Toro 03731 User manual

FormNo.3407-884RevA

27-inchVerticutter

Reelmaster®7000-DCuttingUnit

ModelNo.03731—SerialNo.400000000andUp

Registeratwww.Toro.com.

OriginalInstructions(EN)*3407-884*A

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

ThisproductcomplieswithallrelevantEuropeandirectives.

Fordetails,pleaseseetheDeclarationofIncorporation(DOI)

atthebackofthispublication.

Introduction

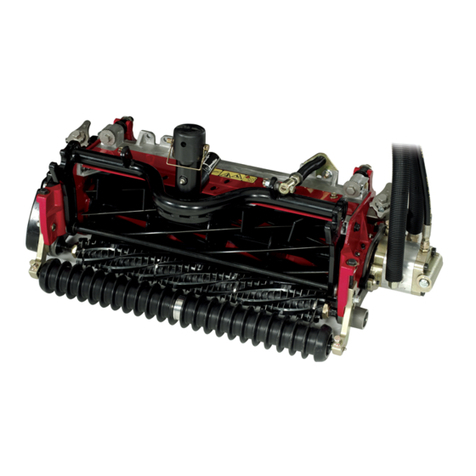

Theverticutterkitsaremountedonaride-onmachineand

isintendedtobeusedbyprofessional,hiredoperators

incommercialapplications.Itisprimarilydesignedfor

verticuttinggrassonwell-maintainedlawnsinparks,sports

elds,andoncommercialgrounds.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

Wheneveryouneedservice,genuineToroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready.Figure1identiesthemodelandserial

numbersontheproduct.Writethenumbersinthespace

provided.

g196973

Figure1

1.Locationofthemodelandserialnumbers

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

g000502

Figure2

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

Contents

Safety...........................................................................3

SafetyandInstructionalDecals.................................3

Setup............................................................................4

1InspectingtheVerticutter.......................................5

2InstallingtheTransportRollers...............................5

3InstallingtheO-ringandtheGrease

Fitting................................................................5

4InstallingtheTurf-CompensationSpring..................6

5AdjustingtheBladeDepth.....................................7

6AdjustingtheRearGrassShield..............................7

7AdjustingtheRollerScrapers..................................8

8AdjustingtheTransportRollers...............................8

9MountingtheVerticutterReel.................................9

10AdjustingtheCutting-UnitSteering.......................9

11AdjustingtheTurf-CompensationSettings.............10

ProductOverview.........................................................11

Specications........................................................11

Operation....................................................................11

TrainingPeriod......................................................11

OperatingTips.......................................................11

Maintenance.................................................................12

LubricatingtheVerticutter.......................................12

RemovingtheVerticutterBladesfromthe

Shaft.................................................................12

InstallingtheVerticutterBlades................................13

ServicingtheRoller.................................................13

©2016—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN554202

Contactusatwww.Toro.com.

PrintedintheUSA

AllRightsReserved

Safety

ThismachinehasbeendesignedinaccordancewithENISO

5395:2013.

Improperuseormaintenanceofthisequipmentcan

resultininjuryordeath.Toreducethepotentialfor

injuryordeath,complywiththefollowingsafety

instructions.

•Read,understand,andfollowallinstructionsinthe

tractionunitOperator’sManualbeforeoperatingthe

verticutters.

•Read,understand,andfollowallinstructionsinthis

Operator’sManualbeforeoperatingtheverticutters.

•Neverallowchildrentooperatethetractionunitorthe

verticutters.Donotallowadultstooperatethetraction

unitortheverticutterswithoutproperinstruction.Only

trainedoperatorswhohavereadthisOperator’sManual

shouldoperatetheverticutters.

•Neveroperatetheverticutterswhentired,ill,orunderthe

inuenceofdrugsoralcohol.

•Keepallshieldsandsafetydevicesinplace.Ifashield,a

safetydevice,oradecalisillegibleordamaged,repairor

replaceitbeforeresumingoperation.Also,tightenany

loosenuts,bolts,andscrewstoensurethattheverticutters

areinsafeoperatingcondition.

•Wearappropriateclothing,includingeyeprotection;

slip-resistant,substantialfootprotection;andhearing

protection.Tiebacklonghairanddonotwearjewelry.

•Removealldebrisorotherobjectsthatmightbepicked

upandthrownbythereelbladesofthecuttingunit.Keep

allbystandersawayfromtheworkingarea.

•Iftheverticutterbladesstrikeasolidobjectortheunit

vibratesabnormally,stopandshutofftheengine.Check

theverticutterfordamagedparts.Repairanydamage

beforestartingandoperatingtheverticutter.

•Parkthemachineonalevelsurface,lowerthecutting

unitstotheground,shutofftheengine,engagethe

parkingbrake,andremovethekeywheneveryouleave

themachineunattended.

•Besurethattheverticuttersareinsafeoperating

conditionbykeepingnuts,bolts,andscrewstight.

