Bender LINETRAXX CTUB103 Series User manual

Manual ENCTUB103_D00410_02_M_XXEN / 09.2022

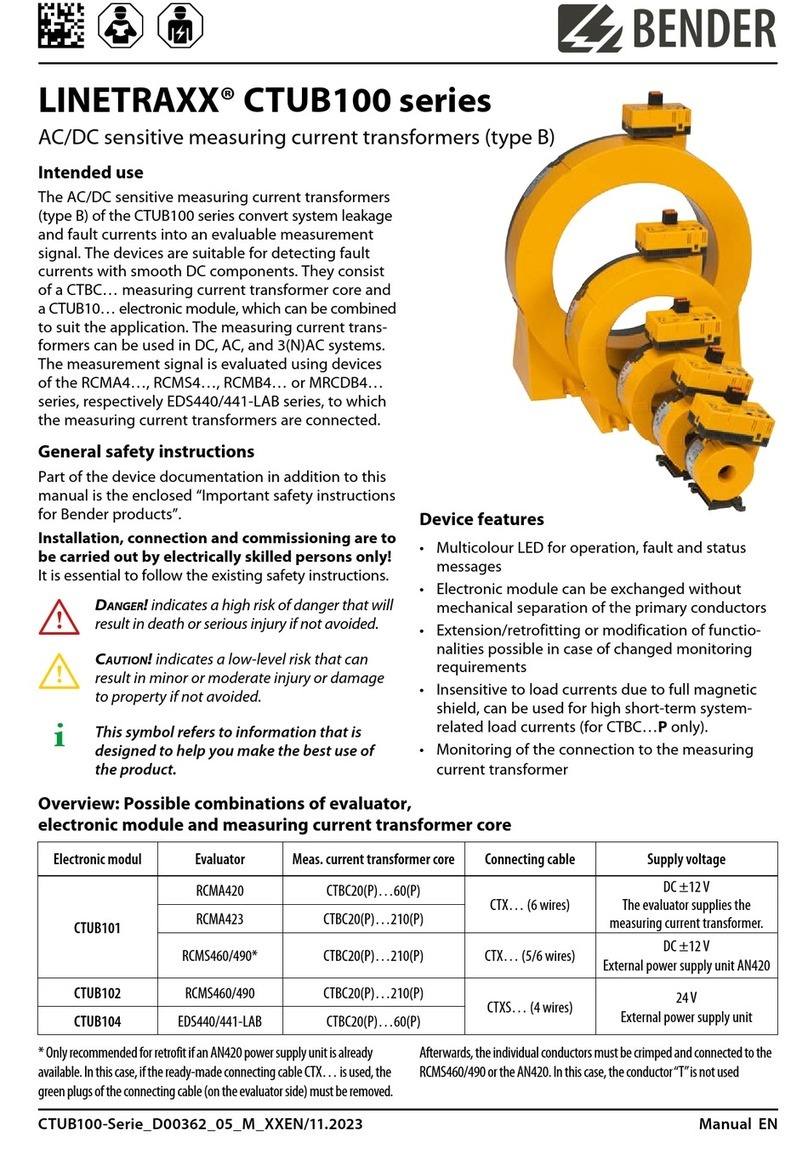

LINETRAXX® CTUB103

AC/DC sensitive measuring current transformer

Intended use

The AC/DC sensitive measuring current transformers

of the CTUB103 series convert system leakage and

fault currents into an evaluable measurement signal.

The devices are suitable for detecting fault currents

with smooth DC components. They consist of a

CTBC… measuring current transformer core and a

CTUB103 electronic module, which can be combined

to suit the application. The measuring current trans-

formers can be used in DC, AC and 3(N)AC systems as

well as in high-resistance grounded systems for mo-

nitoring the star point. The evaluation in resistance

grounded systems is carried out with devices of the

NGRM… series, to which the measuring current

transformers are connected.

General safety instructions

Part of the device documentation in addition to this

manual is the enclosed „Important safety instructions

for Bender products“.

