Benning DSP 2500 User manual

DSP 2500

Inverter System

028-0009-200

Benning Power Electronics

11120 Grader Street

Dallas, TX 75238 USA

214.553.1444

800.910.3601

This manual contains

important safety instructions

that should be followed during

installation and maintenance

of the Power System.

Operations and Maintenance Manual

Preface

Congratulations and thank you for purchasing a Benning DSP 2500 Inverter

System.

We at Benning are committed to supporting the needs of our customers by supplying

the customer with the proper information and documentation needed to properly install

and operate the unit purchased.

Important:

It is imperative that all the information be observed.

This avoids:

Danger during installation and operation.

Danger to operating personnel.

Downtime.

Increases the reliability and lifespan of the system.

This manual explains all the necessary information to unpack, install, and operate the

Benning DSP 2500 Inverter System and related components. Refer questions outside

the scope of this manual to our Customer Service Department.

Customer Service:

We are committed to excellence in dependability and customer satisfaction. If you have

any questions or problems, please contact the Customer Service Department at:

1.800.910.3601 or 214.553.1444 for more information.

Please read all instructions before installing or operating the equipment and save these

manuals for future reference.

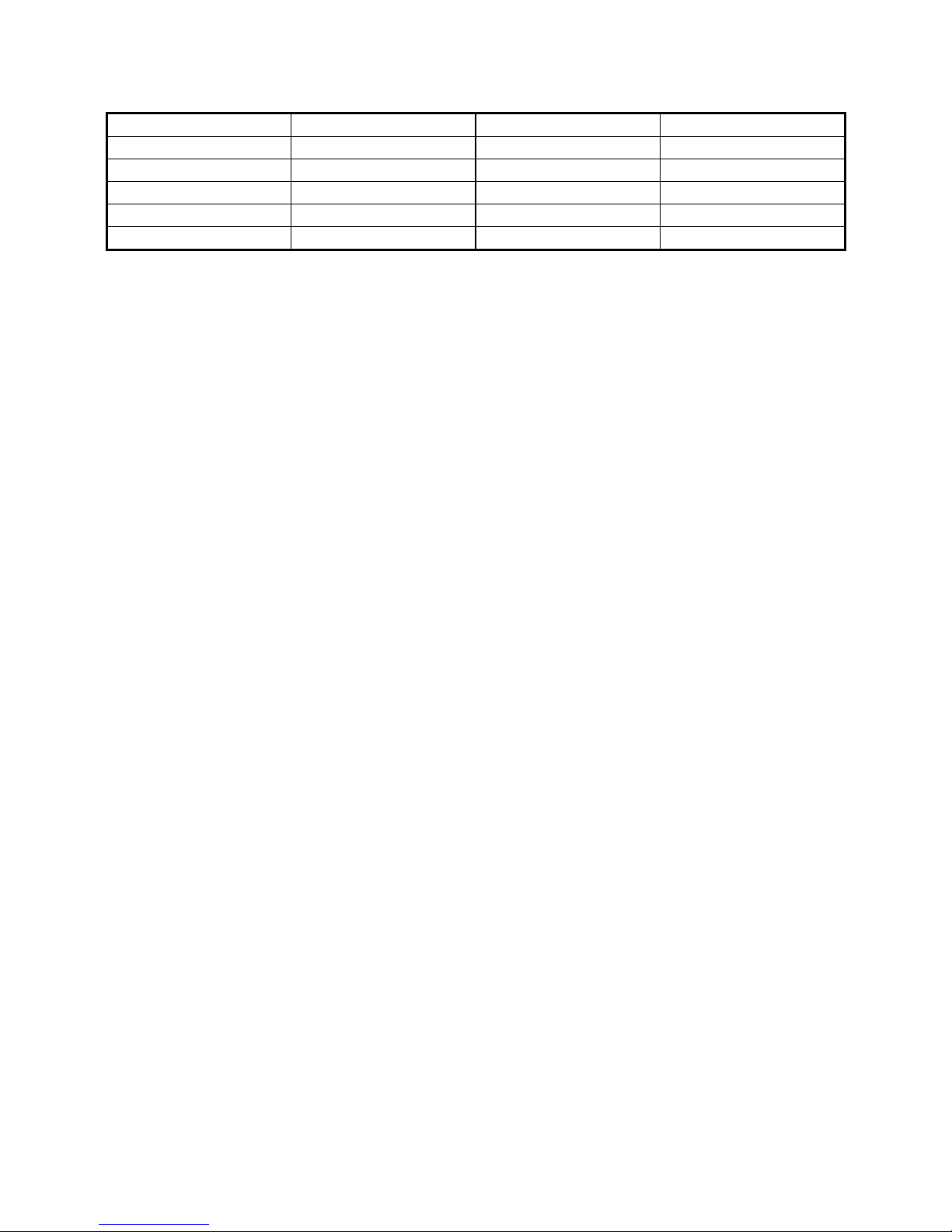

Revision

Date

Originator

Approver

A

10.15.07

C.Tumey

D.Almond

{Revision}

{Date}

{Originator}

{Approver}

{Revision}

{Date}

{Originator}

{Approver}

{Revision}

{Date}

{Originator}

{Approver}

{Revision}

{Date}

{Originator}

{Approver}

Publication Document: Version 1.0

Copyright © 2007 Benning Power Electronics

Proprietary Information: This manual contains proprietary information which is protected

by copyright law. All rights are reserved. No part of this manual may be photocopied,

reproduced, or translated to another language without prior written consent of Benning

Power Electronics. Specifications in this manual are subject to change without notice.