•Removethekeyfromtheswitchtopreventaccidental

startingoftheenginewhenservicing,adjusting,orstoring

themachine.

•Performonlythosemaintenanceinstructionsdescribedin

thismanual.Ifmajorrepairsareeverneededorassistance

isdesired,contactanAuthorizedToroDistributor.

•Toensureoptimumperformanceandcontinuedsafety

certicationofthemachine,useonlygenuineToro

replacementpartsandaccessories.Replacementparts

andaccessoriesmadebyothermanufacturerscouldbe

dangerous,andsuchusecouldvoidtheproductwarranty.

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedormissing.

decal93-6688

93-6688

1.Warning—readthe

instructionsbefore

servicingorperforming

maintenance.

2.Cuttinghazardofhandor

foot—shutofftheengine

andwaitformovingparts

tostop.

3

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescriptionQty.Use

1Verticutter1Inspecttheverticutter.

Transportrollerassembly2

2Cotterpin2Installthetransportrollers.

O-ring1

3Greasetting1InstalltheO-ringandthegreasetting.

Turf-compensationassembly1

Longbolt1

Carriagebolt2

Flangelocknut3

4

Flangenut1

Installtheturf-compensationspring

assembly.

5Nopartsrequired–Adjustthebladedepth.

6Nopartsrequired–Adjustthereargrassshield.

7Nopartsrequired–Adjusttherollerscrapers.

8Nopartsrequired–Adjustthetransportrollers.

9Nopartsrequired–Mounttheverticutterreel.

10Nopartsrequired–Adjustthecutting-unitsteering.

11Nopartsrequired–Adjusttheturf-compensationsettings.

MediaandAdditionalParts

DescriptionQty.Use

Operator'sManual1Reviewthematerialandsaveitinanappropriateplace.

Important:Withouttheseparts,totalsetupcannotbecompleted.

4

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

Note:Whenevertheverticutterhastobetippedtoexpose

theverticutterblades,usethekickstand(suppliedwith

tractionunit)(Figure3).

g195547

Figure3

1.Kickstand

1

InspectingtheVerticutter

Partsneededforthisprocedure:

1Verticutter

Procedure

Aftertheverticutterisremovedfromthebox,inspectthe

following:

1.Checkeachendofthereelforgrease.Greaseshould

bevisiblyevidentinthereelbearingsandintheinternal

splinesofthereelshaft.

2.Ensurethatallnutsandboltsaresecurelytightened.

3.Makesurethatthecarrierframesuspensionoperates

freelyanddoesnotbindwhenmovedbackandforth.

2

InstallingtheTransportRollers

Partsneededforthisprocedure:

2Transportrollerassembly

2Cotterpin

Procedure

1.Ifthecuttingunitsareinstalledonthetractionunit,

parkthemachineonalevelsurface,lowerthecutting

unitstotheground,shutofftheengine,engagethe

parkingbrake,andremovethekey.

2.Secureatransportrollerbrackettoeachsideplatepin

withacotterpin(Figure4).

g195548

Figure4

1.Transportrollerassembly2.Cotterpin

Note:Therollershouldbepositionedtotherearofthe

verticutter.

5

3

InstallingtheO-ringandthe

GreaseFitting

Partsneededforthisprocedure:

1O-ring

1Greasetting

Procedure

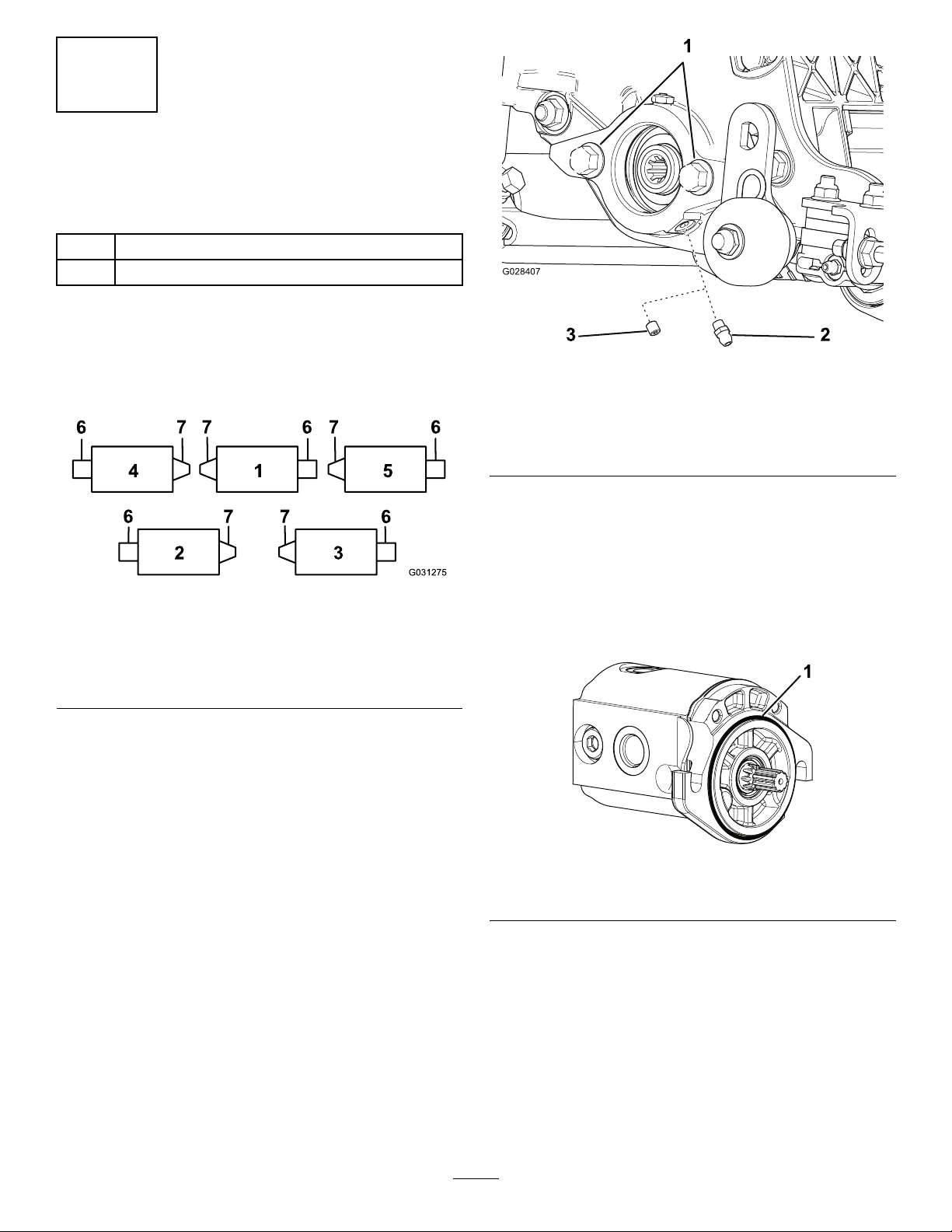

Thegreasettingmustbeinstalledonthereelmotorsideof

theverticutter.Usethefollowingdiagramtodeterminethe

positionofeachreelmotor(Figure5).

g031275

Figure5

1.Verticutter15.Verticutter5

2.Verticutter26.Reelmotor

3.Verticutter37.Weight

4.Verticutter4

1.Removeanddiscardthesetscrewonthereel-motor

sideplate(Figure6).

32

G028407

1

g028407

Figure6

1.Bolts3.Setscrew(removeand

discard)

2.Straightgreasetting

(install)

2.Installthestraightgreasetting(Figure6).

3.Forverticutter2andverticutter4locations(Figure

5),movetheendweighttotheoppositesideofthe

cuttingunit.

4.Iftherearenoboltsonthereel-motorsideplate,install

them(Figure6).

5.InstalltheO-ringonthereelmotor(Figure7).

g191072

Figure7

1.O-ring

6

4

Installingthe

Turf-CompensationSpring

Partsneededforthisprocedure:

1Turf-compensationassembly

1Longbolt

2Carriagebolt

3Flangelocknut

1Flangenut

Procedure

Installtheturfcompensationspringassemblyonthesame

sideasthereelmotor(Figure5andFigure8).

g196548

Figure8

1.Longbolt4.Flangelocknuts

2.Compensationspring

assembly

5.Flangenut

3.Carriagebolts

5

AdjustingtheBladeDepth

NoPartsRequired

Procedure

Note:Themaximumrecommendedbladepenetrationdepth

is6mm(1/4inch).

1.Placetheverticutterreelonalevelsurface.

2.Place2gaugebars,whichhavethedesireddepthof

bladepenetrationbelowtheground,underthefront

andrearrollersoftheverticutterreel(oneachendof

thereel)(Figure9).

g195549

Figure9

1.Gaugebar2.Adjustingbolt

Note:Theverticutterbladesmustnottouchthe

gaugebars.

3.Turntheadjustingboltoneachheight-of-cutbracket

(Figure9)sothatthereelbladescomeincontactwith

thelevelsurfaceonbothends.

Note:Astheverticutterbladeswear,thediameterof

thereelwilldecreaseandthedepthsettingwillchange.

Checkthedepthsettingperiodicallytoensurethatthe

desiredsettingisachieved.

7

6

AdjustingtheRearGrass

Shield

NoPartsRequired

Procedure

Note:Whenoperatinginturfconditionswheremuchdebris

orunusuallyheavythatchisencountered,opentherear

dischargeshieldtohelpallowthedebristodischargefrom

thereel.

