Electrical / Service 6

Step 4. For best ground connection, connect to a ground-

ed lead in the service panel or to a metal under-

ground water pipe or well casing at least 10 ft.

long. If plastic pipe or insulated fittings are used,

run ground wire directly to the metal well casing

or use ground electrode furnished by the power

company.

Before using pump, check your motor

nameplate for voltage. Your electric supply voltage and

the stamped nameplate voltage must agree. Motors

stamped 200 volts only or 230 volts only, must be used

with that voltage only. Motors stamped with two volt-

ages (for example 230/460 volts), may be used with

either supply voltage. For these motors check connec-

tions against wiring diagram on motor nameplate and

make any changes necessary to agree with your supply

voltage. If in doubt, call a licensed electrician. Incorrect

voltage will cause serious damage to the motor.

Some models are equipped with three phase motors.

Three phase motors require magnetic starters.

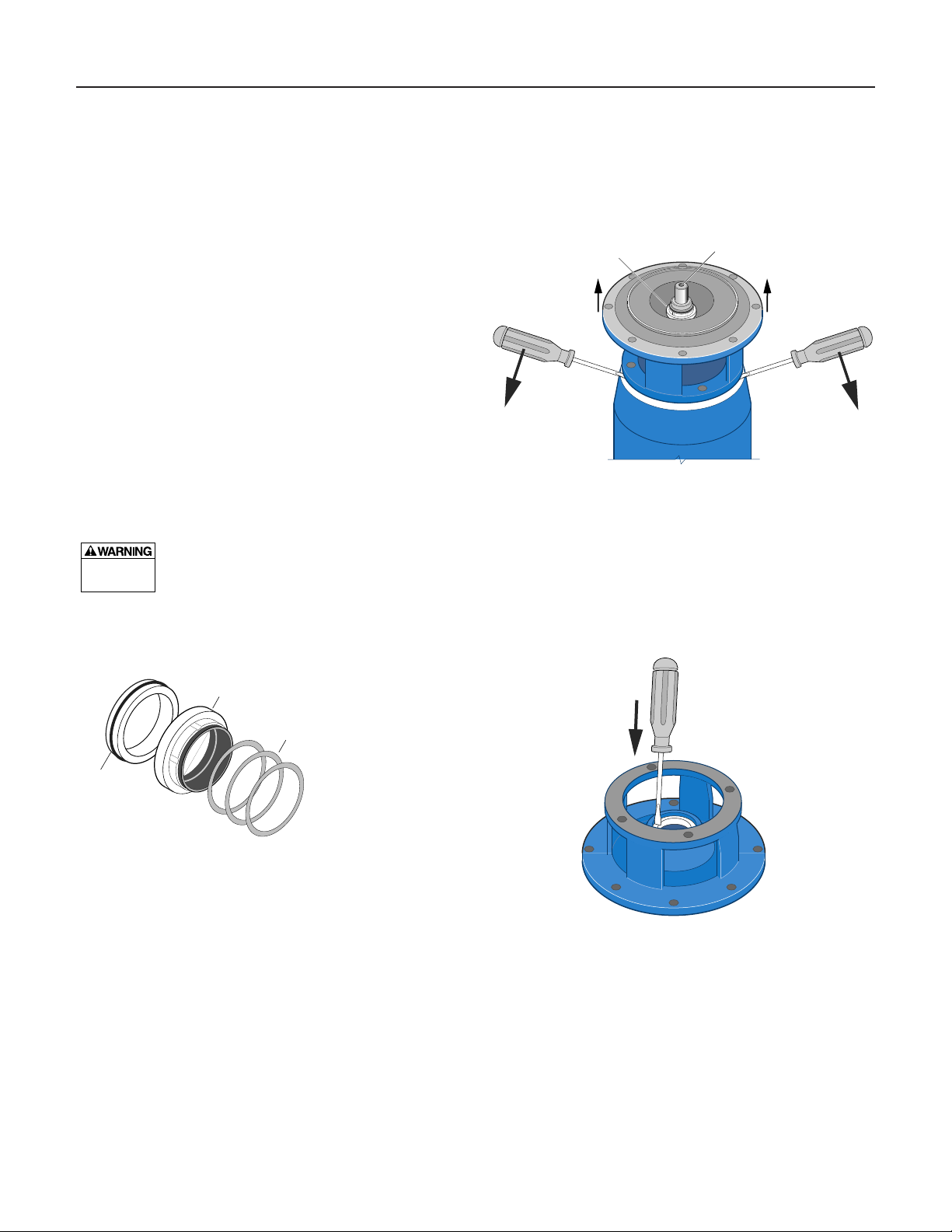

To check motors for proper rotation: The shaft can be

seen through the motor - pump adapter bracket. A mark

can be made on the shaft to make it easier to notice rota-

tion. Jog the motor (start it briefly) and note the rotation. It

should rotate clockwise when viewed from the motor-end.

