Benning Tebevert III User manual

Tebevert III 25kVA

120VDC Inverter System

028-0009-006 Rev. C

Benning Power Electronics

1220 Presidential Drive Suite 100

Richardson, TX 75081 USA

www.benning.us

800.910.3601

This manual contains important

safety instructions that should be

followed during installation and

maintenance of the Power

System.

Operations and Maintenance Manual

TABLE OF CONTENTS

0IMPORTANT INFORMATION..................................................................................................................i

0.1 VERSION..............................................................................................................................i

0.1 PASSWORD..........................................................................................................................ii

0.1 DATA SHEET.......................................................................................................................iii

0.2 PREFACE .............................................................................................................................1

1SAFETY NOTES AND MARKINGS ........................................................................................ 3

2GENERAL ............................................................................................................................ 6

3THE COMPONENTS OF THE TYPICAL INVERTER SYSTEM.................................................. 6

3.1 PSJ TYPE EQUIPMENT CABINET..........................................................................................7

3.2 INVERTER SLOTS...............................................................................................................10

3.3 SBS SLOT ..........................................................................................................................12

3.4 MANUAL MAINTENCE BY-PASS SWITCH..............................................................................12

3.5 INVERTER..........................................................................................................................15

3.5.1 DESIGN OF THE UNIT.....................................................................................................15

3.5.2 TERMINALS AND OPERATING UNITS...............................................................................17

3.5.3 SIGNALLING...................................................................................................................19

3.6 ELECTRONIC SWITCH-OVER SBS UNIT ...............................................................................21

3.6.1 DESIGN OF THE UNIT.....................................................................................................22

3.6.2 TERMINALS AND OPERATING ELEMENTS.........................................................................23

3.6.3 SIGNALLING...................................................................................................................25

3.7 ACD DISTRIBUTIN PANEL...................................................................................................26

3.7.1 NA STYLE SNAP-IN BREAKER PANEL............................................................................26

3.7.2 DIN RAIL STYLE BREAKER PANEL...................................................................................27

3.8 TECHNICCAL DATA..................................................................................................................27

