VCS II User Guide – Bergey WindPower Co.

Rev: 0 June 17, 2016 7

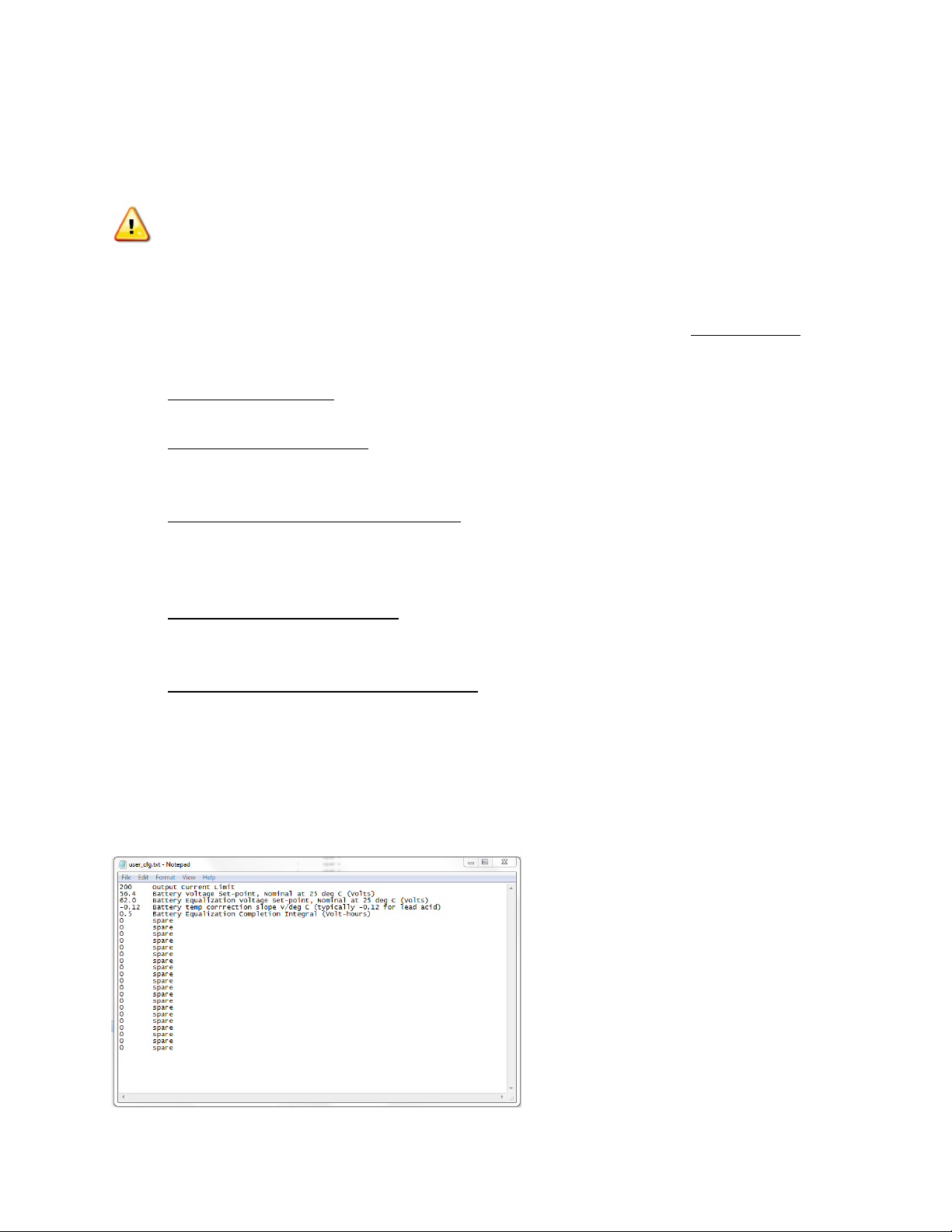

VCS II User Configuration

WARNIN : Confirm factory default settings are appropriate for you battery bank prior to

commissioning to avoid potential battery damage.

The VCS II user configurable parameters are stored on the SD card along with other files which should

not be altered without consultation of Bergey WindPower Co. The file user_cfg.txt is tab delimited and

allows setting all of the configuration settings. The file may be easily configured with any text file editor.

• “Output Current Limit”: [Adc], Factory default is “200”. This setting should not exceed 200

amps, but may be reduced to allow use with smaller battery banks.

• “Battery Voltage Set-point”: [Vdc], Factory default is “ 6.4”, for open celled lead acid

batteries. The voltage regulation is a constant voltage scheme, there are no bulk or float

settings.

• “Battery Equalization Voltage Set-point”: [Vdc], Factory default is “62.0”. The equalization

Voltage is settable, and if a battery temperature sensor is present, the equalization voltage is

temperature compensated. Equalization time is dependant on the “Battery Equalization

Completion Integral”.

• “Battery temp correction slope”: [Vdc/degC], Factory default is “-0.12”, for lead acid batteries.

Battery temperature compensation operates if an optional 10kΩ battery temperature sensor is

installed. There is only a slope correction vs temperature.

• “Battery Equalization Completion ntegral”: [V*hrs], Factory default is “0. ”, essentially

deactivating the equalization feature until the installer changes this value. Consult your battery

manufacturer. This value is defined as Volt*hours. For example at a setting of “4.0”, once

equalization is engaged, the batteries will be held above the nominal voltage either 1 volt for 4

hours, or 2 volts for 2 hours, etc. This allows for the intermittent nature of the wind, and as

soon as the totalized Volt*Hours are completed the controller will return to its normal Battery

Voltage Set-point.