Mounting, connection and commissioning are to be

carried out by electrically skilled persons only! It is es-

sential to follow the existing safety instructions.

I Danger! Indicates a high risk of danger that

will result in death or serious injury if not

avoided.

I Caution! Indicates a low-level risk that can

result in minor or moderate injury or dama-

ge to property if not avoided.

i

Information can help to optimise the use of

the product.

Device features

• Multicolour LED for operation, fault and status

messages

• Electronic module can be exchanged without me-

chanical separation of the primary conductors

• Monitoring of the connection to the measuring

current transformer

• Evaluator: NGRM500, NGRM700

2 CTUB103_D00410_02_M_XXEN / 09.2022

LINETRAXX® CTUB103

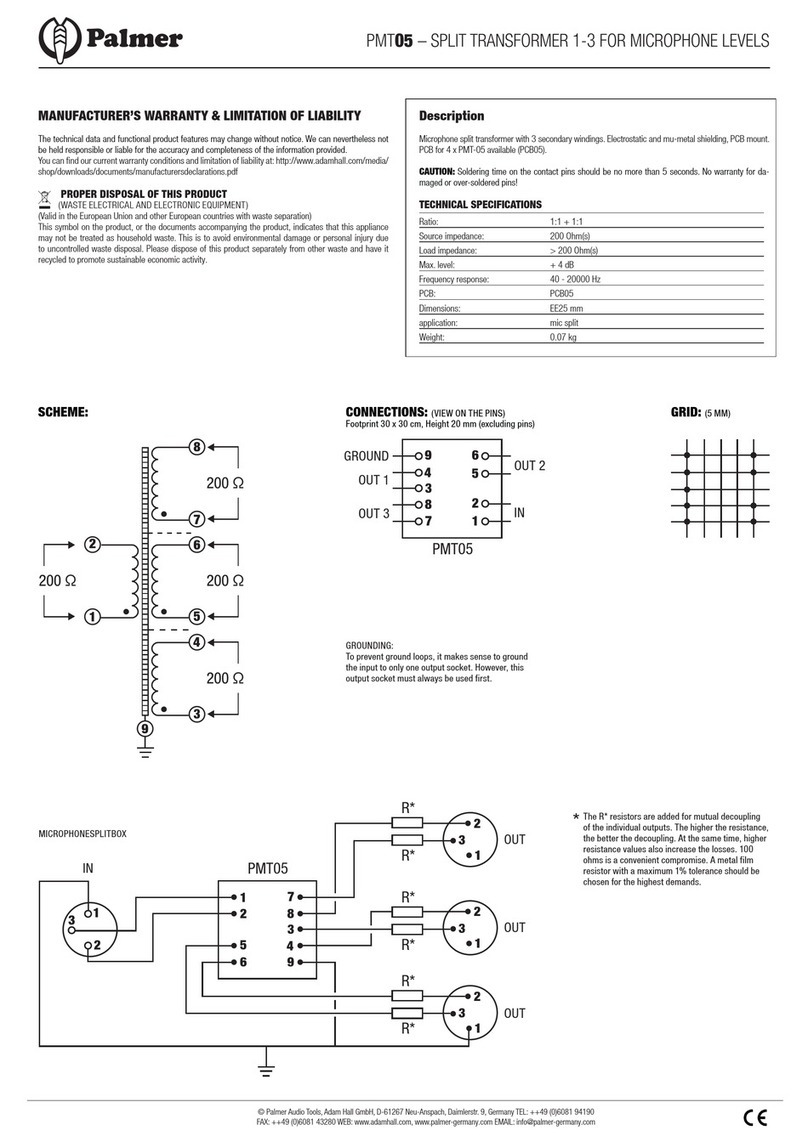

Dimension diagrams

Mountings

Assembly

Slide the electronic module onto the plug contacts of the measuring current transformer.

