Beninca BULL 10M User manual

Other Beninca Garage Door Opener manuals

Beninca

Beninca DU.350V User manual

Beninca

Beninca PONY User manual

Beninca

Beninca VN.M20E User manual

Beninca

Beninca BISON 45 OTI User manual

Beninca

Beninca KEN3 Installer manual

Beninca

Beninca CP.BULL8 OM User manual

Beninca

Beninca MS4 Installer manual

Beninca

Beninca DU.350N Installer manual

Beninca

Beninca JM.3 User manual

Beninca

Beninca Aurora Super Installer manual

Beninca

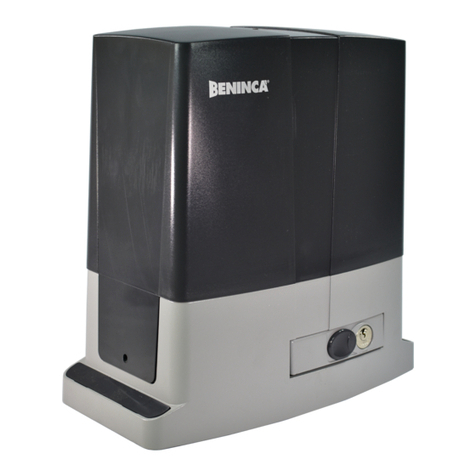

Beninca JUGGERNAUT User manual

Beninca

Beninca BULL 424 ESA User manual

Beninca

Beninca JM.3 User manual

Beninca

Beninca MB Installer manual

Beninca

Beninca BULL 1024 ESA User manual

Beninca

Beninca BRAINY User manual

Beninca

Beninca VN.S20 User manual

Beninca

Beninca BULL 624 TURBO User manual

Beninca

Beninca DU.350E Installer manual

Beninca

Beninca DU.45E User manual

Popular Garage Door Opener manuals by other brands

Craftsman

Craftsman 139.53924 owner's manual

Chamberlain

Chamberlain MyQ 940ESTD owner's manual

Automatic Technology

Automatic Technology GDO-9V1 SecuraLift installation instructions

Westfalia

Westfalia 19 36 07 instruction manual

Chamberlain

Chamberlain HD520EVP manual

Cardin

Cardin BL Series instruction manual