1.Loosentheboltsonthepivotofthegrassshield

(Figure10).

g195550

Figure10

1.Pivotbolt2.Reargrassshield

2.Rotatethegrassshieldtothedesiredsetting,and

tightenthebolts(Figure10).

CAUTION

Throwndebriscouldcausepersonalinjury.

Donotopentherearshieldsothatitishigherthan

leveltoground.

7

AdjustingtheRollerScrapers

NoPartsRequired

Procedure

1.Loosentheangenutsthatsecuretherollerscrapers

(Figure11).

g195551

Figure11

1.Flangenuts3.Rearrollerscraper

2.Frontrollerscraper

2.Movethescraperrodsinorouttoattain0.0to0.75

mm(0.0to0.03inch)clearancebetweenthescraper

andtheroller.

3.Ensurethatthescraperrodisparalleltotherollerand

tothelevelsurface.

4.Tightentheangenutstolocktheadjustment.

8

AdjustingtheTransport

Rollers

NoPartsRequired

Procedure

Beforetheverticuttersareloweredtotheshopooror

removedfromthetractionunit,lowerthetransportrollers

(Figure11)toprotectthebladesfromhardsurfacecontact.

1.Removethecotterpinthatsecuresthetransportroller

brackettothesideplatepin.

2.Positionthetransportrollerasfollows:

•Lowertherollerbracketbeforetheverticutteris

loweredtotheshopoor.

•Raisetherollerbracketaftertheverticutterisraised

totheoperatingposition.

8

3.Securethetransportrollerbrackettothesideplatepin

withthecotterpin.

4.Repeattheprocedureontheoppositeendofthe

verticutter.

9

MountingtheVerticutterReel

NoPartsRequired

Procedure

Important:Whenloweringtheverticutterreels,care

mustbetakentopreventdamagetothereelbladesdue

tocontactwithaconcreteoororapavedsurface.Lower

thetransportrollersbeforeloweringtheverticuttiersto

aconcreteoororapavedsurface.

Figure12showstheorientationofthehydraulicdrivemotor

foreachofthelocations.

Verticutterreelsaremountedtothetractionunitthesame

waycuttingunitsare.RefertothetractionunitOperator's

Manualformountinginstructions.

g031275

Figure12

1.Verticutter15.Verticutter5

2.Verticutter26.Reelmotor

3.Verticutter37.Weight

4.Verticutter4

10

AdjustingtheCutting-Unit

Steering

NoPartsRequired

IncreasedSteeringfortheRearCutting

Units

Increasethesteeringontherearcuttingunitsbyremoving

the2pivotspacers,hexsocketscrews,andangelocknuts

(Figure13)fromthecarrierframesoftherearcuttingunits

(cuttingunits2and3);refertoFigure12.

1

2

3

4

G015978

g015978

Figure13

1.Hexsocketscrew3.Carrierframe

2.Pivotspacer4.Flangelocknut

LockingtheSteering

Tolock(x)thesteeringonthecuttingunits,securethepivot

yoketothecarrierframewiththesnapperpin(Figure14).

9

1

G015977

g015977

Figure14

1.Snapperpin

Note:Fixedsteeringisrecommendedwhencutting

sidehills.

11

Adjustingthe

Turf-CompensationSettings

NoPartsRequired

Procedure

Important:Makethespringadjustmentswiththe

cuttingunitmountedtothetractionunit,pointing

straightaheadandloweredtotheshopoor.

1.Makesurethatthehairpincotterisinstalledintherear

holeinthespringrod(Figure15).

g196971

Figure15

1.Hairpincotter3.Turf-compensationspring

2.Springrod4.Hexnuts

2.Tightenthehexnutsonthefrontendofthespringrod

untilthecompressedlengthofthespringis15.9cm

(6.25inches)(Figure15).

Note:Whenoperatingthemachineonroughterrain,

decreasethespringlengthby12.7mm(1/2inch).

Note:Theturf-compensationsettingwillneedtobe

resetiftheverticutterbladedepthsettingischanged.

10

ProductOverview

Specications

Netweight64kg(140lb)

Operation

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

TrainingPeriod

Beforeoperatingtheverticutterreels,evaluatethe

performanceofthereelatthedesiredsetting.Operateina

clear,unusedareatodeterminewhetherthedesiredresults

willbeachieved.Makeadjustmentsasnecessary.

OperatingTips

1.Operatethetractionunitatfullthrottle,fullreelspeed

(setting9)andatdesiredtractionspeed.

2.Themaximumrecommendedsettingis6mm(1/4

inch)deepbladepenetration.

3.Powerrequirementstooperatetheverticutterreelswill

varywithturfandsoilconditions.Travelspeedmay

needtobereducedinsomeconditions.

4.Whenoperatinginturfconditionswheremuchdebris

isencountered,orunusuallyheavythatch,openthe

frontandreardischargeshieldstohelpallowthedebris

todischargefromthereel.

