Bendof DC-20MV User manual

DC-20MV

Instruction manual

Bruksanvisning

Brugsanvisning

Bruksanvisning

Käyttöohjeet

2

English

OPERATING/SAFETY ORIGINAL INSTRUCTIONS

DC20MV

CORDLESS REBAR CUTTER

TO REDUCE THE RISK OF INJURY, YOU MUST READ AND

UNDERSTAND THESE INSTRUCTIONS

3

English

CE DECLARATION OF CONFORMITY

We declare under our sole responsibility that these products are in conformity

with the following standards or standardized documents EN62841-1,

EN55014-1 and EN55014-2 in accordance with Council Directives 2006/42EC

and 2004/108/EC.

Model: DCC-2036BLH/DC20MV

Beskrivning: Cordless Rebar Cutter

Vibration Information

Vibration total values (triax vector sum) determined according to EN62841

Vibration emission value <2,5 m/s

Noise Information

The measured values were determined according to EN62841-1.

Measured A-weighted sound pressure level: 91.0 dB(A)

Measured A-weighted sound power level: 80.0 dB(A)

Uncertainty KpA: 1.971 dB(A)

24th February 2022

IKK Co., Ltd.

396-59 Ashitaka, Numazu City,

Shizuoka Pref. 410-0001 Japan

4

English

WARNING!

TO AVOID SEVERE PERSONAL INJURY OR PROPERTY DAMAGE, READ THESE

INSTRUCTIONS CAREFULLY BEFORE ATTEMPTING TO USE THE CUTTERS.

Ignorance of proper operating procedures can lead to accidents.

If in doubt about any procedure, contact your nearest authorized agent.

CONTENTS

GENERAL SAFETY RULES

PARTS NAMES

SPECIFICATIONS

OPERATING INSTRUCTIONS

BASIC CUTTING INSTRUCTIONS

PRE-USE CHECKS

CAUTION ON LI-ION BATTERY

BATTERY REMOVAL/INSTALLATION

CHARGING

WARM-UP

STOPPER BOLT ADJUSTMENT

CUTTING

RELEASE VALVE

POINTS OF ATTENTION

MAINTENANCE

CUTTER BLOCKS

CLEANING

OIL-LEVEL CHECK (ADDING OIL)

OIL CHANGE

BOLT TIGHTNESS

OVERHAUL

THESE TOOLS ARE FOR INDUSTRIAL USE ONLY.

*Specifications are subject to change without prior notice

5

7

8

8

8

8

9

9

10

12

12

13

13

13

14

14

14

14

15

15

15

PAGE

5

English

WARNING: READ AND UNDERSTAND ALL INSTRUCTIONS.

Failure to follow all instructions listed below may result in electric shock, fire and/or serious injury.

The term “power tool” in all of the warnings listed below refers to your mains-operated (corded)

power tool or battery-operated (cordless) power tool.

WORK AREA SAFETY

- Keep work area clean and well lit. Cluttered or dark areas invite accidents.

- Do not operate power tools in explosive atmospheres, such as in the presence of

flammable liquids, gases or dust. Power tools create sparks which may ignite the dust

or fumes.

- Keep children and bystanders away while operating a power tool. Distractions can

cause you to lose control.

ELECTRICAL SAFETY

- Power tools plugs must match the outlet. Never modify the plug in any way. Do not

use any adapter plugs with earthed (grounded) power tools. Unmodified plugs and

matching outlets will reduce risk of electric shock.

- Avoid body contact with earthed or grounded surfaces such as pipes,

radiators, ranges and refrigerators. There is an increased risk of electric shock if your

body is earthed or grounded.

- Do not expose power tools to rain or wet conditions. Water entering a power tools will

increase the risk of electric shock.

- Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the

power tool. Keep cord away from heat, oil sharp edges or moving parts. Damaged or

entangled cords increase the risk of electric shock.

- When operating a power tool outdoors, use an extension cord suitable

for outdoor use. Use of a cord suitable for outdoor use reduces the risk of

electric shock.

- Do not use AC only rated tools with a DC power supply.

PERSONAL SAFETY

- Stay alert, watch what you are doing and use common sense when operating a power

tool. Do not use a power tool while you are tired or under the influence of drugs,

alcohol or medication. A moment of inattention while operating power tools may result

in serious personal injury.

- Use safety equipment. Always wear eye protection. Safety equipment such as

protection goggles, dust mask, non-skid safety shoes, hard hat, or hearing protection

used for appropriate conditions will reduce personal injuries.

- Avoid accidental starting. Ensure the switch is in the off-position before plugging in.

Carrying power tools with your finger on the switch or plugging in power tools that have

the switch on invites accidents.

- Remove any adjusting key or wrench before turning the power tool on. A wrench or a

key left attached to a rotating part of the power tool may result in personal injury.

- Do not overreach. Keep proper footing and balance at all times. This enables better

control of the power tool in unexpected situations.

- Dress properly. Do not wear loose clothing or jewelry. Keep your hair, clothing and

gloves away from moving parts. Loose clothes, jewelry or long hair can be caught in

moving parts.

- If devices are provided for the connection of dust extraction and collection facilities,

ensure these are connected and properly used. Use of these devices can reduce

dust-related hazards.

- Keep handles dry, clean and free from oil and grease. Slippery hands can not safely

control the power tool.

GENERAL SAFETY RULES

6

English

POWER TOOL USE AND CARE

- Do not force the power tool. Use the correct power tools for your application.

The correct power tool will do the job better and safer at the rate for which it was

designed.

- Do not use the power tool if the switch does not turn on and off. Any power tool that

cannot be controlled with the switch is dangerous and must be repaired.

- Disconnect the plug from the power source and/or the battery pack from the power tool

before making any adjustments, changing accessories, or storing power tools. Such

preventive safety measures reduce the risk of starting the power tool accidentally.

- Do not cover the power tool’s air vents nor operate the tool on dirt. Use a plywood base

under the tool to keep armature and fan clean. If the vents are covered, the motor will

overheat and may burn out.

- Store idle power tools out of the reach of children and do not allow persons unfamiliar

with the power tool or these instructions to operate the power tool. Power tools are

dangerous in the hands of untrained users.

- Maintain power tools. Check for misalignment or binding of moving parts, breakage of

parts and any other condition that may affect the power tool’s operation. If damaged,

have the power tool repaired before use. Many accidents are caused by poorly

maintained power tools.

- Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp

cutting edges are less likely to bind and are easier to control.

- Use the power tool, accessories and tool bits etc., in accordance with these

instructions and in the manner intended for the particular type of power tool, taking into

account the working conditions and the work to be performed. Use of the power tool

for operations different from those intended could result in a hazardous situation.

BATTERY TOOL USE AND CARE

- Recharge only with the charger specified by the manufacture. A charger that is

suitable for one type of battery pack may create a risk of fire when used with another

battery pack.

- Use power tools only with specifically designated battery packs. Use of any other

battery packs may create a risk of injury and fire.

- When battery pack is not in use, keep it away from other metal objects, like paperclips,

coins, keys, nails, screws or other small metal objects, that can make a connection

from one terminal to another. Shorting the battery terminals together may cause burns

or a fire.

- Under abusive conditions, liquid may be ejected from the battery; avoid contact.

If contact accidentally occurs, flush with water. If liquid contacts eyes, additionally seek

medical help. Liquid ejected from the battery may cause irritation or burns.

- Do not use a battery pack or tool that is damaged or modified. Damaged or modified

batteries may exhibit unpredictable behavior resulting in fire, explosion or risk of injury.

- Do not expose a battery pack or tool to fire or excessive temperature. Exposure to fire

or temperature above 130°C may cause explosion.

- Follow all charging instructions and do not charge the battery pack or tool outside the

temperature range specified in the instructions. Charging improperly or at

temperatures outside the specified range may damage the battery and increase the

risk of fire.

7

English

SERVICE

- Have your power tool serviced by a qualified repair person using only identical

replacement parts. This will ensure that the safety of the power tool is maintained.

- Never service damaged battery packs. Service of battery packs should only be

performed by the manufacturer or authorized service providers.

SPECIFIC SAFETY RULES

- Hold power tool by insulated gripping surfaces when performing an operation where

the cutting tool may contact hidden wiring or its own cord. Contact with a “live” wire will

make exposed metal parts of the tool “live” and shock the operator.

- Use clamps or other practical ways to secure and support the workpiece to a stable

platform. Holding the work by hand or against your body is unstable and may lead to

loss of control.

- Never leave the trigger locked ”ON”. Before plugging the tool in, check that the trigger

lock is ”OFF”. Accidental start-ups could cause injury.

- Keep hands away from the cutting area and moving parts.

- Do not use dull or damaged blades. Damaged part(s) can break easily or could cause

injury.

- Maintain labels and nameplates.

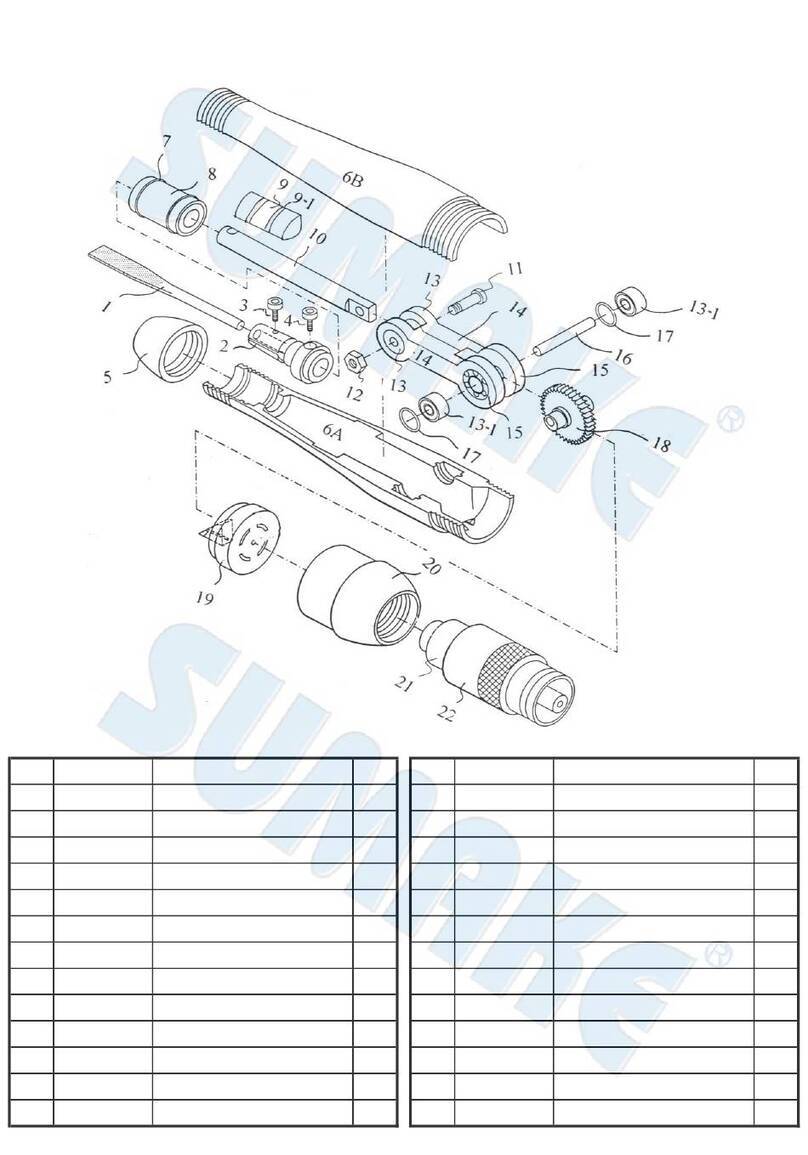

360° Rotatable between pump, case and motor

1. Housing

2. Cutter blocks

3. Switch

4. Oil-plug

5. Release valve

6. Motor

7. Pump case

8. Handle (detachble)

9. Battery

10. Piston

PARTS NAMES

1.

8.

2.

7.

6.

9.

3.

5.

4.

10.

2.

1.

8

English

Model DC20MV

Cutting capacity Up to 20mm (3/4”) diameter

Cutting speed ≥ 4.0 sec. (20mm)

Max. Rebar hardness Tensile strength 490N/mm2

Power Supply Rechargeable battery

Voltage DC36V

Dimensions (LxWxH) 387x103x274 mm (without handle)

Weight 9,3 kg (including battery)

Battery (Li-ion Multi Volt) BSL36A18 : DC36V-2.5Ah / 18V-5.0Ah

Charger UC18YSL3

Charging Time Approx. 32 min.

