

1.1 About this operating manual .............................................................................................. 5

1.2 Technical support .................................................................................................................... 5

1.3 Explanation of symbols and notes ..................................................................................... 6

2. Safety instructions .................................................................................................. 7

2.1 Delivery ........................................................................................................................................ 7

2.2 Intended use .............................................................................................................................. 7

2.3 Skilled persons .......................................................................................................................... 7

2.4 General safety instructions ................................................................................................... 7

2.5 Delivery conditions, guarantee, warranty and liability .............................................. 8

3. System description ................................................................................................. 9

3.1 Function ...................................................................................................................................... 9

3.2 Standard-compliant tests .................................................................................................. 10

3.3 System components ............................................................................................................10

3.4 Controls .................................................................................................................................... 12

4. Operation and configuration ............................................................................. 13

4.1 Commissioning ...................................................................................................................... 13

4.1.1 Connecting a printer ............................................................................................................ 14

4.1.2 Connecting the keyboard and barcode scanner ....................................................... 14

4.2 Principle of operation .......................................................................................................... 14

4.2.1 Operating the device ........................................................................................................... 14

4.2.2 Operation via the keyboard .............................................................................................. 15

4.2.3 Reading in with the barcode reader .............................................................................. 15

4.3 Main menu .............................................................................................................................. 16

4.4 Test engineer catalogue ..................................................................................................... 16

4.5 Device settings ....................................................................................................................... 19

4.5.1 Test probe calibration ......................................................................................................... 20

4.5.2 Device type query ................................................................................................................. 21

4.5.3 Warm-up and cool-down period ..................................................................................... 21

4.5.4 Changing the company name ......................................................................................... 22

4.5.5 Time/date ................................................................................................................................. 22

Inhaltsverzeichnis

4TGH1365en/10.2012

4.5.6 RS-232 parameters ................................................................................................................ 23

4.5.7 Buzzer On/Off ......................................................................................................................... 24

4.5.8 Summer time/winter time ................................................................................................. 24

4.5.9 Language/Sprache ............................................................................................................... 25

4.5.10 Firmware update ................................................................................................................... 25

4.6 Information .............................................................................................................................. 28

5. Testing and measuring ........................................................................................ 29

5.1 Testing via classification ..................................................................................................... 29

5.1.1 Classification ........................................................................................................................... 29

5.1.2 Tests ........................................................................................................................................... 33

5.1.3 Evaluating the test result .................................................................................................... 40

5.2 Recurrent test and device catalogue ............................................................................. 41

5.2.1 Collective printout ................................................................................................................ 42

5.2.2 Backing up the device catalogue .................................................................................... 43

5.3 Single test ................................................................................................................................. 49

6. Maintenance and calibration ............................................................................. 51

6.1 Calibration ............................................................................................................................... 51

6.2 Changing the battery ........................................................................................................... 51

6.3 Error messages ....................................................................................................................... 51

6.4 Disposal .................................................................................................................................... 52

7. Data ......................................................................................................................... 53

7.1 Standards ................................................................................................................................. 53

7.1.1 Application standards ......................................................................................................... 53

7.1.2 Design standards ................................................................................................................... 53

7.2 Test steps .................................................................................................................................. 54

7.3 Technical specifications ...................................................................................................... 56

7.4 Ordering data ......................................................................................................................... 57

INDEX ...........................................................................................................................59

5

TGH1365en/10.2012

1. How to get the most out of this manual

1.1 About this operating manual

This operating manual describes the UNIMET® 300ST with the software version indicated on the cov-

er page. The functions and processes described may vary from those featured in other versions. It is

designed for electrically skilled persons working in electrical engineering and electronics.

Please read this operating manual before using the devices. This documentation must be kept in an

easily accessible location near to the device.

Although great care has been taken in the drafting of this operating manual, it may nevertheless

contain errors and mistakes. The Bender Group cannot accept any liability for injury to persons or

damage to property resulting from errors or mistakes in this manual.

Each of the registered trademarks which appears in this document remains the property of its owner.

1.2 Technical support

As a Bender customer, you will receive technical support and assistance in the event of queries relat-

ing to equipment you have purchased. Please contact our Service Department or your next Bender

agency for more information:

Service-Hotline:

0700-BenderHelp (Telefon und Fax)

Carl-Benz-Straße 8 • 35305 Grünberg • Germany

Tel: +49 6401 807-760 • Fax: +49 6401 807-629

E-Mail: info@bender-service.com • www.bender-de.com

How to get the most out of this manual

6TGH1365en/10.2012

1.3 Explanation of symbols and notes

The following terms and symbols are used to denote hazards and instructions in Bender documen-

tation:

This symbol indicates an immediate risk to life and limb.

Failure to observe the associated instructions and take appropriate precautions

will result in death, serious physical injury or substantial damage to property.

This symbol indicates a potential risk to life and limb.

Failure to observe the associated instructions and take appropriate precautions

may result in death, serious physical injury or substantial damage to property.

This symbol indicates a potentially dangerous situation.

Failure to observe the associated instructions and take appropriate precautions

may result in minor physical injury or damage to property.

This symbol indicates important information about the correct use of the equip-

ment purchased.

Failure to observe the associated instructions can result in equipment malfunc-

tioning or cause problems in the environment in which it is being used.

This symbol indicates tips for using the equipment and particular useful infor-

mation. This type of information will help you to optimise your use of the equip-

ment.

Danger !