Table of Contents

1. SAFETY NOTES......................................................................................................2

2. GENERAL................................................................................................................3

3. INVERTER ...............................................................................................................4

4. DIMENSIONS OF THE UNIT....................................................................................5

Fig. 1: Dimension diagram of the DSP Inverter ......................................................5

5. TERMINALS AND OPERATING ELEMENTS .........................................................6

Fig. 2: Front view of the DSP Inverter.....................................................................6

Fig. 3: Rear view of the DSP inverter .....................................................................8

6. TECHNICAL DATA..................................................................................................9

7. ASSEMBLY AND COMMISSIONING ....................................................................18

8. DEVICE SETTINGS ...............................................................................................19

9. CONNECTING THE INVERTER ............................................................................19

10. INSTALLATION OF THE UNIT..............................................................................21

11. COMMISSIONING THE INVERTER ...................................................................22

12. MAINTENANCE / REPAIR .................................................................................22

13. DESCRIPTION OF FUNCTION ..........................................................................23

14. CONFIGURATION INDEX ..................................................................................25

DSP 2500 Inverter System

10.15.07 1 028-0009-200

Explanation of the symbols used:

Indicates safety instructions which must be followed to avoid

danger to persons!

Indicates instructions which must be followed to avoid

material damage!

All specifications in these operating instructions must be

observed at all times!

General instructions which must be observed

DSP 2500 Inverter System

10.15.07 2 028-0009-200

1. Safety Notes

The inverter is an electronic device which operates at

dangerous voltage and current levels.

For this reason, the following instructions must be followed at all times!

1. The inverter should be installed, operated, repaired and

maintained in accordance with the instructions in this document.

2. Only fully trained and qualified personnel should have access to

the system. Only qualified and authorized personnel should be

able to install the units.

3. Capacitors may be charged even when the unit is disconnected.

These must be correctly discharged by a qualified electrician

before the connections or terminals are touched.

4. When working with the unit, use properly insulated tools at all

times which are suitable for the levels of voltage concerned.

5. All persons working with the unit must be familiar with the first-

aid measures to be adopted in cases of accidents involving

electricity.

6. Always observe the regulations of the local operating company

as well as other safety regulations.

Attention!

The inverter may be operated at 120 (L1, N, G), 240 (L1-

N/L2-G) or 120/240 (L1-N-L2) systems.

The neutral conductor of the inverter is connected internally

to the protective wire. ( )

DSP 2500 Inverter System

10.15.07 3 028-0009-200

2. General

The inverters in the DSP can be utilized for a wide range of applications in the

field of telecommunications and other applications. The output power of the

inverter is 2500VA with 48VDC input model. The inverters utilize Digital Signal

Processor (DSP) technology, programmed with the appropriate algorithms to

carry out control and monitoring of the inverter. Please be aware that this unit is

designed for a 4 post cabinet installation and NOT for relay rack applications

unless a shelf is present.

Attention!

These inverters are designed for parallel operation

with limitations. To be submitted at a later release.