Dimensions [mm (in)],

Tolerance: ±0,5 mm

Typ a b c d e f g

A

CTUB103-CTBC35

97 (3.82) 130 (5.12) 47 (1.85) ø 35 (ø 1.38) 46 (1.81) 61 (2.40) -

B

CTUB103-CTBC60

126 (4.96) 151 (5.94) 57 (2.24) ø 60 (ø 2.36) 56 (2.20) 78 (3.07) -

C

CTUB103-CTBC120

188 (7.40) 225 (8.86) 96 (3.78) ø 120 (ø 4.72) 65 (2.56) 96 (3.78) 139 (5.47)

DCTUB103 74 (2.91) 44 (1.73) 30 (1.18) 32 (1.26) 4,6 (0.18)

b

c

d

a

e

d

e

f

c

b

a

d

e

f

c

b

a

g

a

d

e

c

f

b

a

b

c

CTBC35

a

b

c

CTBC60

a

b

c

CTBC120

Dimensions [mm (in)],

Tolerance: ±0,5 mm

Typ a b c

CTBC35 49

(1.93)

49,80

(1.96)

2 x ø 5,5

(2 x ø 0.22)

CTBC60 56

(2.20)

66

(2.60)

3 x ø 6,5

(3 x ø 0.26)

CTBC120 103

(4.05)

81

(3.19)

4 x ø 6,5

(4 x ø 0.26)

2

1

A B C

D

LINETRAXX® CTUB103

CTUB103_D00410_02_M_XXEN / 09.2022 3

Index Action LED

6 Release the "T" button (9). ashes

red

quickly

7

Calibration successful lights

green

Calibration not successful: repeat calibration ashes

red

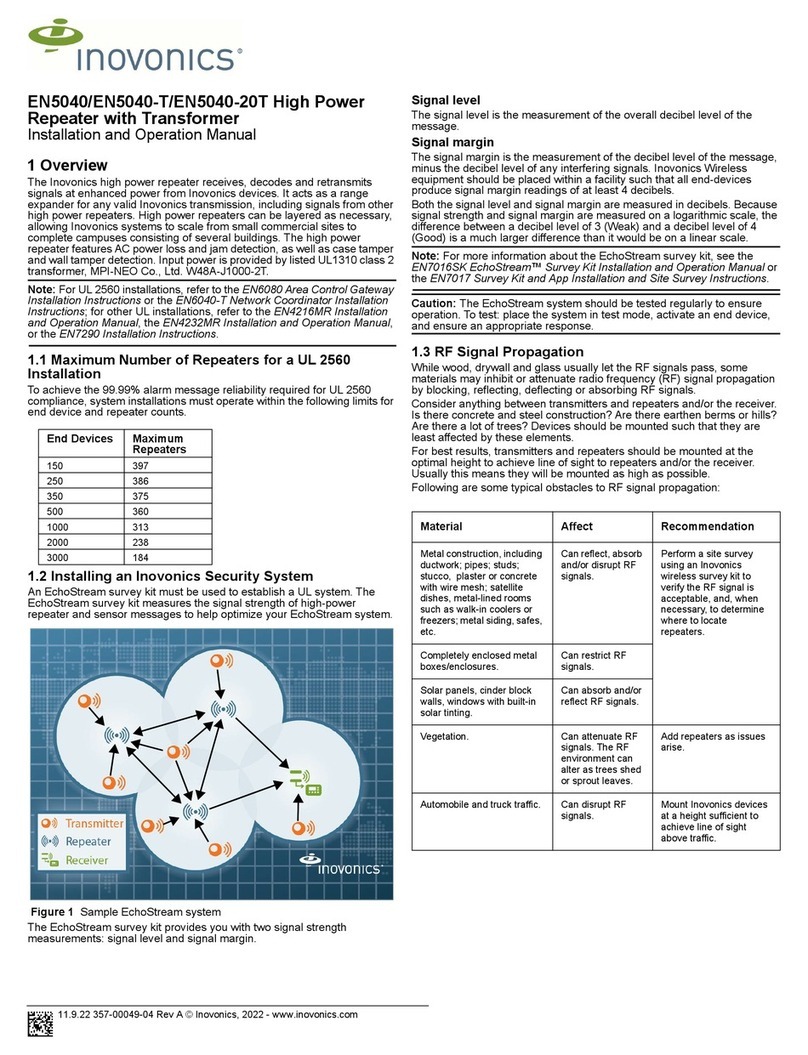

Device view

No. CTUB103 Note

1

Terminal X

S1 (k) Connection measuring current

transformer core/NGRM…

2S2 (l)

3-Not in use

4-

524V Supply voltage US

6GND

7-Not in use

8-

9ButtonT Oset calibration (see below)

10 Combined LED

lights green normal operation

ashes red device error; USis connected, no connection to CTBC.