Battery & Charger (HiKOKI)

OPERATING INSTRUCTIONS

SPECIFICATIONS

BASIC CUTTING INSTRUCTIONS

Important: Always read, understand and obey the safety instructions included with your new

Cordless Rebar Cutters before operating. Use Rebar Cutters on concrete reinforcing bars only.

These tools are not to be used in cutting other kinds of metal or materials. Do not cut ungraded

rebar.

WARNING: There is always a chance that the cut end may shoot out, especially if less than

30 cm in length. Exceeding designated material specifications will greatly increase this risk and

will also damage the tool. Do not attempt to cut rebar harder, thicker or thinner than specified for

the specific tool.

DO NOT CUT SHORT PIECES: Be especially careful when cutting off short lengths (30 cm or less) as

the cut end tends to fly out.

PRE-USE CHECKS

1. WARNING: Do not expose the tool to rain or wet conditions. Water entering a power

tools will increase the risk of electric shock.

2. WARNING: Wear safety goggles, safety glasses with side shields or a face shield when

using these tools.

3. Check that the power source is appropriate to the tool.

CARE: If voltage is too high, the motor will burn out. If voltage is too low, insufficient

power will be generated. Use rechargeable battery BSL36A18/BSL36B18.

4. WARNING: Avoid accidental starting. Ensure the switch is in the off-position before

battery attached.

5. Note that battery must be charged before initial use (see p.10 CHARGING).

6. Check and keep work area clean and enough work space.

9

English

7. Check condition of cutter blocks and tightness of cutter block bolts.

CHECK FOR CRACKS OR DAMAGE, LOOSEN BOLTS

8. Before using, always check that the two bolts on each cutter block are properly

tightened. Using a loose block will result in damage to block and housing. Also check

condition of cutter blocks. If either cutting edge is dull or chipped, remove retaining

bolts and rotate both blocks so that two new edges come into use. Replace and

tighten bolts (Each block has four cutting edges). When all four cutting edges have

been used or if either block is cracked or otherwise damaged, replace both blocks.

CAUTION: A loose or cracked block may result in injury to operator.

CAUTION ON LITHIUM-ION BATTERY

To extend the lifetime, lithium-ion battery equips with the protection to stop the output. In the case

of 1 to 3 described below, when using the tools, even if you are pulling switch, the motor may

stop. This is not the trouble but the result of protection function.

1. When the battery power remaining runs out, the motor stops. In such case, charge it

up immediately.

2. If the tool is overloaded, the motor may stop. In this case, release the switch of the tool

and eliminate causes of overloading. After that, you can use it again.

3. If the battery is overheated under overloaded work, the battery power may stop. In this

case, stop using the battery and let the battery cool. After that, you can use it again.

4. Never short-circuit the battery.

Furthermore, please heed the following warning and caution.

BATTERY REMOVAL/INSTALLATION

1. Battery removal

Hold the handle tightly and push the battery latches to remove the battery.

2. Battery installation

Insert the battery while observing its polarities.

10

English

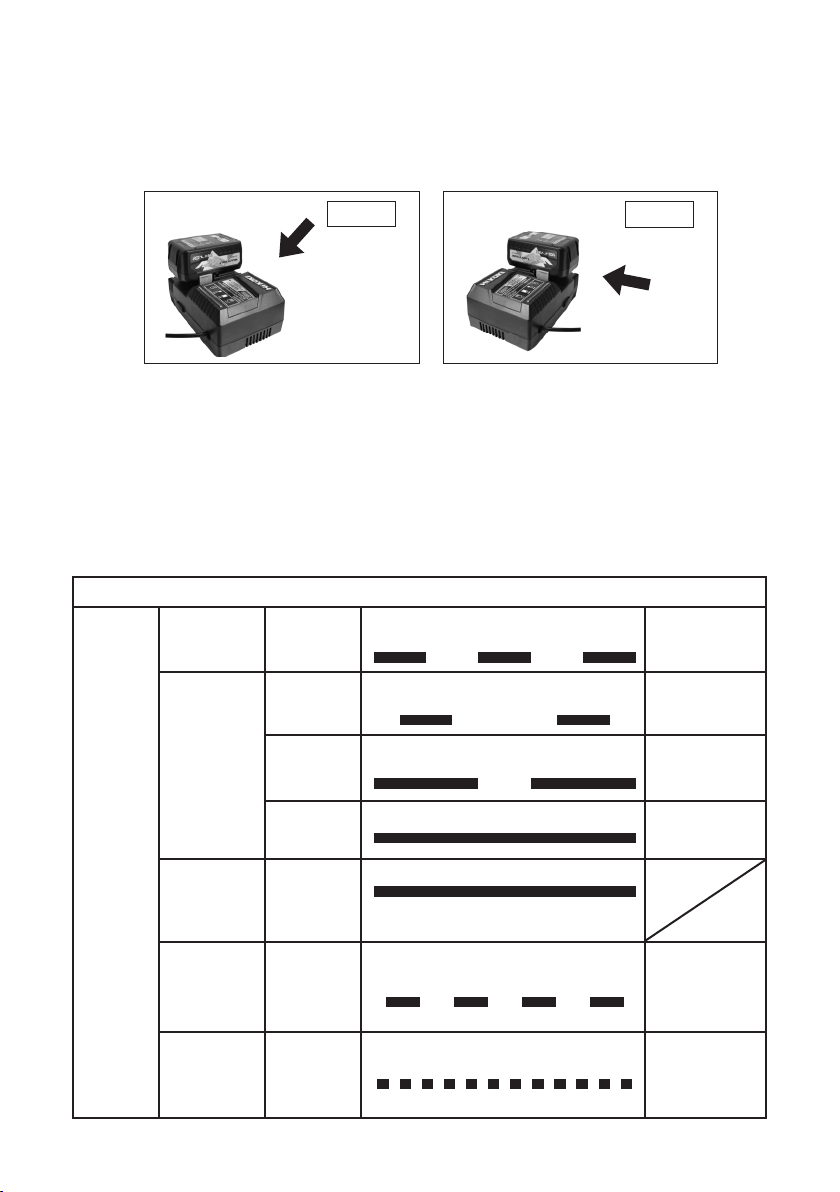

CHARGING (Charger: UC18YSL3)

Before using the tool, charge the battery as follows.