DSP 2500 Inverter System

10.15.07 4 028-0009-200

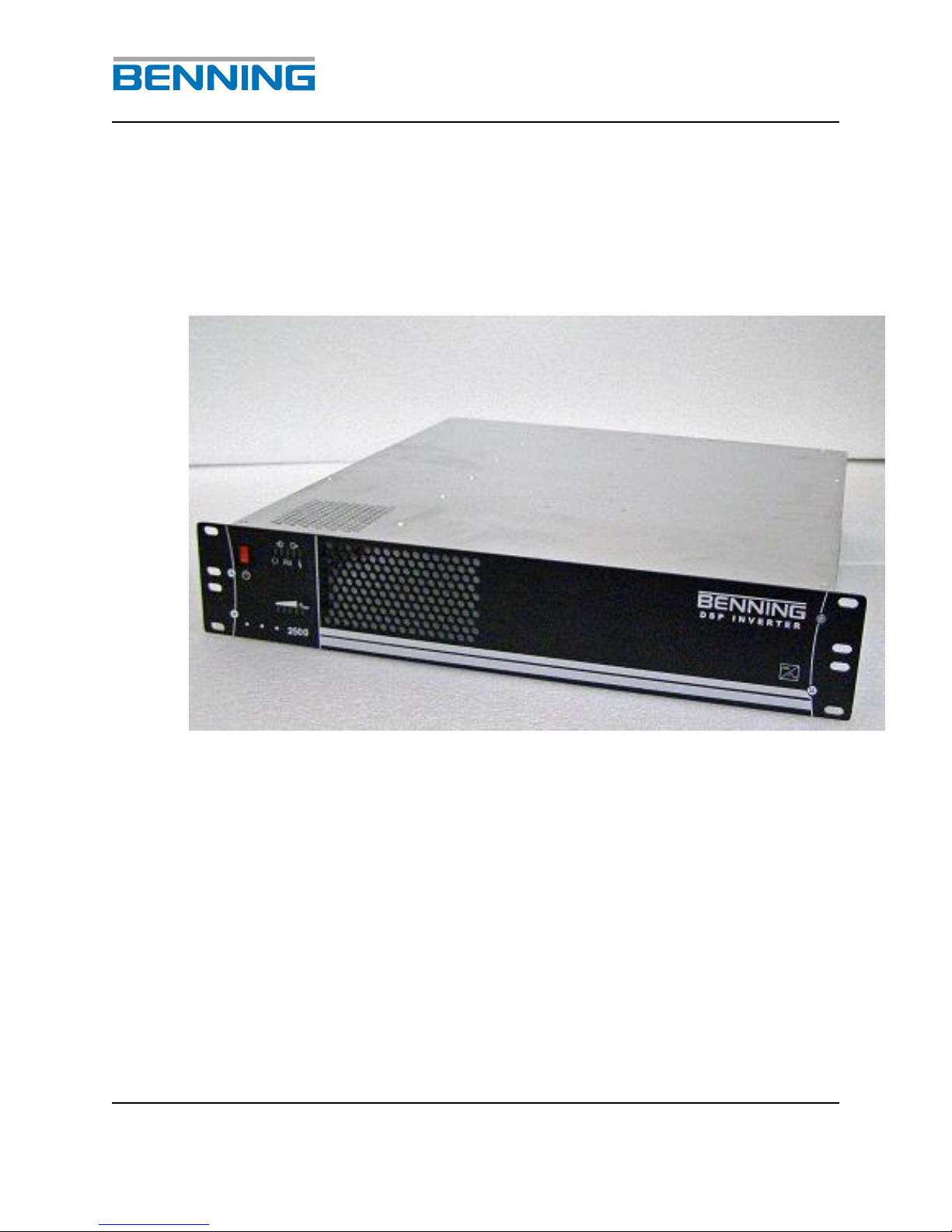

3. Inverter

The DC input voltage of 48 VDC is converted inside the inverter to an AC voltage

of 120, 240 or 120/240VAC at 60Hz.

DSP 2500 Inverter System

10.15.07 5 028-0009-200

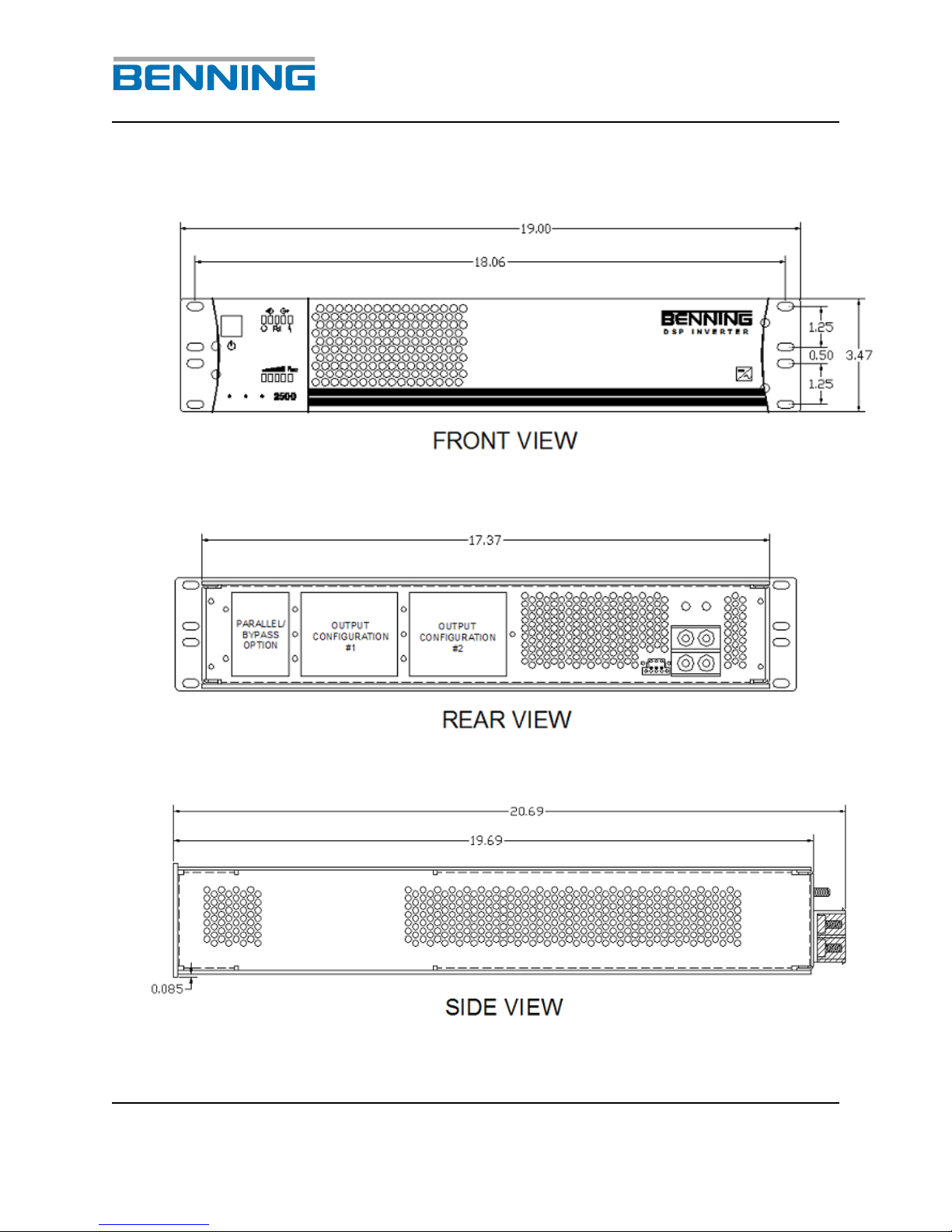

4. Dimensions of the Unit

Fig. 1: Dimension diagram of the DSP Inverter

DSP 2500 Inverter System

10.15.07 6 028-0009-200

5. Terminals and Operating Elements

All operating elements are located on the front, installer connections are found on

the rear the inverter.