CAUTION

Throwndebriscouldcausepersonalinjury.

Donotopentherearshieldsothatitishigher

thanleveltotheground.

11

Maintenance

LubricatingtheVerticutter

Eachverticutterhas5greasettings(Figure16)thatmustbe

lubricatedweeklywithNo.2lithiumgrease.

Thelubricationpointsarethefrontroller(2),therearroller

(2),andthereelmotorsplines(1).

Important:Lubricatingthecuttingunitsimmediately

afterwashinghelpspurgewateroutofthebearingsand

increasesbearinglife.

1.Wipeeachgreasettingwithacleanrag.

2.Applygreaseuntilyouseecleangreasecomingoutof

therollersealsandthebearingreliefvalve(Figure16).

g029271

Figure16

1.Reliefvalve

3.Wipeanyexcessgreaseaway.

RemovingtheVerticutter

BladesfromtheShaft

1.Securetheendoftheverticuttershaft,whichhasonly

onewasherandnut,inavise.

2.Onotherendofshaft,rotatethenutcounter-clockwise

andremovethenut.

CAUTION

Thebladesareextremelysharpandmayhave

burrsthatwillcutyourhands.

Usecautionwhenremovingthebladesfrom

theshaft.

3.Removethesmallspacer,thewasher,thebladesand

thelargespacers.Cleanandlubricatethesquareshaft

withalightcoatingofgreasetosimplifytheassembly

(Figure17).

g010889

Figure17

1.Shaft4.Smallspacer

2.Nut5.Blade(19)

3.Washer6.Largespacer(18)

Important:Donotinverttheverticutterreel

blades.Theorderofdisassemblyisextremely

important.Donotinverttheverticutterreel

bladeswhendisassemblingorreversetheorder

whenassemblingthem.Notetheverticutter

bladesindexhole.Theindexholeisprovidedfor

assemblyinordertoobtaintheproperhelixfor

theverticutterreel.

12

InstallingtheVerticutter

Blades

1.Assembleareelblade(Figure18).

2.Assemblealargespacer.

3.Donotinvertthereelbladeswhenreassemblingthem

ontothereelshaft.

Note:Ifthebladesareinverted,thebladesthatare

inuse(rounded)willbemixedwiththesharpends

ofthebladeswhichwerenotinuse.Thiswillcause

unsatisfactoryperformanceintheverticutterreelunit.

Paycloseattentionwhendisassemblingtheverticutter

bladesfromthereel.

4.Installthenextbladeclockwisesothattheindex

referencehole(Figure18)isnotalignedwiththerst

bladeholebyoneatoftheshaft.

g010890

Figure18

1.Indexreferencehole

5.Continuetoinstallspacersandbladesinthismanner

untilthefullcomplementofbladeshasbeeninstalled.

Note:Whenproperlyassembled,thebladeswillbe

staggeredinsuchamannerastoappearlikeahelix.

6.Installthesmallspacertotheshaft.

7.ApplyBlueLoctite242tothenut.Installthenutonto

theshaft,(withthemachinedsideofthenuttoward

thespacer)andtightenitto108.5to135N∙m(80to

100ft-lb).