Check the connection between CTUB and CTBC, if necessary, snap on the electronic module

again. If LED still ashes red: Contact Service please.

11

Potentiometer

for adjusting the

measuring range

Measuring range

Scaling

5 A 5 A/50 mA 100:1

10 A 10 A/50 mA 200:1

25 A 25 A/50 mA 500:1

1

11

10 9

2 3 4

5678

Offset-Calibration

i

For measuring current transformer cores with an internal diameter ≥ 120 mm, an offset calibration should

always be carried out before the first commissioning. Note that during the offset calibration the system is

switched off and no current flows through the measuring current transformer. For safety reasons, offset

calibration cannot be performed if a current > 15 mA flows through the measuring current transformer

during offset calibration.

Index Action LED

1 Disconnect X plug (1…8) or interrupt US (24V). o

2 Press and hold the "T" button (9). o

3 Connect X plug (1…8) or switch on US (24V).

Continue to hold the "T" button (9) down. lights red

4 Continue to hold the "T" button (9) down. ashes

red

5 Continue to hold the "T" button (9) down. ashes

red

quickly

4 CTUB103_D00410_02_M_XXEN / 09.2022

LINETRAXX® CTUB103

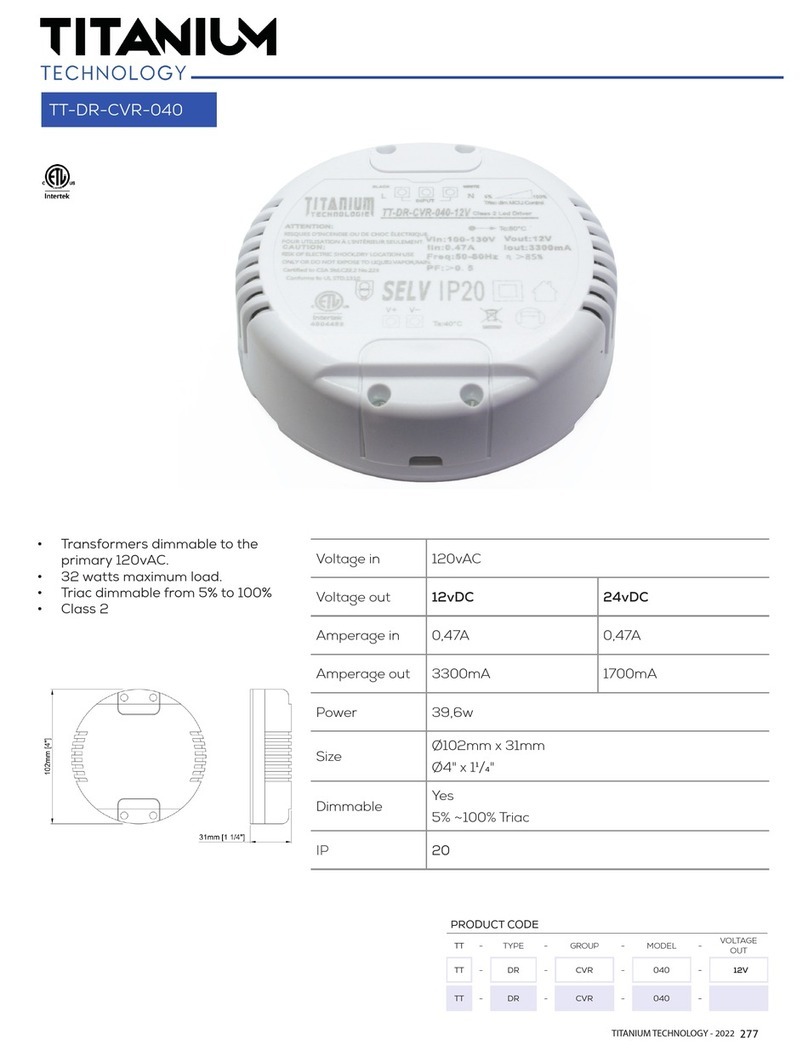

Wiring diagram CTUB103

IDanger of electrocution due to electric shock!

