MGM 600V CLASS DRY Owner's manual

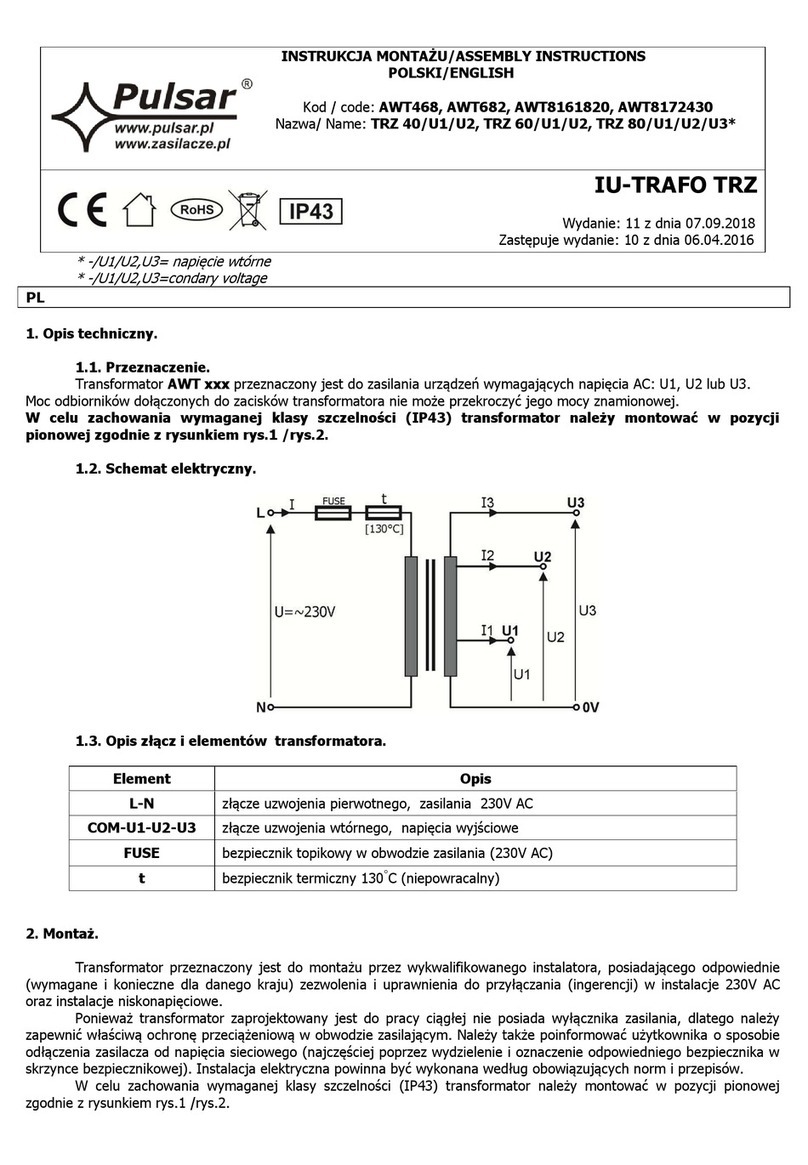

MGM TRANSFORMER COMPANY

5701 SMITHWAY STREET • CITY OF COMMERCE, CALIF. 90040

(323) 726-0888 • FAX (323) 726-8224

www.mgmtransformer.com

600V CLASS DRY - TYPE

DISTRIBUTION TRANSFORMER

INSTALLATION, OPERATION, AND

MAINTENANCE MANUAL

MGM 100-10

MGM TRANSFORMER COMPANY

5701 SMITHWAY STREET • CITY OF COMMERCE, CALIF. 90040

(323) 726-0888 • FAX (323) 726-8224

www.mgmtransformer.com

Installation, Operation

And Maintenance Manual

For Dry Type Transformers

UP TO 600 VOLTS

ALUMINUM OR COPPER

80° C, 115° C or 150° C RISE

WARNING

Electrical potentials hazardous to human life can exist within this equipment when it is

energized. Disconnect all input power before opening the case or touching the internal

parts

The information contained herein may not cover all variations in equipment supplied or

provide for all contingencies that might arise during the installation, operation or

maintenance for this equipment. If there is any question regarding the above items,

contact your supplier.

