Sea-Bird Electronics SBE 45 MicroTSG User manual

Sea-Bird Electronics, Inc.

13431 NE 20th Street

Bellevue, Washington 98005 USA

Tel: 425/643-9866

Fax:425/643-9954

SBE 45 MicroTSG

THERMOSALINOGRAPH

Conductivity and Temperature Monitor

with RS-232 Interface

Serial Number: 4566782-0402

User Manual, Version 015

This page intentionally left blank.

SEA-BIRD ELECTRONICS, INC.

13431 NE 20th St.

Bellevue, Washington 98005 USA

Phone: (425) 643 9866

Fax: (425) 643 9954

Email: [email protected]

SBE 45 MICRO-TSG OPERATING AND REPAIR MANUAL

TABLE OF CONTENTS

Manual Generation Date....................................................................................................................................................................................................................................

1

Limited Liability Statement...............................................................................................................................................................................................................................

2

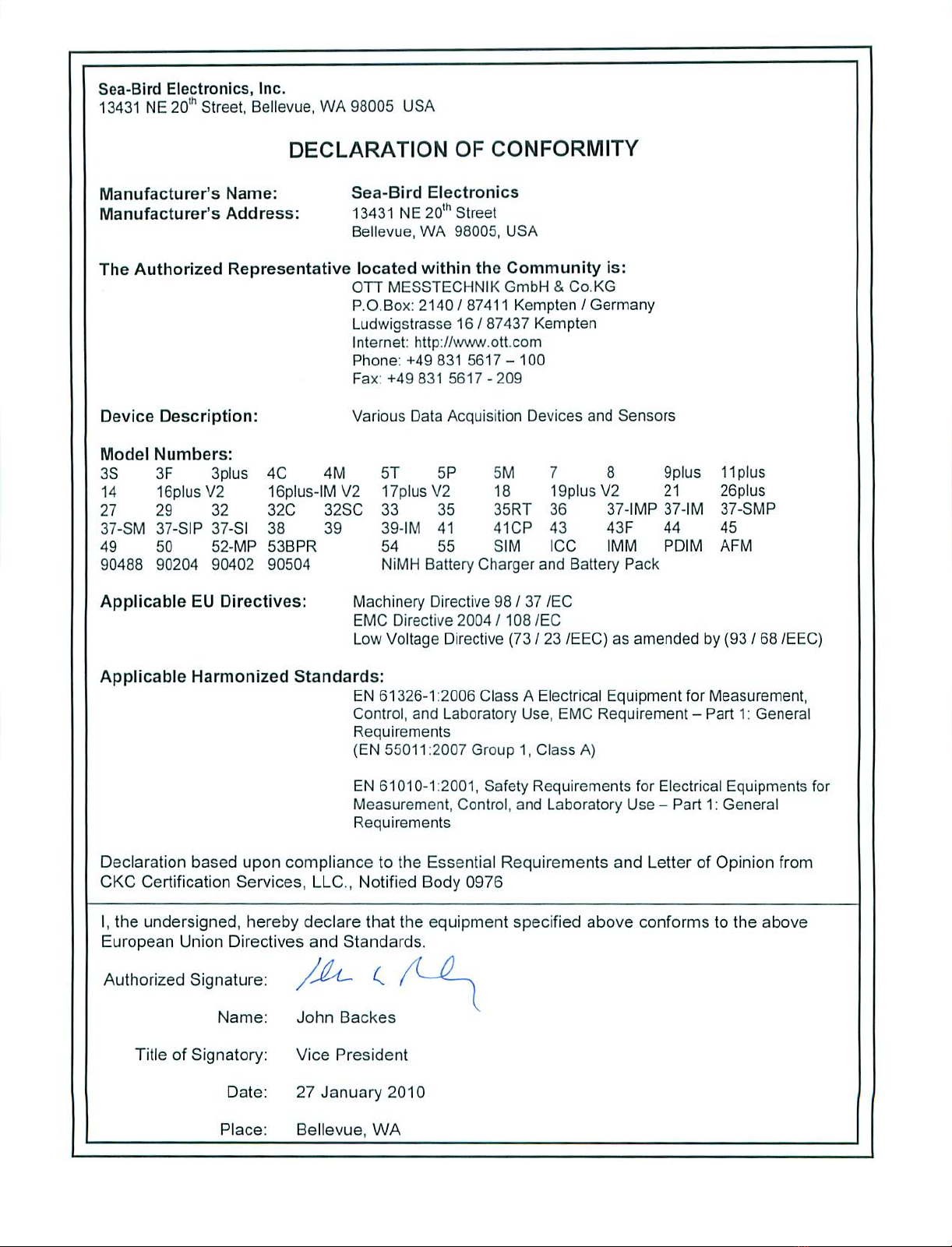

Declaration of Conformity.................................................................................................................................................................................................................................

