Bender LINETRAXX CTUB100 Series User manual

Manual ENCTUB100-Serie_D00362_05_M_XXEN/11.2023

Intended use

The AC/DC sensitive measuring current transformers

(type B) of the CTUB100 series convert system leakage

and fault currents into an evaluable measurement

signal. The devices are suitable for detecting fault

currents with smooth DC components. They consist

of a CTBC… measuring current transformer core and

a CTUB10… electronic module, which can be combined

to suit the application. The measuring current trans-

formers can be used in DC, AC, and 3(N)AC systems.

The measurement signal is evaluated using devices

of the RCMA4…, RCMS4…, RCMB4… or MRCDB4…

series, respectively EDS440/441-LAB series, to which

the measuring current transformers are connected.

General safety instructions

Part of the device documentation in addition to this

manual is the enclosed “Important safety instructions

for Bender products”.

Installation, connection and commissioning are to

be carried out by electrically skilled persons only!

It is essential to follow the existing safety instructions.

I Danger! indicates a high risk of danger that will

result in death or serious injury if not avoided.

I Caution! indicates a low-level risk that can

result in minor or moderate injury or damage

to property if not avoided.

i

This symbol refers to information that is

designed to help you make the best use of

the product.

Device features

• Multicolour LED for operation, fault and status

messages

• Electronic module can be exchanged without

mechanical separation of the primary conductors

• Extension/retrofitting or modification of functio-

nalities possible in case of changed monitoring

requirements

• Insensitive to load currents due to full magnetic

shield, can be used for high short-term system-

related load currents (for CTBC…Ponly).