IT IS EXPECTED THAT ANY INSTALLATION OR MAINTENANCE WILL BE PERFORMED

BY QUALIFIED PERSONNEL ACCORDING TO LOCAL, STATE, AND NATIONAL CODES.

MGM 100-10

FOR ADDITIONAL INFORMATION OR ASSISTANCE VISIT MGM TRANSFORMER COMPANY ONLINE AT

HTTP://WWW.MGMTRANSFORMER.COM

General

Read the entire manual before attempting to perform

installation of this transformer. Dry type transformers are

suitable for indoor or outdoor use depending upon the

construction of the enclosure as well as the ability to

protect the transformer from unwarranted access to live

parts. They are cooled by the free circulation of air

through the enclosures, the average ambient

temperature over 24 hours should not exceed 30° C

(86°F), the maximum ambient temperature should not

exceed 40° C (104°F) or as otherwise specified in the

specification. Overheating may occur if the air flow is

restricted, the transformer is overloaded, it is supplied

with over or under voltage, or operated at other than

rated frequency.

Inspection upon Receipt

Units are shipped in upright position and should arrive

that way. Upon arrival, all units should be inspected for

damage during shipment. Unpack and examine for

broken or loose parts. Careful inspection should be

made of transformer coils, wiring and insulators. What

appears to be minor damage in these areas may result

in an open or short circuit. Claims for damage should be

filed with the transportation company and an MGM

Transformer Company representative must be notified

immediately. For superficial or minor case part damage,

spare parts may be available, contact an MGM

Transformer Company representative.

Handling

All transformers must be kept in the upright position in

which they are shipped. Lifting cables or chains should

be used with spreader bars to avoid damage to the finish

or parts. When there are no external lifting provisions,

the top cover should be removed and cables or chains

secured to the top core-clamping channels or angles

where holes are provided for this purpose.

Lifting with hand trucks or fork lift trucks is permissible if the

blades or forks are long enough to pass completely under

the case. Since most general purpose transformers have

a high center of gravity, extreme caution should be

exercised when lifting or moving the units.

If it is necessary to move ventilated dry-type transformers

during inclement weather then they should be thoroughly

protected against the entrance of moisture.

Storage

Storage areas should be as clean and dry as possible

without extreme temperature variations. Protective

wrappings should be left intact until the transformer is

moved to its permanent location. Dry type transformers

stored under extremely wet or dusty conditions must

have cleaning and drying operations performed before

the unit can be energized. (See Maintenance Section.)

Installation Location

Factors to be kept in mind when choosing a location

for dry type transformers are: accessibility, ventilation,

environmental conditions, and noise (see ‘Reducing

Sound Levels’). Installation should be made in an area

reasonably free from dust, excessive moisture,

fertilizers, chemicals and other corrosive fumes or

vapors and separated from flammable materials in

accordance with the N.E.C.

General purpose dry type transformers are supplied in

enclosures rated for indoor installation. Weathershield

kits are available to convert these enclosures for UL

listed outdoor Nema 3R use. The appropriate kit can be

obtained from an MGM Transformer representative. For

units up to 75 kVA, wall mount brackets are also readily

available. Even with a properly attached weathershield

kit, no transformer should be hosed off, or placed in the

catchment area of a water sprinkler.

In all locations dry type transformers must be installed

in the upright position in an area with free air

circulation. Unless otherwise specified in the N.E.C or

applicable local codes, a minimum distance of six

inches from adjacent structures should be maintained.

Fencing in the transformer to prevent unauthorized

access is strongly recommended.

Room Requirements

Dry-type transformers located indoors should comply

with the application requirements of N.E.C.