1. Connect the charger’s power cord to a receptacle. When the power cord is connected,

the charger’s pilot lamp will blink in red (At 1-second intervals).

2. Firmly insert the battery into the charger.

3. When inserting a battery in the charger, the charge indicator lamp will blink in blue.

When the battery becomes fully recharged, the charge indicator lamp will light up in

green.

(1) Charge indicator lamp indication

The indications of the charge indicator lamp will be as shown in table below, according

to the condition of the charger or the rechargeable battery.

INSERT

CHARGER

INSERT

CHARGER

BATTERY

Indications of the charge indicator lamp

Charge

indicator lamp

(RED/ BLUE/

GREEN/

PURPLE)

Before charging Blinks

(RED)

Lights for 0,5 seconds. Does not light for 0,5 sec.

(Off for 0,5 sec.) Plugged

into power source

While

charging

Blinks

(BLUE)

Lights for 0,5 seconds. Does not light for 1 sec.

(Off for 1 sec.) Battery

capacity at less than

50%

Blinks

(BLUE)

Lights for 1 second. Does not light for 0,5 sec.

(Off for 0,5 sec.) Battery

capacity at less than

80%

Lights

(BLUE)

Lights continuously Battery

capacity at more than

80%

Charging

complete Lights

(GREEN)

Lights continuously

(Continuous buzzer sound:

about 6 seconds)

Overheat standby Blinks

(RED)

Lights for 0,3 seconds. Does not light for 0,3 sec.

(Off for 0,3 sec.) Battery

overheated. Unable

to charge. (Charging

will commence when

battery cools.)

Charging

impossible Flickers

(PURPLE)

Lights for 0,1 seconds. Does not light for 0,1 sec.

(Off for 0,1 sec.)

(Intermittent buzzer sound: about 2 seconds)

Malfunction in the

battery or the charger

11

English

(2) Regarding the temperatures of the rechargeable battery. The temperatures for

rechargeable batteries are between 0°C ~ 50°C, and batteries that have become hot

should be cooled for a while before being recharged.

(3) Recharging time (At 20°C)

Approx. 32 minutes (BSL36A18), but the charging time may vary according to the

ambient temperature.

4. Disconnect the charger’s power cord from the receptacle.

5. Hold the charger firmly and pull out the battery.

NOTE: After operation, pull out batteries from the charger first, and then keep the

batteries properly.

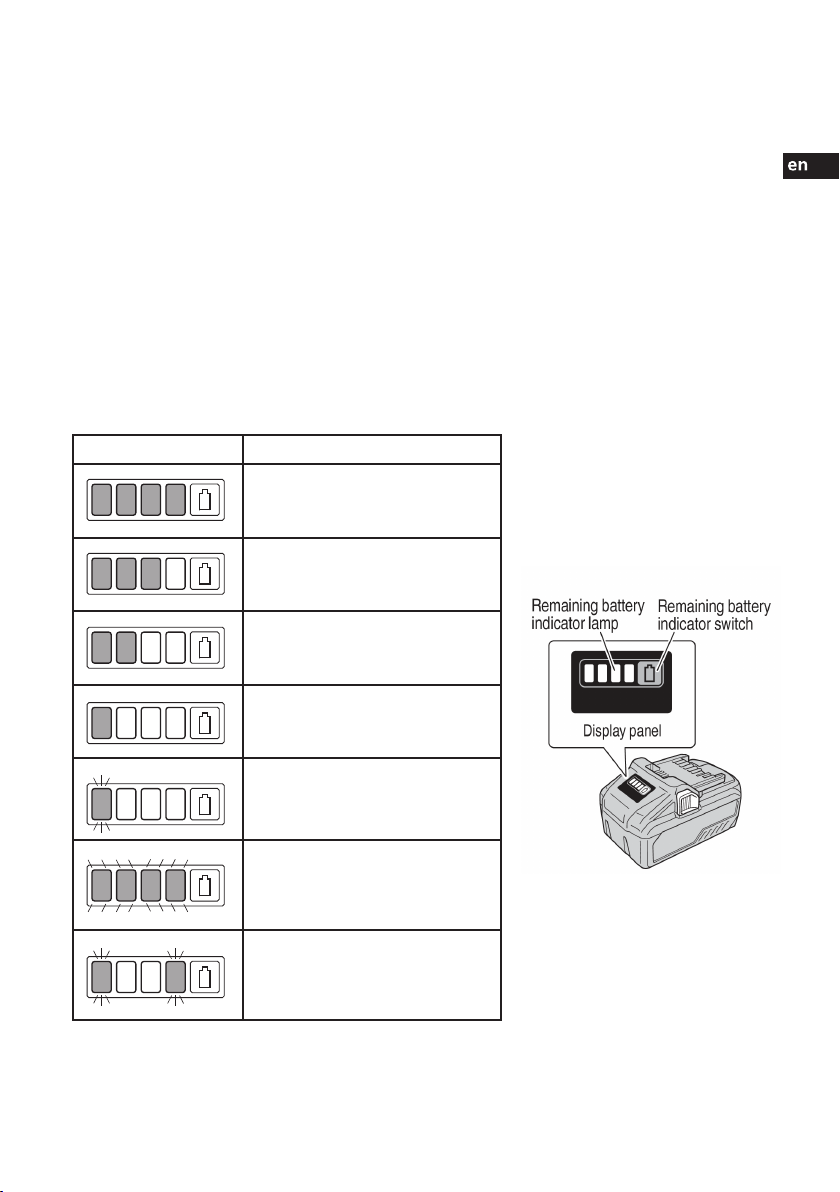

6. About remaining battery indicator

When pressing the remaining battery indicator switch to light the indicator lamp, the

indicator will shut off approximately 3 seconds. It is best to use the remaining battery

indicator as a guide since there are slight differences such as ambient temperature

and the condition of the battery.

State of lamp Battery Remaining Power

Lights:

The battery remaining power is over 75%.

Lights:

The battery remaining power is 50-75%.

Lights:

The battery remaining power is 25-50%.

Lights:

The battery remaining power is less than

25%.

Blinks:

The battery remaining power is nearly

empty. Recharge the battery soonest

possible.

Blinks:

Output suspended due to high temperature.

