Bendix CVS SmarTire TPMS User manual

SmarTire®TPMS Low Frequency (LF) Tool User Manual

1. INTRODUCTION

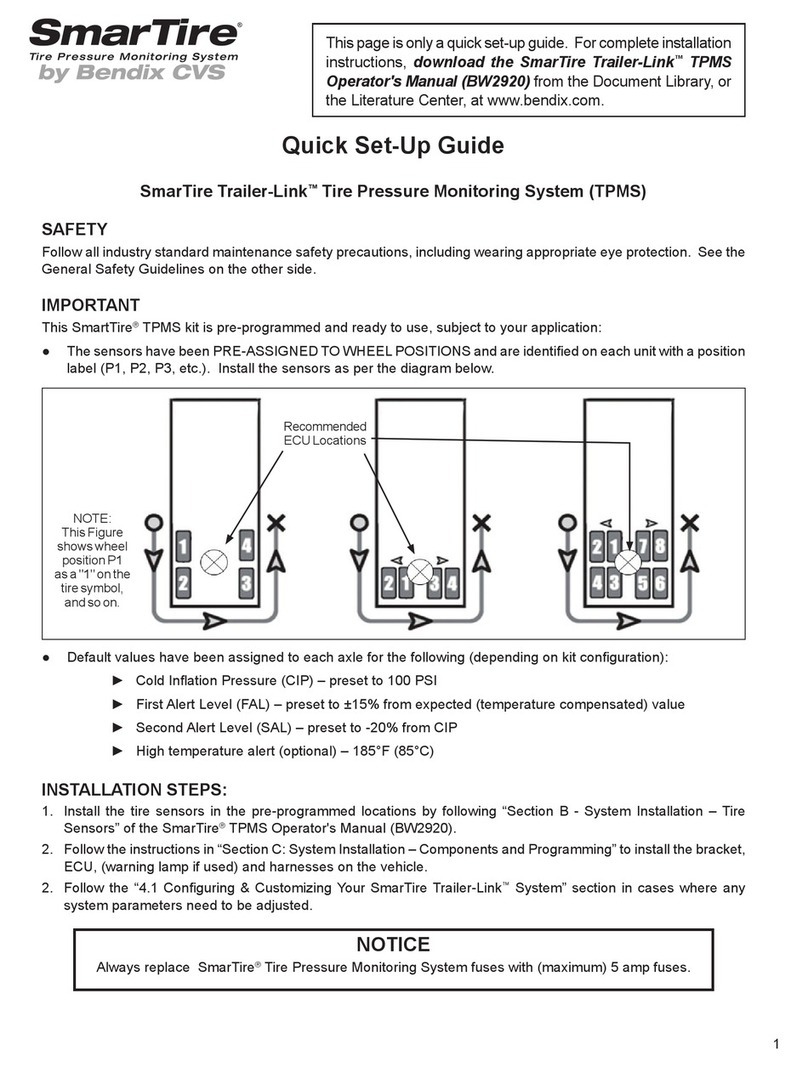

The SmarTire®Tire Pressure Monitoring System (TPMS)

by Bendix CVS consists of sensors (mounted using steel

bands onto the rim of the wheels), an antenna, receiver/

Electronic Control Unit (ECU), and dash display unit or

OEM integrated display.

A Sensor is Installed

Inside Each Tire

Antenna

Receiver/ECU

Dash

Display

Each tire sensor has a unique ID code and it is

important that the system knows the ID of the sensor

used at each tire location on the vehicle.

The SmarTire Low Frequency (LF) tool is a hand-held

device used to communicate with SmarTire-brand tire

pressure monitoring system sensors.

This document will describe how the tool can be used

to program one or more new sensor ID codes into the

receiver (for example, when replacing a sensor or after

repairs/tire rotation, etc.); and how to check that all IDs

are in the expected locations when conducting a vehicle

inspection. (See BW2799 for information about other

procedures, such as loading a system conguration.)