Touching live parts of the system carries the risk of:

- An electric shock

- Damage to the electrical installation

- Destruction of the device

Before installing and connecting the device, make sure that the installation has been de-ener-

gised. Observe the rules for working on electrical installations. Observe the information on no-

minal voltage and supply voltage specified in the technical data!

Connect the device according to the wiring diagram. Please observe the technical data.

CTUB103

NGRM

…

24V GND

S1(k)S2(l)

24V GNDC50m

24V GND

S1(k)S2(l)

NGR

Rs (G1)

E (G)

N

CD...

N

L1

L2

L3

CTBCx

LINETRAXX® CTUB103

CTUB103_D00410_02_M_XXEN / 09.2022 5

diagrams on page 3

Measurement accuracy.......................................................±2 %

Rated continuous thermal current Icth ...................................42 A

Rated short-time thermal current Ith............................ 2.4 kA/1 s

Rated dynamic current Idyn .........................................6 kA/40 ms

Measuring ranges

Measuring range 1...........................................................5 A rms

Permanent overload capacity ................................10.5 A rms

............................................................................. 14.5 A peak

Scaling....................................................... 5 A/50 mA, 100:1

Measuring range 2.........................................................10 A rms

Permanent overload capacity ...................................21 A rms

............................................................................. 29.5 A peak

Scaling......................................................10 A/50 mA, 200:1

Measuring range 3.........................................................25 A rms

Permanent overload capacity ...................................42 A rms

................................................................................ 59 A peak

Scaling......................................................25 A/50 mA, 500:1

Displays

Multicolour LED ...........................................................red, green

Output

Name........................................................................S1 (k), S2 (l)