The room in which dry-type transformers are located

should be sized to permit locating transformers with

sufficient spacing between units and sufficient

clearances to walls and other obstructions (minimum of

six inches or as specified below nameplate) to permit air

circulation. Sufficient space should also be provided to

permit routine inspection and maintenance.

Adequate ventilation is essential for the proper cooling

of transformers. Clean, dry air is desirable. Filtered air at

or above atmospheric pressure may reduce

maintenance if dust or other contaminants present a

particular problem. When transformers are located in

rooms or other restricted spaces, sufficient ventilation

should be provided to hold the air temperature within

established limits when measured near the transformer

inlets. This will usually require approximately 100 ft3/min

of air per kilowatt of transformer loss. The area of

ventilating opening required depends upon the height of

the room, the location of openings, and the maximum

loads to be carried by the transformer. Room ventilation

should not impede normal circulation of air through the

transformer.

When possible, the air inlet to the room should be near the

floor with the outlet in the opposite upper end of the room.

The exhausting air should not exceed 15°C over the inlet

air temperature. When necessary, forced air exhaust

should be used to maintain this maximum differential.

MGM 100-10

FOR ADDITIONAL INFORMATION OR ASSISTANCE VISIT MGM TRANSFORMER COMPANY ONLINE AT

HTTP://WWW.MGMTRANSFORMER.COM

Connections

Cautions: Make only those connections shown on the

nameplate or connection diagram. Before energizing,

check all tap jumpers for proper locations, and all bolted

connections for tightness. All three sets of taps on a

three phase transformer must be connected in the same

location for each phase. For instructions on how to read

nameplates and connection diagrams, please visit the

documentation section of our website at

http://www.mgmtransformer.com .

All transformers, with bottom connections are designed for

easy accommodation of cable sizes in accordance with

NEC. Cables which will carry less than 100 amperes may

have a 60° C temperature rating or higher, and cables

which will carry 100 amperes or more must have a 75° C

temperature rating or higher. All cables should be in the

lower part of the transformer enclosure in accordance with

markings on the enclosure.

Use 90° C cable sized to 75° C ampacity for the units

having terminals located above the coils. After the first

thirty days of service, re-tighten all connecting lugs and

bolts. Depending on the kVA rating, the transformer may

have flexible leads with bolted type wire terminals,

copper/aluminum (CU/AL) lug connectors, or simply termi-

nation pads for mounting your own crimp or lug type

terminations. The table below shows required torque for

installing bolted wire connectors and cables in lug type

connectors.