CONTENTS

1. Introduction . . . . . . . . . . . . . . . . . . . . .1

2. Overview of the Tool Functions . . . . . . . . . . .3

3. Getting Started . . . . . . . . . . . . . . . . . . .3

4. Using the SmarTire LF Tool . . . . . . . . . . . . .3

5. Reprogramming Sensor ID Codes Using the

Smartire®LF Tool and a PC with the Bendix®

ACom®Diagnostic Software. . . . . . . . . . . . .4

6. Programming Sensor ID Codes Using the

Dash Display and the Tool. . . . . . . . . . . . . .6

6.1 To Have the System Learn a Single Tire Position .7

6.2 To Have the System Learn All the Tire Positions . .8

7. Troubleshooting . . . . . . . . . . . . . . . . . .9

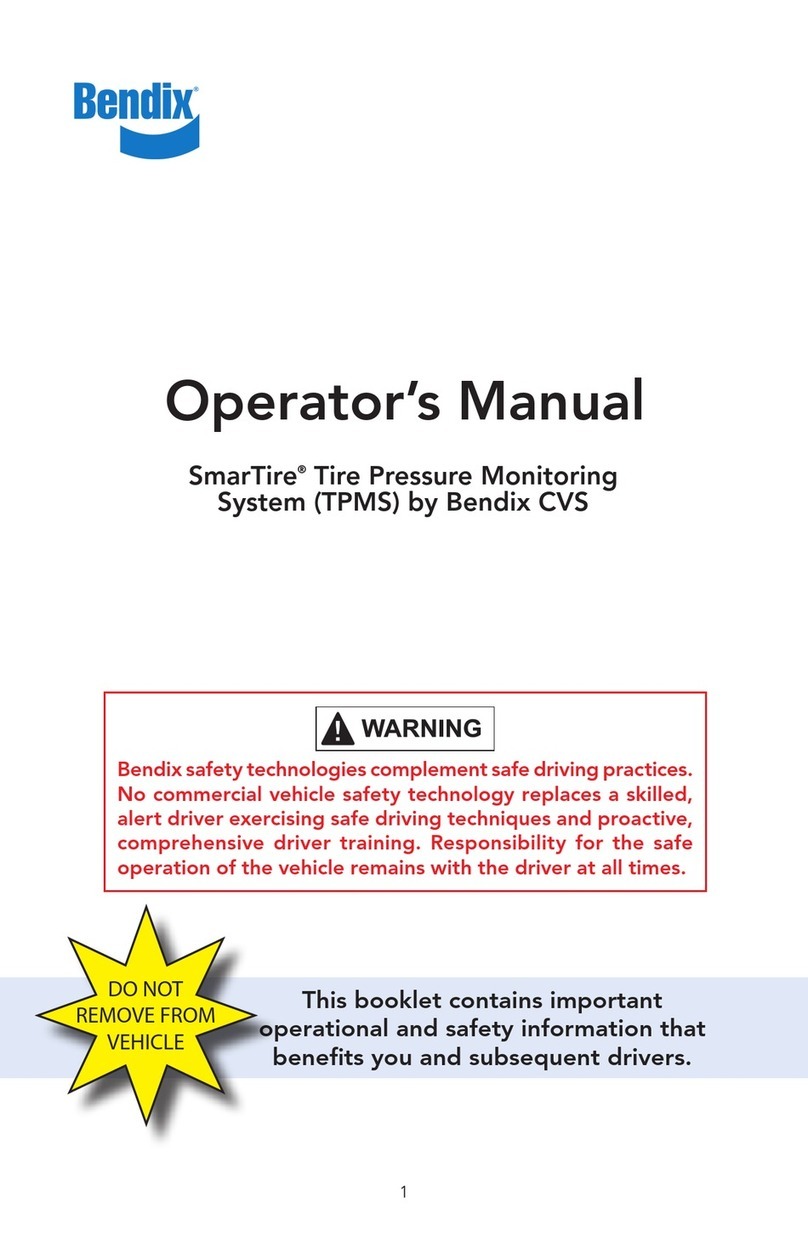

Transmitter

Learn LED

Initiate LED

Low Battery

LED

On/Off/

Mode Select

Button

Initiate/

Learn

Button

Front Back

Battery

Storage

Quick Guide

THE SMARTIRE®TPMS BY BENDIX CVS LOW FREQUENCY (LF) TOOL SHOWING BUTTONS AND LEDs

NOTE: The SmarTire LF tool is compatible ONLY with

SmarTire–brand commercial vehicle tire sensors.

NOTE: For dual-wheel assemblies, it is strongly

recommended that the tire valve stems – where sensors

are typically located – be arranged 180° from each other

to avoid errors when communicating with the sensors.

2

GENERAL SAFETY GUIDELINES

WARNING! PLEASE READ AND FOLLOW THESE INSTRUCTIONS

TO AVOID PERSONAL INJURY OR DEATH:

When working on or around a vehicle, the following guidelines should be observed AT ALL TIMES:

▲Park the vehicle on a level surface, apply the

parking brakes and always block the wheels.

Always wear personal protection equipment.

▲Stop the engine and remove the ignition key

when working under or around the vehicle.

