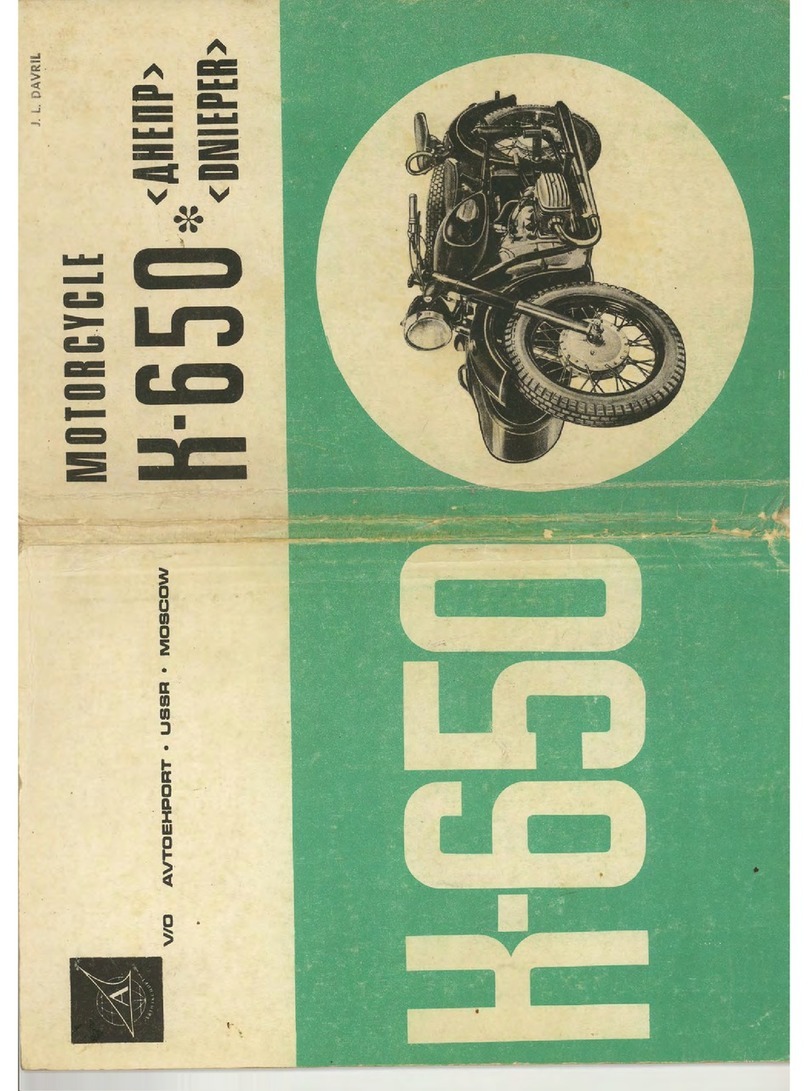

t:NulNt: - ::ingle cyiinaer 4 strOKe - uver lledO vaives - oore :J4 rnm. - .:truKe ::"l mill. - \..yiiiiuei

displacement 123,7cc. - Compression ratio 9,5 to 1 - CV. 16 at 8.800 R.P.M. - Distribution with

stand3rd cam - Intake open 30° BTDC - Intake close 75° ABCD - Exhaust open 75° BBDC - Exhaust

close 30° ATDC - Valve clearance with hot motor 0.006" - Forced lubrication by gear pump

60 L/H Oil capacity 2 qts - Gravity fuel supply 98 to 100 octane - Carburetor UB 22 BS - Ignition

by alternator flywheel magneto with external H.T. coil - Ignition advance 19° - Plus automatic

advance of 25° - Point gap 0.016" - Marell¡ Plug CW 260 L - Champion plug N. 3 - With multiplate

clutch - Costant mesh gear box - Foot shift pedal - Primary transmission by helicoidal gears -

Secondary transmission by chain 1/2" x 5/16".

FRAME . Combination of pressed steel and tubular " Double action hydraulic front fork -

Rear swing arm with adjustable hydraulic shock absorbers.

TIRES - Pirelli 2.75 x 18" (rib.) front wheel - 3.00 x 18" (univ.) rear wheel - Expanding type

brakes.