4

SBE 45 Configuration - S/N 0402...........................................................................................................................................................................................................................

5

SBE 45 Manual - Version 015...............................................................................................................................................................................................................................

6

SBE 45 Reference Sheet - Version 007......................................................................................................................................................................................................................

59

SBE 45 Specification Sheet................................................................................................................................................................................................................................

61

PN 90402 Manual - Version 008.............................................................................................................................................................................................................................

63

SBE 45 Calibrations.......................................................................................................................................................................................................................................

95

Appnotes..................................................................................................................................................................................................................................................

98

Drawings..................................................................................................................................................................................................................................................

125

Warranty..................................................................................................................................................................................................................................................

136

Service Request Form......................................................................................................................................................................................................................................

139

Manual Generation Date: 13 February 2012

1

L I M I T E D L I A B I L I T Y S T A T E M E N T

Extreme care should be exercised when using or servicing this equipment. It should be used or

serviced only by personnel with knowledge of and training in the use and maintenance of

oceanographic electronic equipment.

SEA-BIRD ELECTRONICS, INC. disclaims all product liability risks arising from the use or servicing of

this system. SEA-BIRD ELECTRONICS, INC. has no way of controlling the use of this equipment or of

choosing the personnel to operate it, and therefore cannot take steps to comply with laws pertaining to

product liability, including laws which impose a duty to warn the user of any dangers involved in

operating this equipment. Therefore, acceptance of this system by the customer shall be conclusively

deemed to include a covenant by the customer to defend, indemnify, and hold SEA-BIRD

ELECTRONICS, INC. harmless from all product liability claims arising from the use of servicing of this

system.

2

This page intentionally left blank.

3

4

Instrument Configuration:

Serial Number 37SI64195-8524

Pressure Sensor None

Firmware Version 3.0j

Memory 8192Kb

Interface Type RS-232

Conductivity Range 0-7 S/m

Baud Rate 9600, 8 data bits, no parity

Zero Conductivity 2491.031 Hz

Maximum Depth 7000 meters

SBE45 MicroTSG

(Thermosalinograph)

Conductivity & Temperature Monitor

with RS-232 Serial Interface

CAUTION - This instrument is not intended for

underwater use.

Maximum Depth 0

Power Up Jumper Autopower Pins 1 & 2

Baud Rate 4800

Conductivity Range 0-7 S/m

Interface Type RS-232

Firmware Version V 1.1b

Serial Number 4566782-0402

Instrument Configuration:

5

SBE 45 MicroTSG

(Thermosalinograph)

Conductivity and Temperature Monitor

with RS-232 Interface

Note: NEW ADDRESS

as of January 18, 2010

User’s Manual

Sea-Bird Electronics, Inc.

13431 NE 20th Street

Bellevue, Washington 98005 USA

Telephone: 425/643-9866 Manual Version #015, 01/26/10

Fax: 425/643-9954 Firmware Version 1.1b and later

E-mail: seabir[email protected] Seasave V7 Version 7.20a and later

Website: www.seabird.com SBE Data Processing Version 7.20a and later

6

2

Limited Liability Statement

Extreme care should be exercised when using or servicing this equipment. It should be used or serviced

only by personnel with knowledge of and training in the use and maintenance of oceanographic

electronic equipment.

SEA-BIRD ELECTRONICS, INC. disclaims all product liability risks arising from the use or servicing

of this system. SEA-BIRD ELECTRONICS, INC. has no way of controlling the use of this equipment

or of choosing the personnel to operate it, and therefore cannot take steps to comply with laws

pertaining to product liability, including laws which impose a duty to warn the user of any dangers

involved in operating this equipment. Therefore, acceptance of this system by the customer shall be

conclusively deemed to include a covenant by the customer to defend, indemnify, and hold SEA-BIRD

ELECTRONICS, INC. harmless from all product liability claims arising from the use or servicing of

this system.

7

Table of Contents SBE 45

3

Table of Contents

Section 1: Introduction ........................................................................ 5

About this Manual .............................................................................................5

Quick Start .........................................................................................................5

Unpacking MicroTSG........................................................................................6

Section 2: Description of MicroTSG .................................................. 7

System Description ............................................................................................7

Specifications.....................................................................................................9

Dimensions and Connector ..............................................................................10

Sample Timing.................................................................................................11

Baud Rate, Cable Length, Power, and Data Transmission Rate ......................12

Remote Temperature Sensor (optional) ...........................................................14

Section 3: Installing System .............................................................. 15

Installing Software...........................................................................................15

System Schematic and Installation Guidelines ................................................16

Power-Up Jumper Check .................................................................................18

Installing MicroTSG ........................................................................................19

Section 4: Setting Up MicroTSG ...................................................... 20

Communications Test and Setup......................................................................20

Sampling Modes ..............................................................................................24