When working in the engine compartment,

the engine should be shut off and the ignition

key should be removed. Where circumstances

requirethattheengine beinoperation,EXTREME

CAUTION should be used to prevent personal

injury resulting from contact with moving,

rotating, leaking, heated or electrically-charged

components.

▲Do not attempt to install, remove, disassemble

or assemble a component until you have read,

and thoroughly understand, the recommended

procedures. Use only the proper tools and

observe allprecautions pertaining to use ofthose

tools.

▲If the work is being performed on the vehicle’s

air brake system, or any auxiliary pressurized air

systems, make certain to drain the air pressure

from all reservoirs before beginning ANY work

on the vehicle. If the vehicle is equipped with a

Bendix®AD-IS®air dryer system,aBendix®DRM™

dryer reservoir module, or a Bendix® AD-9si®air

dryer, be sure to drain the purge reservoir.

▲Following the vehicle manufacturer’s

recommended procedures, deactivate the

electrical system in a manner that safely removes

all electrical power from the vehicle.

▲Never exceed manufacturer’s recommended

pressures.

▲Never connect or disconnect a hose or line

containing pressure; it may whip and/or cause

hazardous airborne dust and dirt particles. Wear

eye protection. Slowly open connections with

care, and verify that no pressure is present. Never

remove a component or plug unless you are

certain all system pressure has been depleted.

▲Use only genuine Bendix®brand replacement

parts, components and kits. Replacement

hardware, tubing, hose, ttings, wiring, etc. must

be of equivalent size, type and strength as original

equipment and be designed speci cally for such

applications and systems.

▲Components with stripped threads or damaged

parts should be replaced rather than repaired.

Do not attempt repairs requiring machining or

welding unless speci cally stated and approved

by the vehicle and component manufacturer.

▲Prior to returning the vehicle to service, make

certain allcomponents and systems are restored

to their proper operating condition.

▲For vehicles with Automatic Traction Control

(ATC), the ATC function must be disabled (ATC

indicator lamp should be ON) prior to performing

any vehicle maintenance where one or more

wheels on a drive axle are lifted off the ground

and moving.

▲The power MUST be temporarily disconnected

from the radar sensor whenever any tests USING

A DYNAMOMETER are conducted on a vehicle

equipped with a Bendix® Wingman®system.

▲You should consult the vehicle manufacturer's operating and service manuals, and anyrelated literature,

in conjunction with the Guidelines above.

3

Initiate/Learn Button: After selecting the initiate or

learn mode, press this button to request the

appropriateresponsefrom a sensor. Initiation

transmissions are used to obtain new sensor

readings for the SmarTire gauge or the

diagnostics software.

Low Battery LED: The low battery LED

will ash amber once every second when

thetool is onandtheonboard9-Voltbattery

isnearempty. Approximately20 additional

Initiate/Learn operations can be performed after the

battery LED blinks for the rst time. The battery LED will

lightupsolid amber during the shut downprocesstosignal

that the user can release the ON/OFF button.

3. GETTING STARTED

TheSmarTireTPMS Low Frequency(LF)tool is powered

byastandard9-Voltbattery.To install the battery,openthe

battery access panel on the back of the tool and connect

the supplied battery to the 9-Volt battery connector.

4. USING THE SMARTIRE LF TOOL

Read and understand the General Safety Guidelines

on page two of this document before beginning any

maintenance work on a vehicle.

IMPORTANT

It is important to make sure that there is no loss of

power to the SmarTire TPMS during the Learn Sensor

procedure. Power interruptions will result in some -

and potentially all - stored sensor location information

being lost, requiring the technician to start over again.

A. To switch on the SmarTire LFTool, press and hold

the On/Off/Mode Select button ( ) for two (2)

seconds.

B. Enter the Learn ( ) or the Initiate ( )

Mode by toggling the On/Off/Mode

Selectswitch ( ) and thenpressingthe

Mode Select button.

C. Hold the tool approximately two(2)in. (5cm) away

from the tire’s surface, at the center of the tire’s

sidewall,closetothevalvestem. (Therecommended

location for all SmarTire TPMS sensors is at the

valve and rim-mounted labels indicate their

location). Donot touch therimwith the tool. Press

andrelease the Initiate/Learn ( )button (a single

beepwillbeheard)andholdthe tool in place for

ve (5) seconds until four (4) quick beeps are heard

tosignalthatthetoolandsensorhavecommunicated

successfully.