4INSTALLATION AND COMMISSIONING........................................................................... 28

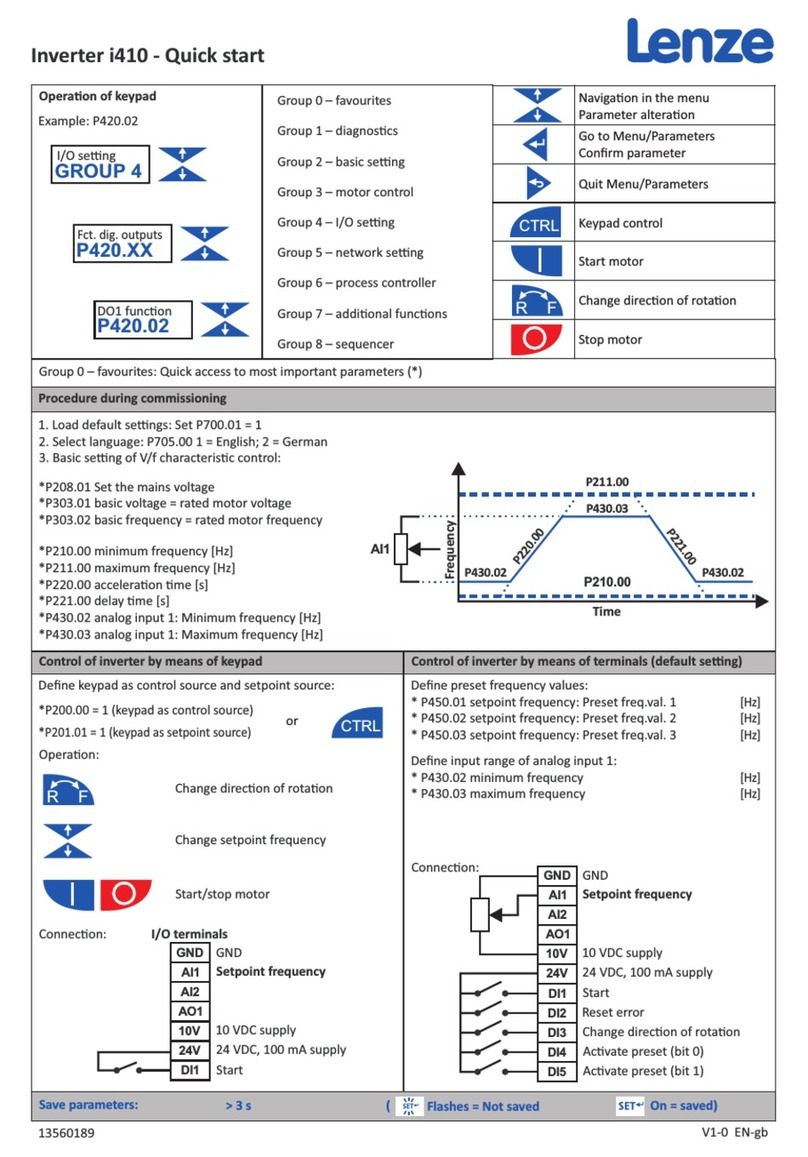

4.1 INVERTER SETTINGS .........................................................................................................29

4.2 SETTINGS OF THE ELECTRONIC SWITCH –OVER/SBS UNIT.................................................30

4.3 PANEL WRITING ................................................................................................................32

4.3.1 DC CABLE REQUIREMENTS FOR 25kVA, 120, INDIVIDUAL DC INPUT (DIN RAIL TERMINAL

BLOCK).....................................................................................................................................34

4.3.2 DC CABLE REQUIREMENTS FOR 25kVA, 120VDC, BULK DC INPUT SYSTEM .......................34

4.3.3 AC CABLE REQUIREMENTS FOR 25kVA, 120 VAC AC INPUT RATINGS. .............................35

4.3.4 AC CABLE REQUIREMENTS FOR 25kVA, 120/240 VAC INPUT SYSTEM. ..............................35

4.3.5 AC CABLE REQUIREMENTS FOR 25kVA, 208 VAC INPUT SYSTEM......................................35

4.3.6AC CABLE REQUIREMENTS FOR 25kVA, 220 VAC INPUT SYSTEM .....................................36

4.3.7AC CABLE REQUIREMENTS FOR 25kVA, 240 VAC INPUT SYSTEM .....................................36

4.3.8AC CABLE REQUIREMENTS FOR 25kVA, 480 VAC INPUT SYSTEM ......................................36

4.3.9

TORQUE TABLE FOR ALL TERMINATIONS

........................................................................37

4.4 INSTALLATION OF THE UNITS............................................................................................60

4.4.1 INSTALLATION OF THE STATIC BY-PASS SWITCH (SBS)..................................................39

4.4.2 INSTALLATION OF THE INVERTERS ................................................................................40

4.5 SWITCHING ON THE INVERTER SYSTEM.............................................................................40

5 PERFORMANCE TESTING ................................................................................................. 42

5.1 PRELIMINARIES TO PERFORMANCE TEST ...........................................................................42

5.2 TEST EQUIPMENT..............................................................................................................43

5.3 TEST OF THE INVERTERS...................................................................................................43

5.3.1 INVERTER TEST ACTIVITIES...........................................................................................43

5.4 TEST OF THE SBS UNIT......................................................................................................45

5.4.1 SBS TEST ACTIVITIES ....................................................................................................46

5.5 FINAL STEPS......................................................................................................................47

6MAINTENANCE ................................................................................................................. 47

6.1 USE OF THE MANUAL BY-PASS SWITCH..............................................................................47

6.2 EXCHANGE OF UNITS.........................................................................................................50

6.3 UPGRADING THE SYSTEM ..................................................................................................51

7DESCRIPTION OF FUNCTION........................................................................................... 51

7.1 TOTAL SYSTEM..................................................................................................................51

7.2 INVERTER..........................................................................................................................52

7.2.1 MONITORING THE INPUT VOLTAGE...............................................................................52

7.2.2 MONITORING THE OUTPUT VOLTAGE.............................................................................54

7.2.3 MONITORING THE TEMPERATURE ..................................................................................54

7.2.4 OVERLOAD BEHAVIOR....................................................................................................54

7.2.5 SHORT-CIRCUIT BEHAVIOR............................................................................................55

