Introduction

DIAPERFEEDER IP54 - I.1 -

INTRODUCTION

Congratulations for choosing a BTSR product.

With our DIAPERFEEDER IP54 yarn feeding devices, you got an innovative,

unique solution able to offer you multiple advantages concerning quality of your

production.

The ideal solution to maintain the elastic yarn tension constant

The DIAPERFEEDER IP54 device comes from the experience built-up by BTSR in

the field of yarn feeling at constant tension.

The DIAPERFEEDER IP54 devices are in fact high precision measurement and

control instruments providing a real time display of the exact yarn tension and

guaranteeing, through an accurate adjustment, a constant tension feeding of the

yarn itself in every working condition.

Thanks to the IP54 protection degree, the device is able to work with critical

environmental conditions, like humidity, dustiness, etc.

The DIAPERFEEDER IP54 devices are fully programmable and can easily be

adapted to any kind of yarn or tension adjustment and to any operating speed of

the textile machine on which they are installed. Furthermore these devices are

manufactured using very high quality and precision electronic components which

guarantee an exact display of the yarn tension as well as an accurate real-time

control of the tension itself, exclusive characteristics of BTSR systems.

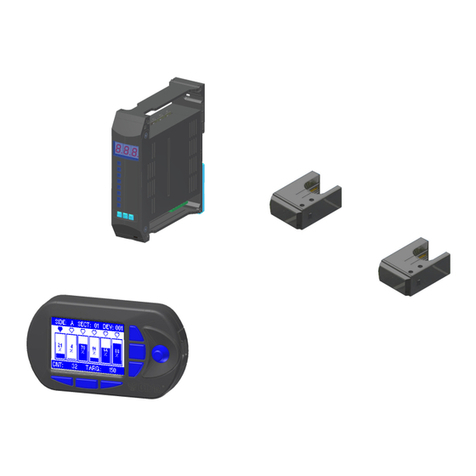

Thanks to its modularity characteristics, the DIAPERFEEDER IP54 device is

capable of managing not only the TS44.. tension sensor, but also the IS3F.. image

scanning sensor, thus allowing the user to obtain a complete quality control for

what concerns both the yarn tension and the correct yarn running condition.

DUOLOOP solution for automatic diaper production lines

Since, for space reason it is not always possible to install DIAPERFEEDER IP54

feeding devices on the exact application point of the elastic yarns along the

production line, an innovative solution based upon two independent (yet

interactive) tension control/adjustment systems has been developed:

•A first yarn tension control system at the application point, consisting of

TS55 sensors (BTSR Patent).

•A second yarn feeding tension control/adjustment system consisting of one

or more creels located at a certain distance from the actual elastic yarn

application point and based upon DIAPER FEEDER motor-driven devices

(BTSR Patent).

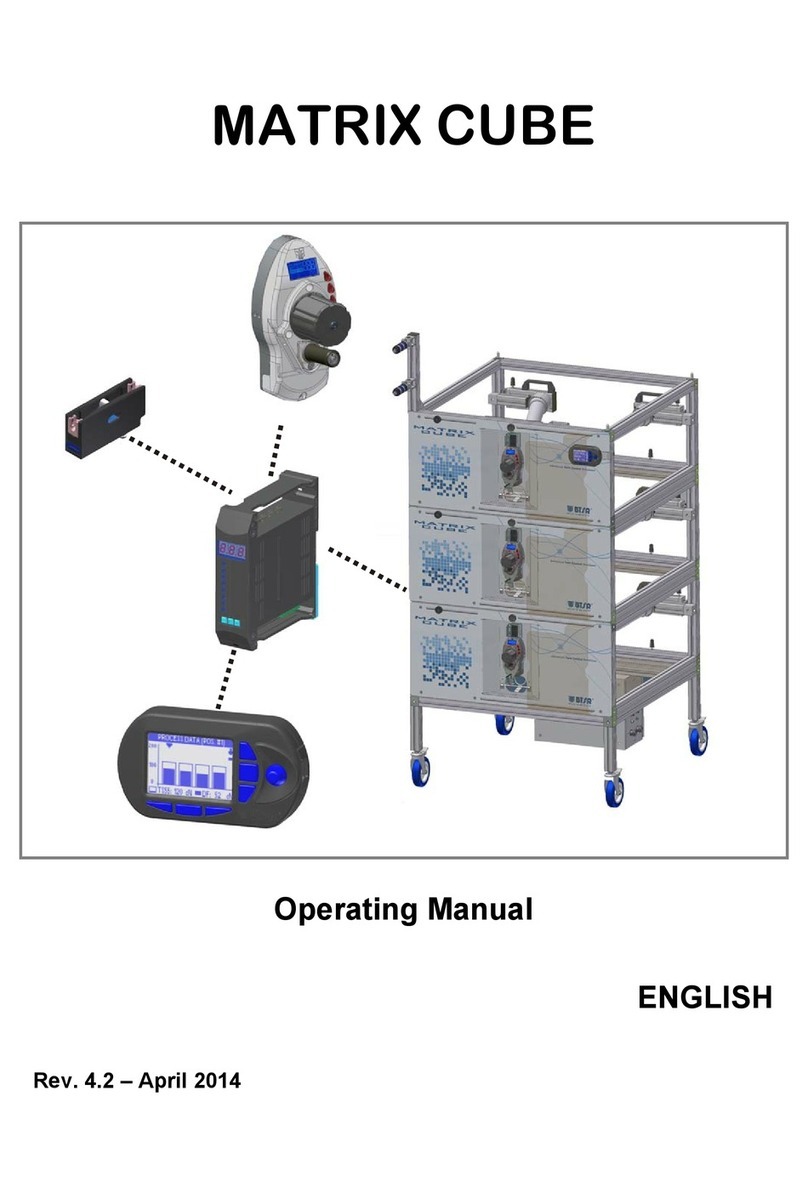

The two control systems are controlled and coordinated by a CPU consisting of a

SM-DIN/DUOLOOP/** Board capable of communicating both with the TS55..

sensors and with the DIAPER FEEDER devices via RS485 serial lines.

The control/adjustment parameters of TS55.. sensors and of DIAPER FEEDER

devices can be programmed through a SMART MATRIX BTSR terminal; or they

can be directly programmed from the production line control system by means of

field bus interface (PROFIBUS), through the SM-DIN/DUOLOOP control board.