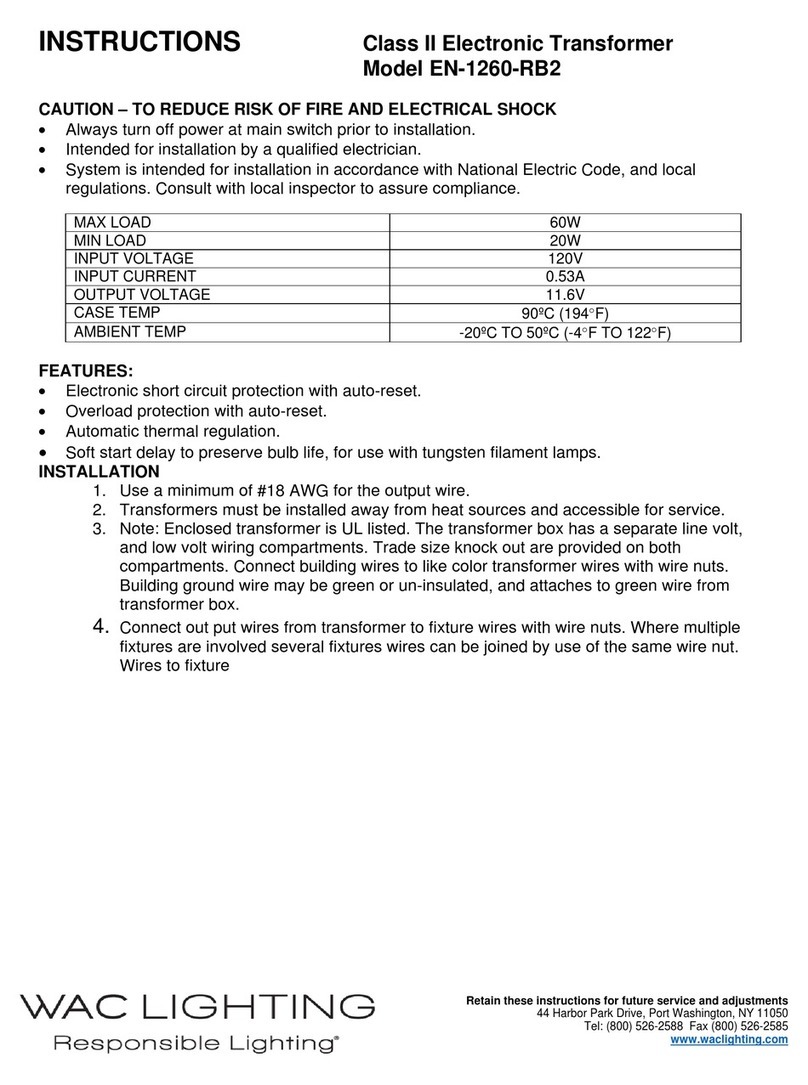

Bolted Wire Connections Lug Type Connectors

Bolt Size Torque

Foot Pounds

Wire Size (AWG) Torque

Inch Pounds

1/4 – 20

5/16 – 18

3/8 – 16

1/2 – 13

5/8 – 11

3/4 – 10

10

15

20

40

55

80

#14 to #8

#6 to #4

#3 to #1

1/0 to 2/0

3/0 to 200 MCM

250 to 400 MCM

500 to 750 MCM

70

100

120

150

210

250

300

NOTE: Tighten, wait several seconds, then re-tighten all

connecting lugs and bolts.

Always use two wrenches when tightening or

loosening bolted connections to prevent damage.

Minimum electrical clearances in the installation of lugs

and cables must be per ANSI and NEMA Standards. All

electrical clearances that are questionable must be

insulated for the applied voltage. Particular care should

be taken with shielded cables, so that the ground termi-

nation of the cables has sufficient clearance from all the

manufacturers installed live parts, including parts that

appear to be insulated.

Grounding

It is the responsibility of the installer to ground the

transformer enclosure assembly to the ground system in

accordance with the latest revision of the NEC Section

450-10, NEC Article 250 and ANSI/IEEE Std. 144.

Reducing Sound Levels

Transformer noise originates within the steel core. It is

an inherent characteristic of all transformers and cannot

be completely eliminated. Therefore, care should be

exercised in the selection of the transformer location,

particularly in buildings where the ambient sound level is

quite low. A transformer's sound level is quite often

unintentionally amplified by improper installation, which

makes the transformer appear to be considerably louder

than it actually is. Transformer sound levels are

amplified by sound waves in the air being reflected from

surrounding objects and resonance of mounting

construction and electrical connections. This situation

should be avoided wherever possible. Transformer

sound level problems can also be further minimized by

following these installation suggestions:

1. The core and coil assembly is isolated from the case

with vibration mounts, which are tightened to

prevent damage during shipment. Loosen the bolts

which secure the core and coil to the case by one

turn to reduce the pressure on the vibration pads.

Make sure to re-tighten these bolts before moving

the transformer to another location. If the

transformer is located in a Seismic Zone 4 location it

is best to keep the bolt tightened.

2. The case may be installed on vibration mounts for

additional reduction of sound levels.

3. Flexible conduit couplings should be used to reduce

vibration transfer from the case to the incoming and

outgoing conduit.

4. The installation should be in an area where the

sound will be least objectionable.

5. Avoid stairway and hall areas or reflecting objects

which resonate or echo. Concrete or masonry walls,

floors and ceilings are excellent sounding boards. If

these and other reflecting surfaces cannot be

avoided, acoustic absorbing materials should be

used to cover them.