Polled Sampling........................................................................................24

Autonomous Sampling .............................................................................25

Serial Line Synchronization (Serial Line Sync)........................................26

Timeout Description ........................................................................................26

Command Descriptions....................................................................................27

Data Output Format .........................................................................................32

Setting Up Configuration (.xmlcon or .con) File .............................................33

Section 5: Operating System ............................................................. 34

Acquiring Real-Time Data with Seasave.........................................................34

Processing Data................................................................................................36

Section 6: Routine Maintenance and Calibration .......................... 37

Corrosion Precautions......................................................................................37

Cleaning and Storage .......................................................................................37

Replacing Anti-Foulant Device (SBE 45)........................................................39

Sensor Calibration............................................................................................40

Section 7: Troubleshooting................................................................ 41

Problem 1: Unable to Communicate with MicroTSG......................................41

Problem 2: Nonsense or Unreasonable Data....................................................41

Problem 3: Salinity Lower than Expected .......................................................41

Glossary .............................................................................................. 42

8

Table of Contents SBE 45

4

Appendix I: Functional Description................................................. 43

Sensors.............................................................................................................43

Sensor Interface ...............................................................................................43

Appendix II: Electronics Disassembly/Reassembly ........................ 44

Appendix III: Command Summary ................................................. 45

Appendix IV: AF24173 Anti-Foulant Device .................................. 47

Appendix V: Replacement Parts ...................................................... 51

Index.................................................................................................... 52

9

Section 1: Introduction SBE 45

5

Section 1: Introduction

This section includes a Quick Start procedure, and photos of a standard

SBE 45 MicroTSG shipment.

About this Manual

This manual is to be used with the SBE 45 MicroTSG Conductivity and

Temperature Monitor. It is organized to guide the user from installation

through operation and data collection. We’ve included detailed specifications,

command descriptions, maintenance and calibration information, and helpful

notes throughout the manual.

Sea-Bird welcomes suggestions for new features and enhancements of our

products and/or documentation. Please contact us with any comments or

suggestions (seabird@seabird.com or 425-643-9866). Our business hours are

Monday through Friday, 0800 to 1700 Pacific Standard Time (1600 to 0100

Universal Time) in winter and 0800 to 1700 Pacific Daylight Time (1500 to

0000 Universal Time) the rest of the year.

Quick Start

Follow these steps to get a Quick Start using the MicroTSG.

The manual provides step-by-step details for performing each task:

1. Perform pre-check procedures (see Sections 3 and 4):

A. On the Configuration Sheet (in the manual), check the factory-set

power-up mode jumper setting. For a description of how the jumper

setting affects operation, see Power-Up Jumper Check in Section 3:

Installing System.