7.3 ELECTRONIC SWITCHING/SBS UNIT...................................................................................55

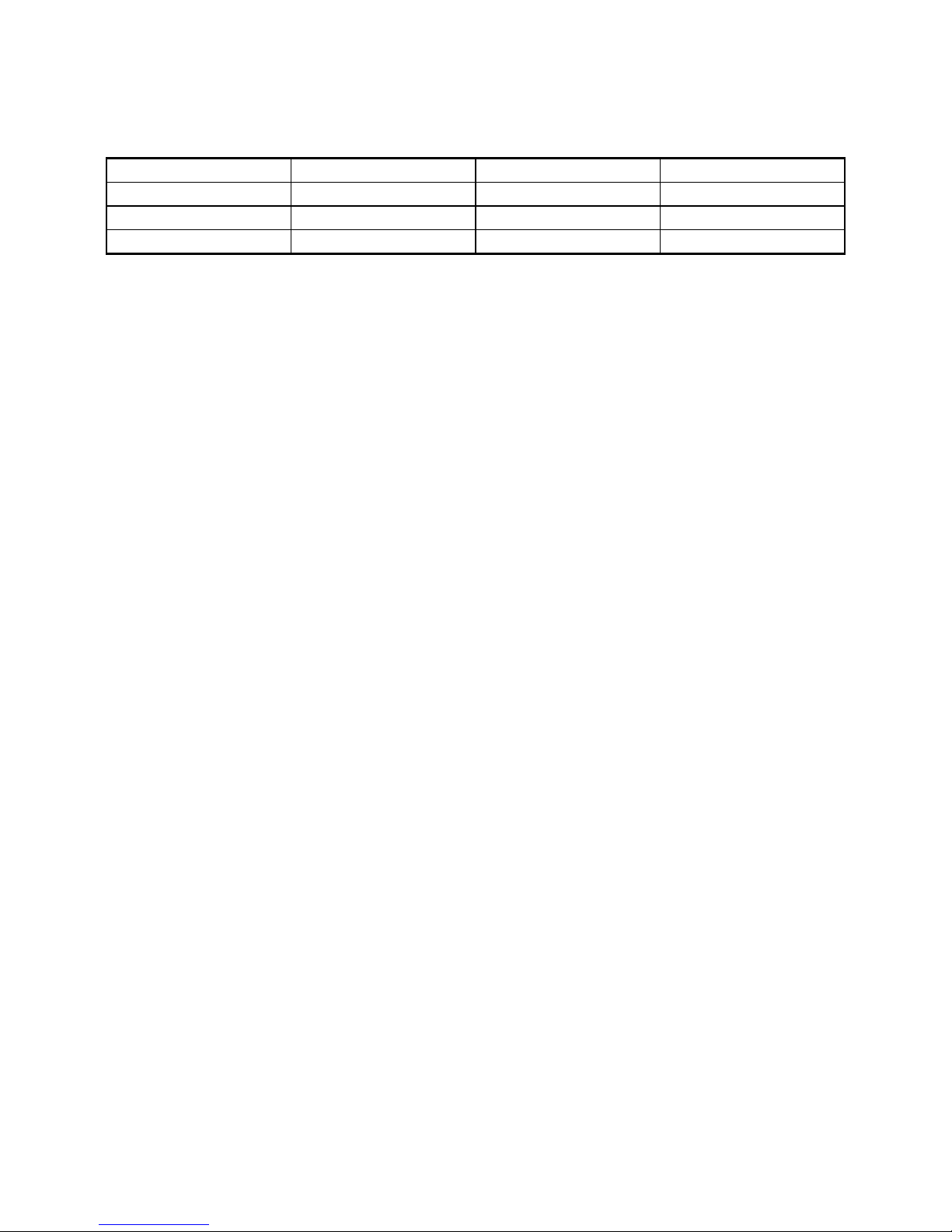

VERSION:

Revision

Date

Originator

Approver

A 06.01.08 C.Tumey D.Almond

B 03.12.10 C.Tumey E.McDonald

C

07.08.11

A.Waggott/J.Almond

D.Almond

Publication Document: Version 1.1

Copyright © 2007 Benning Power Electronics

Proprietary Information: This manual contains proprietary information which is

protected by copyright law. All rights are reserved. No part of this manual may be

photocopied, reproduced, or translated to another language without prior written

consent of Benning Power Electronics. Specifications in this manual are subject to

change without notice.