2. OVERVIEW OF THE TOOL FUNCTIONS

Transmitter: The top part of the tool must be pointed

towards the tire to communicate with the sensor. See the

diagram below. For dual-wheel assemblies it is strongly

recommended that the tires are installed with their valve

stems arranged 180° from each other to help make sure

that the transmission reaches the correct sensors.

OUTBOARD

TIRE INBOARD

TIRE

LF TOOL

TRANSMITTER

ON/OFF/Mode Select Button: Press and hold this

button for two (2) seconds to power ON the tool. The tool

will sound a beep and the Initiate LED will illuminate to

show that the tool is ON. To toggle the tool

betweenthesensor Initiate and sensorLearn

functions, press the button briey. The green

LED for the current mode will be illuminated.

To shut down the tool, press and hold the

button for four (4) seconds. The battery LED

illuminates to show that you can now release the button.

Initiate LED: The Initiate LED will be ON (green) as long

astheInitiate Modeisselected. WhenpressingtheInitiate

button, the LED will blink rapidly for ve (5) seconds and

then change to one (1) blink per second after

the initiation has been completed. In service,

thesensorautomatically communicates every

3-5 minutes, however the tool prompts an

immediate response.

Learn LED: TheLearn LEDwillbeON(green)as long as

theLearnMode is selected. Learn transmissionsareused

whenreprogramming sensor ID codesintotheSmarTire®

TPMS receiver, either by using the PC-based

Bendix®ACom®Diagnostic software, or by

using the dash-mounted display. When

pressing the Learn button, the LED will blink

rapidly for ve (5) seconds and then change

to one (1) blink per second after the Learn transmission

has been completed. Upon being prompted, the sensor

communicates its unique ID code to the receiver.

4

5. REPROGRAMMING SENSOR ID CODES

USING THE SMARTIRE®LOW FREQUENCY

(LF) TOOL AND A PC WITH THE BENDIX®

ACOM®DIAGNOSTIC SOFTWARE

IMPORTANT

It is important to make sure that there is no loss

of power to the SmarTire®TPMS during the Learn

Sensor procedure. Power interruptions will result in

some - and potentially all - stored sensor location

information being lost, and the procedure will have

to be repeated.

For SmarTire TPMS system maintenance,

Version 6.5 (or higher) of the Bendix®ACom®

Diagnostic Software is required.

Read and understand the General Safety Guidelines

on page two of this document before beginning any

maintenance work on the vehicle.

Bendix ACom Diagnostic Software is an RP-1210

compliant PC-based diagnostic software program that

provides the highest level of diagnostic support for the

SmarTire TPMS system. The latest version of the

software is available for download at www.bendix.com.

These instructions will cover the use of the software to

program sensor IDs. For details about other functions

such as: setting system warning parameters; retrieving

Diagnostic Trouble Codes (DTCs); and verifying System

congurations, please see BW2799.

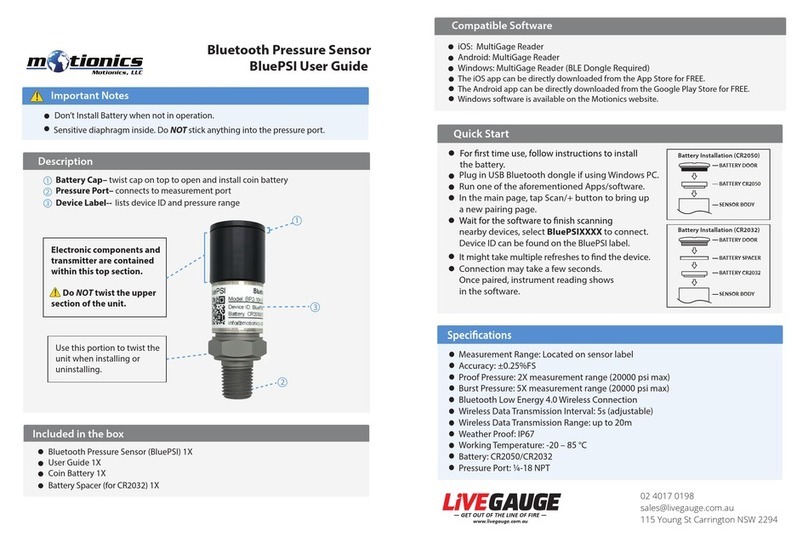

Connect the SmarTire ECU in the receiver to your PC

throughthevehicle’sdiagnosticconnectorviaanRP-1210

compliant communications device.