6. Mounting the transformer on walls, balconies or

floors which have relatively light mass should also

be avoided. The possibility of amplifying the sound

waves in the structure will be greatly reduced if the

weight of the mounting surface corresponding to the

projected area of the transformer is equal to, or

greater than the weight of the transformer. Surfaces

which may distort or strain the transformer case

should be leveled or squared before installation.

7. Shrubbery can be planted near the unit on outdoor

installations to break up the sound pattern. Make

sure all sprinklers are aimed away from the

transformer.

MGM 100-10

FOR ADDITIONAL INFORMATION OR ASSISTANCE VISIT MGM TRANSFORMER COMPANY ONLINE AT

HTTP://WWW.MGMTRANSFORMER.COM

Prior To Energizing

After the installation is completed, remove any debris

from the bottom of the cable compartment and from

under the transformer. After the transformer has been

installed, but before it is energized, all shipping braces

should be removed. Tighten securely all external bolts to

eliminate any vibrations. Check tap jumpers for proper

location, and all bolted connections for tightness. (use

two wrenches)

Parallel Connecting

The transformer may be connected in parallel with other

transformers if the phase angle shift is the same; phase

rotation is the same; transformers’ turns ratios and

voltages are within a 0.5% range; and the percent of

impedance on the same kVA base is within a ± 7.5%

range.

Maintenance

Although dry type transformers require less maintenance

than liquid filled transformers and other electrical

devices, periodic cleaning and inspection on the average

of at least once a year should be performed except

under extraordinary conditions, in which case the

inspections should be made more often.

The unit must be de-energized before checking for loose

connections or parts, accumulations of dirt on insulating

surfaces, and dust which tends to restrict air flow. The

windings may be cleaned with a vacuum cleaner, a

blower, or with compressed air. The use of a vacuum

cleaner is preferred as the first step in cleaning followed

by the use of compressed air or nitrogen. The

compressed air or nitrogen should be clean and dry and

should be applied at not more than 25 psi. Lead

supports, taps, terminal boards, bushings and other

major insulation surfaces should be brushed or wiped

with a dry cloth. The use of liquid cleaners is undesirable

because some of them have a deteriorating effect on

most insulating materials.

As long as the transformer is energized, humidity

conditions are unimportant. In the event that a dry type

transformer is de-energized and allowed to cool to

ambient, consideration must be given to the possible

effects of humidity. If moisture is noted, it should be

removed by drying with heated air from a blower, with

the maximum temperature of 110°C or 230°F. The heat

must be distributed in the enclosure. Incandescent

lamps or heaters may also be used if the same

temperature limitations are observed.

Lighting Tap Applications

Most transformers with 240V delta secondaries have a

120V single-phase lighting tap. The maximum single-phase

120V load can not exceed 10% of the three-phase kVA

rating. The load must also be balanced at 5% maximum

between X1 and X4 and 5% between X2 and X4. The

three-phase kVA rating will be reduced by 15% when

lighting tap is used to maximum capacity.

Dielectric Insulation

Transformer insulation system is designed to protect the

integrity of the transformer to the BIL rating on the

nameplate. If exposed to lightning, switching surges or

severe transients, additional protection such as surge

arrestors, surge capacitors or a higher BIL rating should

be provided.

Ambient Temperature

Limiting ambient temperatures for normal service

conditions are specified in ANSI Standards for

Transformers. Transformers depend entirely on the

surrounding air for adequate ventilation. The ambient

should not exceed 40° C (104° F) and the average

temperature of the air for any 24 hour period should not

exceed 30°C (86° F). For operation at higher ambient

temperatures, transformer loading should be reduced

0.6% of rated kVA for each degree above 30° C average

ambient to a maximum of 50° C. The use of transformers

in cooling air above 50° C is not covered by this guide,

and the manufacturer should be consulted before such

installations are made.

Altitude

Transformers are normally designed for operation at

altitudes up to 1000 meters (3300 feet). To operate a

transformer above 1000 meters, it is necessary to

reduce the kVA load and to increase the electrical

insulation clearances between energized terminals.