i

PASSWORD:

Password Level 1: PW 1

Password Level 2: PW 2

Password Level 3: PW 3

Password Level 4: PW 4

NOTE:

PUT A SPACE BETWEEN PW AND THE

NUMBER

ii

Tebevert III_120 (R1_07) © Benning Power Electronics 2007

Specifications are subject to change without notice

Key Features

TEBEVERT III MODULAR

5-25 kVA INVERTER SYSTEM

The TEBEVERT III Modular Inverter System is designed

to address the critical AC powering requirements of

Industrial and Utility applications. The TEBEVERT III

Modular Inverter System can be scaled in 5 kVA

increments up to 25 kVA (non-redundant). Unlike

conventional stand alone inverters, these parallel

operating inverters can also be scaled to operate with

N+1 redundancy. N+1 redundancy insures optimal

availability for your critical load applications. If an

inverter failure should ever occur, the faulty inverter

module will automatically be removed from the output

bus before a disruption in the output is seen by the

critical load. In this mode of operation, a failure of one

inverter will not effect the operation of your critical load.

Since all units are designed for “hot swap” replacement,

a faulty module can easily be unplugged and replaced

to maintain power to your critical load.

Hot Swap 5 kVA Inverter Modules

Hot Swap Static Switch Module

Supports High Inrush Current Loads

High Efficiency Operation, Lowers Operating Costs

Low Distortion Output Voltage

Integrated Maintenance Bypass Switch

Meets EN 55022 Class B Requirements

Automatic Master-Slave Operation

Up to Five Inverter Modules Can Be Paralleled As Load

Increases

No Single Points Of Failure

User Friendly Display Of Operating Mode

Optional—Seismic Zone 4 Certified

Optional—Internal AC Load Distribution Circuit Breakers

120VDC Tebevert III

System

Tebevert III_120 (R1_07) © Benning Power Electronics 2007

Specifications are subject to change without notice

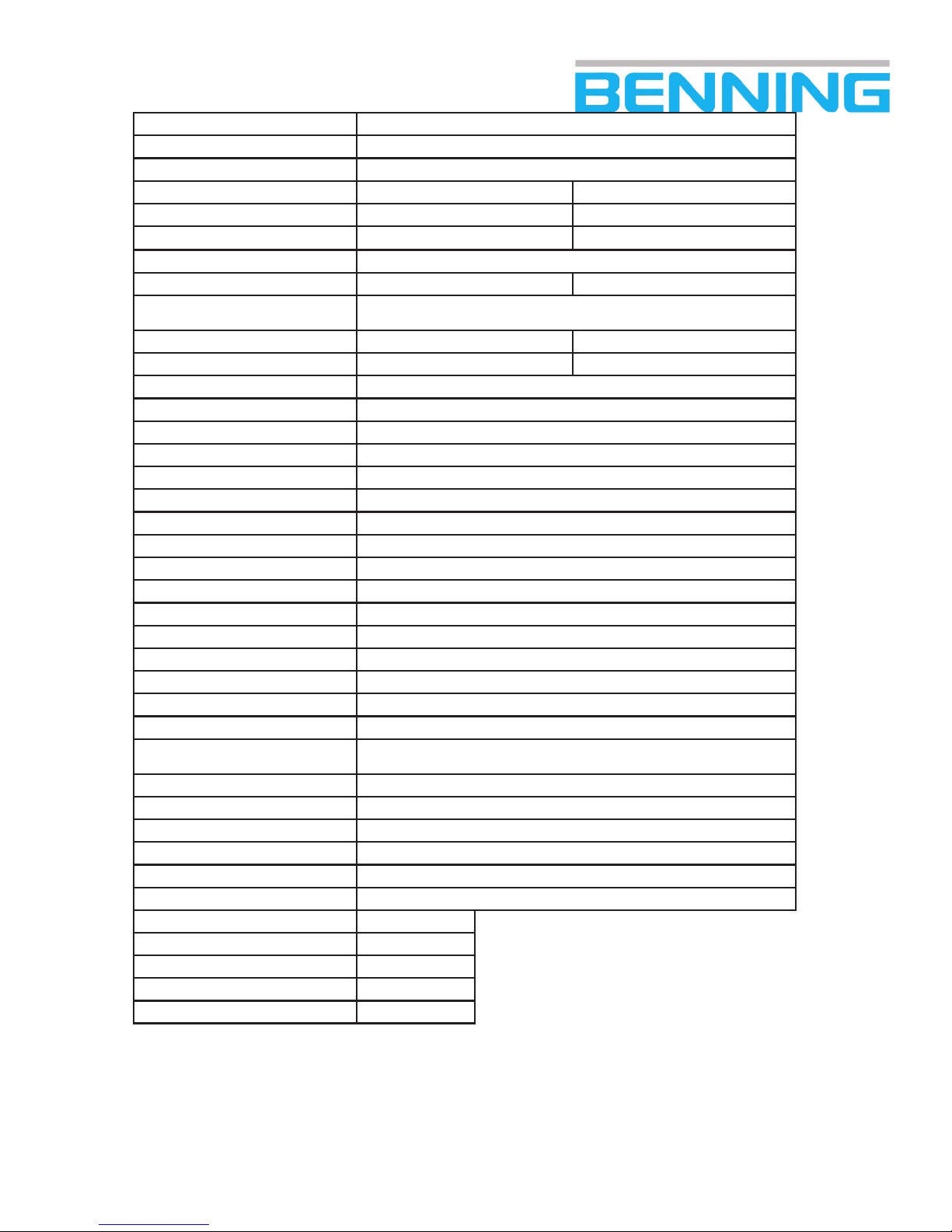

Technical Specifications

Benning Power Electronics, Inc. Toll Free: 800.910.3601

11120 Grader St . Dallas . TX 75238 Outside the US: 214.553.1444

E-Mail: sales@benning.us Fax: 214.553.1355

WEB:www.benning.us

60HZ Models