B. Test power and communications.

C. Establish setup and operating parameters.

D. Check status (DS) and calibration coefficients (DC) to verify setup.

2. Deploy the MicroTSG (see Sections 3,4, and 5):

A. Verify the AF24173 Anti-Foulant Device is installed.

B. Install the MicroTSG.

C. Send commands to run the system.

10

Section 1: Introduction SBE 45

6

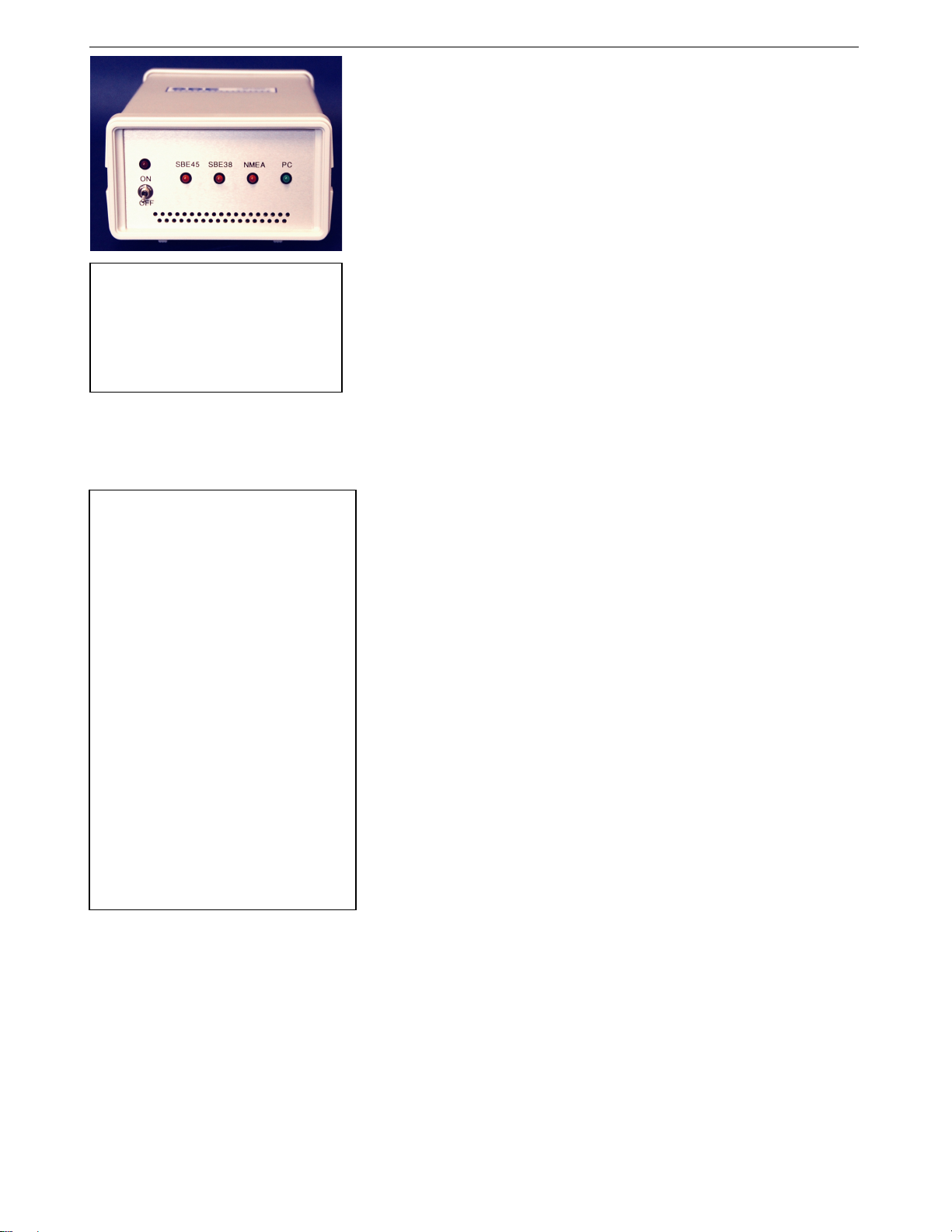

Unpacking MicroTSG

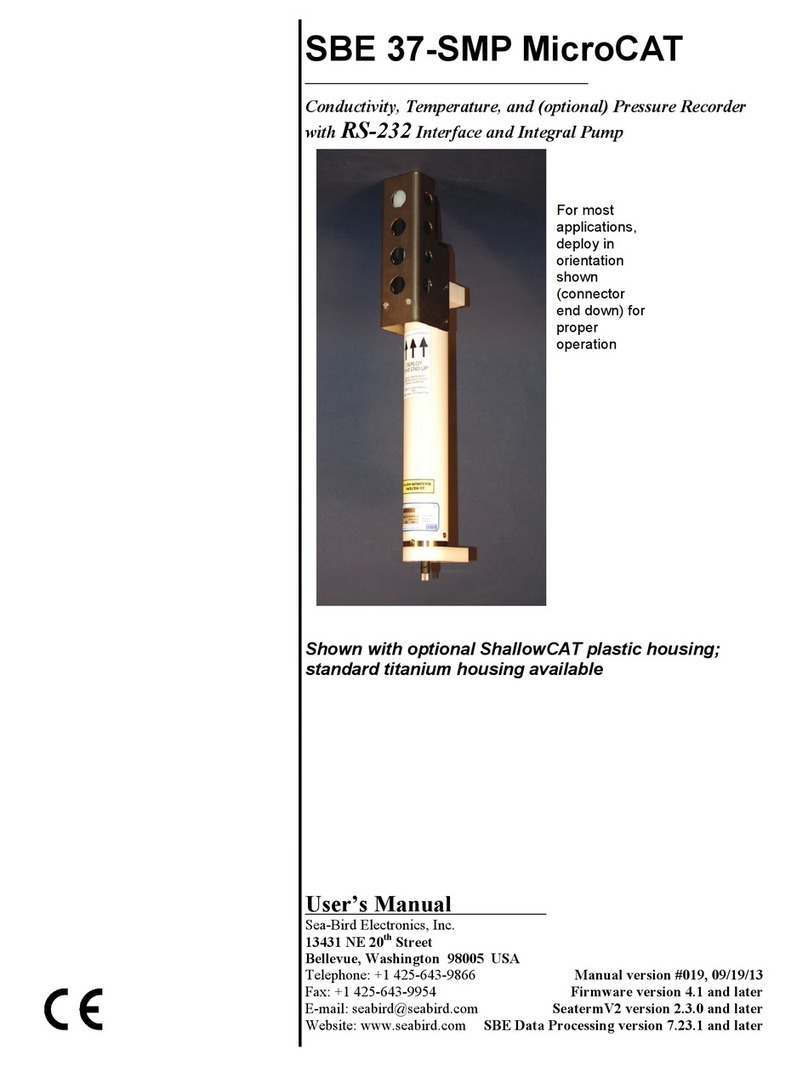

Shown below is a typical MicroTSG shipment.