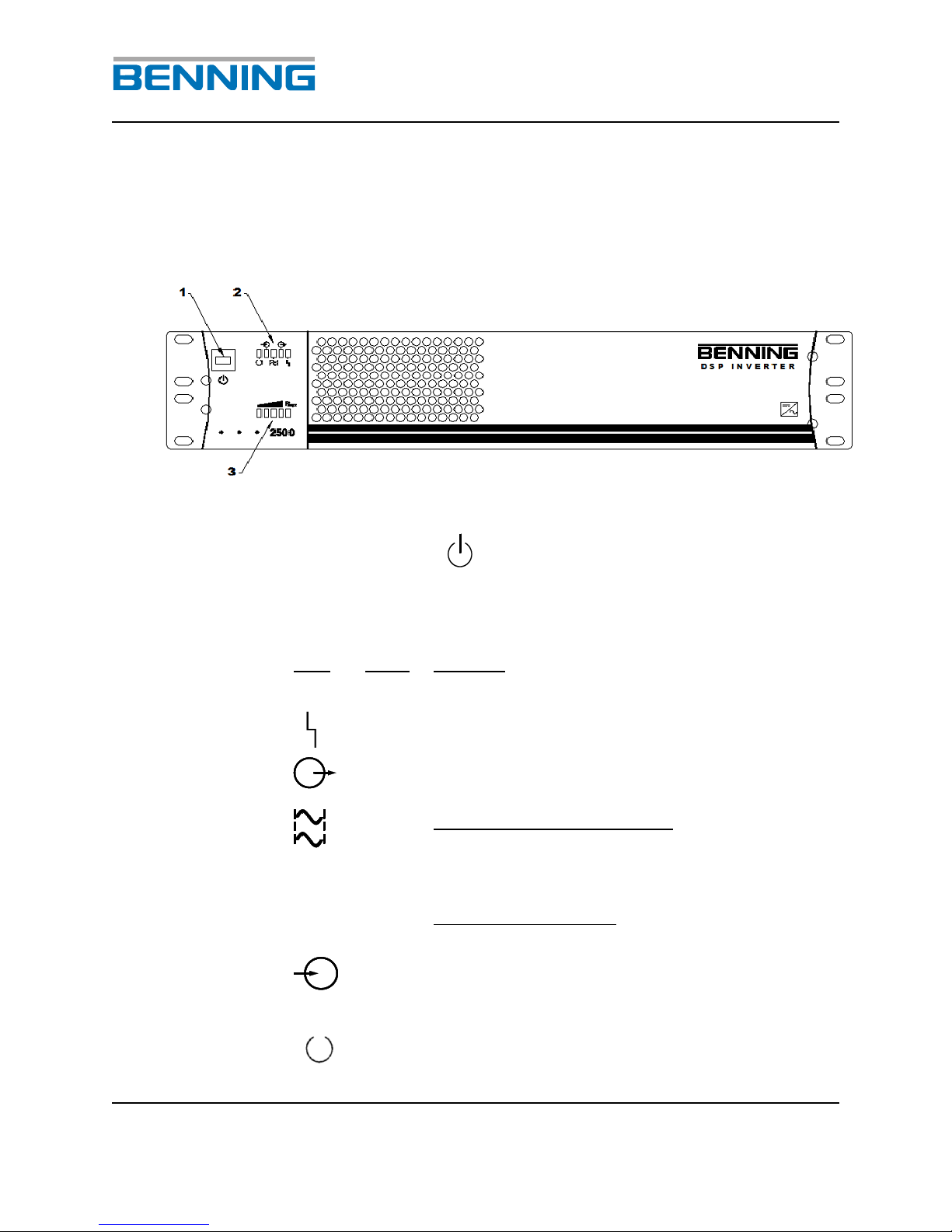

Fig. 2: Front view of the DSP Inverter

1Unit switch ON/OFF

2LED’s for indicating the inverter status

LED

Color

Meaning

red

Error

green

Output voltage present and connected

through to the load receptacles

green

LED in continuous operation:

The output voltage of the inverter is phase

locked to the other inverters in the system;

parallel operation only

LED in flashing mode:

MASTER functionality; parallel operation only

green

The DC input voltage is within the acceptable

input range. If light is blinking the DC voltage

is out of range.