Warning

Caution

7

TGH1365en/10.2012

2. Safety instructions

2.1 Delivery

Inspect the dispatch packaging and equipment packaging for damage, and compare the contents

of the package with the delivery documents. Equipment damaged in transit must not be used. If

equipment has been damaged in transit, contact Bender immediately.

Equipment may only be stored in areas where it is protected against dust, damp, spray water and

dripping water and where the specified storage temperatures can be assured.

The selling company’s "General conditions of sale and delivery" always apply.

2.2 Intended use

The UNIMET®300ST has been designed exclusively for use in the area of application stipulated in the

chapter entitled "System description" on page 9.

Intended use also implies:

Observance of all instructions in this operating manual and

Compliance with any test intervals

Use which deviates from or is beyond the scope of these technical specifications is considered non-

compliant. The Bender Group cannot accept any liability for damage resulting from such use.

2.3 Skilled persons

Only electrically skilled persons may work on Bender products. Personnel who are familiar with the

installation, commissioning and operation of the equipment and have undergone appropriate train-

ing are considered skilled persons. Such personnel must have read this manual and understood all

instructions relating to safety.

2.4 General safety instructions

Bender devices are designed and built in accordance with the state of the art and accepted rules in

respect of technical safety. However, the use of such devices may introduce risks to the life and limb

of the user or third parties and/or result in damage to Bender devices or other property.

Only use Bender equipment:

– As intended

– In perfect working order

– in compliance with the accident prevention regulations and guidelines applicable at the loca-

tion of use

Eliminate all faults that may endanger safety immediately

Do not make any unauthorised changes and only use replacement parts and optional accesso-

ries purchased from or recommended by the manufacturer of the equipment. Failure to

observe this requirement can result in fire, electric shock and injury

Information plates must always be clearly legible. Replace damaged or illegible plates immedi-

ately.

Safety instructions

8TGH1365en/10.2012

2.5 Delivery conditions, guarantee, warranty and liability

The conditions of sale and delivery set out by Bender apply.

For software products, the "Softwareklausel zur Überlassung von Standard-Software als Teil von

Lieferungen, Ergänzung und Änderung der Allgemeinen Lieferbedingungen für Erzeugnisse und

Leistungen der Elektroindustrie" (software clause in respect of the licensing of standard software as

part of deliveries, modifications and changes to general delivery conditions for products and servic-

es in the electrical industry) set out by the ZVEI (Zentralverband Elektrotechnik- und Elektronikindus-

trie e.V., the German Electrical and Electronic Manufacturers' Association) also applies.

Delivery and payment conditions along with a copy of the software clause can be obtained from

Bender in printed or electronic format.

9

TGH1365en/10.2012

3. System description

3.1 Function

The UNIMET® 300ST is used to test electrical safety. It has been designed for following areas of use:

Hospital and care beds

"Prüfung nach Instandsetzung, Änderung elektrischer Geräte - Wiederholungsprüfung elek-

trischer Geräte" (Inspection after repair, modification of electrical appliances - Periodic inspec-

tion on electrical appliances) DIN VDE 0701-0702 (VDE 0701-0702):2008-06

with appropriate adapter*also protection class I and II three-phase electrical equipment

according to DIN VDE 0701-0702 and DIN EN 62353

* Use the DS32DCT three-phase current adapter to test devices not being in operation.

Use the DS32A three-phase current adapter to test devices during operation.

The test system supplies measurement results which it evaluates immediately in order to classify the

test as "passed" or "failed". The test sequence which follows classification contains a visual inspection

and a functional test in addition to the electrical tests. The test sequence can be carried out automat-

ically or manually depending on the device under test.

The test results can be displayed on the screen, saved or printed out using an external printer. In the

event of unexpected results, the DUT can be inspected in more detail by carrying out a single test.

The device catalogue provides memory space for the test results from up to 600 tested beds or de-

vices.

Tests can be transferred to a PC software program via the RS-232 interface. This software is included

with the UNIMET®300ST. For recurrent tests, the data stored in the PC software are transferred back

to the UNIMET® 300ST. The RS-232 interface is also used for any subsequent updates of the internal

operating software on the test system.

The test engineer catalogue can be beneficial if more than one person is working with the test sys-

tem. Test engineers already registered on the system are simply selected from this folder. There is no

need to re-enter the name of the test engineer. The names of up to ten test engineers can be stored.

The LC display is backlit. For entering data, a standard keyboard or barcode reader can be connected

to the PS/2 interface.

UNIMET® 300ST has been designed solely for use with earthed systems. If the test

system is used other than as intended, i.e. on an IT system, the measured values

of any leakage currents will not be reproducible. The test result cannot be used.

Alternative measurements of leakage currents, however, carried out with the

UNIMET® 300ST in IT systems will deliver correct test results.

System description

10 TGH1365en/10.2012

3.2 Standard-compliant tests

The UNIMET® 300ST carries out measurements and tests according to the following standards (see

also chapter "7.1 Standards"):

IEC 62353:2007-05

DIN EN 62353 (VDE 0751-1):2008-08

ÖVE/ÖNORM EN 62353:2009-01-01

DIN VDE 0701-0702 (VDE 0701-0702):2008-06

ÖVE E8701-1:03-01

The UNIMET® 300ST carries out the following measurements and tests:

Visual inspection

System voltage

Measurement of current consumption and calculation of power consumption

PE resistance for Protection Class I equipment

Insulation resistance

Equipment leakage current according to the differential measurement method or by direct

measurement

Equipment leakage current -Alternative method

Touch or PE conductor current according to the differential measurement method or by direct

measurement

Functional test

3.3 System components

The following accessories are supplied with the UNIMET® 300ST test system:

1Carrying bag For the storage and transport of the test system

and its accessories. Accessories are kept in the side

pocket and the inside pocket.

