9

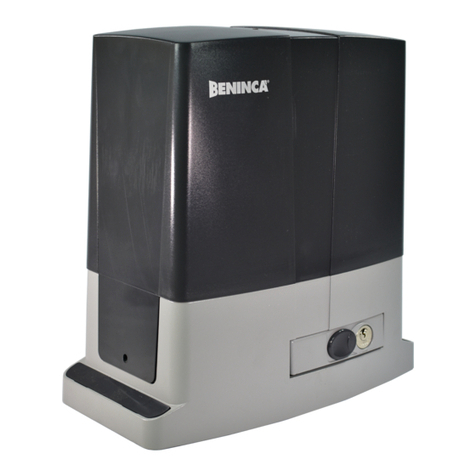

5) INSTALLATION (FIG.1)

Overall dimensions of the gear motor expressed in mm.

5.1) FITTING OF THE RACK

Rack in nylon (Fig.8).

Position the rack at a height of 102 mm from the centre line of the fixing slot

provided on the base on which the foundation plate will be fitted. At that

height, drill a hole on the gate and provide for a M6 threading.

Keep to the P tooth pitch, even from a section of rack and another. To this

purpose, it could be useful to join another section of rack (Part. C)

Then fix the rack with V screws, taking care, once the actuator is installed,

that 1-mm backlash is left between the rack and the tow wheel (seei Fig.7).

To this purpose, use the slots on the rack.

Rack in Fe 12x30mm (Fig.9).

Position the spacers D by welding them or fitting them with screws to the

gate, at 135 mm height from the centre line of the fixing slot provided on the

base on which the foundation plate will be fitted. Fix the rack.

Keep to the P tooth pitch, for all sections of the rack. To this purpose, it

could be useful to connect another section of rack (Part. C)

Then fix the rack with V screws, taking care, once the actuator is installed,

that 1-mm backlash is left between the rack and the tow wheel (seei Fig.7).

To this purpose, use the slots on the rack.

5.2) POSITIONING OF THE FOUNDATION PLATE (FIG.5-6)

It is very important to keep to dimension X shown in Fig.2. This value de-

pends on the type of rack used:

X = 11 mm for rack in nylon

X = 13 mm for rack in iron, 12x30mm

Preset a corrugated tube (Fig.2 -A) for the passage of power supply cables

and connection wires for the accessories.

Check that, at the end of the fitting, the foundation plate is perfectly parallel

with respect to the wing.

Fitting with screw anchors on cement base (fig. 3)

Through 4 “T” screw anchors in steel (not supplied), firmly anchor the

foundation plate to ground by means of 4 bolts “B” (not supplied). Use the

foundation plate as drilling template.

Fix the geared motor to the plate by means of the 4 screws V (M10x70), with

the relevant plain washers R and knurled washers, as indicated in the figure 6.

Installation with cement (fig. 4-5)

In this case, after providing for an adequate foundation hole, pour cement

on the plate, taking care of the plate level. Check that the threaded inserts

(I) for the fitting screws are clean and cement free.

Wait for the hardening of the cement.

Fix the geared motor to the plate by means of the 4 screws V (M10x70), with

the relevant plain washers R and knurled washers, as indicated in the figure 6.

Height adjustment of the geared motor

The height of the geared motor (10mm max) can be adjusted in height, with

respect to the foundation base, by 4 dowels G.

In this case, BEFORE fitting the geared motor to the plate, apply the 4

adjustment dowels G, by inserting the 4 nuts D in the special housings

located at the bottom of the geared motor.

Then adjust the 4 dowels by lifting the geared motor at the desired height.

Fix the motor by firmly tighten the 4 screws V4 (M10x70) and related flat

washers R and knurled washers Z, as shown in the figure 6.

5.3) POSITIONING OF THE LIMIT SWITCH BRACKETS (FIG.10)

Manually open the gate and leave a clearance from 1 to 3cm according to

the weight of the gate between the main door and the mechanical stopper

A. Fix the bracket to the limit switch S by using the grains G, so that the limit

switch microswitch F is pressed. The same operation should be repeated

with gate in the closing phase.

N.B.: The limit switch bracket should be positioned so that the gate can be

stopped without hitting the mechanical stopper.

6) MANUAL OPERATION (FIG.11)

Should a power failure or malfunction occurs, to manually operate the

gate proceed as follows:

- After inserting the customised key C, turn it anti-clockwise and pull

the lever L.

- The gear motor is unlocked and the gate can be moved by hand.

- To return to the normal operating mode, close the lever L again and

manually activate the gate until it is geared.

7) WIRE DIAGRAM (FIG.13)

For the wire connections of the system and to adjust the operating modes,

please refer to the Instruction Manual of the control unit.

In particular, the anti-crash device (encoder) should be adjusted ac-

cording to regulations in force.

Please remember that the device should be earthed by means of the

appropriate terminal.

Fig.10 shows wiring for a standard installation. Before proceeding to wir-

ing, check that the type of cables used is consistent with those required

for accessories.

Dimension H stands for the installation height of photocells. A clearance

between 40 and 60 cm is advisable.

Key of components:

1 Gear motor with incorporated BULL control unit

2 M4 rack, Nylon/Fe

3 Limit switch brackets

4 Photocells

5 Mechanical stoppers

6 Key selector or digital keyboard

7 Flashing light

8 Antenna

8) BUFFER BATTERIES (FIG.12)

An optional kit of buffer batteries BULL24.CB is available. This permits the

operation of the system also in case of power failure.

The batteries can be installed inside the gear motor, fixed through a bracket

on the rear of the container of the control unit, as shown in Fig.14.

For further information, please see instructions supplied with the product.

WARNING

The RC product insurance policy, which covers any injuries or damages to

objects caused by manufacturing defects, requires the use of Benincà’s

original accessories.