Remove the battery from the tool and allow

it to fully cool down.

Blinks:

Output suspended due to failure or mal-

function. The problem may be the battery,

please contact your dealer.

12

English

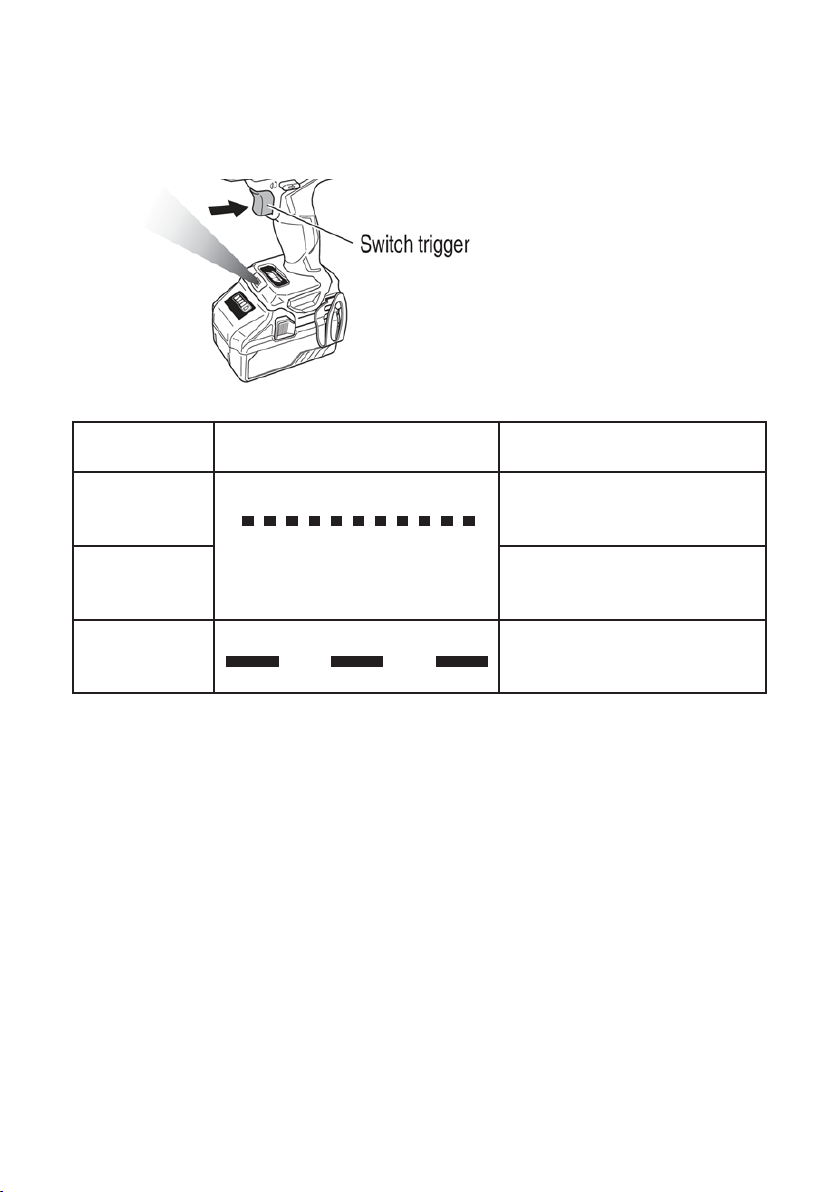

Safeguard

Function LED Light Display Corrective Action

Overburden

Protection

On 0,1 second/off 0,1 second If the operating with the shift knob set on

HIGH, adjust to LOW and continue operation.

Remove the cause of the overburdening.

Reactive Force

Control

Remove the cause of the over

burdening. When operating the tool, firmly

hold the tool to make sure it doesn’t jerk.

Temperature

Protection

On 0,5 second/off 0,5 second

Allow the tool and battery thoroughly cool.

7. How to use the LED light

While the switch is pulled, the LED light will automatically light up the tip portion of the

tool. The LED light will automatically turn off 10 seconds after the switch is released.

The LED light also functions as a warning signal that lights up during use.

WARM-UP

If in cold weather, you should warm up the tool for 30-60 seconds so that the hydraulic oil

reaches the proper viscosity. Pull trigger-switch (ON) to extend piston then release the switch

(OFF) when it has reached its full stroke. Repeat 5-7 times without rebar.

STOPPER BOLT ADJUSTMENT

The adjustable stopper functions to maintain the rebar in the correct position during cutting and

must be properly set for each size of rebar before making a cut. Screw in the stopper to provide

sufficient clearance for the rebar. Keeping rebar at right angles (90 degrees) to front cutter block,

screw out the stopper until it is just touching the rebar. Once set, the stopper needs no further

adjustment while cutting rebar of the same diameter, but must be reset for a different size rebar.

WARNING: Failure to correctly set the stopper will result in excessive wear of cutter blocks and

may cause cut end to fly out.

13

English

Release value

WARNING: Failure to correctly set the stopper

will result in excessive wear of cutter blocks

and may cause cut end to fly out.

RELEASE VALVE

In the event that piston should fail to return

automatically for any reason (e.g. the piston

has become jammed by some reasons), use

4 mm hexagon key provided to slightly loosen

release valve. Make sure to tighten the release

valve before making the next cut.

CUTTING

1. Insert rebar between stopper bolt and front cutter block, making sure that it is

properly seated in U-shaped support. Keeping rebar at right angles (90 degrees) to

front cutter block.

2. WARNING: Flying ends are a hazard to all personnel in the vicinity. Erect safety screens.

3. Pull trigger-switch and keep depressed while piston advances and rebar is cut (If the

switch is released at an intermediate point, the piston will stop).

4. When cut is completed, release the switch. The piston retracts automatically (Note that

the switch cannot be re-activated until the piston has fully retracted).

POINTS OF ATTENTION

1. Be especially careful when cutting off short lengths (30cm or less) as the cut end tends

to fly out.

WARNING: Flying ends are a hazard to all personnel in the vicinity. Erect safety screens.

2. Do not cover air vents.

CARE: If vents are covered, motor will overheat and may burn out.

3. If hydraulic oil exceeds 70 degrees C (158 degrees F) in temperature, power will drop.

Allow the tool to cool before resuming operation. Be particularly careful in summer

when the aluminum pump case heats up quicker.