green

Inverter ON

DSP 2500 Inverter System

10.15.07 7 028-0009-200

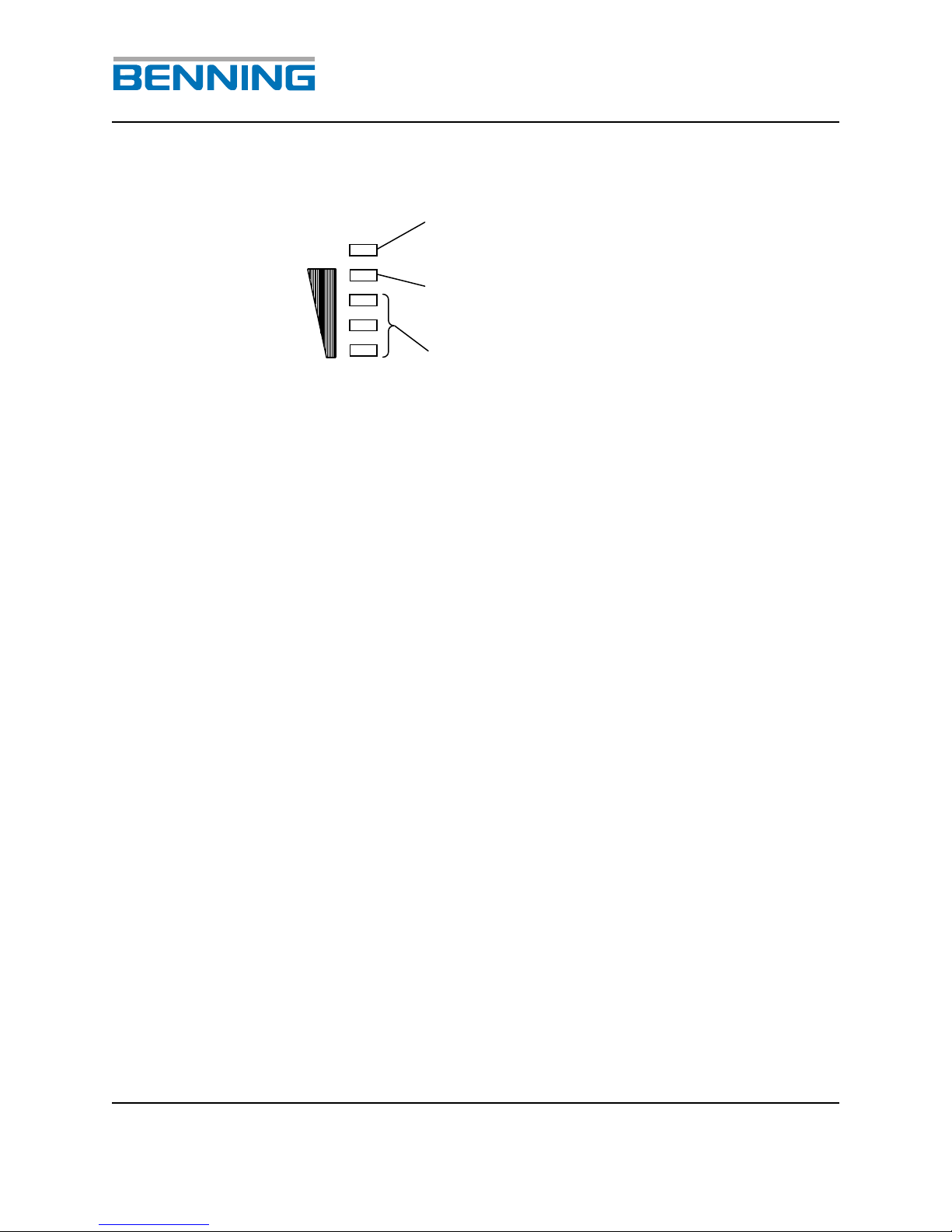

3 LED’s for signalling the actual inverter output power

The inverter is overloaded if the LED is flashing

(RED)

When this LED is lit the inverter is loaded nearly

to the limit (YELLOW)

The lit LED’s indicate the approximate load level.

(Green)