2Test probe For testing accessible parts of the DUT

3Test terminal (safety claw grip) For connection to accessible parts of the DUT

4Interface cable (null modem

cable)

Enables data to be exchanged between the test

system and a PC (RS-232 interface)

5Calibration certificate Proof of the calibration carried out in the factory

6Technical device manual on CD Test system manual

7UNIData300 PC software (CD) UNIData300 software for

- backing up the device catalogue on a PC

- transferring a firmware update to the

UNIMET® 300ST

8VK701-6 Adapter Schuko

(German)

For testing extension cables and socket strips

9VK701-7 Adapter for non-

heating appliances

For testing device connecting cables

10 USB1.1 RS-232 converter Enables data exchange between the RS-232

interface of the UNIMET® 300ST and the USB port

of a PC (with installation CD)

System description

12 TGH1365en/10.2012

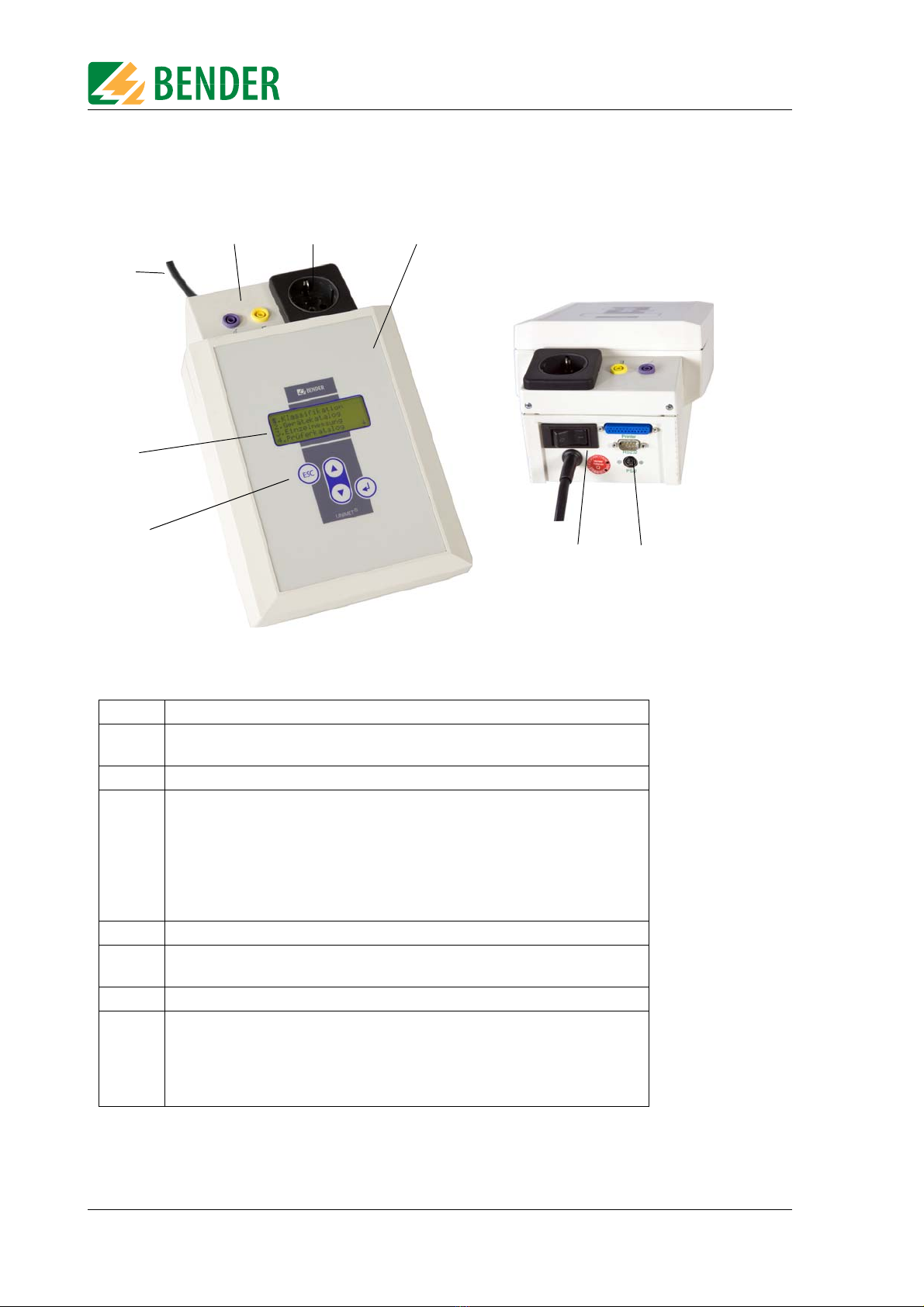

3.4 Controls

1 Control buttons

2 Backlit LCD for displaying the user menu and the measurement results. Four

lines of 20 characters each.

3 Permanently attached power cable for connection to the supply voltage.

4Sockets

- violet: Connection for test probe for testing accessible parts of the

device under test.

- yellow (E): for a second measuring lead when the low-resistance continuity

of the PE conductor is to be measured between two points (e.g.,

on single-phase, permanently installed devices or extension

cables).

5 Test socket: This is where the DUT's power supply cable is plugged in.

6 Durable plastic enclosure, with pushbuttons for safe storage in the carrying

bag.