Output Capacity 5 - 25.0 KVA

Maximum Number of Modules The inverter cabinet supports a maximum of 5 inverter modules

Nominal Bypass AC Input 120 VAC 208, 220, 240, 480VAC

# of Bypass AC Phases 1 2

Bypass AC Input Wiring L, N, PE L1, L2, PE

Nominal DC Input 120VDC

DC Input Range -15%, +20%

Reflected DC Ripple, 120VDC < 2mV reverse smoothing

< 5% RMS

Nominal AC Output Voltage 120VAC 120VAC

Optional AC Output Voltage 120/240VAC 120/240VAC

Output Voltage Regulation +/- 5% for all combinations of line, load and temperature

Output Power Factor 0.7 lagging to 0.8 leading

Output Voltage Waveform PWM sine-wave

Output Crest Factor 2:8:1

Output Voltage Distortion < 3.5% @ 100% rated linear load

Output Overcurrent Protection Electronic current limiting

Overload Rating (Inverters) 200% for approx. 75 cycles (1.25 seconds)

Overload Rating (Static Bypass) 500% for 100ms

System Operating Efficiency > 89% (typical)

Frequency Stability +/- 0.1% free running, +/- 3% when AC present

Module Capacity 5.0kVA/4.0kW

Static Switch Transfer Time < 2ms

Cooling Temperature controlled fans

Maintenance Bypass Switch Standard make-before-break mechanically interlocked switch provided on all models

Remote Alarming (1) Form-C Summary Alarm, Optional Relay Card (8 Alarms)

LED indicators (Inverter Modules) Output present, fault, overload, AC synchronized, parallel operation

LED indicators (Static Bypass Switch) Power flow diagram, normal, fault, ac present, dc present, overload, load on bypass, load on

inverter

Metering (4) segment LCD display switchable between output voltage and current

Cabinet Dimensions (H x W x D) 84” (2134 mm) x 23.6” (600 mm) x 23.6” (600 mm)

Radio Interference EN 55022, class B

Altitude 6000 ft (1800 m), 13, 000 ft. (4000 m) at 30°C

Operating Temperature -5 to +40° C

Operating Humidity 0-95% non-condensing

Module Data 5.0kVA

Power Rating 5000VA/4000W

Nominal Input Current 120 VDC 38.0A

Maximum Input Current 120VDC 44A

Output Current NOM 120VAC 41.6A

TEBEVERT III INVERTER SYSTEM (120 VDC)

07.11.2011 1 028-0009-006

PREFACE

Congratulations and thank you for purchasing a Benning TEBEVERT III

Inverter System!

