MAINTENANCE

This ice machine requires the following types of maintenance:

•Remove the build up of mineral scale from the ice machine’s water and internal sensor system

•Sanitize all parts of the ice machine’s water system and storage bin

•Clean or replace the air lter and condenser

It is the user’s responsibility to maintain the ice machine and storage bin in a sanitary condition. Without doing this regularly, the

machine will become unsanitary. Ice machines also require occasional cleaning of their water systems with specic chemicals

used to dissolve the mineral build up that occurs over time.

EXTERIOR CLEANING

To properly clean the exterior of the unit, wipe all surfaces with a damp washcloth to remove dirt and dust. It is recommended to

use a mild soap and warm water solution to help remove heavier buildup of grease and dirt. To prevent damage to the exterior

never use steel wool or abrasive pads for cleaning. Never use bleach or citrus based cleaners on the outside of the unit.

DESCALING AND SANITIZING

It is important to descale and sanitize the ice machine every six months. This process removes lime, scale and mineral deposits

throughout the entire water system and keeps the unit in line with health code requirements. It is recommended to have this

cleaning process performed by a authorized professional to ensure its done correctly. You will need descaler and sanitizing

solutions to properly perform this cleaning process.

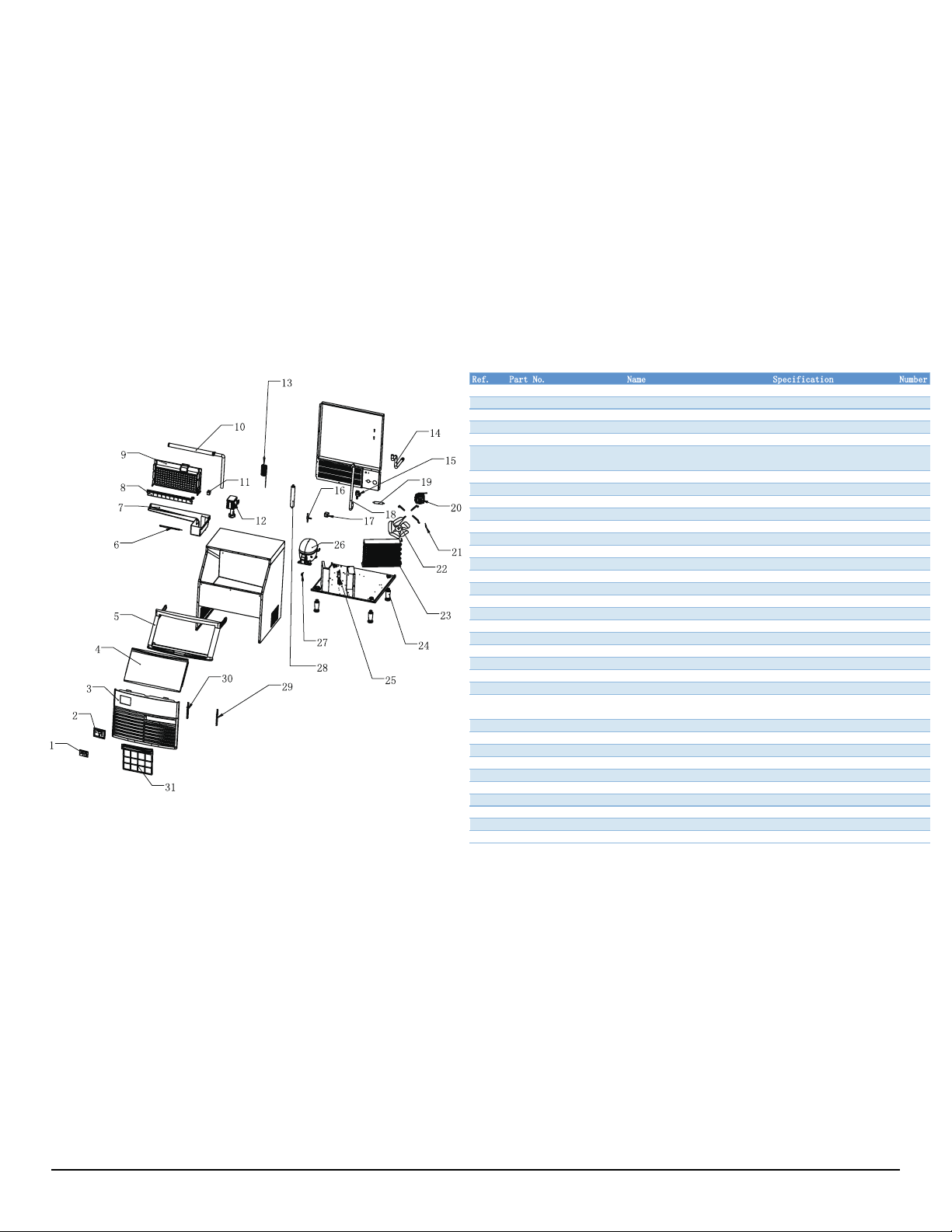

1. Remove the front panel by unscrewing the four screws located in each corner

2. Remove the evaporator cover.

3. Remove all ice from the storage bin and dispenser.

4. On the control panel push the “CLEAN” button to start the cycle.

5. Pour descaler into the reservoir. The unit will circulate the descaler, drain and ush it through the internal water system. This

process will take about 20-30 minutes. Once completed, the machine will stop circulating.

6. To clean the internal components, in a pail mix together 1 oz of descaler to 12 ounces of water. The components that need to

be sanitized are the water distributor, ice thickness sensor, adjustment screw, water level sensor and evaporator cover. These

components need to be removed from the machine and sanitized individually. Once sanitized, return the components to their

places inside the machine and run the “CLEAN” cycle again to fully ush away all of the sanitizing solution. Once the initial

harvest cycle has run, the reservoir will ll up again. Pour sanitizing solution into the reservoir to begin the next sanitizing cycle.

This cycle will take about 20-30 minutes to run. Once completed, the machine will stop circulating.

7. Once unit has completed the “CLEAN” cycle, replace evaporator cover and re-attach the front panel.

ICE STORAGE BIN

1. To clean the ice storage bin, rst remove and discard all ice.

2. Mix together a solution of descaler and water following the instructions on the descaler bottle.

3. Wash all interior surfaces of the ice storage bin to remove any mineral scale build up. Flush excess cleaning solution through

the bin’s drain.

4. Mix a solution of sanitizer and water following the instructions on the bottle.

5. Wash all interior surfaces of the ice storage bin and ush out excess sanitizer solution through the bin’s drain.

AIR FILTERS

It is important to clean the air lters regularly and prevent them from getting dirty. If not properly cleaned, the machine will not

run efciently.

1. Pull all of the air lters out.

2. Wash off dust and grease on the lter with warm water.

3. Return lter to its original position. Do not operate unit without the air lters in place. To remove air lter,

pull out from side.

November 2020