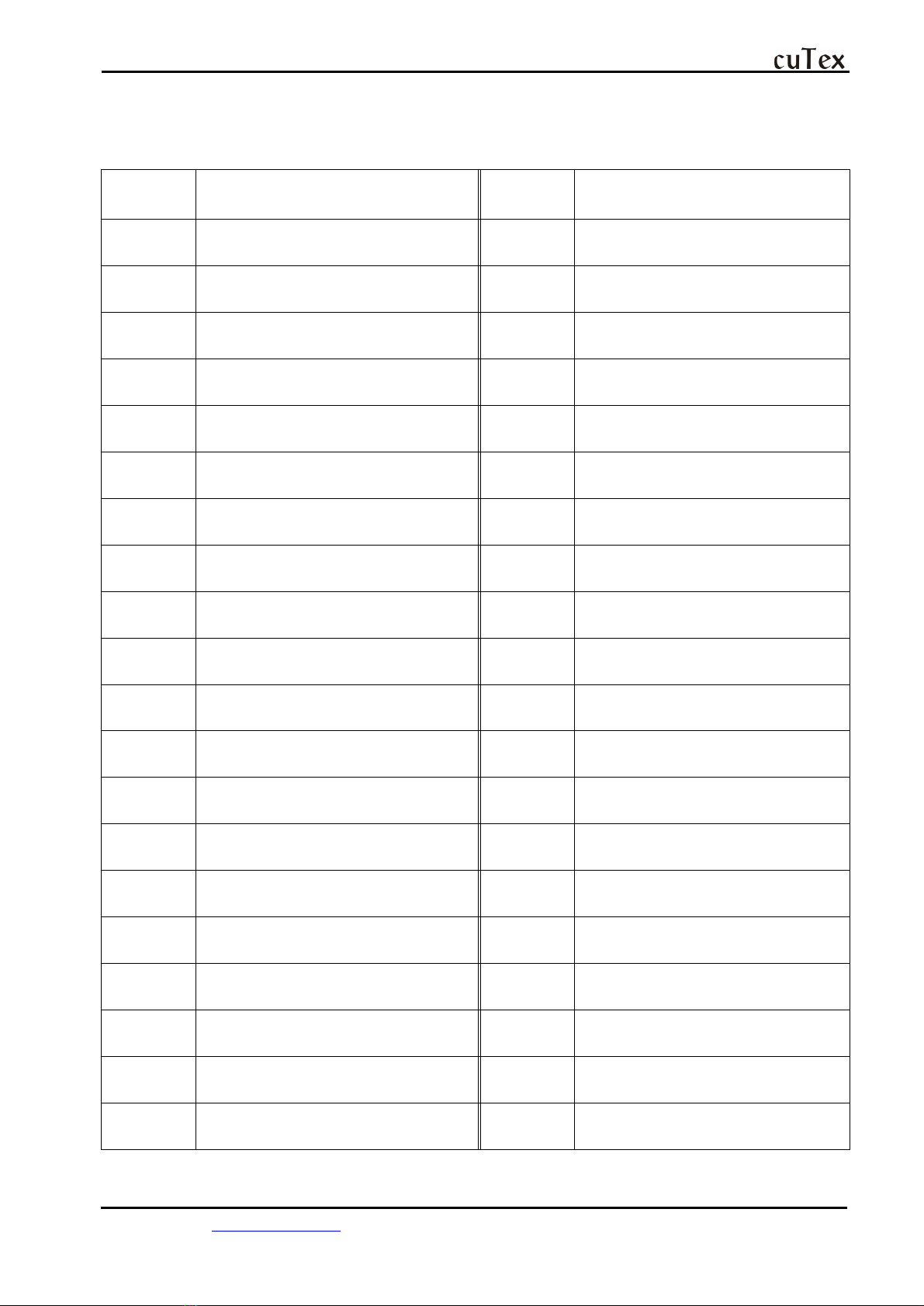

Description Part No. Description

A-1 CONTROL CASE A-30 SAFETY COVER

A-2 FAN A-31 ANGLE NUT

A-3 TERMINAL A-32 LEFT FRAME

A-4 TRANSFORMER A-33 ANGLE NUT

A-5 CONTROL BASE A-34 ANGLE NUT

A-6 CONDENSER A-35 UPPER COVER

A-7 DRIVE BOARD A-36 FRONT COVER

A-8 RELAY A-37 SUPPORT

A-9 DRIVE A-38 PRODUCT GUIDE

A-10 WHEEL A-39 REAR COVER

A-11 ANGLE FRAME A-40 CONTROL ANGLE NUT

A-12 ANGLE SHAFT A-41 ROLLER BEARING HOUSING

A-13 RIGHT FRAME A-42 BEARING

A-14 BREAING A-43 LOWER ROLLER

A-15 GUIDE ROLLER A-44 UPPER ROLLER

A-16 REAR GUIDE SIX ANGLE PIN A-45 UPPER ROLLER SHAFT

A-17 MOTOR A-46 FIXING RING

A-18 ANGLE SHAFT A-47 LEVER

A-19 FORNT COVER A-48 HANDLE BOLT

A-20 REAR GUIDE SIX ANGLE PIN A-49 PRESSURE CONTROL SPRING COVER

A-21 REAR GUIDE SIDE A-50 PRESSURE SPRING

A-22 REAR GUIDE ROLLER BEARING HINGE A-51 UPPER ROLLER GUIDE BLOCK

A-23 TIME GEAR A-52 GUIDE SHAFT

A-24 ANGLE NUT A-53 GUIDE SHAFT

A-25 ROLLER BEARING HOUSING

(LEFT) A-54 GUIDE SHAFT

A-26 TIME BELT A-55 PANEL

A-27 TIME GEAR A-56 OP BOARD

POWER SWITCHA-57ROLLER TANSTION BRACKETA-28

CONTROL BOARD (MB)A-58SAFETY COVER SUPPORTA-29