Pmax

DSP 2500 Inverter System

10.15.07 8 028-0009-200

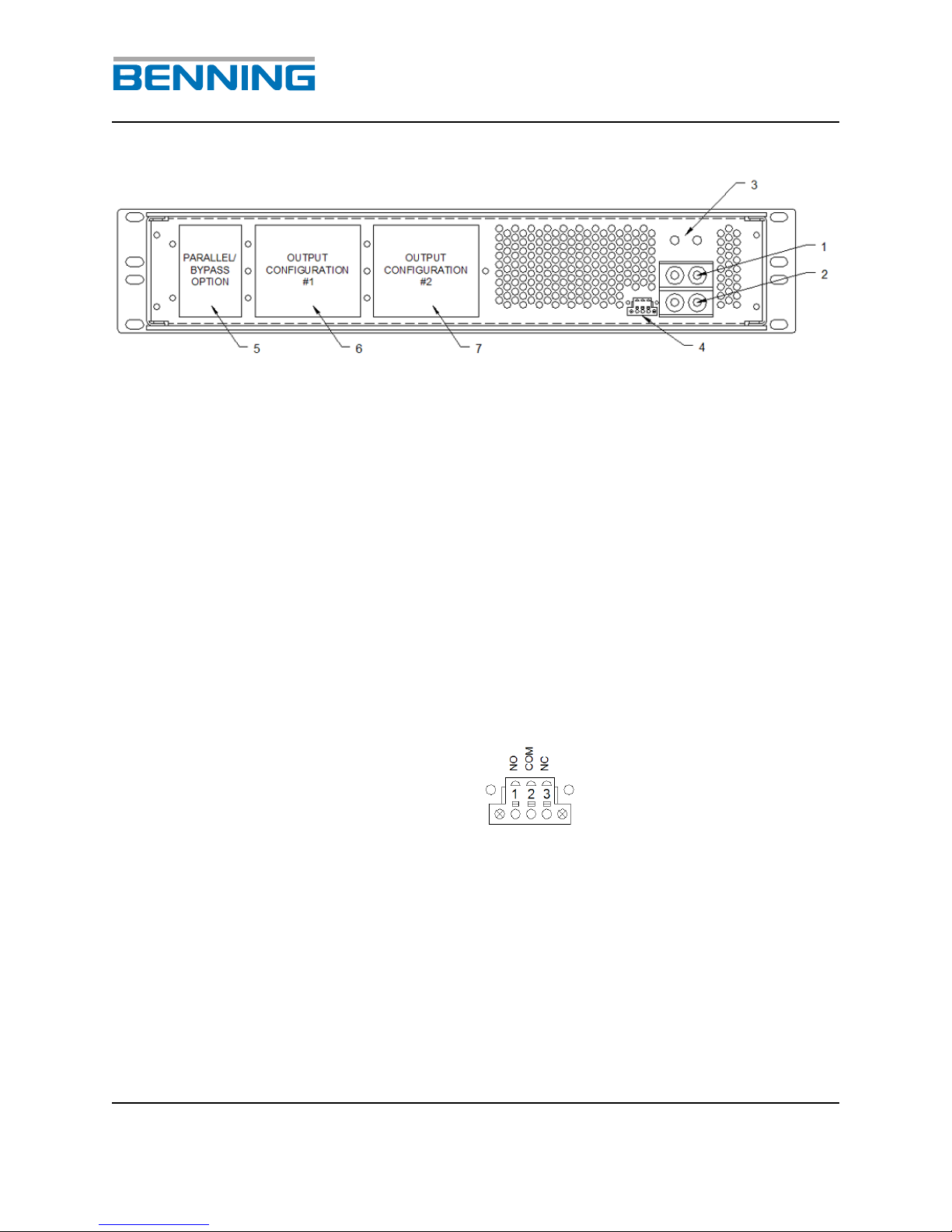

Fig. 3: Rear view of the DSP inverter

1(+); Copper bar / threaded stud; plus (+) connection for the DC

input of the inverter. Arranged for ¼” x 5/8”, two-hole crimp lug

2(-); Copper bar / threaded stud; negative (-) connection for the

DC input of the inverter. Arranged for ¼” x 5/8”, two-hole crimp

lug.

3Grounding location (PE).