Spare parts kit

MicroTSG

MicroTSG User Manual

Conductivity cell cleaning

solution (Triton X-100)

I/O cable

Software, and Electronic Copies of

Software Manuals and User Manual

11

Section 2: Description of MicroTSG SBE 45

7

Section 2: Description of MicroTSG

This section describes the functions and features of the MicroTSG, including:

•System description

•Specifications

•Dimensions and connector

•Sample timing

•Baud rate, cable length, and power requirements

•Optional remote temperature sensor

System Description

The SBE 45 MicroTSG is an externally powered, high-accuracy, conductivity

and temperature monitor, designed for shipboard determination of sea surface

(pumped-water) conductivity and temperature.

Communication with the MicroTSG is over an internal, 3-wire, RS-232C link,

providing real-time data transmission. Commands can be sent to the

MicroTSG to provide status display, data acquisition setup, data acquisition

and display, and diagnostic tests. User-selectable operating modes include:

•Polled sampling – On command, the MicroTSG takes one sample and

sends the data to the computer.

•Autonomous sampling – At pre-programmed intervals, the MicroTSG

samples and sends the data to the computer. The MicroTSG does not enter

quiescent (sleep) state between samples.

•Serial Line Sync - A pulse on the serial line causes the MicroTSG to

wake up, sample, and enter quiescent (sleep) state automatically.

Calibration coefficients stored in EEPROM allow the MicroTSG to transmit

data in engineering units. The MicroTSG retains the temperature and

conductivity sensors used in the SBE 21 Thermosalinograph, but has improved

acquisition electronics that increase accuracy and resolution, and lower power

consumption. The MicroTSG’s aged and pressure-protected thermistor has a

long history of exceptional accuracy and stability (typical drift is less than

0.002 °C per year). Electrical isolation of the conductivity electronics

eliminates any possibility of ground-loop noise.

The MicroTSG’s internal-field conductivity cell is unaffected by external

fouling. A plastic cup with O-ring retainer at one end of the cell retains the

expendable AF24173 Anti-Foulant Device.

12

Section 2: Description of MicroTSG SBE 45

8

An optional AC- or DC-powered 90402 - SBE 45 Power, Navigation, and

Remote Temperature Interface Box provides:

•Power and an opto-isolated RS-232C interface for the MicroTSG

•An opto-isolated NMEA receiver for an optional NMEA navigation

device which supports NMEA 0183 protocol, outputting data in GGA,

GLL, RMA, RMC, or TRF format (NMEA navigation device not supplied

by Sea-Bird)

•Power and an RS-232C interface for an optional SBE 38 remote

temperature sensor

•An RS-232C computer interface

Decoded Latitude, Longitude, date, and time and SBE 38 temperature data are

appended to the MicroTSG data stream in the Interface Box. The data is

transmitted to the computer for storage and/or display.

The MicroTSG is supplied with a powerful 2000/XP software package,

Seasoft©V2, which includes:

•SEATERM – terminal program for easy communication and data

retrieval, can send commands to the MicroTSG to provide status display,

data acquisition setup, data display and capture, and diagnostic tests.

•Seasave V7 – program for acquiring, saving, and displaying real-time or

archived data.

•SBE Data Processing – program for calculation and plotting of

conductivity, temperature, data from auxiliary sensors, and derived

variables such as salinity and sound velocity.

Notes:

•Help files provide detailed

information on the software.

•Software manuals on CD-ROM

contain detailed information on

Seasave V7 and SBE Data

Processing.

•Sea-Bird also supplies an older

version of Seasave, Seasave-

Win32. However, all Seasave

instructions in this manual are

written for Seasave V7. See

Seasave-Win32’s manual and/or

Help files if you prefer to use the

older software.

•Sea-Bird supplies the current

version of our software when you

purchase an instrument. As software

revisions occur, we post the revised

software on our FTP site. See our

website (www.seabird.com) for the

latest software version number, a

description of the software changes,

and instructions for downloading the

software from the FTP site.

Note:

See the Interface Box manual for

operation of the MicroTSG with the

Interface Box. The Interface Box can

be added to the system at any time,

and does not need to be part of the

original MicroTSG order.