• Monitoring of the connection to the measuring

current transformer

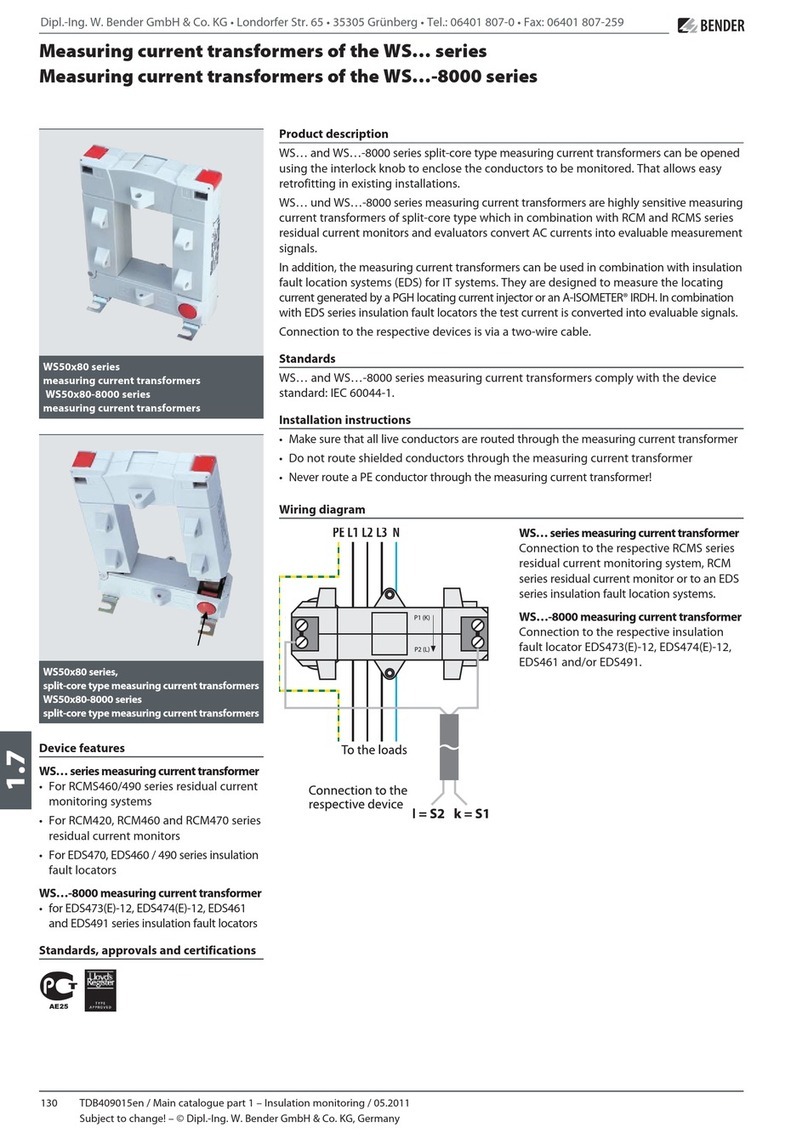

Overview: Possible combinations of evaluator,

electronic module and measuring current transformer core

Electronic modul Evaluator Meas. current transformer core Connecting cable Supply voltage

CTUB101

RCMA420 CTBC20(P)…60(P) CTX… (6 wires)

DC ±12V

The evaluator supplies the

measuring current transformer.

RCMA423 CTBC20(P)…210(P)

RCMS460/490* CTBC20(P)…210(P) CTX… (5/6 wires) DC ±12V

External power supply unit AN420

CTUB102 RCMS460/490 CTBC20(P)…210(P) CTXS… (4 wires) 24V

External power supply unit

CTUB104 EDS440/441-LAB CTBC20(P)…60(P)

* Only recommended for retrofit if an AN420 power supply unit is already

available. In this case, if the ready-made connecting cable CTX… is used, the

green plugs of the connecting cable (on the evaluator side) must be removed.

Afterwards, the individual conductors must be crimped and connected to the

RCMS460/490 or the AN420. In this case, the conductor“T”is not used

LINETRAXX® CTUB100 series

AC/DC sensitive measuring current transformers (type B)