7 Power switch with thermo-magnetic circuit-breaker.

8Interfaces

- RS-232 interface, 9-pin, galvanically isolated, for connection to a PC

- Centronics interface for connection to a printer

- PS/2 port for connection to an external standard keyboard and a barcode

reading wand or scanner.

2

8

7

6

5

4

3

1

13

TGH1365en/10.2012

4. Operation and configuration

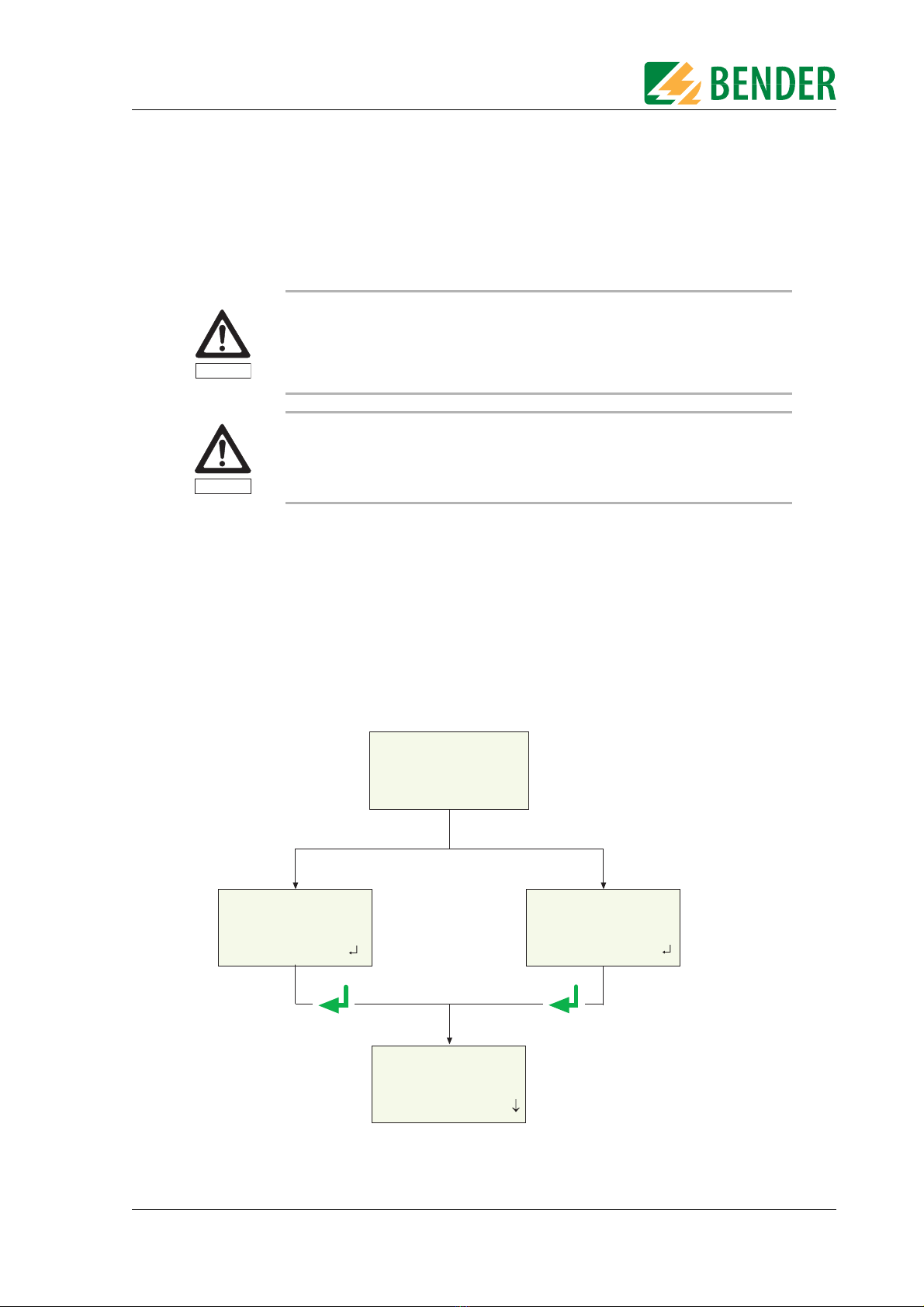

4.1 Commissioning

1. Lay the UNIMET® 300ST down on an even surface with the coloured edges of the bag facing

up. Open the two covers (Velcro fasteners).

2. Connect the UNIMET® 300ST to the supply voltage using the permanently attached power

cable.

3. Switch on the device using the power switch.

The test system logs on with a beep (only when the buzzer is switched on) and displays the welcome

text:

The test system is now ready for operation. The main menu appears.