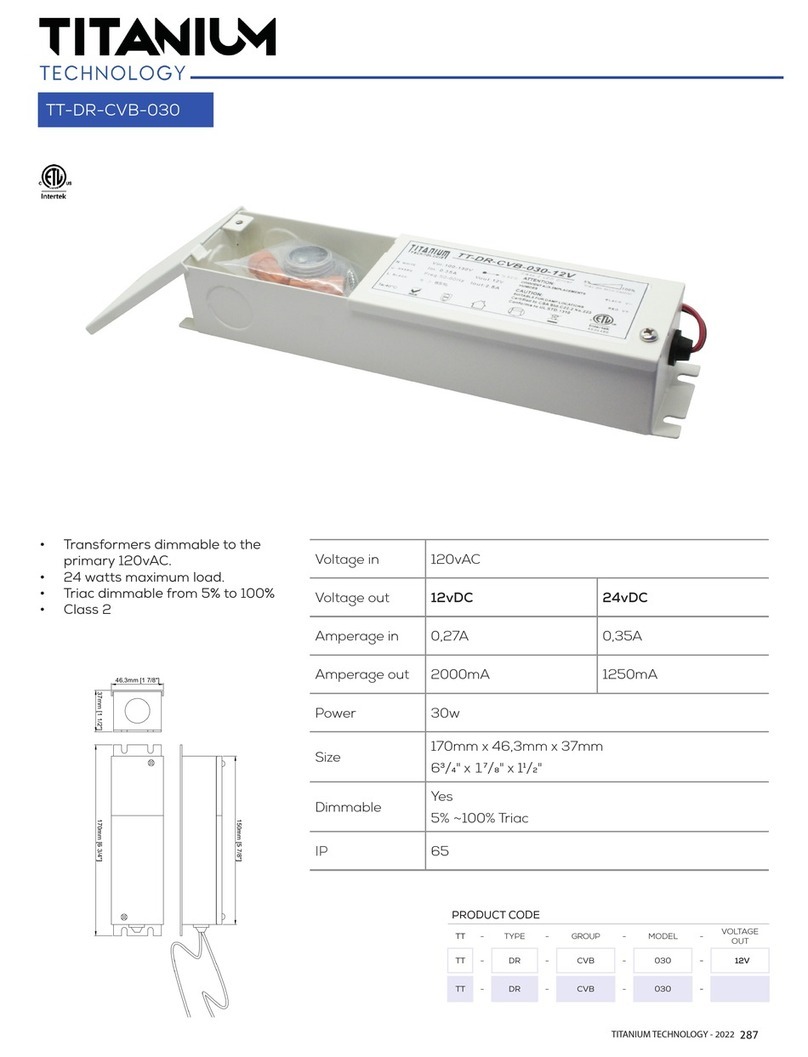

Installation instructions measuring current

transformer

I Caution! Device damage due to interference

pulses! The connecting cable (supply, analo-

gue interface, ...) must not be routed directly

past the current transformer core.

i

Do not route any shielded cables through the

measuring current transformer.

The measuring current transformer must be connec-

ted to the corresponding evaluator before the first

use and before commissioning of the monitored ins-

tallation. Pay attention to the following:

The cables must be aligned with the centre of the measuring

current transformer.

All current-carrying cables must be routed through the meas-

uring current transformer.

Never route an existing protective conductor through the

measuring current transformer.

PE

L1

L2

L3

N

P1 (K): YE P2 (L): GY

*

*

The primary conductors may only be bent from the specified

minimum distance. The minimum bending radius specified by

the manufacturers for the conductors used must be observed.

Distance to 90° angle = 2 * outer diameter

Technical data

Insulation coordination acc. to IEC 60664-1/IEC 60664-3

Definitions

Measuring circuit (IC1) ..primary conductors routed through the

current transformer

Secondary (IC2) ............................................ connections X plug

Rated voltage......................................................................800 V

Overvoltage category............................................................... III

Area of application ........................................... ≤ 2000 m AMSL

Rated impulse voltage (IC1/IC2) ...........................................8 kV

Rated insulation voltage (reinforced insulation; IC1/IC2)

........................................................................................... 800 V

Pollution degree ........................................................................2

Supply voltage CTUB103

Description...................................................................24 V, GND

Supply voltage Us........................................................... DC 24 V

Operating range of Us........................................................±20 %

Ripple Us............................................................................≤ 1 %

Power consumption........................................................≤ 5.3 W

Inrush current...........................................................1 A for 1 ms

Measuring circuit

Internal diameter measuring current transformer see dimension

i

Application in railway vehicles/DIN EN 45545-2:2016!

If the horizontal or vertical distance to adjacent components which do not meet the requirements in table

2 of DIN EN 45545-2 is less than 20 mm or less than 200 mm respectively, they are to be regarded as

grouped. Refer to DIN EN 45545-2 chapter 4.3 Grouping rules.

6 CTUB103_D00410_02_M_XXEN / 09.2022

LINETRAXX® CTUB103

Max. voltage......................................................................±10 V

Max. current..................................................................±100 mA

Max. cable length ................................................................30 m

Load......................................................................................68 Ω

Environment/EMC

EMC ..........................................................................IEC 61000-6

Operating temperature ............................................ -25…55 °C

Classification of climatic conditions acc. to IEC 60721 (ex-

cept condensation and formation of ice)

Stationary use (IEC 60721-3-3) .............................................3K5

Transport (IEC 60721-3-2) ...................................................2K11

Long-term storage (IEC 60721-3-1) ...................................1K22

Classification of mechanical conditions acc. to IEC 60721

Stationary use (IEC 60721-3-3).............................................3M4

Transport (IEC 60721-3-2) ................................................... 2M4

Long-term storage (IEC 60721-3-1) .................................. 1M12

Connection

Use 60 °C/75 °C copper lines only.