Laptop

Computer

USB

Cable

Noregon®Adapter

J2497 (PLC) or

J1939

To have the system learn a sensor position:

A. ConnectthePCto the vehicle and open theBendix

ACom Diagnostic Software. Select TPMS (for

tractorsystems)orBendix™Trailer-Link™(fortrailer

systems) module and select the “Start with ECU”

button.

B. Onceconnected to the ECU,select

theSetupmodebypressingtheSet

Up icon displayed here.

Select which sensor you would like to replace by

clicking on the tire icon for that position. The tire

symbol will be highlighted (it changes to green).

See the illustration at the top of the next page.

C. Select the Learn Sensor button in the sensor

conguration box (bottom right of the screen).

D. Thescreen will indicatethatthesystemis searching

for a sensor.

E. The technician has three (3) minutes to use the

SmarTire LF Tool to send a request to the sensor

in that tire, to transmit its ID. Switch on the

SmarTire LF tool by pressing and holding the On/

Off/Mode Select button ( ) for 2 seconds. Toggle

the tool mode to the Learn Sensor function by

pressingtheOn/Off/ModeSelect button ( ) again.

5

F. HoldtheSmarTire®TPMSLowFrequency(LF)tool

withthetransmissionendpointedtowardsthetire’s

sidewall adjacent to the sensor’s location

approximately two (2) inches away from the tire’s

surface.Pressand release the Initiate/Learn Button

( )(a single beep willbeheard) and keep thetool

in place for ve (5) seconds until four (4) quick

beeps are heard.

Note: Do not hold down the Initiate/Learn button ( ).

G. Oncetriggered,itcan take up to 30seconds forthe

system to receive the transmission and complete

the learn process. The ID code edit box for the

wheel position will update with the new ID code

and the Bendix®ACom®symbol for that location

will turn yellow after a successful communication.

H. Repeat this process for all the wheel positions that

need to be programmed.

Note:Thefollowingwarning may appearifyouarelearning

more than one tire position:

“Learn process may fail if sensors are relocated or

swapped and the conguration is not written to ECU.

Would you like to continue the learn process anyway?”

Press the OK button to continue the process.

I. It is important to save the changes you have just

made. After the system has learned the ID codes

for the targeted wheels, select the Write to ECU

button to save them.

A dialog box will appear showing the progress.

Look for the following conrmation dialogue box.

“The conguration has been successfully written to the

ECU.”

6

6. PROGRAMMING SENSOR ID CODES

USING THE DASH DISPLAY AND THE TOOL

IMPORTANT

As stated earlier, it is important to make sure that

there is no loss of power to the SmarTire®TPMS

during the Learn Sensor procedure.

Note: Not all functionality may be accessible using the

dash display; if a menu item shown here is not visible on

your display, it may be disabled, or not available because

ofthe version of dashdisplaybeingused. UsetheBendix®

ACom®Diagnosticsoftwareforaccess to full functionality.