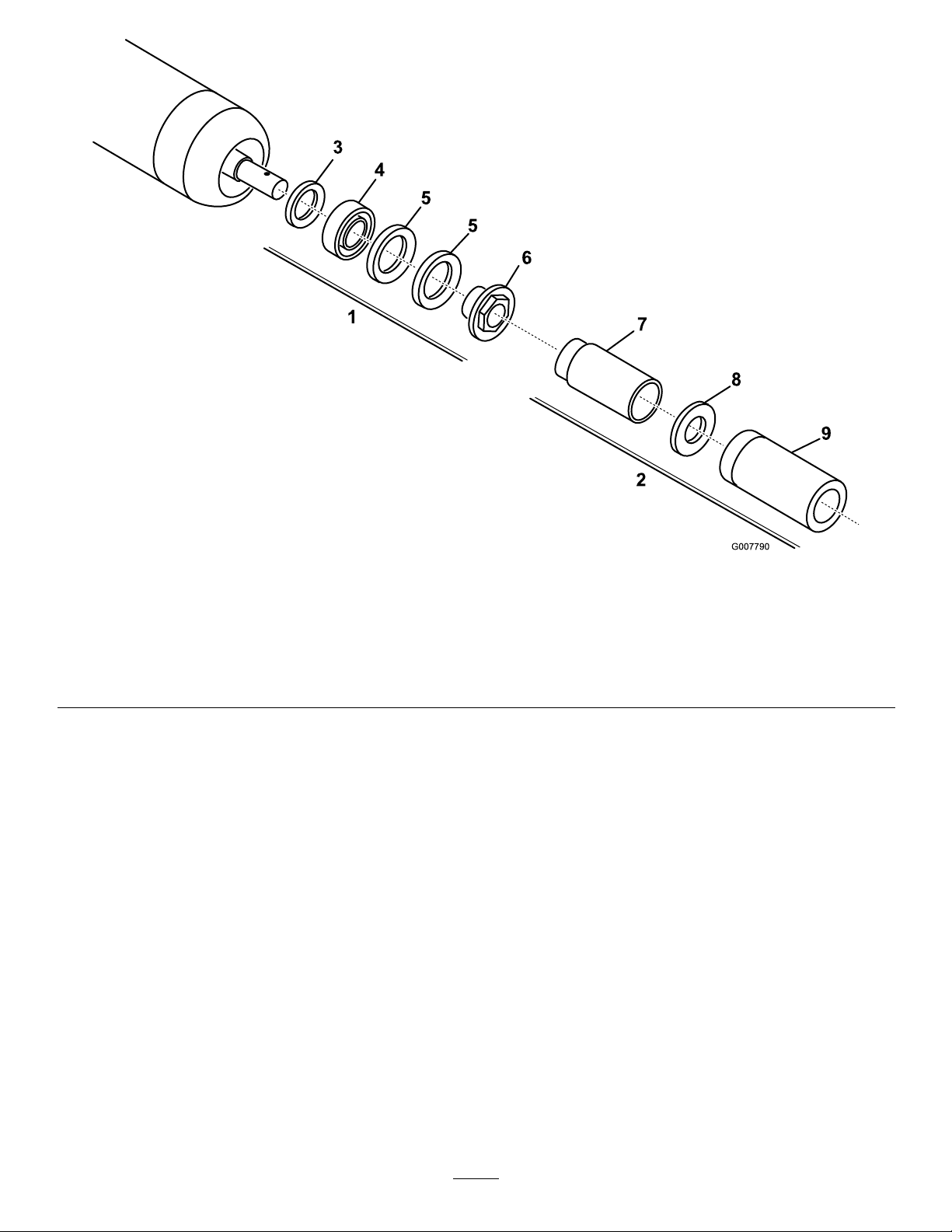

ServicingtheRoller

ARollerRebuildKit,Part114-5430andaRollerRebuild

ToolKit,Part115-0803(Figure19)areavailableforservicing

theroller.TheRollerRebuildKitincludesallthebearings,

bearingnuts,innerseals,andoutersealstorebuildaroller.

TheRollerRebuildToolKitincludesallthetoolsandthe

installationinstructionsrequiredtorebuildarollerwiththe

rollerrebuildkit.Refertoyourpartscatalogorcontactyour

distributorforassistance.

13

g007790

Figure19

1.Rebuildkit(PartNo.114–5430)6.Bearingnut

2.Rebuildtoolkit(PartNo.115–0803)7.Innersealtool

3.Innerseal8.Washer

4.Bearing9.Bearing/outersealtool

5.Outerseal

14

Notes:

Notes:

Notes:

DeclarationofIncorporation

TheT oroCompany,8111LyndaleAve.South,Bloomington,MN,USAdeclaresthatthefollowingunit(s)

conform(s)tothedirectiveslisted,wheninstalledinaccordancewiththeaccompanyinginstructionsontocertain

ToromodelsasindicatedontherelevantDeclarationsofConformity.

ModelNo.SerialNo.ProductDescriptionInvoiceDescriptionGeneralDescriptionDirective

03731400000000andUp

27-inchVerticutter,

Reelmaster7000-D

CuttingUnit

RM700027IN

VERTICUTTERCUVerticutter2006/42/EC

RelevanttechnicaldocumentationhasbeencompiledasrequiredperPartBofAnnexVIIof2006/42/EC.

Wewillundertaketotransmit,inresponsetorequestsbynationalauthorities,relevantinformationonthispartly

completedmachinery.Themethodoftransmissionshallbeelectronictransmittal.

ThismachineryshallnotbeputintoserviceuntilincorporatedintoapprovedT oromodelsasindicatedonthe

associatedDeclarationofConformityandinaccordancewithallinstructions,wherebyitcanbedeclaredin

conformitywithallrelevantDirectives.

Certied:EUT echnicalContact:

MarcelDutrieux

ManagerEuropeanProductIntegrity

ToroEuropeNV

Nijverheidsstraat5

2260Oevel

DavidKlisBelgium

Sr.EngineeringManager

8111LyndaleAve.SouthTel.+3216386659

Bloomington,MN55420,USA

November15,2016

EuropeanPrivacyNotice

TheInformationToroCollects

ToroWarrantyCompany(Toro)respectsyourprivacy.Inordertoprocessyourwarrantyclaimandcontactyouintheeventofaproductrecall,weaskyou

tosharecertainpersonalinformationwithus,eitherdirectlyorthroughyourlocalTorocompanyordealer.

TheT orowarrantysystemishostedonserverslocatedwithintheUnitedStateswhereprivacylawmaynotprovidethesameprotectionasapplies

inyourcountry.