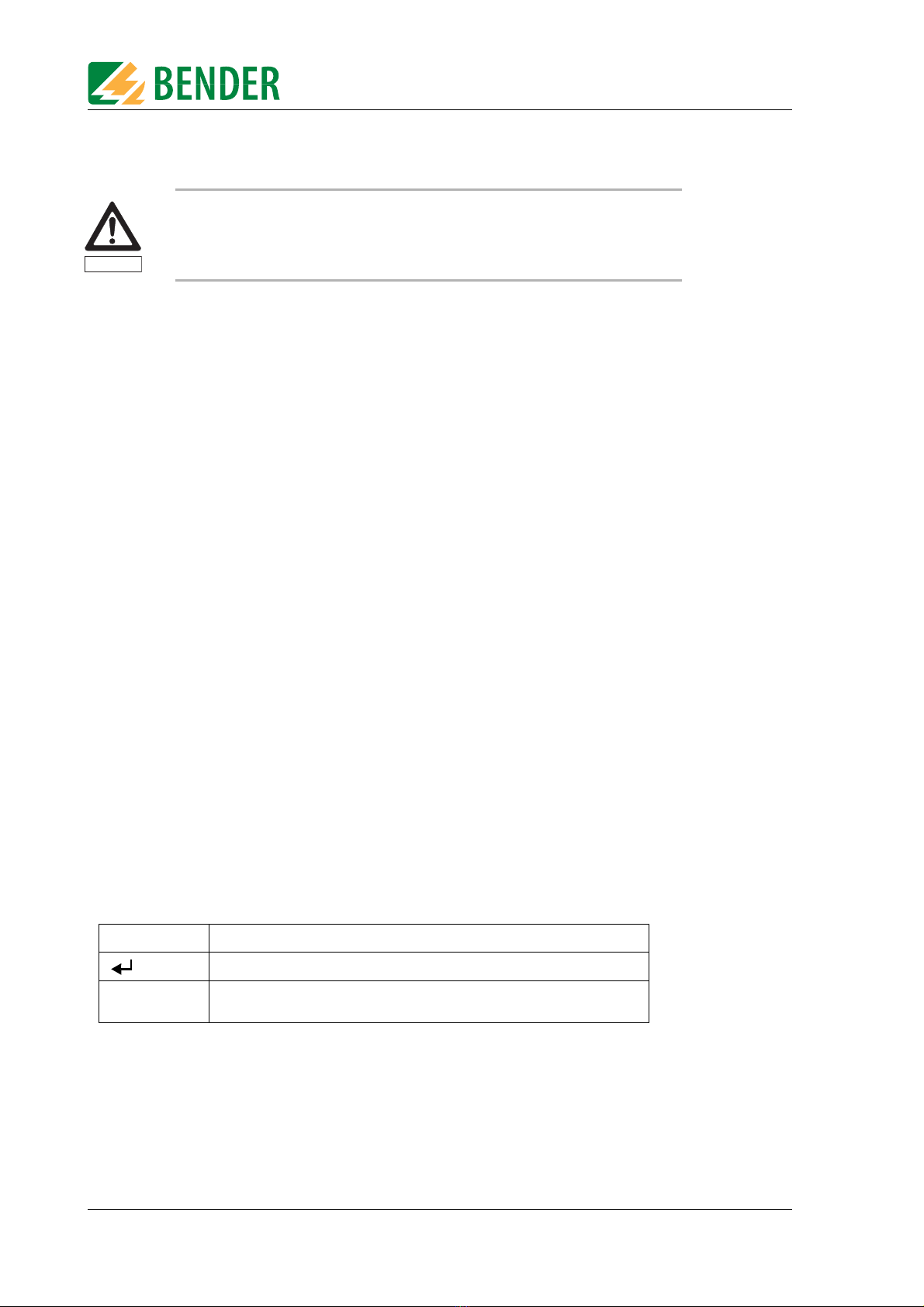

Inspect UNIMET® 300ST, its supply cable and measuring leads connected to it for

visible damage on the outside. Do not operate equipment showing any visible

damage.

The UNIMET® 300ST must always be connected to the supply voltage indicated

on the nameplate. Failure to observe this requirement may damage the test sys-

tem and any device under test connected to it.

Warning

Caution

------------------------------

Test eng. logged on:

Hofmann

Next:

** WARNiNG **

No test engineer

logged on!

Next:

UNIMET300ST

Test system for

electrical safety

BENDER GMBH & CO.KG

1. Classification

2. Device catalogue

3. Single test

4. Test eng. catalog

If no test engineer

has logged on yet

If a test engineer has

already logged on

Main menu

Press the ENTER key

or wait 3 seconds

leads to main menu

Operation and configuration

14 TGH1365en/10.2012

4.1.1 Connecting a printer

A printer can be connected to print out the test results. Providing that:

The printer used has an IBM 8-bit character set

The printer is set to IBM emulation

GDI printers (GDI = Graphic Device Interface) are not suitable for the UNIMET®300ST.

You need a standard printer cable (25-pole D-Sub plug to Centronics) to connect the printer. This ca-

ble is not included with the equipment.

4.1.2 Connecting the keyboard and barcode scanner

A keyboard and/or barcode reading wand or barcode scanner can be used to make it easier to input

the ID numbers and names of test engineers. UNIMET® 300ST supports the PS/2 interface to which

either a standard keybboard, a PS/2 barcode-pen reader or PS/2 barcode scanner can be connected.

If an AR100 barcode-pen reader is connected to a PS/2 keyboard switch cable (see “Ordering data”

auf Seite 57.), it can be connected to a keyboard at the same time. If no keyboard is connected, then

plug the keyboard simulator supplied with the AR100 barcode-pen reader to this port.

The keyboard and barcode pen reader or barcode scanner can be plugged in and unplugged during

operation. Adjustments on the UNIMET are not necessary. The keyboard and barcode pen reader

must not be connected before switching on the UNIMET. This increases flexibility during testing.

When the UNIMET detects a PS/2 keyboard, then the "Num-Lock" LED lights up. The LED indicates

that the keyboard is ready.