13

Section 2: Description of MicroTSG SBE 45

9

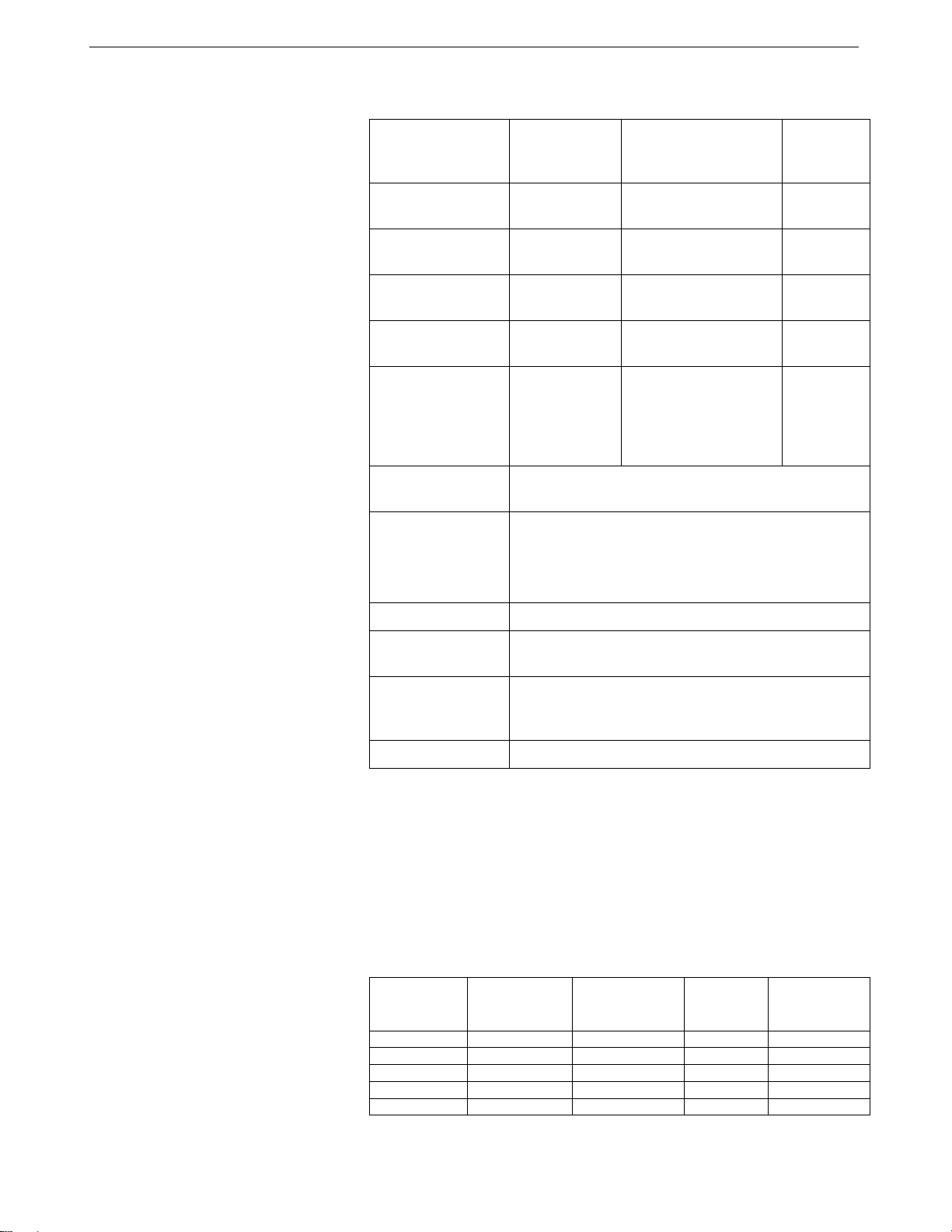

Specifications

Temperature

(°C) 1

Conductivity

(S/m)

Salinity

(PSU),

typical

Measurement

Range -5 to +35 0 to 7

(0 to 70 mS/cm) -

Initial Accuracy 0.002 0.0003

(0.003 mS/cm) 0.005

Typical Stability

(per month) 0.0002 0.0003

(0.003 mS/cm) 0.003

Resolution 20.0001 0.00001

(0.0001 mS/cm) 0.0002

Sensor

Calibration

Range

+1 to +32

0 to 6; physical

calibration over the

range 2.6 to 6 S/m,

plus zero

conductivity (air)

-

Counter

Time-Base

Quartz TCXO, ±2 ppm per year aging;

±5 ppm vs. temperature (-5 to +30 °C)

Input Power

8 - 30 VDC

Quiescent (sleep) Current: 10 microamps

Operating Current: 34 milliamps at 8 VDC

30 milliamps at 12-30 VDC

Materials PVC housing

Recommended

Flow Rate

10 to 30 milliliters/second

(0.16 to 0.48 gallons/minute)

Maximum Safe

Operating

Pressure

34.5 decibars (50 psi)

Weight 4.6 kg (10.2 lbs)

Notes:

1Temperature specifications above are for MicroTSG’s temperature sensor.