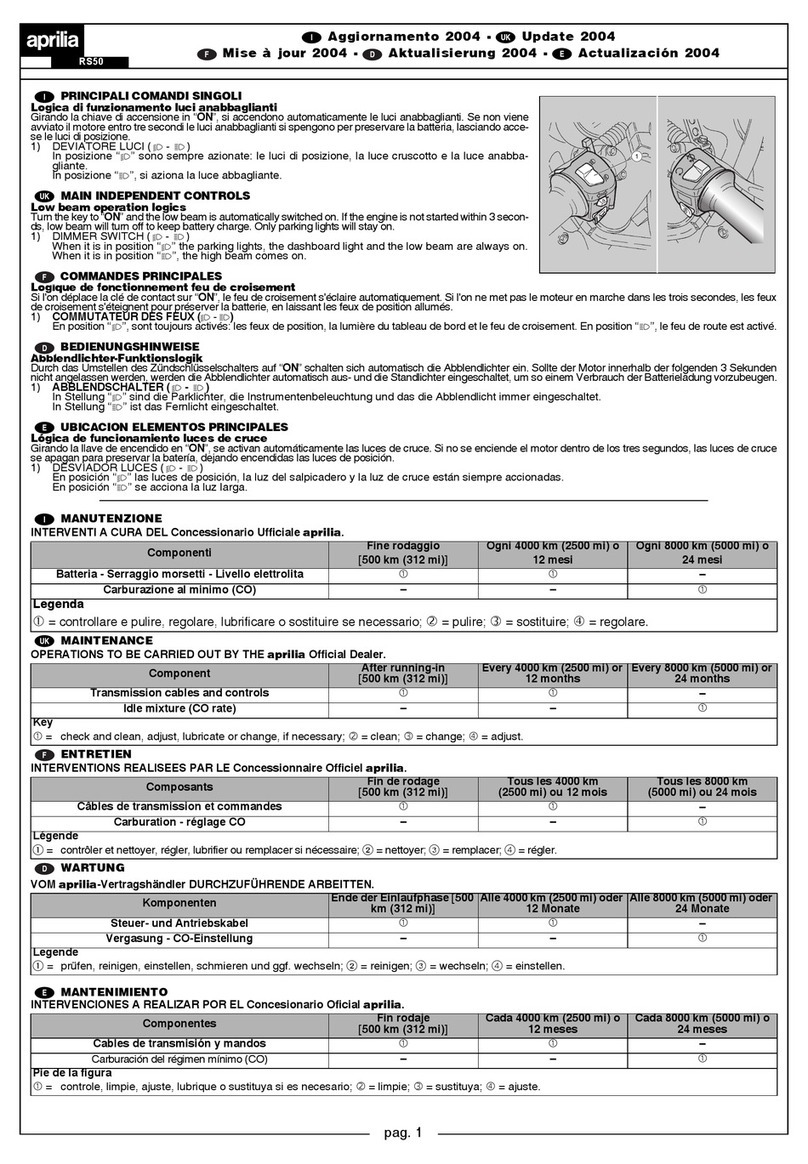

LIGHTING EQUIPMENT - Alternating current 6V 7 amp equipped with battery to ensure

steady supply of current to lights and horn - Large 130 mm. headlight - Headlight: 6\1 25/25

S. B.

OVERALL DIMENSIONS - Length 76.44" - Width 27" - Height 36.64" Weight 229 Ibs. (DRY) -

Fuel tank capacity 3,5 gallons - Reserve .05 gallons . Maximum speed 7~ MPH - Fuel

consumption 90 MPG.

MOTORCYCLE 200cc. (Technical data different from 125cc.)

ENGINE. Bore 66,5 mm. - Stroke 57 mm. - Cylinder displacement 197,9cc. - Compression

ratio 8,8 to 1 - CV. 19,5 at 8.600 R.P.M. -Carburetor UB 22 B5 - Ignition advance 9" 30' -

Plus automatic advance of 29" with flywheel magneto ADP 791 AN.

. (Note: with flywheel magneto ADP 54/2ANB ignition advance 17' - plus automatic advance

of 25").

TIRES - Pirelli 3.00 x 18" rib. front whee! - 3.00 x 18" univ. rear wheeL.

OVERALL DIMENSIONS. Weight 231 Ibs. (DRY) - Maximum speed 90 MPH - Fuel consum-

ption 85 MPG.

MOTORCYCLE 250cc. (Technical data different -from-1-25cc.)--------------------

ENGINE. Bore 74 mm - Stroke 57 mm - Cylinder displacement 245.1cc. - Compresskin ratio

8,5 to 1 - CV. 24 at 8.500 R.P.M. - Carburetor US 24 B5 2 - Ignition advance 9'" 30' - Plus

automatic advance of 29° with flywheel magneto ADP 79/AN and ADP 78/2ANB.

TIRES. Pirelli 3.00 x 18" univ. front wheel - 3.25 x 18" univ. rear wheeL. .

OVERALL DIMENSIONS. Weight 232 Ibs. (DRY) - Maximum speed 95 MPH - Fuel cons'Jmption

80 MPG.

2