Page 4 of 39

BERINGER Middle East FZC Fujairah Free Zone Phase III Fujairah, U. A. E

Phone: +971 9 277 48 51

Homepage: www.beringer-behaelter.com E-Mail: info-uae@beringer-behaelter.com

13. To ensure before initial operation:

1) Before initial operation, the reducer has to be inspected by the operator. Don’t operate the reducer

before having made a proper inspection. Please especially check the labelling.

2) Please pay attention to all labels with danger and safety instructions.

3) Fix all loose parts on the machine.

4) All lids and cover panels have to be closed before initial operation and after maintenance works.

5) The interlock at the cleanout door has to be locked.

6) Make sure that nobody is working in or on the compactor.

7) During operation nobody is allowed to be in the sphere of the hydraulic jack / heading tool. Danger of

squeezing by pivoting cylinder!

Attention: Doors / Flaps have to be closed.

14. For special employment the reducer has to be equipped with specific safety devices. In this case only

operate the reducer if those are assembled and all maintenance doors are closed.

15. Inspection, maintenance and repair works (instruction p. 11)

1) For maintenance and repair works please proceed as described in the following:

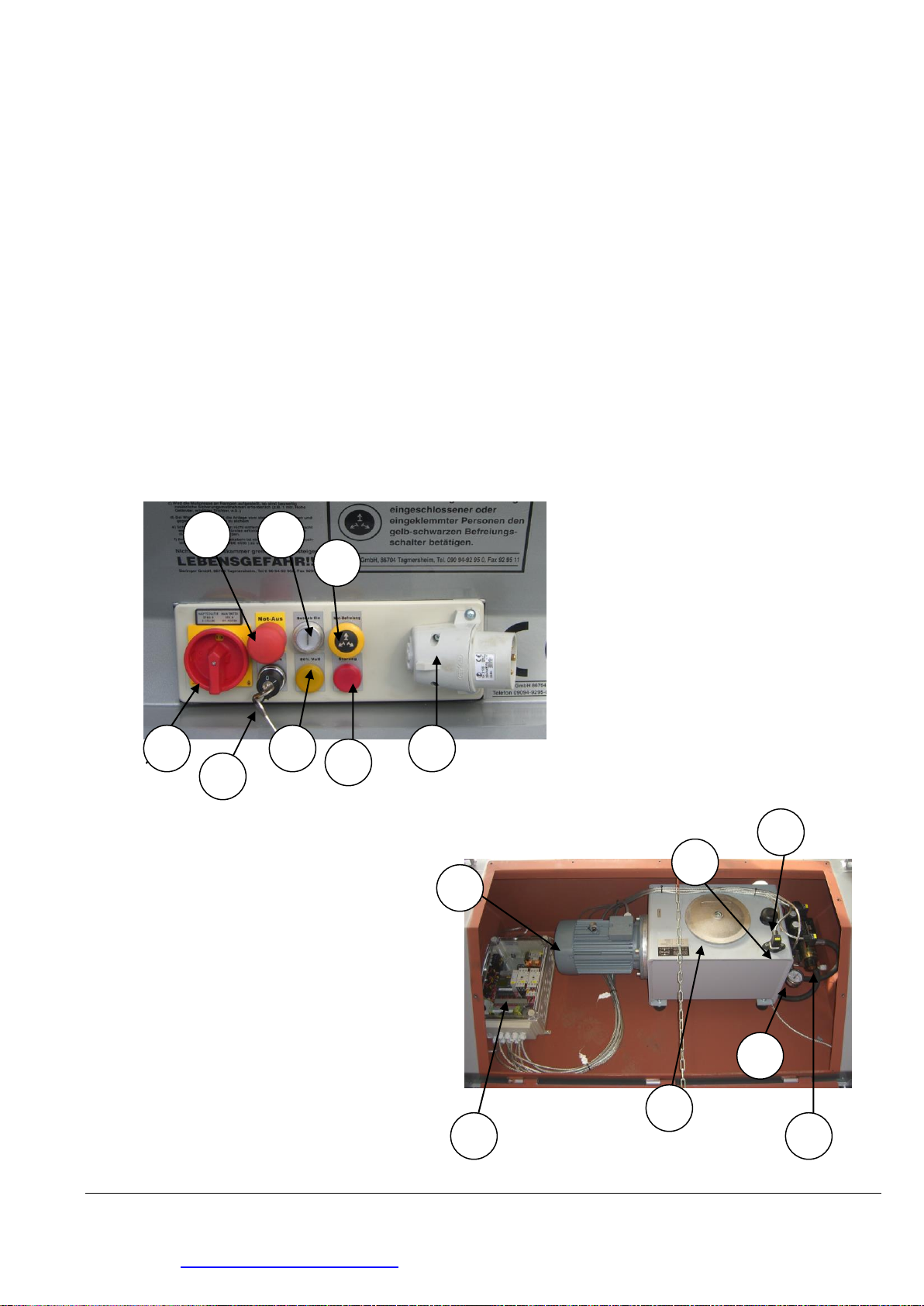

(1) Switch off motor.

(2) Switch off main switch.

(3) The key at the key switch has to be taken off in 0-position.

(4) Plug off power cable.

(5) Main switch has to be locked with a padlock against switch on.

2) The system sections and pressure pipes of the hydraulic have to be at zero pressure before repair

works.

3) Make sure that all fixtures and protective shields against vibrations, abrasion and heat accumulation

are installed according to instructions.

4) The electric installation has to be inspected by an electrician. All damages like loose connections or

wore down cables should immediately be repaired by an expert.

5) Check in periodical intervals all cables, hydraulic hoses and hydraulic connections for leaks and

damages.

6) Hydraulic oil has to be changed in cooled down condition.

7) Never jump off the compactor. Use intended footstep, ladder or base to climb down.

16. Never operate a damaged compactor. Repair all damages immediately.

17. Cleaning the reducer:

1) Be aware while using wear parts and additives. Don’t use inflammable liquids.

2) All openings where no water should impinge during cleaning have to be closed, glued or removed.