2 CTUB100-Serie_D00362_05_M_XXEN/11.2023

LINETRAXX® CTUB100 series

d

b

f

c

a e

A

g

a

d

e

c

f

b

D

b

c

d

a

e

C

d

e

f

c

b

a

B

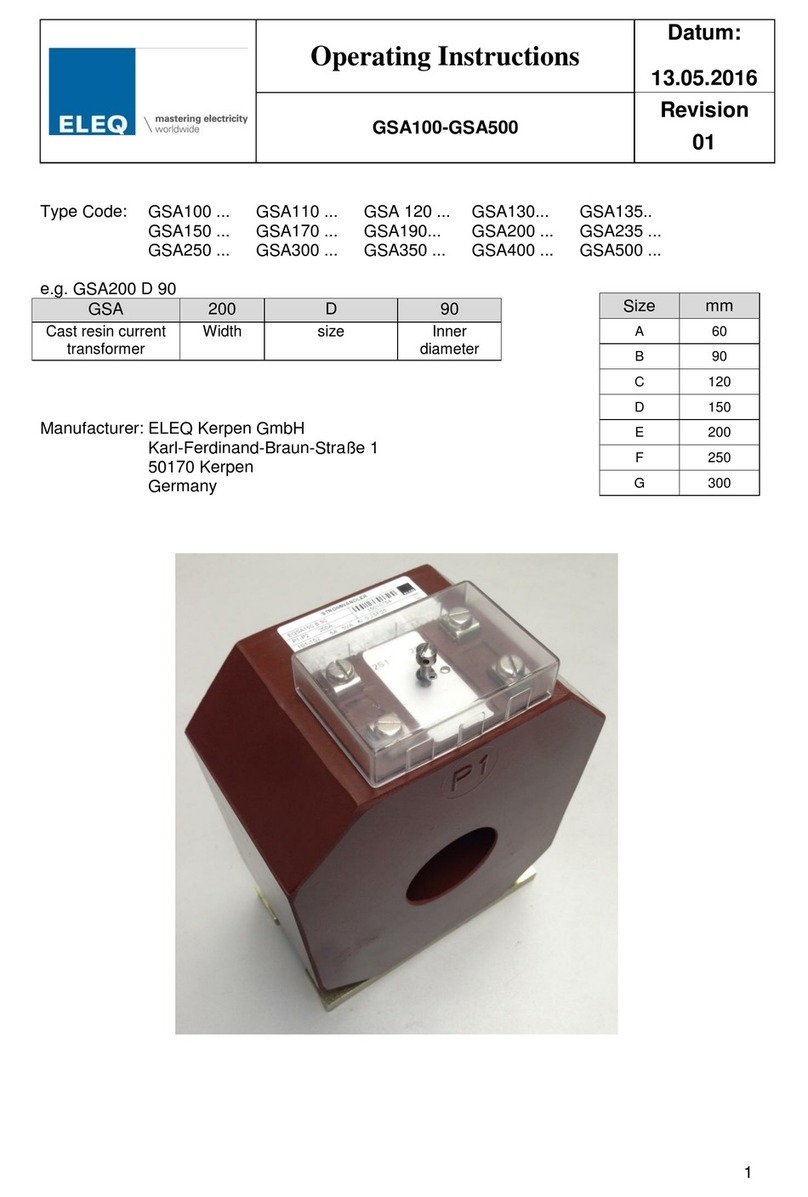

Dimensions (mm),

Tolerance: ±0.5 mm

Type a b c d e f g

ACTUB…-CTBC20(P) 75 83 37 ø 20 46 60,5 –

CTUB…-CTBC35(P) 97 130 47 ø 35 46 61 –

B CTUB…-CTBC60(P) 126 151 57 ø 60 56 78 –

CCTUB…-CTBC120(P) 188 225 96 ø 120 65 96 139

CTUB…-CTBC210(P) 302 339 153 ø 210 67 113 277

D CTUB…74 44 30 32 4.6 – –

Dimension diagrams

Mountings (mm)

a

b

c

CTBC20(P), CTBC35(P)

a

b

c

CTBC60(P)

a

b

c

CTBC120(P), CTBC210(P)

Typ a b c

CTBC20(P) 31.4 49 2 x ø 5.5

CTBC35(P) 49.8 49 2 x ø 5.5

CTBC60(P) 56 66 3 x ø 6.5

CTBC120(P) 103 81 4 x ø 6.5

CTBC210(P) 180 98 4 x ø 6.5

Assembly

Slide the electronic module onto the plug contacts of the measuring current transformer.

2

1

i

Avoid repeated plugging

and unplugging of the elec-

tronics (10 plugging cycles).

CTUB100-Serie_D00362_05_M_XXEN/11.2023 3

LINETRAXX® CTUB100 series

Device view

No. CTUB101 CTUB102 CTUB104 Note

1

Terminal

S1 (k) Connection measuring

current transformer core

2S2 (l)

3–Not in use

4–

5+12V 24V 24V

Supply voltage US

6GND

7-12V – –

8T – – Connection external test

9Test button T a) Offset calibration *

b) Internal functional test **

10 Combined LED Lights green normal operation

Flashes red device error ***

11

Potentio-

meter for

adjusting

the mea-

suring

range

– –

Response value RCM… Measuring range peak

I∆n ≤ 0.1 A 0…900 mA

0.1 A < I∆n ≤ 0.5 A 0…3.5 A

I∆n > 0.5 A 0…20 A

Select the measuring range according to the response value IΔn set on the RCM… evaluator.

If a larger measuring range is selected, the accuracy will decrease.

1

11

10 9

2 3 4

5678

* Test button T: Offset calibration

i

For measuring current transformer cores with

an internal diameter ≥ 120 mm, an offset

calibration should always be carried out be-

fore the first commissioning. Note that during

the offset calibration the system is switched off

and no current flows through the measuring

current transformer.

Offset calibration sequence

Action LED

1

Install the measuring current

transformer in the system,

assemble the electronic

module and the measuring

current transformer core, US

disconnected

off

2 Press and hold the“T”button off

Action LED

3a

Press and hold“T”, supply the

electronic module with supply

voltage US

lights red permanently

(not ready for operation)

3b flashes red slowly after

approx. 2 s (ready for calibration)

3c flashes red quickly after a total

of 5 s (calibration mode)

4 Start calibration: release“T”

when the LED flashes red quickly flashes red quickly

5 Calibration in progress flashes red quickly

6a Calibration successful, values

are accepted lights green permanently

6b

Calibration not successful.