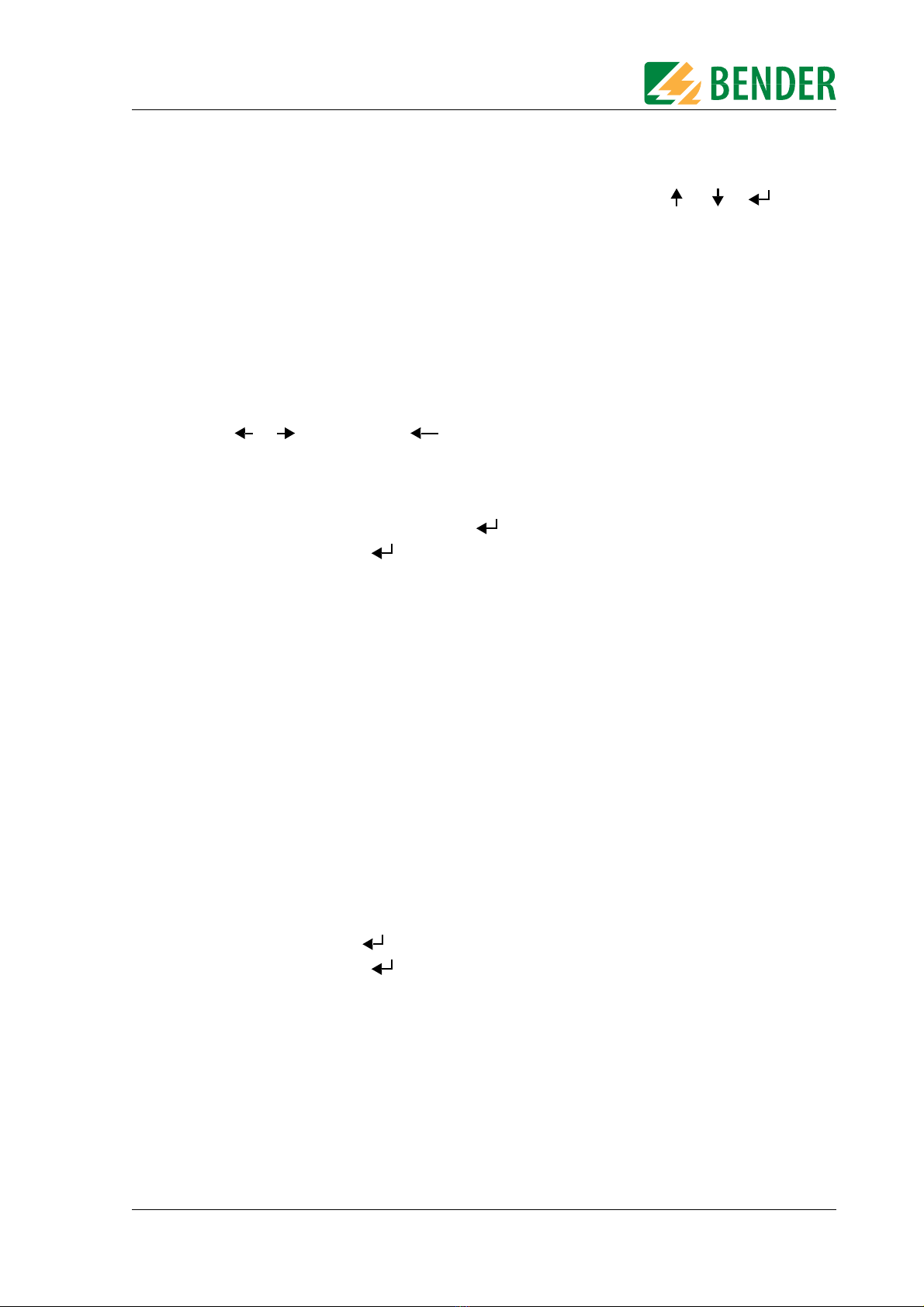

4.2 Principle of operation

4.2.1 Operating the device

All the functions of the UNIMET®300ST are controlled using the four control keys and the displays on

the screen. The current position on the menus is indicated by a flashing marker (cursor).

Earthed printers can affect the measurements. Therefore, during the measure-

ments, make sure that either

- the Centronics interface is not connected to an earthed printer or

- the Centronics interface is electrically isolated via a suitable component.

Use the arrow buttons to move the cursor up or down on the menus.

Use the Enter button to confirm selection of the current menu item.

ESC The ESC button enables you to leave functions without making

changes. It also enables you to return to the main menu.

Caution

Operation and configuration

15

TGH1365en/10.2012

4.2.2 Operation via the keyboard

An external keyboard makes it easy to enter the names and ID numbers of the test engineers. You

can also operate the UNIMET entirely via the keyboard. The Cursor block " ", " ", " " "ENTER"

and "ESC" keys have the same function as the buttons on the front of the UNIMET.

Note when entering text:

The text entry cannot be longer than 20 characters. The UNIMET will truncate longer entries to

20 characters.

You can enter all characters which can be selected directly on UNIMET.

Upper and lower case is available but not umlauts.

The numeric keypad can only be used to enter digits. The LED "Num-Lock" therefore lights up

constantly.

When entering text, the following keys can be used to edit the text:

" ", " " (Cursor block), " " (Backspace), Del, Home.

Entries via the keyboard can also be combined with texts read in from the barcode scanner and

barcode reading wand.

Save the entry after entering the last character by

– by holding down the Enter button " " on the UNIMET for approx. 3 seconds

– or by pressing the " " ENTER key on the keyboard once.

4.2.3 Reading in with the barcode reader

Refer to the operating instructions for the barcode reading wand or barcode scanner.

The AR100 barcode reading wand (see “Ordering data” auf Seite 57.) reads more reliably by sweep-

ing it quickly over the barcode. Also follow the instructions for the barcode reading wand. Barcodes

can be read both forwards and backwards.