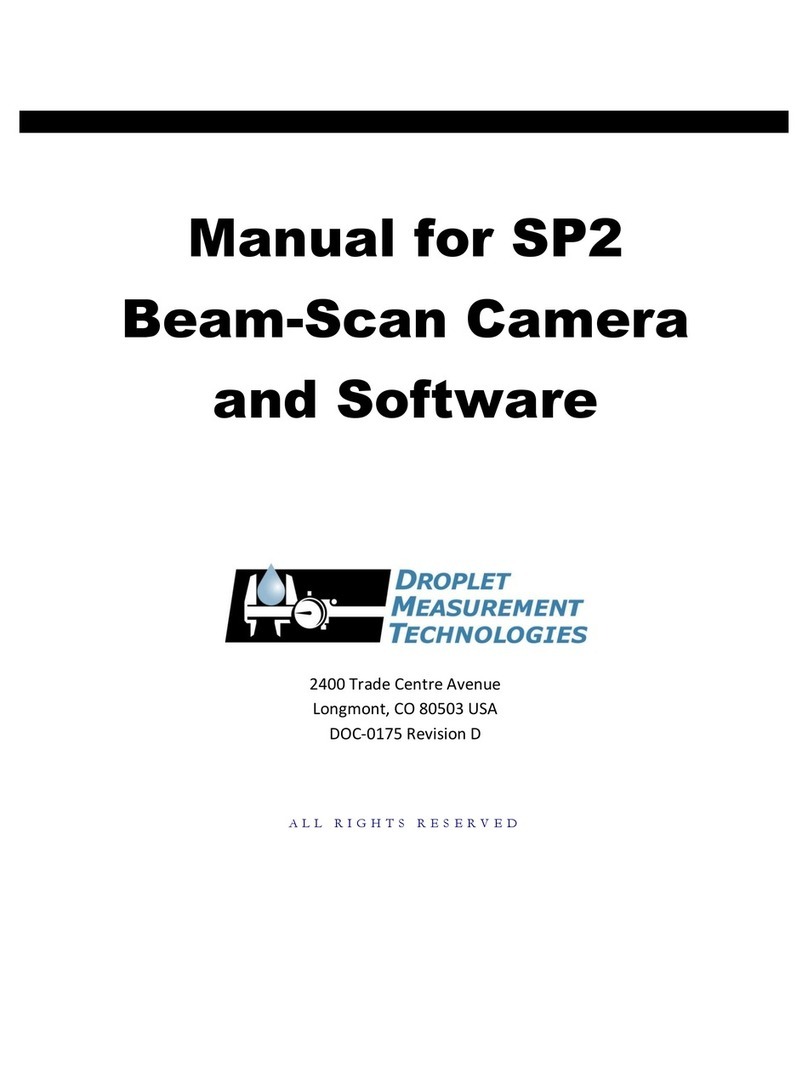

TPMS Ready

Left

(typical action:

“scroll down”)

Right

(typical action:

“scroll across”)

This icon is only

displayed when

Trailer TMPS is

detected

Center

(typical action: “select”)

For systems that are congured to require a password:

Press and hold the center button for two seconds and

the display will show a password entry screen.

To enter a password, press the left button to scroll

the rst digit from 9 to 0. When the correct digit is

displayed, press the right button to move to the

next digit in sequence. Repeat this action until all

four digits are entered correctly and then push the

right button to enter the password. If the password

is correct, the display will enter Setup Mode. If the

password is incorrect, the display will indicate that

the wrong password was entered and return to the

password entry screen.

NOTE: If the system is not congured to use a password,

the system will go directly to the setup mode.

To enter the Setup Mode, on the dash display press the

center button repeatedly until the TPMS Ready screen

is displayed.

Above: With no active Diagnostic Trouble Codes (DTCs).

Above: If there are any active pressure or temperature

DTCs present, a symbol with an exclamation point inside

a triangle will be displayed.

When in Setup Mode, scroll to the “Learn Sensors” menu

item. Press the right button to select the Learn Sensor

function.

Depending on the version of the display installed, the

following screen may vary.

Go to 6.1

Go to 6.2

In cases where the “Learn All Tires” option is not shown,

the vehicle has an older version of the dash display, and

the technician will have to repeat Section 6.1 as many

times as needed to learn the missing tire IDs.

7

6.1 TO HAVE THE SYSTEM LEARN A SINGLE

TIRE POSITION

IMPORTANT

As stated earlier, it is important to make sure that

there is no loss of power to the SmarTire®TPMS

during the Learn Sensor procedure.

6.1.1 Press the right button on the dash display to select

the learn single tire option. The display will now

show the rst axle on the vehicle. Press the left

button to scroll through the axles, and then use the

right button, if necessary, to scroll until the desired

tire is selected. Then press and hold the center

button for two seconds.

6.1.2 The next screen displayed will depend on the

display and receiver versions installed.

Select the Hand Tool option (scroll down using the

left button, then the right button to select it).

Earlier versions of software may instead take you

directly to the next step.

6.1.3 The screen will then show “Deleting Tire” and the

selected wheel position will ash.

6.1.4 WhentheID for the selectedtire hasbeendeleted,

the screen will show “Learn in Progress”.

6.1.5 The technician has three (3) minutes to use the

SmarTire Low Frequency (LF) Tool to send a

request to the sensor inside that tire, to transmit

its ID.

To do this, hold the SmarTire LF tool with the

transmissionend pointed towards thetire’ssidewall

adjacenttosensor’slocationapproximately two (2)

inches away from the tire’s surface. Press and

releasetheInitiate/Learn( ) Button (a single beep

will be heard) and keep the tool in place for

ve (5) seconds until four (4) quick beeps are heard.

Note: Do not hold down the Initiate/Learn ( ) button.

6.1.6 After the receiver registers the transmission, it can

take up to 30 seconds for the learn process to be

completed. Look for the “Learn Complete” screen

to be displayed.

LEARN COMPLETE

IMPORTANT: Press the centerbuttononcetosave

the changes and exit the “Learn” function.

PressthecenterbuttonrepeatedlytoexittheSetup

Mode.

Potential error messages are:

Learn Time Out. This may occur when the three (3)

minutewindowforreceivingtheresponse from the sensor

is exceeded.