Calibration value is not

accepted.The device is in an

error state. Either carry out

another offset measurement or

clear the error by switching the

device off and on again.

flashes red slowly

4 CTUB100-Serie_D00362_05_M_XXEN/11.2023

LINETRAXX® CTUB100 series

** Test button T:

Internal functional test

Press test button“T”for 5…10 s.

When the LED flashes green quickly, release the button.

Function test begins, varying measured values are

output.Their amplitude depends on the setting of the

detent potentiometer.

After completion of the function test, the LED lights

up green.

Possible cause of error Action

Connection between CTUB…

and CTBC… is not correct

Check connection or disconnect

CTUB… and CTBC… and reconnect

Error after offset calibration

(possibly system not switched

off and therefore DC residual

current too high)

Either carry out an offset calibration

again or clear the error by switching

the device off and on again. either

carry out an offset calibration again

or clear the error by switching the

device off and on again

Supply voltage US incorrect

(±12V or 24V)

Apply correct supply voltage Us

Possible cause of error Action

Detent potentiometer (11) is

not correctly engaged in one

position, but is between two

positions

Engage the detent potentiometer

correctly

Detent potentiometer is not

set correctly, evaluators display

error E.01 (CT error)

Set correct response value on

detent potentiometer

If the fault cannot be eliminated, contact Bender Service.

Wiring diagrams

I Danger of electrocution due to electric shock!

Touching live parts of the system carries the

risk of:

- An electric shock

- Damage to the electrical installation

- Destruction of the device

Before installing and connecting the device,

make sure that the installation has been

de-energised. Observe the rules for working on

electrical installations. Observe the information

on rated voltage and supply voltage specified

in the technical data!

i

Application in railway vehicles/

DIN EN 45545-2:2016!

If the horizontal or vertical distance to adjacent

components which do notmeet the require-

ments in table 2 of DIN EN 45545-2 is less than

20 mm orless than 200 mm respectively, they

are to be regarded as grouped. Refer to DIN EN

45545-2 chapter 4.3 Grouping rules.

i

The wires can be routed in any direction.

Connect the device according to the wiring diagram.

Please observe the technical data.

*** Device error

i

In the event of a device error, a high DC residual

current (in the level of the respective measu-

ring range end value) is additionally output so

that the error is visible at the evaluator.

5…10 s

t

2 s

5 s

varying measured value output

test endsrelease T

test begins

button Tpressed

press T

test

LED

CTUB100-Serie_D00362_05_M_XXEN/11.2023 5

LINETRAXX® CTUB100 series

Wiring diagram

CTX-…

CTBCx

CTUB101

+12V -12V TGND

S1(k)S2(l)

1 m

2,5 m

5 m

10 m

50 mm

250 mm

to the loads

CTXS-…

CTBCx

CTUB102

CTUB104

24V GNDk l

1 m

2,5 m

5 m

10 m

50 mm

250 mm

24V GND

S1(k)S2(l)

to the loads

RCMS460/490

(with CTUB102)

EDS440/441-LAB

(with CTUB104)

Ext. power supply

+

SPD

The use of a type 2 surge protection device (SPD) is mandatory due

to possible impulse voltages and in order to comply with normative

requirements.The surge protection device must be connected upstream

of the power supply unit on the supply side (not required for CTUB104).

Features of the surge protection device:

- Nominal discharge current In(8/20 μs): 20 kA

- Response time: 25 ns

- two-stage: 1 varistor + 1 spark gab

Alternatively, the power supply unit must be connected to a CAT II supply

without a surge protection device.

I Caution!

When using several CTUB100 measuring current

transformers, the power supply (24V, GND)

must not be daisy-chained from current trans-

former to current transformer but should be

star-shaped (e.g. using a potential distributor).

6 CTUB100-Serie_D00362_05_M_XXEN/11.2023

LINETRAXX® CTUB100 series

The cables must be aligned with the centre of the measuring

current transformer.