Refer to NEMA ST20-1986 for detailed guidelines.

References

All transformers are manufactured per NEMA and

ANSI/IEEE standards. Where the UL Label is affixed,

the transformer conforms to UL requirements.

Further information may be found in ANSI/IEEE

Standard C57.94. Recommended Practice For

Installation, Application, Operation And Maintenance Of

Dry Type General Purpose Distribution And Power

Transformers.

When you need Service

If you need service on products manufactured by MGM

Transformer we are ready to serve you. Contact the

nearest Sales Office for more information.

Terms and Conditions

Please refer to your copy of the “Terms and Conditions” for

warranty and product liability information. The “Terms and

Conditions” arrived along with your order acknowledgment,

are printed on the reverse page, and are available online at

www.MGMTransformer.com.

MGM TRANSFORMER COMPANY

5701 SMITHWAY STREET • CITY OF COMMERCE, CALIF. 90040

(323) 726-0888 • FAX (323) 726-8224

www.mgm-transformer.com

APPLICABLE LAW: MGM Transformer is a

California corporation doing business in California

and as such requires that any litigation brought

against the company have exclusive venue in

California. Applicable law may be either the laws

of the state of California, or the U.C.C. This

requirement of California jurisdiction is mandatory

despite the fact that MGM ships products

nationwide.

STANDARD CONDITIONS OF SALE: The

information contained herein covers the terms and

conditions under which MGM Transformer

Company products are sold. Any modifications of

these terms and conditions, unless agreed to in

writing, will not be recognized.

CHANGES: Prices, conditions and terms of sale

are subject to change without notice.

TERMS: Terms are 1% ten days, net thirty (30)

days from date of invoice. The Company may at

any time require full or partial payment in advance.

If the purchaser delays shipments, payment shall

become due from the date when the Company is

prepared to make shipment. Apparatus held for the

purchaser shall be at the risk and expense of the

purchaser.

QUOTATIONS: Quotations, written or verbal, are

subject to the conditions of sale listed herein.

Written quotations automatically expire thirty (30)

calendar days from the date issued and are subject

to withdrawal by notice within that period. Verbal

quotations automatically expire twenty-four (24)

hours from the time issued.

ACCEPTANCE OF ORDERS: All orders shall be

written and are subject to acceptance at the factory.

EQUIPMENT DESTINED FOR FEDERAL,

STATE, OR LOCAL GOVERNMENT: MGM is

not bound to honor quotations for equipment

destined for Federal, State, or Local Government

unless MGM knows at the time of quoting that it is

a government job as these orders frequently involve

higher administration costs.

TAXES: Prices do not include sales, use, excise, or

other taxes. If any products or materials delivered

hereunder are determined to be taxable under any

sales, use, excise, or other taxes applicable to the

sale or delivery of personal property, Purchaser

shall be liable for and pay the same without

recourse against Seller, or in lieu thereof furnish

Seller with a tax-exemption certificate acceptable to

taxing authorities.

ERRORS: All stenographic and clerical errors are

subject to correction.

DELIVERY: MGM can arrange for apparatus to be

sold F.O.B, point of shipment; or freight prepaid.

UNLOADING AND DEMURRAGE: Unless

stated otherwise in our quote, it is the customer’s

responsibility to unload all shipments whether by

rail or truck. All demurrage charges are customer

responsibility.

MGM recognizes that sometimes the size or weight

of shipments requires the customer to make prior

unloading arrangements. In such cases the

customer shall advise MGM prior to shipment the

hours during which shipments cam be received and

the notice required before delivery. MGM will then

reflect these arrangements on the bill of lading.

Origin method of shipment and routing: The

company will determine the point of origin, method

of transportation, and the routing of shipment.

Purchasers requiring other routings will be billed

any excess in transportation charges.

PENALTY CLAUSES: The Company will not

pay or be liable for any penalty, either liquidated

or otherwise, for late delivery or installation.