Duplicate Sensor ID. When the ID code received is

already being used on the vehicle.

See the Troubleshooting Section (Section 7) for more

information.

8

6.2 TO HAVE THE SYSTEM LEARN

ALL THE TIRE POSITIONS

IMPORTANT

As stated earlier, it is important to make sure that

there is no loss of power to the SmarTire®TPMS

during the Learn Sensor procedure.

To learn alltirepositions,follow the steps under Section 6

above, but instead of selecting the “Learn Single Tire”

option, use the “Learn All Tires” option instead. (The

display may vary.)

When learning all tire positions, the display will expect

the responses from the tire sensors be received starting

with the front left tire and moving around the vehicle in a

counterclockwise pattern based upon the stored vehicle

conguration. (Note that a spare tire may also be included

in the tires to be identied).

Above tractors, below trailers

For dual tire axles, the inner tire is learned rst and then

the outer tire. Follow the prompts on the display as it will

indicate the current position to be learned.

6.2.1 The next screen will permit you to select the “Hand

Tool” option. (The display may vary.)

These instructions will cover the use of the hand

tool to program the sensor IDs. For details about

the Manual ID entry option, please see BW2799.

6.2.2 The next screen will prompt you to choose to

overwrite the existing prole.

Select “Yes” (press the right button) to continue.

The “Initializing Prole” screen will display the

system’s progress in erasing the old prole.

6.2.3 Wait for the status bar to compete and the “Learn

in Progress” message to be displayed before

continuing.

TheIDforthewheelpositiontobeprogrammedwill

bedisplayednext and the SmarTireLowFrequency

(LF) Tool must be used at that location within three

(3) minutes.

LEARN COMPLETE

6.2.4. Usethetechniquedescribed in 6.1.5 to request the

sensor to transmit its ID to the receiver.

6.2.5 Check that the “Learn Complete” has been

displayed (this may take up to 30 seconds) and

then move to the next tire position to be learned.

Repeat these steps until all wheel positions are

programmed.

6.2.6 IMPORTANT: Press the center button once to save

the changes and exit the “Learn” function.

PressthecenterbuttonrepeatedlytoexittheSetup

Mode.

Potential error messages are:

Learn Time Out. This may occur when the three (3)

minutewindowforreceivingtheresponse from the sensor

is exceeded.

Duplicate Sensor ID. When the ID code received is

already being used on the vehicle.

See the Troubleshooting Section (Section 7) for more

information.

9

7. TROUBLESHOOTING

The following messages may be displayed at the end of

the Learn process if it was not completed successfully:

A. Learn Time Out. The receiver did not receive an

expectedresponsefrom a sensor within three(3)minutes

after being requested to learn a tire, and so the system

“timed- out”. Re-attempt to communicate at least twice.

If unsuccessful, a sensor may be pointing directly down

into the ground, or away from the Gateway or Antenna,

causing the signal reception to be disrupted. In these

cases, it may be useful to move the vehicle forward or

backward about a half-turn of the wheels, to reposition

the sensor, and then retry.

It can be useful to look to see if the tire stems for dual-

wheel assemblies are installed with their valve stems

arranged 180° from each other, as recommended. If still

unsuccessful,tryto initiate the sensoratthebottom of the

wheel, no matter where the valve stem is located. If this

attempt was successful, rotate the wheel 180 degrees

forward and initiate the sensor again at the BOTTOM of

the wheel. If the second initiation also provided a result,

itis evidence ofa broken cradle and/orstrap. The sensor

is simply falling to the lowest point in the wheel after each

rotation. Removethetireandreplacethecradleandstrap.

Dependingonthedamagedonetothesensor itself, it may

simply be pressed into a new cradle for reuse, however,

do not reuse the strap.

It is also important to check that the tool is held about

two(2) inches from the tire during the procedure – and

not touching the rim.

B. Duplicate Sensor ID. Thesensor ID that was received

for the wheel position is already programmed into the

system at another wheel position. (This may occur when

rotatingwheelsifthe original set of locations hasnot been

erased.) Repeat the process, ensuring you are initiating

the sensor you wish to learn. Take care when working

with dual tire assemblies to communicate with the correct

tire position.

It can be useful to look to see if the tire stems for dual-

wheel assemblies are installed with their valve stems

arranged 180° from each other, as recommended. You

can verify the location of the sensor in most cases, by

lookingforthe label attached to therimduringinstallation.