BYSHARINGYOURPERSONALINFORMATIONWITHUS,YOUARECONSENTINGTOTHEPROCESSINGOFYOURPERSONALINFORMATION

ASDESCRIBEDINTHISPRIVACYNOTICE.

TheWayToroUsesInformation

Toromayuseyourpersonalinformationtoprocesswarrantyclaims,tocontactyouintheeventofaproductrecallandforanyotherpurposewhichwetell

youabout.T oromayshareyourinformationwithToro'safliates,dealersorotherbusinesspartnersinconnectionwithanyoftheseactivities.Wewillnot

sellyourpersonalinformationtoanyothercompany.Wereservetherighttodisclosepersonalinformationinordertocomplywithapplicablelawsand

withrequestsbytheappropriateauthorities,tooperateoursystemsproperlyorforourownprotectionorthatofotherusers.

RetentionofyourPersonalInformation

Wewillkeepyourpersonalinformationaslongasweneeditforthepurposesforwhichitwasoriginallycollectedorforotherlegitimatepurposes

(suchasregulatorycompliance),orasrequiredbyapplicablelaw.

Toro'sCommitmenttoSecurityofYourPersonalInformation

Wetakereasonableprecautionsinordertoprotectthesecurityofyourpersonalinformation.Wealsotakestepstomaintaintheaccuracyandcurrent

statusofpersonalinformation.

AccessandCorrectionofyourPersonalInformation

Ifyouwouldliketorevieworcorrectyourpersonalinformation,pleasecontactusbyemailat[email protected].

AustralianConsumerLaw

AustraliancustomerswillnddetailsrelatingtotheAustralianConsumerLaweitherinsidetheboxoratyourlocalToroDealer.

374-0282RevC

TheToroWarranty

ATwo-YearLimitedWarranty

ConditionsandProductsCovered

TheToroCompanyanditsafliate,T oroWarrantyCompany,pursuant

toanagreementbetweenthem,jointlywarrantyourT oroCommercial

product(“Product”)tobefreefromdefectsinmaterialsorworkmanship

fortwoyearsor1500operationalhours*,whicheveroccursrst.This

warrantyisapplicabletoallproductswiththeexceptionofAerators

(refertoseparatewarrantystatementsfortheseproducts).Wherea

warrantableconditionexists,wewillrepairtheProductatnocosttoyou

includingdiagnostics,labor,parts,andtransportation.Thiswarranty

beginsonthedatetheProductisdeliveredtotheoriginalretailpurchaser.

*Productequippedwithanhourmeter.

InstructionsforObtainingWarrantyService

YouareresponsiblefornotifyingtheCommercialProductsDistributoror

AuthorizedCommercialProductsDealerfromwhomyoupurchasedthe

Productassoonasyoubelieveawarrantableconditionexists.Ifyouneed

helplocatingaCommercialProductsDistributororAuthorizedDealer,or

ifyouhavequestionsregardingyourwarrantyrightsorresponsibilities,

youmaycontactusat:

ToroCommercialProductsServiceDepartment

ToroWarrantyCompany

8111LyndaleAvenueSouth

Bloomington,MN55420-1196

952–888–8801or800–952–2740

E-mail:[email protected]

OwnerResponsibilities

AstheProductowner,youareresponsibleforrequiredmaintenanceand

adjustmentsstatedinyourOperator'sManual.Failuretoperformrequired

maintenanceandadjustmentscanbegroundsfordisallowingawarranty

claim.

ItemsandConditionsNotCovered

Notallproductfailuresormalfunctionsthatoccurduringthewarranty

periodaredefectsinmaterialsorworkmanship.Thiswarrantydoesnot

coverthefollowing:

•Productfailureswhichresultfromtheuseofnon-T ororeplacement

parts,orfrominstallationanduseofadd-on,ormodiednon-Toro

brandedaccessoriesandproducts.Aseparatewarrantymaybe

providedbythemanufactureroftheseitems.

•Productfailureswhichresultfromfailuretoperformrecommended

maintenanceand/oradjustments.Failuretoproperlymaintainyour

ToroproductpertheRecommendedMaintenancelistedinthe

Operator’sManualcanresultinclaimsforwarrantybeingdenied.

•ProductfailureswhichresultfromoperatingtheProductinanabusive,

negligent,orrecklessmanner.

•Partssubjecttoconsumptionthroughuseunlessfoundtobedefective.

Examplesofpartswhichareconsumed,orusedup,duringnormal

Productoperationinclude,butarenotlimitedto,brakepadsand

linings,clutchlinings,blades,reels,rollersandbearings(sealedor

greasable),bedknives,sparkplugs,castorwheelsandbearings,tires,

lters,belts,andcertainsprayercomponentssuchasdiaphragms,

nozzles,andcheckvalves,etc.