The data string which is read in can be up to 20 characters long. The UNIMET will truncate longer en-

tries to 20 characters.

When reading in the names and ID numbers of new test engineers, the input screen will remain

open. This allows you to check the entry and change or replace it if necessary. .

You can delete the entry and go to the previous menu by holding down

– the "ESC" button on the UNIMET for approx. 3 seconds

– or by pressing the "ESC" key on the external keyboard once.

Save the entry by holding down

– the Enter button " " on the UNIMET for approx. 3 seconds

– or by pressing the " " Enter key on the external keyboard once.

You can use the barcode scanner or barcode reading wand to call up tests from the device catalogue

again using the ID number. In this case, after successfully reading in the barcode, it will immediately

switch to the next screen of the operating process.

Operation and configuration

16 TGH1365en/10.2012

4.3 Main menu

All UNIMET®300ST functions and submenus can be accessed from the main menu.

Each submenu is accessed by selecting it with the arrow buttons and confirming by pressing the

" " button.

4.4 Test engineer catalogue

The names of the test engineers are stored in the "Test engineer catalogue".The test engineer whose

name appears in the test protocol is also logged on here. You should therefore set the name of the

test engineer before carrying out the first test.

The test catalogue can be particularly beneficial if more than one person is working with the test sys-

tem. Test engineers already registered on the system are simply selected from the test catalogue us-

ing the arrow buttons. There is no need to re-enter the name of the test engineer.

A name of a test engineer cannot be longer than twenty characters. The names of up to ten test

engineers can be stored.

Menu item Function Page

1. Classification Answer the questions that appear on the screen. The

test system will identify the required test steps and

limits to be observed. The assisted test sequence will

guide you through all necessary steps to be taken.

29

2. Device catalogue The test results, tests and limits of the device tested by

the test system are stored in the device catalogue.

41

3. Single test Test steps can be called up in the form of single tests

and repeated as often as required.

49

4. Test engineer

catalogue

Select test engineer, enter new test engineer, delete

test engineer

16

5. Device setting Settings for test probe, type query, warm-up period,

company name, clock, RS-232 interface, buzzer,

language and update

19

6. Info Provides information about the device names,

software version and serial number of the device.

28

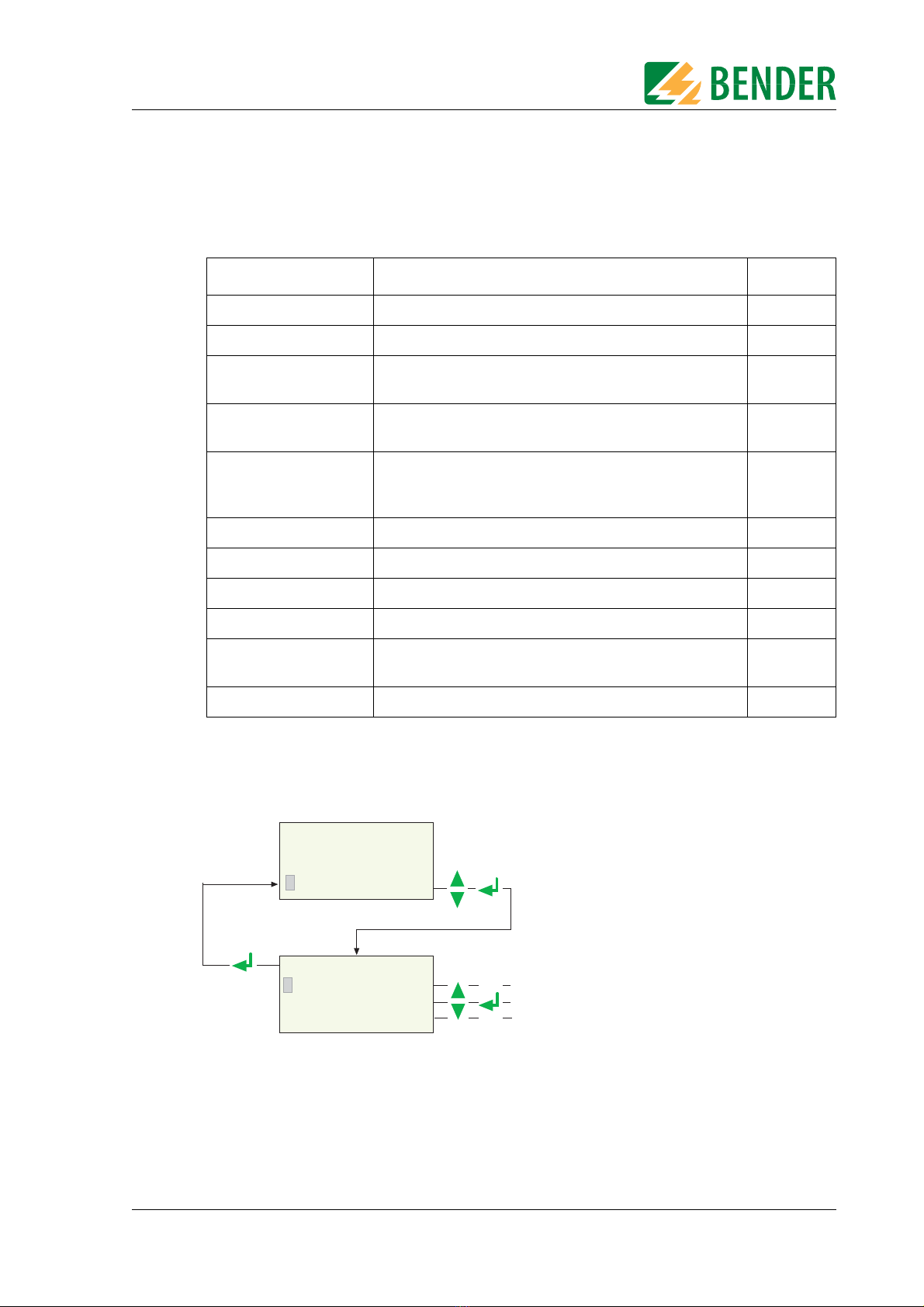

Main menu

1. Select "Test eng. catalog."

ESC - Select and log on test engineer

- Enter and log on new test engineer

- Delete existing test engineer

2. select required function:

1. Exit

2. Select test eng.

3. Enter new test eng

4. Delete test eng.

1. Classification

2. Device catalogue

3. Single test

4. Test eng. catalog.

Operation and configuration

17

TGH1365en/10.2012

Select the name of a test engineer (log on) as follows:

To enter the name of a new test engineer:

SELECT TEST ENGINEER

Test engin.: ( 3/ 4)

HENRY STONE

Select: , Confirm:

1. Call up

“Select test eng.” function

2. Use the arrow keys to select

the test engineer

3. Confirm with ENTER key

-----------------------------

Test eng. logged on:

HENRY STONE

-----------------------------

Selected test engineer is

displayed for approx. 3 seconds

ESC

1. Exit

2. Select test eng.

3. Enter new test eng

4. Delete test eng.

ENTER TEST ENG. NAME:

_

Char.: A-Z, 0-9, -. /

Exit: ESC Next:

1. Select “Enter new test eng”

2. Use the arrow keys to select the first characters

and then press the ENTER key

4. After entering the last character,

press and hold down the

ENTER key for approx. 3 seconds.

3. Select all the remaining characters also

Briefly press the ESC key

= edit previous character

Press and hold down the ESC key

= Exit menu without making changes

The new test engineer is

saved and logged on

3 s

ENTER TEST ENG. NAME:

JOHN MEYER

Char.: A-Z, 0-9, -. /

Exit: ESC Next:

ESC

ESC

ESC

ESC

1. Exit

2. Select test eng.

3. Enter new test eng

4. Delete test eng.

1. Exit

2. Select test eng.

3. Enter new test eng

4. Delete test eng.

Operation and configuration

18 TGH1365en/10.2012

To delete the name of a test engineer:

1. Call up “Delete test eng.”

function

2. Use the arrow keys to select

the test engineer

3. Confirm with ENTER key

Confirmation is displayed

for approx. 3 seconds

The selected test

eng. will be deleted

from the catalogue.

Please wait!

1. Exit

2. Select test eng.

3. Enter new test eng

4. Delete test eng.

SELECT TEST ENGINEER

Test engin.: ( 3/ 4)

PETER MILLER

Select: , Confirm:

ESC

Operation and configuration

19

TGH1365en/10.2012

4.5 Device settings

Some of the following settings are used in generating reports to record the test

results. You should therefore check these settings before carrying out the first test.

To access the device settings:

Menu item Function Page

1. Exit Returns to the main menu -

2. Test probe calibration Zero calibration test probe 20

3. Device type query This is where you determine whether another device type

is to be queried and stored in addition to the device ID.

21

4. Warm-up/cool-down Setting for devices which require a warm-up period before

the test and cool-down period after the test.

21

5. Change comp. name The company name entered here will appear on the

printout of the test report and after switching on the

device on line 4 of the welcome menu.

22

6. Time/date Set system time and date 22

7. RS-232 parameters Set data transfer speed 23

8. Buzzer On/Off Switch buzzer on or off 24

9. Summer/wintertime Automatic switchover from summer time to winter time 24

10. Language/Sprache Select German or English for user menus and protocol

text. Activate settings for use in Austria.

25

11. Firmware update Load new version of operating software 25

Main menu

1. Select “Device setting”

ESC 2. Select required function

1. Exit

2. Test probe calibr.

3. Device type query

4. Warm-up/cool-down

2. Device catalogue

3. Single test

4. Test eng. catalog.

5. Device setting

Operation and configuration

20 TGH1365en/10.2012

4.5.1 Test probe calibration

Zero balance must be carried out for the UNIMET® 300ST test probe. As with an ohmmeter, this en-

sures that the ohmic resistance of the test probe will not affect the PE conductor test result.

Recalibrate each time after connecting

– another test probe,

– another measuring lead,

– or a three-phase adapter

to the test system.

Proceed as follows to calibrate the test probe:

*) With permanently connected Protection class I devices or extension cables al-

so, the low resistance continuity of the PE conductor can be tested. The measure-

ment is carried out between the test probe and the measuring lead connected to

the yellow socket E.

Before the test, a single zero calibration must be carried out with the test probe

and the measuring lead.

Carry out a zero calibration again if you want to run the PE conductor test with

the test probe on equipment with Schuko plug.

Failure to follow these instructions may lead to false test results.

Device setting

1.Select “Test probe calibr.”

2. Hold the test probe on the earth contact

of the test socket*).

Make sure that the test probe

remains there during the entire

calibration process.

*** CALIBRATION ***

Insert test probe

and contact PE of

socket outl. Next:

*** CALIBRATION ***

Testprobe/Cable

Please wait !

3. Start calibration.

1. Exit

2. Test probe calibr.

3. Device type query

4. Warm-up/cool-down

ESC

Table of contents

Other Bender Test Equipment manuals