We at Benning are committed to supporting the needs of our customers by supplying

the customer with the proper information and documentation needed to properly install

and operate the unit purchased.

Important:

It is imperative that all the information be observed.

This avoids:

Danger during installation and operation.

Danger to operating personnel.

Downtime.

Increases the reliability and lifespan of the system.

This manual explains all the necessary information to unpack, install, and operate the

Benning BLI Inverter System and related components. Refer questions outside the

scope of this manual to our Customer Service Department.

Customer Service:

We are committed to excellence in dependability and customer satisfaction. If you have

any questions or problems, please contact the Customer Service Department at:

1.800.910.3601 or 214.553.1444 for more information.

Please read all instructions before installing or operating the equipment and save these

manuals for future reference.

TEBEVERT III INVERTER SYSTEM (120 VDC)

07.11.2011 2 028-0009-006

Switched-Mode Modular

Series TEBEVERT

(HOT-PLUG-Version)

Inverter System

Model:

5.0kVA-25.0kVA (120VDC Input, 120 VAC Output

Modules)

TEBEVERT III INVERTER SYSTEM (120 VDC)

07.11.2011 3 028-0009-006

1 SAFETY NOTES AND MARKINGS

This operating manual contains important information for the installation,

operation, and maintenance of the inverter system. This manual must be retained

and observed at all times!

Explanation of the symbols used:

Indicates safety instructions which must be followed to

avoid danger to persons!

Indicates instructions which must be followed to avoid

material damage!

All specifications in these operating instructions must be

observed at all times!

Index of abbreviations:

A Amps

AC Alternating Current

DC Direct Current

I Current

LVD Low Voltage Detector

CB Circuit Breaker

G Ground

L Line

N Neutral

SNMP Simple Network Management Protocol

V Volts

W Watts

TEBEVERT III INVERTER SYSTEM (120 VDC)

07.11.2011 4 028-0009-006

Further symbols, diagrams and pictures are explained at the appropriate

places within this operating manual.

Explanation of the abbreviations and definitions used:

SBS Static By-Pass Switch (SBS)

DVA Digital volt-ammeter

Mains Commercial AC input power source

By-pass Input Commercial AC Mains voltage providing an alternative AC

source to the connected load equipment. The By-pass

input is used by either the manual maintenance by-pass

or the SBS for back-up support in the event of an

inverter system failure.

TEBEVERT III INVERTER SYSTEM (120 VDC)

07.11.2011 5 028-0009-006

The inverter system is an electrical unit with dangerous

voltage and current levels. For this reason, the following

safety instructions must be observed.

1. Installation, operation, maintenance, and repair should be carried out in

strict accordance with the instructions in this document.

2. Ensure that only fully trained and qualified personnel have access to the

system. Only qualified and authorized personnel should be able to open

the units.

3. Even when the unit is completely switched off, some of its interior

components remain live as long as they are connected to the mains

supply or the battery.

4. Installed capacitors may be charged even when the system is

disconnected. These must be correctly discharged by a qualified

technician before the connections or terminals are touched.

5. When working at the unit, use properly insulated tools at all times which

are suitable for the levels of voltage concerned.

6. All persons working with the unit must be familiar with the first-aid

techniques to be adopted in cases of accidents involving electricity.

7. The regulations of the local power supply companies and all other

applicable safety regulations must be observed at all times.

TEBEVERT III INVERTER SYSTEM (120 VDC)

07.11.2011 6 028-0009-006

2 GENERAL

The TEBEVERT III family of modular inverter systems consists of: modular

hot-plug, inverters, and an electronic static by-pass switch (SBS). All

electrical connections are automatically disconnected or connected when

the modules are pulled out of or pushed into the system cabinet. This may

take place during normal operation without interruption in power to the

connected load equipment. This design provides an uninterrupted supply

of AC current and satisfies the highest requirements with respect to the

expansion of the system, ease of maintenance and operating safety.

The TEBEVERT III is available for DC voltages of 120VDC. Each inverter

module is available in 5.0kVA/4.0kW. Parallel operation of maximum of

five (5) inverter modules provides a maximum system rating of

25.0kVA/20kW. The output voltage is 120VAC or 120/240VAC and can be

adjusted to 50Hz or 60Hz according to the application.