Installation instructions measuring current transformer

Technical data

Insulation coordination acc. to IEC 60664-1/IEC 60664-3

Definitions

Measuring circuit (IC1) .......................................................................

..............primary conductors routed through the current transformer

Secondary (IC2) ...................................... connections terminal block

Rated voltage.............................................................................800 V

Overvoltage category...................................................................... III

Area of application .................................................. ≤ 2000 m AMSL

Rated impulse voltage (IC1/IC2) ..................................................8 kV

Rated insulation voltage (reinforced insulation; IC1/IC2)

.................................................................................................. 800 V

Pollution degree ...............................................................................2

Supply voltage

CTUB101

Description ........................................................+12 V, GND, -12 V

Supply voltage Us............................................................DC ±12 V

Operating range of Us............................................................±2 %

Ripple Us...............................................................................≤ 1 %

Power consumption...........................................................≤ 2.5 W

CTUB102 and CTUB104

Description .....................................................................24 V, GND

Supply voltage Us.............................................................. DC 24 V

Operating range of Us..........................................................±20 %

Ripple Us...............................................................................≤ 1 %

Power consumption...........................................................≤ 2.5 W

Inrush current..............................................................1 A for 1 ms

Measuring circuit

Internal diameter measuring current transformer..............................

.................................................................... see dimension diagrams

Rated current I...........................RCM application / MRCD application

CTBC20 at IΔn ≥ 30 mA..................................................63 A / 40 A

CTBC20 at IΔn ≥ 300 mA................................................80 A / 63 A

CTBC20P ........................................................................80 A / 80 A

I Caution! Existing protective conductors and

low-resistance conductor loops must not be

routed through the measuring current trans-

former! Otherwise, high currents could be in-

duced into the conductor loop due to the AC/DC

sensitive measuring technology used.

I Caution! The connecting cable (supply, secondary

connection etc.) must not be routed directly past

the current transformer core, otherwise inter-

ference pulses may occur.

I Caution! The measuring current transformer

must be connected to the corresponding eval-

uator before the first use and before commis-

sioning of the monitored installation.

i

Do not route any shielded cables through the

measuring current transformer.

Pay attention to the following:

All current-carrying cables must be routed through the measuring

current transformer.

PE

L1

L2

L3

N

P1 (K): YE P2 (L): GY

Never route an existing protective conductor through the

measuring current transformer.

The primary conductors may only be bent from the specified

minimum distance. The minimum bending radius specified by the

manufacturers for the conductors used must be observed.

* Distance to 90° angle = 2 x outer diameter.

*

*

CTUB100-Serie_D00362_05_M_XXEN/11.2023 7

LINETRAXX® CTUB100 series

CTBC35 at IΔn ≥ 30 mA................................................125 A / 80 A

CTBC35 at IΔn ≥ 300 mA............................................160 A / 125 A

CTBC35P ....................................................................160 A / 160 A

CTBC60 at IΔn ≥ 30 mA..............................................200 A / 160 A

CTBC60 at IΔn ≥ 300 mA............................................400 A / 250 A

CTBC60P ....................................................................400 A / 320 A

CTBC120 at IΔn ≥ 100 mA..........................................400 A / 330 A

CTBC120P at IΔn ≥ 100 mA........................................630 A / 630 A

CTBC210 at IΔn ≥ 300 mA..........................................630 A / 630 A

CTBC210P at IΔn ≥ 100 mA........................................630 A / 630 A

CTBC210P at IΔn ≥ 300 mA....................................1000 A / 1000 A

Measurement accuracy................................. ±1 % of full scale value

Test winding................................................................................. yes

Rated continuous thermal current 1) Icth.....................................125 A

at UL applications ............................................................30 A

Rated short-time thermal current 1) Ith................................2.4 kA/1 s

Rated dynamic current 1) Idyn.............................................6 kA/40 ms

1) refers to the residual current

Possible response values (set on the evaluator)