For optional remote temperature sensor (SBE 38), which can be integrated

with optional 90402 Interface Box -

Measurement range: -5 to +35 °C Initial accuracy: 0.001 °C

Resolution: 0.0003 °C Calibration: -1 to +32 °C

Typical stability: 0.001 °C in 6 months, certified

2Resolution

Typical RMS noise with fixed resistors on temperature and conductivity inputs:

NCycles * Temperature

(°C)

Conductivity

(S/m)

Salinity

(psu)

Sound

Velocity

(m/sec)

1 0.000190 0.000014 0.00027 0.00066

2 0.000170 0.000010 0.00016 0.00057

4 0.000150 0.000005 0.00015 0.00055

8 0.000087 0.000005 0.00009 0.00033

16 0.000078 0.000004 0.00007 0.00025

* NCycles = number of measurements to average per sample.

14

Section 2: Description of MicroTSG SBE 45

10

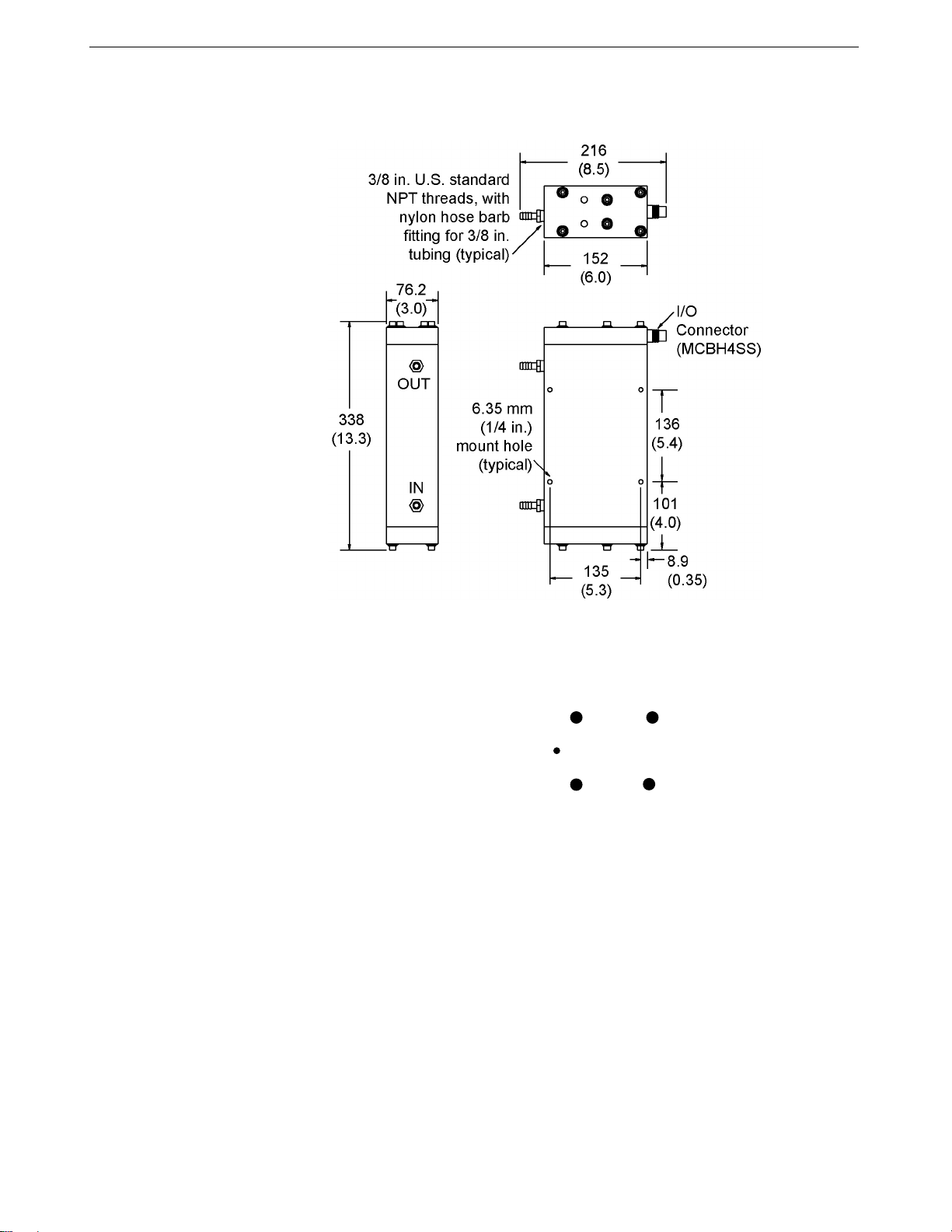

Dimensions and Connector

Dimensions in millimeters (inches)

Ground pin = Computer data common (pin 1)

Receive pin = RS-232C receive data transmitted from computer (pin 2)

Transmit pin = RS-232C transmit from MicroTSG to computer (pin 3)

Power pin = 8-30 VDC (pin 4)

Orientation Pin

Ground Pin 1

Transmit Pin 3Power Pin 4

Receive Pin 2

MCBH4SS

15

Section 2: Description of MicroTSG SBE 45

11

Sample Timing

The time to acquire the temperature and conductivity varies, depending on the

mode of operation.