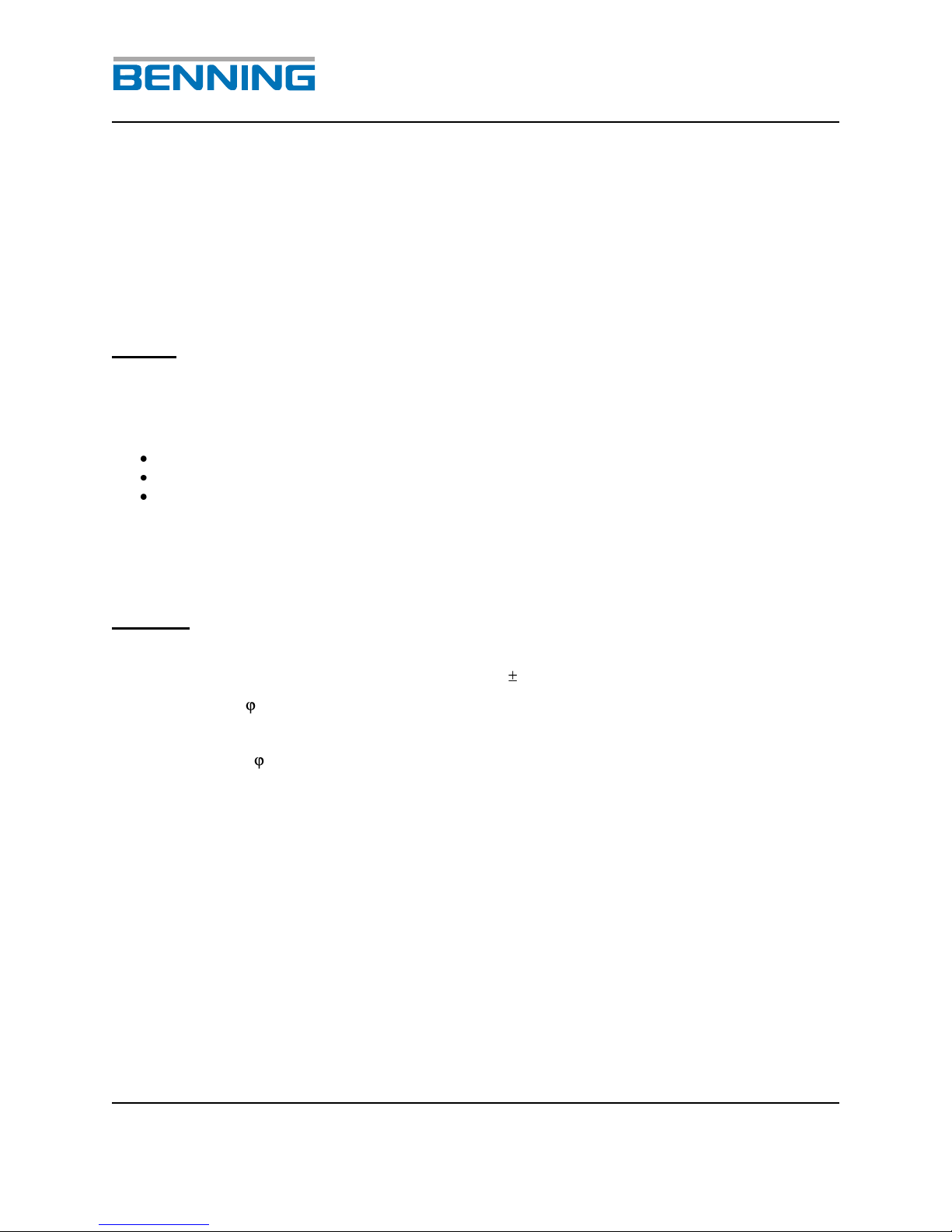

4Potential free central fault signal.

5 Parallel Bypass Option Panel. (See section 14 for options)

6 Output Configuration #1 Panel. (See section 14 for options)

7 Output Configuration #2 Panel. (See section 14 for options)

DSP 2500 Inverter System

10.15.07 9 028-0009-200

6. Technical Data

Tebevert DSP (2500VA @ 120VAC)

The inverter module features DSP controlled high frequency, switch mode PWM

technology. The module converts the incoming DC voltage to computer grade

120VAC 60Hz power for use by the connected customer equipment.

DC Input

Nominal DC voltage: 48 VDC

Permissible deviation from the rated value: +20%; -15%

Input current at nominal real power

Rated voltage 100%: (48V) 47.0 A

Overvoltage 120%: (48V x 1.2V) 39.0 A

Undervoltage 85%: (48V x .85V) 55.0 A

Input current at no load operation at rated voltage: 1.4 A

Permissible ripple of input voltage: 5% eff.

Breaker or fuse requirement 70 AMP

AC Output

Alternating voltage: 120 VAC

Static voltage tolerance: 1%

Rated power (cos =0, 8): 2.5 kVA (total)

Nominal real power: 2.0 kW (total)

Rated current: (cos =0, 8) 20.8A @ 120VAC

Short-circuit behavior: >6000VA (total) for 4 s, after that cut-off

(DIN VDE 0100 - 410)

Overload behavior: 2xINfor 4 s, after that reduction to 1.2xINfor

60s,

after that unit turns off

Overload capacity-permanent: 1.1xIN(total)

Crest factor: 2.8

max. peak current 2.8xIN, the permissible

effective nominal current decreases in case of

higher crest factor

Frequency: 60Hz

DSP 2500 Inverter System

10.15.07 10 028-0009-200

Frequency stability: 0.1% crystal controlled

Distortion factor: 2% at linear load

Permissible power factor: cos = 0.7 ind. to cos = 0.8 cap.

Efficiency at nominal real power: > 88 %

Internal output fuse: T30A/250V

Physical/Environmental

Weight: 30 lbs.

Permissible temperature range (non condensing): 0°C .... +40°C without derating

+41°C ... +55°C with linear derating of 100% to 60%

output at a rate of 2.5%PN/°C

(shutdown at +55°C, automatic restart at +53°C)

Cooling mode: Temperature controlled forced cooling, front to

back

Color: Black Textured Powder Coat Faceplate

Radio interference degree: B (EN 55022)

Protection Class: UL 1950

Input/Output Connections

DC Input: Two pole terminal block accepting a 2 hole lug,

5/8”cc, ¼” studs, 1 AWG Max

(2AWG to 2/0 possible with narrow tongue lug)

Frame Ground: 5/8”cc, ¼” studs, 1 AWG Max

(2AWG to 2/0 possible with narrow tongue lug)

120VAC Output Options: Three NEMA 5-15 output receptacles protected by a

15A push to reset circuit breaker

DSP 2500 Inverter System

10.15.07 11 028-0009-200

Three NEMA Output receptacles protected by a 20A

push to reset circuit breaker

One 120VAC Bulk Terminal Block Output (L, N, G)

protected by a single-pole 30A rocker style breaker

Parallel Module Option: Dual RJ-45 receptacles and 120VAC Bulk Terminal

Block Input (L, N, and G) for parallel unit operation

Alarm: Potential free contact (NO, C, NC), issued when

Output AC is no longer present

Phoenix “Spring Clamp” style connector

Indicators

Optical Display: Output voltage present

Mains synchronized

Parallel module synchronized

Fault

Overload

Agency Approvals

Listed to UL 1950

DSP 2500 Inverter System

10.15.07 12 028-0009-200

Tebevert DSP (2500VA @ 240VAC)

The inverter module features DSP controlled high frequency, switch mode PWM

technology. The module converts the incoming DC voltage to computer grade

240VAC 60Hz power for use by the connected customer equipment.

DC Input

Nominal DC voltage: 48 VDC

Permissible deviation from the rated value: +20%; -15%

Input current at nominal real power

Rated voltage 100%: (48V) 47.0 A

Overvoltage 120%: (48V x 1.2V) 39.0 A

Undervoltage 85%: (48V x .85V) 55.0 A

Input current at no load operation at rated voltage: 1.4 A

Permissible ripple of input voltage: 5% eff.