•Failurescausedbyoutsideinuence.Conditionsconsideredtobe

outsideinuenceinclude,butarenotlimitedto,weather,storage

practices,contamination,useofunapprovedfuels,coolants,lubricants,

additives,fertilizers,water,orchemicals,etc.

•Failureorperformanceissuesduetotheuseoffuels(e.g.gasoline,

diesel,orbiodiesel)thatdonotconformtotheirrespectiveindustry

standards.

•Normalnoise,vibration,wearandtear,anddeterioration.

•Normal“wearandtear”includes,butisnotlimitedto,damagetoseats

duetowearorabrasion,wornpaintedsurfaces,scratcheddecalsor

windows,etc.

Parts

Partsscheduledforreplacementasrequiredmaintenancearewarranted

fortheperiodoftimeuptothescheduledreplacementtimeforthatpart.

Partsreplacedunderthiswarrantyarecoveredforthedurationofthe

originalproductwarrantyandbecomethepropertyofToro.Torowillmake

thenaldecisionwhethertorepairanyexistingpartorassemblyorreplace

it.Toromayuseremanufacturedpartsforwarrantyrepairs.

DeepCycleandLithium-IonBatteryWarranty:

DeepcycleandLithium-Ionbatterieshaveaspeciedtotalnumberof

kilowatt-hourstheycandeliverduringtheirlifetime.Operating,recharging,

andmaintenancetechniquescanextendorreducetotalbatterylife.Asthe

batteriesinthisproductareconsumed,theamountofusefulworkbetween

chargingintervalswillslowlydecreaseuntilthebatteryiscompletelyworn

out.Replacementofwornoutbatteries,duetonormalconsumption,

istheresponsibilityoftheproductowner.Batteryreplacementmaybe

requiredduringthenormalproductwarrantyperiodatowner’sexpense.

Note:(Lithium-Ionbatteryonly):ALithium-Ionbatteryhasapartonly

proratedwarrantybeginningyear3throughyear5basedonthetime

inserviceandkilowatthoursused.RefertotheOperator'sManualfor

additionalinformation.

MaintenanceisatOwner’sExpense

Enginetune-up,lubrication,cleaningandpolishing,replacementoflters,

coolant,andcompletingrecommendedmaintenancearesomeofthe

normalservicesToroproductsrequirethatareattheowner’sexpense.

GeneralConditions

RepairbyanAuthorizedToroDistributororDealerisyoursoleremedy

underthiswarranty.

NeitherTheToroCompanynorToroWarrantyCompanyisliablefor

indirect,incidentalorconsequentialdamagesinconnectionwiththe

useoftheToroProductscoveredbythiswarranty,includingany

costorexpenseofprovidingsubstituteequipmentorserviceduring

reasonableperiodsofmalfunctionornon-usependingcompletion

ofrepairsunderthiswarranty.ExceptfortheEmissionswarranty

referencedbelow,ifapplicable,thereisnootherexpresswarranty.All

impliedwarrantiesofmerchantabilityandtnessforusearelimitedto

thedurationofthisexpresswarranty.

Somestatesdonotallowexclusionsofincidentalorconsequential

damages,orlimitationsonhowlonganimpliedwarrantylasts,sotheabove

exclusionsandlimitationsmaynotapplytoyou.Thiswarrantygivesyou

speciclegalrights,andyoumayalsohaveotherrightswhichvaryfrom

statetostate.

Noteregardingenginewarranty:

TheEmissionsControlSystemonyourProductmaybecoveredby

aseparatewarrantymeetingrequirementsestablishedbytheU.S.

EnvironmentalProtectionAgency(EPA)and/ortheCaliforniaAirResources

Board(CARB).Thehourlimitationssetforthabovedonotapplytothe

EmissionsControlSystemWarranty.RefertotheEngineEmissionControl

WarrantyStatementsuppliedwithyourproductorcontainedintheengine

manufacturer’sdocumentationfordetails

CountriesOtherthantheUnitedStatesorCanada

CustomerswhohavepurchasedT oroproductsexportedfromtheUnitedStatesorCanadashouldcontacttheirT oroDistributor(Dealer)toobtain

guaranteepoliciesforyourcountry,province,orstate.IfforanyreasonyouaredissatisedwithyourDistributor'sserviceorhavedifcultyobtaining

guaranteeinformation,contacttheToroimporter.374-0253RevD

This manual suits for next models

1

Table of contents

Other Toro Cutter manuals

Popular Cutter manuals by other brands

Hypertherm

Hypertherm HD4070 PC-104 Field Service Bulletin

Wolfcraft

Wolfcraft LC 250 operating instructions

Hitachi

Hitachi CM4SB2 - 11.6 Amp Dry-Cut Masonry Circular... instruction manual

Central Machinery

Central Machinery 62518 Owner's manual & safety instructions

Makita

Makita DCO140 instruction manual

Larzep

Larzep CC01120 quick start guide