4. If a drop in power is observed and motor is unusually hot, check battery.

5. If piston should ever fail to retract completely, push rear cutter block backwards to

manually retract piston or check under piston to remove any debris keeping the piston

from retracting.

CAUTION: Use a rebar or flat metal bar for this purpose.

Never push cutter block with any part of the hand, even if gloved. Once piston has

been retracted, pull trigger-switch long enough to partially advance the piston.

Disconnect battery. Check piston and housing for accumulated dirt and iron filings that

may be jamming the piston (See p.14 CLEANING). If, after cleaning, the piston still

does not automatically retract when fully extended, the piston itself may be damaged.

Return the tool to an authorized repair center.

6. Check that power source is appropriate to the tool.

CARE: If voltage is too high, the motor will burn out. If voltage is too low, insufficient

power will be generated. Use rechargeable battery BSL36A18/BSL36B18.

Rebar

Adjustable

stopper Cutter

blocks

14

English

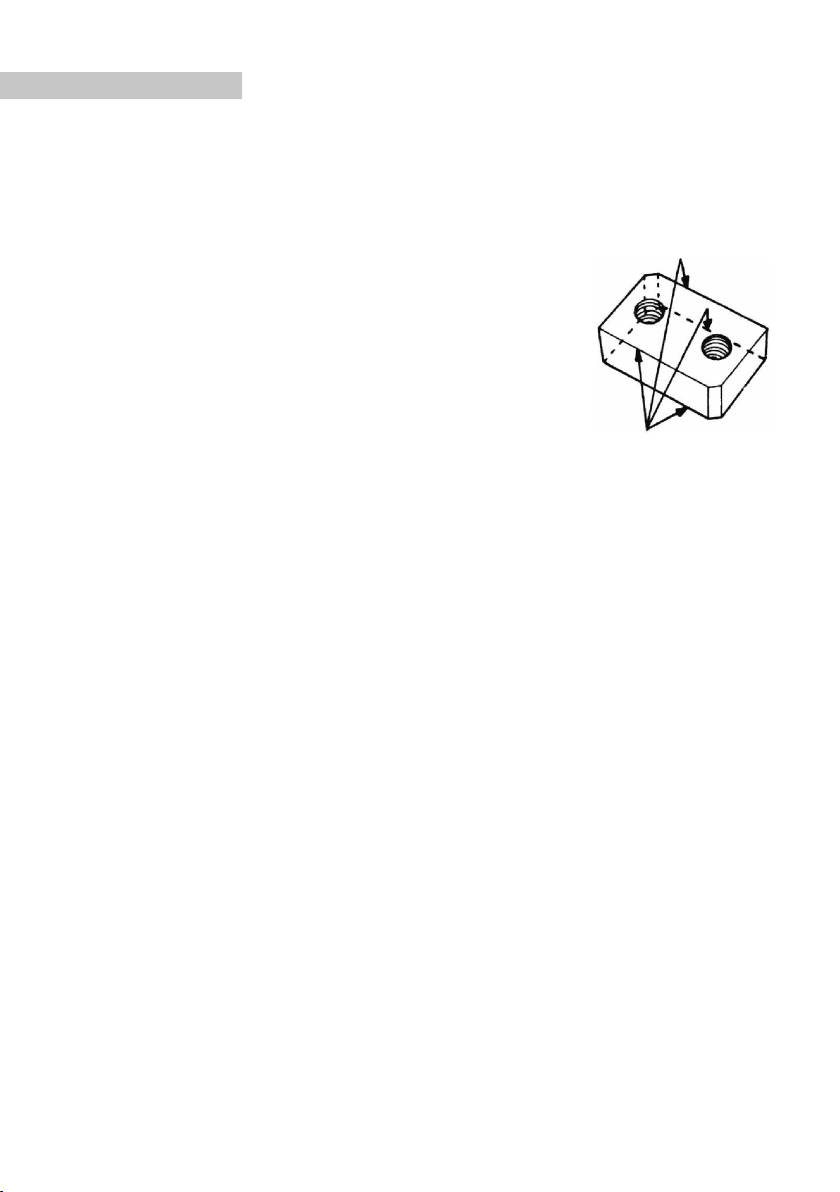

CUTTER BLOCKS

Before using, always check that the two bolts on each cutter block are

properly tightened. Using a loose block will result in damage to block

and housing. Also check condition of cutter blocks. If either cutting

edge is dull or chipped, remove retaining bolts and rotate both blocks

so that two new edges come into use. Replace and tighten bolts

(Each block has four cutting edges). When all four cutting edges have

been used or if either block is cracked or otherwise damaged, replace

both blocks.

CAUTION: A loose or cracked block may result in injury to operator.

CLEANING

Clean your tool every day, preferably immediately after use.

CAUTION: Wear gloves to protect hands from metal splinters. Do not use

an air gun: blasting with air can cause metal filings and/or dust to get

into eyes and respiratory system. Wipe or brush away all dirt and metal

filings.

WARNING: DISCONNECT BATTERY before performing any maintenance.

OIL-LEVEL CHECK (ADDING OIL)

As the cutters are hydraulically operated, the oil-level must be checked at frequent intervals,

preferably every day. Failure to maintain the oil at the proper level results in a drop in pressure

and loss of cutting power.

CAUTION: Hydraulic oil is highly flammable. Keep away from sparks and naked flame. Do not

smoke. Hydraulic oil may cause inflammation of the eyes and skin. If ingested, it could cause

diarrhea and vomiting. In case of eye contact, rinse in clean water for at least 15 minutes and

consult a physician. In case of skin contact, wash thoroughly with soap and water. In case of

ingestion, consult a physician immediately. Do not induce vomiting.

1. Oil should be warm but not hot. Warm up the tool if it is cold.

2. If piston is still moving, pinch a piece of rebar, stopping just before it breaks off (It is a

1/2 movement of piston).

3. Disconnect battery and place the tool so that the oil-plug is uppermost.

4. Remove oil-plug and seal washer (packing).

CAUTION: Never remove oil-plug when the tool is hot or oil will spurt out.

5. Check that oil is level with bottom of plug hole (i.e. that pump case is full to the brim).

If oil level is too low, top up with fresh hydraulic oil with anti foam and anti-abrasion

properties (ISO viscosity grade VG32, e.g. Tellus 32 (Shell), DTE-24 (Mobil) or

Uni-Power VG32 (Esso).