Shipping dates are estimated and are dependent

upon prompt receipt of all information and material

necessary. The Company shall also not be liable for

any unforeseen delay, i.e. acts of God or inability to

obtain necessary labor, materials, or manufacturing

facilities due to such causes.

CANCELLATION: Buyer shall not have the

right to cancel purchase orders because of

reasonable delays in deliveries. Any order or

contract if cancelled requires payment based on the

followingtable:

Purchase Order Released……..20%

Engineering Complete………..50%

Purchasing Complete………..100%

Changes: The customer has the right to change

their order, in writing, if agreed upon by seller.

Should such changes alter the amount due or time

required for production, an equitable adjustment of

price and/or time shall be made. Changes affecting

function or performance of item ordered may not be

made without prior written consent from MGM.

Warranty: MGM transformers are guaranteed to

be of the highest quality. They are further

guaranteed, when used for the purpose intended and

operated under normal conditions to give

continuous and efficient service. MGM Transformer

Company agrees to correct any defect in

workmanship or material, which may develop under

proper or normal use during the period of one year

from date of shipment. Should a transformer fail

within the warranty period, MGM will issue

authorization to return the failed transformer to one

of MGM’s plants, freight prepaid. At MGM’s

option the failed transformer will be repaired,

replaced or credit will be issued depending on the

nature of the failure. A repaired transformer or

replacement will be delivered to the purchaser

F.O.B. point of shipment with freight prepaid.

Repair, replacement or issuance of credit with

regards to the defective transformer will constitute

fulfillment of all MGM’s liabilities in respect to

said transformer. This guarantee does not include

incidental expenses, such as expense of removing

and replacing the transformers from service. This

warranty is exclusive and in lieu of all other

warranties of quality whether written, oral or

implied (including any warranty of merchantability

or fitness for purpose.)

LIMITATION OF LIABILITY: MGM shall not

be liable in contract or in tort for special, indirect,

incidental, or consequential damages, such as but

not limited to, loss of profits or revenue, loss of use

of power system, cost of capital, cost of purchased

or replacement power, or claim of customers of

purchaser for service interruptions set forth herein

are exclusive, and the liability of MGM with respect

to any contract, or anything done in connection

therewith such as the performance of breach

thereof, or from the manufacture, sale, delivery, re-

sale, installation, repair or use of any equipment

covered by of furnished under this contract whether

in contract, in tort, or otherwise, shall not exceed

the price of the equipment or part on which such

liability is based.

RETURNING APPARATUS:

A. In no case are goods to be returned without

first obtaining the Company’s written

permission.

B. Any material returned and not authorized will

not be signed for and will be returned back

deadhead to the sender.

C. Material accepted for credit is subject to a

MINIMUM restocking charge of 20% plus all

transportation charges.

D. Material built to order is not subject for credit

under any circumstances.

E. If return is caused by fault of the Company,

full credit will be allowed.

EXPORT PACKING: Refer to factory for

additional cost of export packing.

SPECIAL CONDITIONS FOR POWER

TRANSFORMERS: Because of their nature, size,

and weight, the following additional policies apply

topowertransformers:

A. MGM Transformer Company reserves the

right to determine the best mode of shipping.

All shipments will be made by truck unless

size or weight makes this impossible.

B. Prices quoted for power transformers do not

include high voltage or low voltage bushing

connectors unless specified in the inquiry and

quotation.

C. Field inspection or supervision is not

included

D. Standard testing is included. Special testing

or witness testing are extra cost items.

1. In the event of default by buyer of any

obligation buyer agrees to pay costs and

expenses including attorney fees, costs of suit

and interest at 2% per month.

Terms and Conditions

Table of contents

Popular Transformer manuals by other brands

JUMO

JUMO IPC 300 operating manual

EINHELL

EINHELL BT-VT 100 Original operating instructions

WAC Lighting

WAC Lighting EN-1260-RB2 Instructions for use

ELEQ

ELEQ RM27 installation guide

Monacor

Monacor CARPOWER FGA-22 manual

Charles

Charles Isotransformer 93-IXFMR3/6-A Installation instructions & owner's manual