CTBC20, CTBC20P.................................................... 10 mA…500 mA

CTBC35, CTBC35P, CTBC60, CTBC60P............................ 30 mA…10 A

CTBC120, CTBC120P, CTBC210P ................................. 100 mA…10 A

CTBC210..................................................................... 300 mA…10 A

Measuring ranges CTUB101, CTUB102

Measuring range 1 (I∆n ≤ 0.1 A) .......................... 0…900 mA (peak)

Measuring range 2 (0.1 A < I∆n ≤ 0.5 A).................. 0…3.5 A (peak)

Measuring range 3 (I∆n > 0.5 A) ............................... 0…20 A (peak)

Measuring range CTUB104

Measuring range.......................................................... DC 0…70 mA

Indication

Multicolour LED ........................................................... see pages 3/4

Output

Name .............................................................................. S1 (k), S2 (l)

Scaling.............................................................................400 mV/1 A

Max. voltage.............................................................................±10 V

Max. connector length................................................................10 m

Output resistance..................................................................... 172 Ω

Input

Name ................................................................ T (for CTUB101 only)

Current load .......................................................................< 300 mA

Environment/EMC

EMC (CTUB101, CTUB102)............................................... IEC 62020-1

EMC (CTUB104)............................................................ IEC 61326-2-4

Operating temperature ...................................................-25…70 °C

Classification of climatic conditions acc. to IEC 60721

Stationary use (IEC 60721-3-3) ..................................................3K22

Transport (IEC 60721-3-2) ..........................................................2K11

Long-term storage (IEC 60721-3-1) ...........................................1K22

Classification of mechanical conditions acc. to IEC 60721

Stationary use (IEC 60721-3-3)..................................................3M11

Transport (IEC 60721-3-2) .......................................................... 2M4

Long-term storage (IEC 60721-3-1) ......................................... 1M12

Connection

Max. connection length..............................................................10 m

Connecting cables are optionally available.

Use 60/75 °C copper lines only.

Terminal block

Manufacturer ...........................................................Phoenix Contact

Type ................................................................DFMC 1.5/4-ST-3.5 BK

The connection conditions of the manufacturer apply.

Connection properties

rigid ..............................................0.2…1.5 mm² (AWG 24…16)

flexible ................................................................... 0.2…1.5 mm²

with ferrule ....................................................... 0.25…0.75 mm²

Mounting CTBC…

Screw type

CTBC20…60(P)........................................... DIN EN ISO 7045 - M5

CTBC120…210(P) .......................................DIN EN ISO 7045 - M6

Washer type

CTBC20…60(P)..................................... DIN EN ISO 7089/7090 - 5

CTBC120…210(P) ................................ DIN EN ISO 7089/7090 - 6

Tightening torque

CTBC20…35 (P)................................................................. 0.6 Nm

CTBC60…210(P) .................................................................. 1 Nm

Other

Operating mode ...............................................continuous operation

Mounting ....................................................................... any position

Degree of protection, built-in components (DIN EN 60529).........IP40

Degree of protection, terminals (DIN EN 60529)..........................IP20

Flammability class .............................................................. UL94 V-0

Software ....................................................................................D591

Weight

CTUB10x-CTBC20 ..............................................................≤ 230 g

CTUB10x-CTBC20P.............................................................≤ 290 g

CTUB10x-CTBC35...............................................................≤ 310 g

CTUB10x-CTBC35P.............................................................≤ 390 g

CTUB10x-CTBC60...............................................................≤ 530 g

CTUB10x-CTBC60P.............................................................≤ 690 g

CTUB10x-CTBC120 ......................................................... ≤ 1460 g

CTUB10x-CTBC120P........................................................ ≤ 1820 g

CTUB10x-CTBC210.......................................................... ≤ 4290 g

CTUB10x-CTBC210P........................................................ ≤ 4940 g

The use of the power supply units listed at “Accessories” is

recommended. The use of a surge protection device is mandatory

for these power supply units (not required for CTUB104).

Bender GmbH & Co. KG

Londorfer Straße 65

35305 Grünberg

Germany

Tel.: +49 6401 807-0

info@bender.de

www.bender.de

© Bender GmbH & Co. KG, Germany

Subject to change! The specified

standards take into account the edition

valid until 11/2023 unless otherwise

indicated.