6. After topping up, extract air from the system. Gently tilt the tool lengthwise and return it

to a level position. Top up again and tilt in the opposite direction. Repeat this process

until all air has been extracted.

CARE: Tool cannot function properly if oil contains air bubbles.

7. Replace seal washer (packing) and oil-plug. The operation is now complete.

MAINTENANCE

15

English

OIL CHANGE

The hydraulic oil should be changed at least once a year, sooner if it appears dirty.

NOTE: Hydraulic oil should be warm before draining.

1. Disconnect battery. Remove oil-plug and seal washer (packing). Turn the tool over and

drain oil into a suitable receptacle. When oil ceases to drain out, tilt the tool to rear so

that oil trapped in piston housing can run out. When housing is empty, tilt the tool in the

opposite direction to empty the residue in pump case.

2. With drain-hole uppermost, slowly fill the tool with fresh oil. Replace plug and lightly

tighten. Connect battery and advance piston two or three times. Disconnect battery

and remove oil-plug. Top up oil level and replace oil-plug.

3. Finally, follow procedure for OIL-LEVEL CHECK (Steps 2-6)

NOTE: Dispose of hydraulic oil in accordance with local regulations. Do not pour into

the sea, a river, a lake of drains.

BOLT TIGHTENESS

Once a week, or after every 500 cuts, check the tightness of all bolts; especially, those bolts

securing the housing to the cylinder. Loose bolts will result in a loss of power. Always make sure

that the bolts holding both cutter blocks are also tight.

OVERHAUL

Return the tool to an authorized distributor for overhaul at least once every two years, sooner if

subject to heavy use.

16

Svenska

ORIGINAL BRUKS-/SÄKERHETSANVISNINGAR

DC20MV

BATTERIDRIVEN ARMERINGSKLIPPARE

FÖR ATT MINSKA RISKEN FÖR SKADOR SKA DU FÖRST LÄSA

OCH FÖRSTÅ DESSA INSTRUKTIONER

17

Svenska

sv

VARNING!

FÖR ATT UNDVIKA ALLVARLIGA PERSON- ELLER SAKSKADOR SKA BRUKSANVISNINGEN

LÄSAS IGENOM NOGA INNAN VERKTYGET ANVÄNDS.

Om inte anvisningarna följs kan det leda till olyckor.

Kontakta närmaste auktoriserad återförsäljare om det är något du undrar över.

INNEHÅLL

ALLMÄNNA SÄKERHETSBESTÄMMELSER

DELARNAS NAMN

SPECIFIKATIONER

BRUKSANVISNINGAR

GRUNDLÄGGANDE KLIPPANVISNINGAR

KONTROLLER FÖRE ANVÄNDNING

ATT TÄNKA PÅ RÖRANDE LI-ION-BATTERI

BORTTAGNING/INSTALLATION AV BATTERI

LADDNING

UPPVÄRMNING

INSTÄLLNING AV STÄLLSKRUV

KLIPPNING

IMPULSVENTIL

ATT OBSERVERA

UNDERHÅLL

KLIPPHUVUD

RENGÖRING

KONTROLL AV OLJENIVÅ (PÅFYLLNING)

OLJEBYTE

ÅTDRAGNING AV SKRUVAR

SERVICE

DESSA VERKTYG ÄR ENDAST AVSEDDA FÖR PROFESIONELL ANVÄNDNING.

*Specifikationer kan ändras utan föregående meddelande.

18

20

21

21

21

21

22

22

23

25

25

26

26

26

27

27

27

27

28

28

28

Sida

18

Svenska

VARNING! LÄS OCH FÖRSTÅ ALLA ANVISNINGAR.

Om nedanstående instruktioner inte följs kan det medföra elstöt, brand och/ eller allvarlig person-

skada. Termen ”elverktyg” i varningarna nedan syftar på ditt nätanslutna (med sladd) elverktyg

eller batteridrivna (sladdlösa) elverktyg.

SÄKERHET PÅ ARBETSPLATSEN

- Håll arbetsplatsen ren och väl upplyst. Röriga eller mörka platser inbjuder till olyckor.

- Använd inte elverktyg i explosiv miljö, t.ex. i närheten av lättantända vätskor, gaser eller

damm. Elverktyg genererar gnistor som kan antända damm eller ångor.

- Håll barn och åskådare på avstånd när elverktyget används. Om du blir distraherad

kan du förlora kontrollen.

EL-SÄKERHET

- Elverktygets stickkontakt måste passa uttaget. Stickkontakten får inte modifieras på

något sätt. Använd inte adapterkontakter tillsammans med (jordade) elverktyg. Stick-

kontakt i originalutförande och passande uttag minskar risken för elektriska stötar.

- Undvik kroppskontakt med jordade ytor som t.ex. rör, element, spisar och kylskåp.

Risken för elstötar ökar om du är jordad.

- Utsätt inte elverktyg för regn eller väta. Vatten som tränger in i elverktyget ökar risken

för elektriska stötar.

- Var rädd om elkabeln. Använd aldrig elkabeln för att dra ut stickkontakten eller för att

bära/dra verktyget. Skydda elkabeln från värme, oljor, vassa kanter eller rörliga delar.

Skadade eller intrasslade elkablar ökar risken för elektriska stötar.

- Använd en förlängningssladd som är avsedd för utomhusbruk när elverktyget

används utomhus. Risken för elstötar minskar om man använder kabel som är avsedd

för utomhusbruk.

- Använd inte likströmsbaserad strömförsörjning till verktyg som endast är avsedda för

växelström.

PERSONSÄKERHET

- Var uppmärksam, tänk på vad du gör och använd sunt förnuft när du ar- betar med ett

elverktyg. Använd inte elverktyg när du är trött eller påverkad av droger, alkohol eller

mediciner. Ett ögonblicks ouppmärksamhet kan leda till allvarliga personskador.

- Använd säkerhetsutrustning. Använd alltid skyddsglasögon. Skydds- utrustning som

t.ex. skyddsglasögon, andningsmask, halksäkra skyddsskor, hjälm eller hörselskydd

minskar risken för personskador.

- Undvik oavsiktlig start. Kontrollera att strömbrytaren är avstängd innan du ansluter

verktyget. Det inbjuder till olyckor att bära elverktyg med fingret på avtryckaren eller att

ha det tillslaget när spänningen kopplas in.