Polled Sampling Mode

Polled Sampling Mode is in effect when:

•PCB J1 jumper is set to Normal or Autopower, AutoRun=N, and

sampling is started with Go (if SingleSample=Y) or with a polled

sampling command

Time from end of take sample command to beginning of reply (seconds)

= (NCycles * 0.1336) + 0.459

Autonomous Sampling Mode

Autonomous Sampling Mode is in effect when:

•PCB J1 jumper is set to Normal or Autopower, AutoRun=Y, and

SingleSample=N, or

•PCB J1 jumper is set to Normal (pins 2 and 3), AutoRun=N,

SingleSample=N, and sampling is started with Go

Time to acquire temperature and conductivity (seconds)

= (NCycles * 0.1336) + 0.287

Serial Line Sync Mode

Serial Line Sync Mode is in effect when:

•PCB J1 jumper set to Normal (pins 2 and 3), AutoRun=Y, and

SingleSample=Y

Time from wake-up to beginning of reply (seconds)

= (NCycles * 0.1336) + 1.643

Total Sampling Time

Once temperature and conductivity are acquired, the time to calculate the

desired parameters is not a function of the mode of operation:

•Time to compute temperature = 8.8 msec

•Time to compute conductivity = 15.4 msec

•Time to compute salinity = 83 msec

•Time to compute sound velocity = 35 msec

Total time required for sample =

time to acquire temperature and conductivity

+ time to compute selected parameters

+ time to transmit computed parameters

Notes:

•The time to transmit computed

parameters is dependent on baud

rate. See Baud Rate, Cable

Length, Power, and Data

Transmission Rate.

•For autonomous sampling, if the

total time required for the sample

is greater than the user-input

sample interval (Interval=), the

MicroTSG begins the next sample

as soon as it finishes transmitting

the current sample.

Note:

See Command Descriptions in

Section 4: Setting Up MicroTSG

for descriptions of AutoRun=, Go,

SingleSample=, NCycles=, and

Interval=.

16

Section 2: Description of MicroTSG SBE 45

12

Baud Rate, Cable Length, Power, and Data Transmission Rate

Baud Rate, Cable Length, and Data Transmission Rate

The rate that data can be transmitted from the MicroTSG is dependent on the

amount of data to be transmitted per scan and the serial data baud rate:

Time to transmit data =

(number of characters * 10 bits/character) / baud rate

where

Number of characters is dependent on the included data and output

format (see Data Output Format in Section 4: Setting Up MicroTSG).

Add 2 to the number of characters shown in the output format, to

account for the carriage return and line feed at the end of each scan.

Include decimal points, commas, and spaces when counting the

number of characters.

Note that the MicroTSG transmits data after it has completed the previous

sample and before it starts the next sample. See Sample Timing above for

information on sampling time.

The length of cable that the MicroTSG can drive to transmit real-time data is

also dependent on the baud rate. The allowable combinations are:

Maximum Cable Length (meters) Maximum Baud

800 1200

400 2400

200 4800 (factory set default)

100 9600

50 19200

25 38400

Notes:

•Baud rate is set with Baud=.

•Real-time output rate is set

with Interval=.

•Output format is set with

OutputCond=, OutputSal=, and

OutputSV=.

See Command Descriptions in

Section 4: Setting Up MicroTSG for

command details.

Example –

What is the minimum transmission time over 100 m of cable with OutputCond=Y, OutputSal=Y, OutputSV=Y, and

OutputFormat=0?

With 100 meters of cable, the MicroTSG requires a baud rate of 9600 or less.

Number of characters (from Data Output Format in Section 4: Setting Up MicroTSG) =

8 (T) + 2 (comma & space) + 8 (C) + 2 (comma & space) + 8 (salinity) + 2 (comma & space) + 8 (sound velocity)

+ 2 (carriage return & line feed) = 40

Time required to transmit data = (40 characters * 10 bits/character) / 9600 = 0.042 seconds = 42 msec

What is the minimum total time required per sample (Interval=), if averaging 4 measurements/sample (NCycles=4)

and operating in Autonomous Sampling Mode?

In Autonomous mode, time to acquire T and C (from Sample Timing above)

= (NCycles * 0.1336) + 0.287 = (4 * 0.1336) + 0.287 = 0.82 seconds

Total sampling time

= time to acquire T and C + time to compute parameters (from Sample Timing above) + time to transmit data

= 0.82 + (.0088 + .0154 + .083 + .035) + .042 = 1.00 second

Therefore, set Interval=1, transmitting 1 sample every second.

17

Table of contents

Other Sea-Bird Electronics Measuring Instrument manuals