X plug

Manufacturer .................................................... Phoenix Contact

Type .........................................................DFMC 1.5/4-ST-3.5 BK

The connection conditions of the manufacturer apply.

Connection properties

rigid ......................................0.2…1.5 mm² (AWG 24…16)

flexible ..................................0.2…1.5 mm² (AWG 24…16)

with ferrule ............................................... 0.25…0.75 mm²

Mounting CTBC…

Screw type

CTBC35, CTBC60................................... DIN EN ISO 7045 - M5

CTBC120 .............................................. DIN EN ISO 7045 - M6

Washer type

CTBC35, CTBC60............................. DIN EN ISO 7089/7090 - 5

CTBC120 ........................................ DIN EN ISO 7089/7090 - 6

Tightening torque

CTBC35........................................................................ 0.6 Nm

CTBC60, CTBC120 .......................................................... 1 Nm

Other

Operating mode ........................................continuous operation

Mounting ................................................................ any position

Degree of protection, built-in components (DIN EN 60529)..IP40

Degree of protection, terminals (DIN EN 60529)...................IP20

Flammability class ....................................................... UL94 V-0

Software .............................................................................D591

Weight

CTUB103- CTBC35......................................................≤ 310 g

CTUB103- CTBC60......................................................≤ 530 g

CTUB103- CTBC120 ................................................ ≤ 1460 g

Odering information

CTUB103-Sets

ø CT Set Zulässiger Mess-

bereich Art.-No.

35 mm CTUB103-CTBC35 5 A, 10 A B78120030

60 mm CTUB103-CTBC60 5 A, 10 A, 25 A B78120031

120 mm CTUB103-CTBC120 5 A, 10 A, 25 A B78120032

Accessories

Power supplies

max. CTs Type Art. No.

4

STEP-PS/1 AC/24 DC/0.5

B94053110

14

STEP-PS/1 AC/24 DC/1.75

B94053111

34

STEP-PS/1 AC/24 DC/4.2

B94053112

Replacement parts

Measuring current transformer cores

ø Wandler

Typ

Art. No.

35 mm

CTBC35

B98120003

CTBC35P

B98120004

60 mm

CTBC60

B98120005

CTBC60P

B98120006

120 mm

CTBC120

B98120007

CTBC120P

B98120020

Electronic-Modules

U

sType Art. No.

DC 24V

CTUB103

B78120052

Required terminals are optionally available.

The variant B78120052 of the CTUB10x series meets

the requirements of DIN EN 45545-2.

LINETRAXX® CTUB103

CTUB103_D00410_02_M_XXEN / 09.2022 7

LINETRAXX® CTUB103

Alle Rechte vorbehalten.

Nachdruck und Vervielfältigung

nur mit Genehmigung des Herausgebers.

Bender GmbH & Co. KG

Postfach 1161 • 35301 Grünberg • Deutschland

Londorfer Str. 65 • 35305 Grünberg • Deutschland

Tel.: +49 6401 807-0 • Fax: +49 6401 807-259

All rights reserved.

Reprinting and duplicating

only with permission of the publisher.

Bender GmbH & Co. KG

PO Box 1161 • 35301 Grünberg • Germany

Londorfer Str. 65 • 35305 Grünberg • Germany

Tel.: +49 6401 807-0 • Fax: +49 6401 807-259

CTUB103_D00410_02_M_XXEN/09.2022/pdf/©BenderGmbH&Co.KG,Germany–Subjecttochange!Thespeciedstandardstakeintoaccounttheeditionvaliduntil09/2022unlessotherwiseindicated.

This manual suits for next models

4

Table of contents

Other Bender Transformer manuals

Popular Transformer manuals by other brands

Anslut

Anslut 008469 operating instructions

Fleischmann

Fleischmann 670601 Operating instruction

Audioplex

Audioplex LM-2 installation manual

Ormazabal

Ormazabal velatia transforma.earth General instructions

GE

GE KOTEF-72 instruction manual

LEGRAND

LEGRAND LE06499AE Instructions for installation, use and maintenance manual