- Ta bort eventuellt justeringsverktyg eller skruvnycklar innan elverktyget startas.

En skruvnyckel eller liknande som lämnas kvar i en roterande del av elverktyget kan

förorsaka personskada.

- Sträck dig inte för långt. Behåll alltid balansen och stå stadigt på fötterna. Då har du

bättre kontroll över elverktyget i oväntade situationer.

- Bär lämplig klädsel. Bär inte löst hängande plagg eller smycken. Håll hår, kläder och

handskar borta från rörliga delar. Lösa kläder, smycken eller långt hår kan fastna i

rörliga delar.

- Se till att tillbehör för uppsamling och utsug av damm ansluts och används på rätt sätt.

Dessa hjälpmedel kan minska dammrelaterade skador.

- Håll alltid handtagen torra, rena och fria från olja och fett. Hala händer/ handtag gör

det omöjligt att ha kontroll över elverktyget.

ALLMÄNNA SÄKERHETSBESTÄMMELSER

19

Svenska

sv

ANVÄNDING OCH VÅRD AV ELVERKTYG

- Överbelasta inte elverktyget. Använd rätt elverktyg för det aktuella arbetet. Rätt elverk

tyg gör jobbet bättre och säkrare, i den hastighet som det har konstruerats för.

- Använd inte elverktyget om verktyget inte kan styras via strömbrytaren. Elverktyg som

inte kan manövreras med strömbrytaren är farliga och måste repareras.

- Ta ur stickkontakten från strömkällan och/eller batteriet från elverktyget innan du gör

några justeringar, byter tillbehör eller lägger undan elverkty- get. Sådana förebyggan

de säkerhetsåtgärder minskar risken för att verkty- get startar oavsiktligt.

- Täck inte över elverktygets luftventiler, använd inte verktyget direkt på marken. Placera

ett stöd av plywood under verktyget för att hålla beslag och fläkt rena.

Om ventilöppningarna täcks igen överhettas motorn och kan skadas.

- Förvara elverktyg som inte används utom räckhåll för barn och låt inte personer som

inte är bekanta med elverktyg eller dessa instruktioner använda elverktyget. Elverktyg

är farliga i händerna på ovana användare.

- Underhåll elverktygen. Kontrollera om rörliga delar är fel uppriktade eller kärvar, om

några delar är trasiga eller om det är några andra förhållanden som kan påverka

elverktygets funktion. Reparera ett skadat elverktyg innan det används. Många olyckor

orsakas av dåligt underhållna elverktyg.

- Håll skärande verktyg skarpa och rena. Riktigt underhållna skärverktyg med skarpa

skärkanter löper mindre risk att kärva och är lättare att kontrollera.

- Använd elverktyg, tillbehör och verktygsdelar etc. i enlighet med dessa instruktioner

och på sådant sätt som är avsett, med hänsyn tagen till arbetsförhållandena och det

arbete som ska utföras. Användning av elverktyg för andra arbeten än de som

verktygen är konstruerade för kan leda till farliga situationer.

ANVÄNDNING OCH VÅRD AV BATTERIVERKTYG

- Ladda endast med den laddare som tillverkaren har angett. En laddare som är lämplig

för en typ av batteri kan utgöra en risk för brand om den används med ett annat batteri.

- Använd endast el-verktyg med specifikt avsedda batterier. Användning av andra

batterier kan utgöra en risk för personskador och brand.

- När batteriet inte används ska det förvaras på avstånd från andra metall- föremål, till

exempel gem, mynt, nycklar, spik, skruvar eller andra små metallföremål som kan

skapa en förbindelse mellan polerna. Om batteripolerna kortsluts kan det orsaka

brännskador eller brand.

- Vid felaktiga förhållanden kan vätska läcka ut från batteriet. Undvik kontakt. Spola

genast med vatten vid oavsiktlig kontakt med batterivätska. Om vätskan kommer i

kontakt med ögonen ska läkare genast uppsökas. Vätska som läcker ut från batteriet

kan orsaka irritation eller brännskador.

- Använd inte ett batteri eller verktyg som är skadat eller modifierat. Skadade eller

modifierade batterier kan uppvisa oförutsägbart beteende och kan orsaka brand,

explosion eller risk för personskador.

- Utsätt inte ett batteri eller verktyg för eld eller hög temperatur. Exponering för eld eller

temperaturer över 130°C kan orsaka explosion.

- Följ alla laddningsanvisningar och ladda inte batteriet eller verktyget utanför det

temperaturintervall som anges i bruksanvisningen. Felaktig laddning eller laddning vid

temperaturer utanför det specificerade intervallet kan skada batteriet och öka

brandrisken.

20

Svenska

SERVICE

- Serva ditt elverktyg hos en auktoriserad reparatör, som endast använder

originalreservdelar. Därmed säkerställs det att elverktygets säkerhet upprätthålls.

- Utför aldrig service på skadade batterier. Service av batteripaket får endast utföras av

tillverkaren eller auktoriserad serviceleverantör.

SÄRSKILDA SÄKERHETSREGLER

- Håll verktyget i de isolerade handtagen om du utför arbete där det finns risk för att

skärverktyget kommer i kontakt med dolda ledningar eller den egna elkabeln. Kontakt

med spänningsförande ledningar innebär att verktygets nakna metalldelar blir

strömförande och ger elektriska stötar.

- Använd tvingar eller andra praktiska sätt att säkra och stödja arbetsstycket mot en

stabil plattform. Att hålla arbetsstycket med händerna eller mot kroppen är ostabilt och

kan göra att du förlorar kontrollen.

- Håll händerna borta från kapningsområdet och rörliga delar.

- Använd inte slöa eller skadade skär. Skadade delar kan brytas eller leda till

personskador.

- Håll etiketter och märkplåt läsliga.

Kan roteras 360° mellan pump, hölje och motor.

1. Hus

2. Klipphuvud

3. Avtryckare

4. Oljeplugg

5. Returventil

6. Motor

7. Pumphus

8. Handtag (avtagbart)

9. Batteri

10. Kolv

DELARNAS NAMN

1.

8.

2.

7.

6.

9.

3.

5.

4.

10.

2.

1.

Table of contents

Languages:

Other Bendof Cutter manuals