Warning!

Several inverter systems may not be operated in parallel.

This may lead to the destruction of the inverter systems.

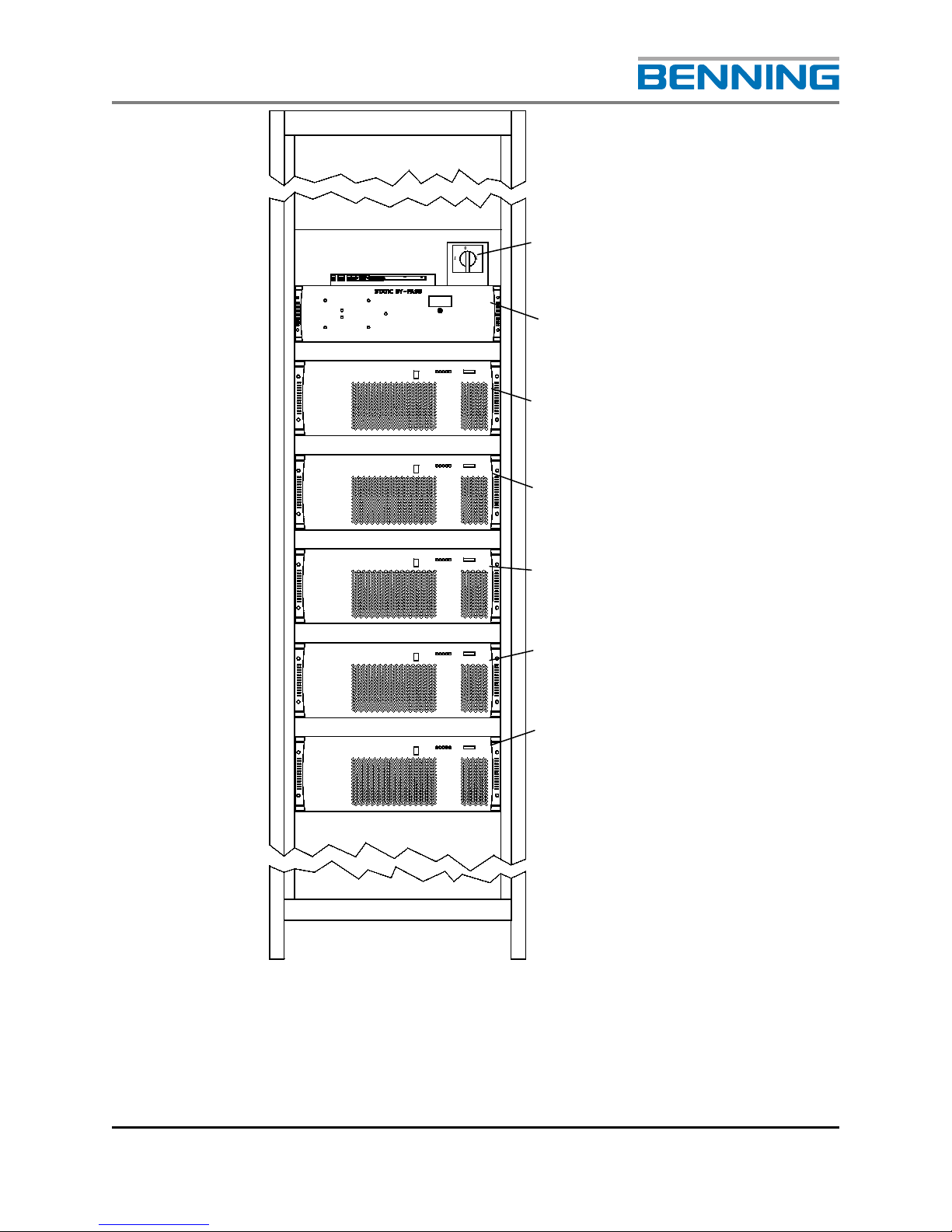

3 THE COMPONENTS OF THE TYPICAL INVERTER

SYSTEM

The design and arrangement of the components of the inverter system are

generally standardized.