Breaker or fuse requirement 70 AMP

AC Output

Alternating voltage: 240 VAC

Static voltage tolerance: 1%

Rated power (cos =0, 8): 2.5 kVA (total)

Nominal real power: 2.0 kW (total)

Rated current: (cos =0, 8) 10.7A @ 240VAC

Short-circuit behavior: >6000VA (total) for 4 s, after that cut-off

(DIN VDE 0100 - 410)

Overload behavior: 2xINfor 4 s, after that reduction to 1.2xINfor 60s,

after that unit turns off

Overload capacity-permanent: 1.1xIN(total)

Crest factor: 2.8

max. peak current 2.8xIN, the permissible effective

nominal current decreases in case of higher crest

factor

Frequency: 60Hz

DSP 2500 Inverter System

10.15.07 13 028-0009-200

Frequency stability: 0.1% crystal controlled

Distortion factor: 2% at linear load

Permissible power factor: cos = 0.7 ind. to cos = 0.8 cap.

Efficiency at nominal real power: > 88 %

Internal output fuse: T15A/250V

Physical/Environmental

Weight: 30 lbs.

Permissible temperature range (non condensing): 0°C .... +40°C without derating

+41°C ... +55°C with linear derating of 100% to 60%

output at a rate of 2.5%PN/°C

(shutdown at +55°C, automatic restart at +53°C)

Cooling mode: Temperature controlled forced cooling, front to

back

Color: Black Textured Powder Coat Faceplate

Radio interference degree: B (EN 55022)

Protection Class: UL 1950

Input/Output Connections

DC Input: Two pole terminal block accepting a 2 hole lug,

5/8”cc, ¼” studs, 1 AWG Max

(2AWG to 2/0 possible with narrow tongue lug)

Frame Ground: 5/8”cc, ¼” studs, 1 AWG Max

(2AWG to 2/0 possible with narrow tongue lug)

240VAC Output Options: Two IEC 320 (C13 or 19) output receptacles

protected by a 15A push to reset circuit breaker

DSP 2500 Inverter System

10.15.07 14 028-0009-200

One 240VAC Bulk Terminal Block Output (L1, L2, G)

protected by a double-pole 20A rocker style breaker

Parallel Module Option: Dual RJ-45 receptacles and 240VAC Bulk Terminal

Block Input (L1, L2, G) for parallel unit operation

Alarm: Potential free contact (NO, C, NC), issued when

Output AC is no longer present

Phoenix “Spring Clamp” style connector

Indicators

Optical Display: Output voltage present

Mains synchronized

Parallel module synchronized

Fault

Overload

Agency Approvals

Listed To UL 1950

DSP 2500 Inverter System

10.15.07 15 028-0009-200

Tebevert DSP (120/240VAC @ 2500VA)

The inverter module features DSP controlled high frequency, switch mode PWM

technology. The module converts the incoming DC voltage to computer grade

120/240VAC 60Hz power for use by the connected customer equipment.

DC Input

Nominal DC voltage: 48 VDC

Permissible deviation from the rated value: +20%; -15%

Input current at nominal real power

Rated voltage 100%: (48V) 47.0 A

Overvoltage 120%: (48V x 1.2V) 39.0 A

Undervoltage 85%: (48V x .85V) 55.0 A

Input current at no load operation at rated voltage: 1.4 A

Permissible ripple of input voltage: 5% eff.

Breaker or fuse requirement 70 AMP

AC Output

Alternating voltage: 120 VAC

Static voltage tolerance: 1%

Rated power (cos =0, 8): 2.5 kVA (total)

Nominal real power: 2.0 kW (total)

Rated current: (cos =0, 8) 20.8/10.4A @ 120/240VAC

Maximum Load Imbalance No greater than a +/- 10% L1 to L2 imbalance

Short-circuit behavior: >6000VA (total) for 4 s, after that cut-off

(DIN VDE 0100 - 410)

Overload behavior: 2xINfor 4 s, after that reduction to 1.2xINfor 60s,

after that unit turns off

Overload capacity-permanent: 1.1xIN(total)

Crest factor: 2.8

max. peak current 2.8xIN, the permissible effective

nominal current decreases in case of higher crest

factor

Frequency: 60Hz

Table of contents

Other Benning Inverter manuals

Popular Inverter manuals by other brands

SMA

SMA Inverter Manager installation manual

EINHELL

EINHELL BT-PG 4000 Original operating instructions

Mitsubishi Electric

Mitsubishi Electric FR-D700 Series instruction manual

TM

TM TMP Series instruction manual

Aeca

Aeca StecaGrid 8000 3ph Installation and operating manual

Cenga Power

Cenga Power BACKUP INVERTER user manual

MULTIQUIP

MULTIQUIP GA-6HA Starting instructions

Toshiba

Toshiba DEV002Z instruction manual

Outback Power Systems

Outback Power Systems FX Series installation manual

Omron

Omron SYSDRIVE MX2 SERIES user manual

Xantrex

Xantrex XPower 450 owner's manual

Tripp Lite

Tripp Lite PowerVerter DC-to-AC Inverter/Charger... owner's manual