If still unsuccessful, try to initiate the sensor at the bottom

ofthewheel,no matter where the valve stemis located. If

thisattemptwassuccessful,rotatethewheel180degrees

forward and initiate the sensor again at the BOTTOM of

the wheel. If the second initiation also provided a result,

itis evidence ofa broken cradle and/orstrap. The sensor

is simply falling to the lowest point in the wheel after each

rotation. Removethetireandreplacethecradleandstrap.

Dependingonthedamagedonetothesensor itself, it may

simply be pressed into a new cradle for reuse, however,

do not reuse the strap.

For more in-depthtroubleshooting, consult the SmarTire®

TirePressureMonitoring System (TPMS) byBendixCVS

Operator’sManual (BW2799), availablefordownloadfrom

the Bendix website www.bendix.com.

10

FCC NOTICE

This device complies with Part 15 of the FCC Rules. The

SmarTire®TPMS Low Frequency (LF) tool is a Part 15

low-power transmitter below 1705 kHz. The device has

a rated RF power output of less than 0.2 micro Watts.

Due to the frequency range of the transmitter – and the

low-level of output power – the device is not subject to

the routine RF exposure valuation as per Section 2.1093

of the FCC rules.

Operation is subject to the following two conditions:

1. Thisdevicemay not cause harmfulinterference; and,

2. This device must accept any interference received,

including interference that may cause undesired

operation.

Thisequipment has been tested andfoundtocomply with

the limits for a Class B digital device, pursuant to Part 15

of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference in a

residential installation. This equipment generates, uses

andcanradiate radio frequencyenergyand,ifnotinstalled

and used in accordance with the instructions, may cause

harmful interference to radio communications. However,

there is no guarantee that interference will not occur in a

particular installation.

If this equipment does cause harmful interference to

radio or television reception, which can be determined by

turning the equipment off and on, the user is encouraged

to try to correct the interference by one, or more, of the

following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and

the receiver.

• Connect the equipment into an outlet on a circuit

different from that to which the receiver is connected.

• Consult the dealer or an experienced radio/TV

technician for help.

Changes or modifications to this device without the

expressapprovalof the manufacturer may voidtheuser’s

authority to use this device.

Duplication of this document in whole or in part for any

purposes other than those for which it was originally

intended, without the written approval of Bendix

Commercial Vehicle Systems LLC is strictly prohibited.

Theinformationprovided in thismanualisforinformational

purposes only and is subject to change without notice

andshould not beconstruedas a commitmentby Bendix.

Bendixassumesnoresponsibilityor liability for any errors

or inaccuracies that may appear in this publication.

EUROPEAN REGULATIONS

This device complies with R&TTE 1999/5/EC through

harmonized standards (EN301 489-1 and EN330 330-1).

The equipment has been tested and found to comply

with the above directive and in addition it meets the

requirements for low powered transmitters/receivers

as dened by the relevant radio approval authority and

complies with low voltage directive 73/23/EEC. The

directive is designed to provide reasonable protection

against harmful interference or susceptibility. Changes

made to this device without the express approval of the

manufacturer may void the user’s authority to use this

device

RSS210, RSSGEN

This device complies with Industry Canada’s licence-

exempt RSSs. Operation is subject to the following two

conditions:

1. This device may not cause interference; and

2. This device must accept any interference, including

interference that may cause undesired operation of

the device.

TRADEMARKS

The SMARTIRE trademark is owned by Bendix

Commercial Vehicle Systems LLC. Any references in

this catalog to any other company or trademark are

solely for identication purposes. The trademarks are

the property of their respective companies and are not

afliated with or endorsing Bendix Commercial Vehicle

Systems LLC. Bendix Commercial Vehicle Systems

LLC does not represent any parts shown as products

manufactured or remanufactured by the companies so

named herein.

11

NOTES

12

901 Cleveland Street • Elyria, Ohio 44035 • 1-800-AIR-BRAKE (1-800-247-2725)

6900 Graybar Road #2110 • Richmond, British Columbia, Canada V6W 0A5 • 604-242-7400

®

BW2820 ©2015 Bendix Commercial Vehicle Systems LLC, a member of the Knorr-Bremse Group • 11/15 • All Rights Reserved • www.bendix.com

Table of contents

Other Bendix CVS Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

PCB Piezotronics

PCB Piezotronics 320C17 Installation and operating manual

Bosch

Bosch DLE 70 Professional Original instructions

Agilent Technologies

Agilent Technologies TapeStation 4200 Software & User Information

PCE Instruments

PCE Instruments PCE-HT 70 user manual

Environmental Express

Environmental Express IAQ 15 Connect Operating instructions manual

Ahlborn

Ahlborn ALMEMO 2490-1A operating instructions