Alle Rechte vorbehalten.

Nachdruck und Vervielfältigung nur mit

Genehmigung des Herausgebers.

All rights reserved.

Reprinting and duplicating only with

permission of the publisher.

LINETRAXX® CTUB100 series

Ordering details

USø CT´s Shielding Type Art. No.

Consistent with RCMA420 / RCMA423

DC

±12V

20 mm CTUB101-CTBC20 B78120010

CTUB101-CTBC20P B78120020

35 mm CTUB101-CTBC35 B78120012

CTUB101-CTBC35P B78120022

60 mm CTUB101-CTBC60 B78120014

CTUB101-CTBC60P B78120024

120 mm CTUB101-CTBC120 B78120016

CTUB101-CTBC120P B78120026

210 mm CTUB101-CTBC210 B78120018

CTUB101-CTBC210P B78120028

Consistent with RCMS460 / RCMS490

DC

24V

20 mm CTUB102-CTBC20 B78120011

CTUB102-CTBC20P B78120021

35 mm CTUB102-CTBC35 B78120013

CTUB102-CTBC35P B78120023

60 mm CTUB102-CTBC60 B78120015

CTUB102-CTBC60P B78120025

120 mm CTUB102-CTBC120 B78120017

CTUB102-CTBC120P B78120027

210 mm CTUB102-CTBC210 B78120019

CTUB102-CTBC210P B78120029

Consistent with EDS440 / EDS441

DC

24V

20 mm CTUB104-CTBC20P B78120033

35 mm CTUB104-CTBC35P B78120034

60 mm CTUB104-CTBC60P B78120035

Accessories

Voltage supply DC 24 V for CTUB102 and CTUB104

max. connected CT´s Type Art. No.

4 STEP-PS/1 AC/24 DC/0.5 B94053110

14 STEP-PS/1 AC/24 DC/1.75 B94053111

34 STEP-PS/1 AC/24 DC/4.2 B94053112

Connecting cables

Length (m) Connection to Name Art. No.

1

RCMA42x

CTX-100 B98110080

2.5 CTX-250 B98110081

5 CTX-500 B98110082

10 CTX-1000 B98110083

1

RCMS46x

EDS44x

CTXS-100 B98110090

2.5 CTXS-250 B98110091

5 CTXS-500 B98110092

10 CTXS-1000 B98110093

Replacement parts

Measuring current transformer cores

ø CT´s Type Art. No.

20 mm CTBC20 B98120001

CTBC20P B98120002

35 mm CTBC35 B98120003

CTBC35P B98120004

60 mm CTBC60 B98120005

CTBC60P B98120006

120 mm CTBC120 B98120007

CTBC120P B98120020

210 mm CTBC210 B98120008

CTBC210P B98120021

Electronic modules

UsType Art. No.

DC ±12V CTUB101 B78120050

DC 24V CTUB102 B78120051

DC 24V CTUB104 B78120053

Required terminals or connecting cables are optionally available.

Standards

The measuring current transformers of the CTUB10x

series comply with the requirements of the standard

DIN EN 45545-2.

This manual suits for next models

3

Table of contents

Other Bender Transformer manuals

Popular Transformer manuals by other brands

CHOWEL

CHOWEL PATC--150A-EU instruction manual

Honeywell

Honeywell Krom Schroeder TZI operating instructions

F&F

F&F TR-24 quick start guide

MuxLab

MuxLab Quad Audio Balun Quick installation guide

Camille Bauer

Camille Bauer SIRAX CT6 Series operating manual

Monacor

Monacor IMG STAGELINE LTR-102 operating instructions

Larson Electronics

Larson Electronics DCP-25-3XDP-6FT instruction manual

Atexor

Atexor SLAM TrafoEx 400 Instructions for safe use

Pro-Ject Audio Systems

Pro-Ject Audio Systems MC Step Up Box S3 Instructions for use

Smart power

Smart power LC Plus user guide

HAMPTON BAY

HAMPTON BAY SL-60-12-SV Use and care guide

Ascon Pool

Ascon Pool TURMION PRO TXF1 manual