The standard components are:

•(1) PSJ type equipment shelf

•5 positions for the inverters

•(1– 5) inverter modules

•(1) position for the static by-pass switch (SBS)

•(1) manual maintenance by-pass switch

TEBEVERT III INVERTER SYSTEM (120 VDC)

07.11.2011 7 028-0009-006

The input of the terminals and distribution positions within the cabinet

depend on the supplied configuration. Refer to the equipment elevation

drawing for specific terminal sizes and placement.

The inverter’s static by-pass switch is only operational when properly

installed into its corresponding position.

3.1 PSJ TYPE EQUIPMENT CABINET

The Benning TEBEVERT III system is built and supplied into a 19” PSJ

type, fully enclosed, floor standing cabinet (23.6” X 23.6” X 7’0” outside

overall dimension). Cabinets are available for New Equipment building

Standards (NEBS) and non-NEBS applications. Deep cabinets (600mm x

800mm or 23.6” x 31.5” x 7’0”) are available for special applications i.e.

raised floor, etc. consult with Benning at time of order.

TEBEVERT III INVERTER SYSTEM (120 VDC)

07.11.2011 8 028-0009-006

Input Terminals and distribution

position

(depending on the application)

Static By-Pass Switch (SBS) shelf

Inverter module shelf 5

(A5)

Inverter module shelf 4

(A4)

Inverter module shelf 3

(A3)

Inverter module shelf 2

(A2)

Inverter module shelf 1

(A1)

Transformers.

Fig. 1: Typical design of top feed cabinet

TEBEVERT III INVERTER SYSTEM (120 VDC)

07.11.2011 9 028-0009-006

Manual by-pass switch (Q10)

SBS module (A6)

Inverter Module 5 ( A5 )

Inverter Module 4 ( A4 )

Inverter Module 3 ( A3 )

Inverter Module 2 ( A2 )

Inverter Module 1 ( A1 )

Figure 2: Typical Inverter System (shown

with inverter modules, static by-pass)

0

12

TEBEVERT III INVERTER SYSTEM (120 VDC)

07.11.2011 10 028-0009-006

TYPICAL INPUT/OUTPUT TERMINALS FOR AN

INDIVIDUAL FEED CONFIGURATION

TYPICAL SNMP OPTION

Figure 3

Figure 4

TEBEVERT III INVERTER SYSTEM (120 VDC)

07.11.2011 11 028-0009-006

3.2 INVERTER MODULE SHELF

•Data line factory connected to the next inverter slot or the SBS slot (X1)

•Data connector for the inverter connection (X3)

•Load connector for the AC connection of the inverter output (X6) 3 poles

(2.5kVA) 5 poles (5.0kVA)

•Data line factory connected to the next inverter slot (X2)

•Female connector for the DC connection of the inverter (+)

•Female connector for the DC connection of the inverter

•Female connector for the protective earth of the inverter ( )

•*Each inverter carrier is equipped with two guiding rails insuring the

inverter is accurately positioned and a reliable contact is made.

TEBEVERT III INVERTER SYSTEM (120 VDC)

07.11.2011 12 028-0009-006

3.3 SBS MODULE SHELF

•Terminal block for the connection of the auxiliary DC supply to the SBS (X26)

•Terminal block for the voltage-free collective fault messaging system of the

inverter system (X25)

•Terminal block for the connection of the auxiliary contact signifying the by-

pass switch is in the “manual by-pass inverter” position (X27)

•Terminal block for the connection of the auxiliary contact signifying the by-

pass switch is in the "manual by-pass mains" position (X28)

•D-SUB connector for the optional connection of the inverter system to the

MCU remote monitoring system (X23)

•DIP switches, without function (S1)

•Data line to the inverter slot (X10) (This is used if there are inverters

arranged above the SBS. Not standard!)

•Manual by-pass switch with locking mechanism for the SBS (Q10)

•Female connector for the neutral contact mains input (N)

•Female connector for the neutral contact mains input (N)

Table of contents

Other Benning Inverter manuals

Popular Inverter manuals by other brands

Xantrex

Xantrex PROWATT SW SW 1000 owner's guide

MPP Solar

MPP Solar 1KVA-5KVA user manual

HiQ Solar

HiQ Solar TrueString TSXL380-8k-VN Installation & operator's manual

DeWalt

DeWalt DXGNI 2500 instruction manual

Outback Power Systems

Outback Power Systems FX 2012MT Specification sheet

Stephill

Stephill SE6000D4 Handbook