DESCRIPTION

This Submersible Sump Pump is designed to drain flooded

basements, excavations, and construction sites of rain, clear

and dirty water. Operates automatically or manually. 115V, 60

Hz., single phase, permanently split capacitor motor.

Permanently lubricated ball bearings never need lubrication.

Automatic thermal overload protection. Unit is equipped with

a 10’ 3-prong grounding-type power cord.

Housing and base are made of high impact corrosion resis-

tant plastic. Non-clog composite impeller, ceramic shaft

sleeve, and two Buna-N lip seals. Casing, shaft, and external

hardware are stainless steel.

NOTE: This unit is not designed for applications involving salt

water or brine! Use with salt water or brine will void warranty.

Pump water only with this pump.

SPECIFICATIONS

Power supply required ......................................115V, 60 HZ.

Motor duty ..........................................................Continuous*

Liquid Temp. Range...........................32°F to 77°F (0°-25°C)

Circuit Requirement (minimum) ...............................15 Amps

Discharge Adapter:.............................................1-1/4" FNPT

*NOTE: For continuous operation, water depth must be at

least 2" (5 cm).

UNPACKING AND INSPECTION

Handle with care. Check items received against packing list

to be sure that all equipment has been received. Inspect for

shipping damage. If found, file claim with carrier immediately.

INSTALLATION

1. Install pump in sump pit with minimum diameter of 10"

(25,4 cm). Sump depth should be 18" (45,7 cm).

Construct sump pit of tile, concrete, steel, or plastic.

Check local codes for approved materials.

2. Install pump in pit so that switch operating mechanism

has maximum possible clearance.

3. Pump should not be installed on clay, earth, or sand sur-

faces. Clean sump pit of small stones and gravel which

could clog pump. Keep pump inlet screen clear.

NOTE: Do not use ordinary pipe joint compound on plas-

tic pipe. Pipe joint compound can attack plastics.

4. Install discharge plumbing. Use rigid plastic pipe and

wrap threads with Teflon tape or use Plasto Joint Stik1.

Screw pipe into pump hand tight +1 – 1-1/2 turns.

*Lake Chemical Co., Chicago, Illinois

Risk of flooding. If a flexible discharge hose

is used, make sure pump is secured in sump to prevent

movement. Failure to secure pump may allow pump move-

ment, switch interference, and prevent pump from starting or

stopping.

5. To reduce motor noise and vibrations, a short length of

rubber hose (1-7/8" I.D., e.g. radiator hose) can be con-

nected into discharge line near pump using suitable

clamps.

6. Install an in-line check valve (provided with pump) to pre-

vent flow backwards through pump when pump shuts off.

7. Power Supply: Pump is designed for 115 V., 60 Hz.,

operation and requires a minimum 15 amp. circuit. Both

pump and switch are supplied with 3-wire cord sets with

grounding-type plugs. For automatic operation, switch

plug is inserted directly into outlet and pump plug inserts

into opposite end of switch plug. For manual operation,

pump plug is inserted directly into outlet.

Pump should always be electrically

grounded to a suitable electrical ground such as a

grounded water pipe or a properly grounded metallic

raceway, or ground wire system. Do not cut off round

ground pin.

8. If pump discharge line is exposed to outside sub-freezing

atmosphere, portion of line exposed must be installed so

any water remaining in pipe will drain to the outfall by

gravity. Failure to do this can cause water trapped in dis-

charge to freeze which could result in damage to pump.

9. After piping and check valve have been installed, unit is

ready for operation.

10. Check operation by filling sump with water and observing

pump operation through one complete cycle.

Failure to make this operational check

may lead to improper operation, premature failure, and

flooding.

2

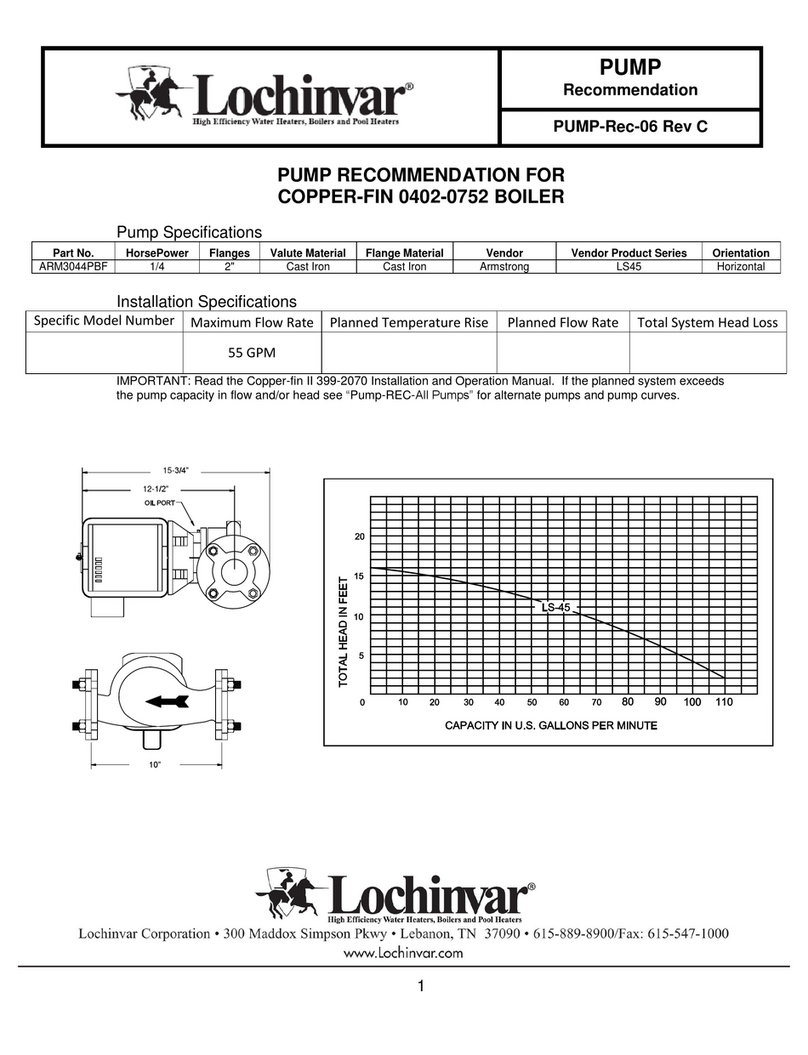

GPM (LPM) AT TOTAL FEET (m)

510152025Shut Off

Model HP (1.5m) (3m) (4.6m) (6m) (7.6m)

CAPACITY GALLONS(L)/MINUTE

30.9 24.0 16.9 – – 20

D125110VB 1/4 (117.0) (90.8) (64.0) (–) (–) (75.7)

35.2 28.0 20.8 11.4 – 24

D133110VB 1/3 (133.2) (106.0) (78.7) (43.3) (–) (90.8)

42.0 33.8 25.0 15.5 4.8 27

D150110VB 1/2 (159.0) (128.0) (94.6) (58.6) (18.2) (102.2)

No flow at

height shown

below

PERFORMANCE

Model Motor Minimum Full Circuit Cord Switch Setting in inches (mm)

Number HP Load Amps Required (Amps) Length On Off

D125110VB 1/4 2.5 15 10’ 7-9" (178-229) 1-2" (25-51)

D133110VB 1/3 2.7 15 10’ 7-9" (178-229) 1-2" (25-51)

D150110VB 1/2 3.0 15 10’ 7-9" (178-229) 1-2" (25-51)

MOTOR, SWITCH, & CORD SPECIFICATIONS