If rotation is not clockwise, see motor nameplate for

hookup information. BE SURE power is off to the motor

when working on electrical connections.

Motor normally operates at high tempera-

ture and will be too hot to touch. Before handling pump

or motor, stop motor and allow it to cool for 20 minutes.

SERVICE

Never run pump dry. Running pump with-

out water may cause pump to overheat, damaging seal

and possibly causing burns to persons handling pump.

Fill pump with water before starting.

Never run pump against closed discharge.

To do so can boil water inside pump, causing hazardous

pressure in unit, risk of explosion and possibly scalding

persons handling pump.

PRIMING THE PUMP

Atee installed in the discharge opening of the pump, and

provided with a priming plug at the top position, will

enable you to fill the pump with liquid. Once filled and

the priming plug replaced, the pump will prime. The

pump should prime itself time after time, as long as the

built-in check valve functions.

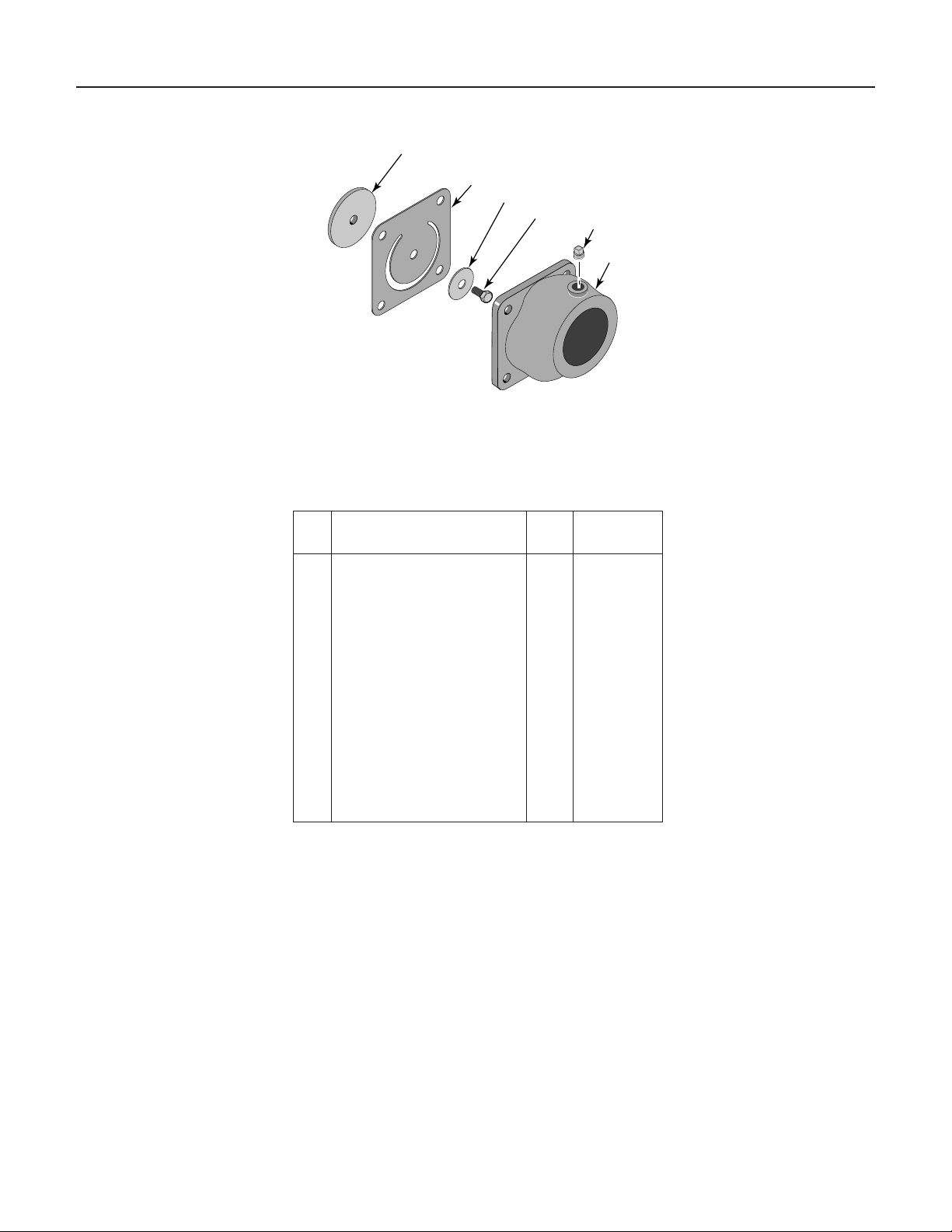

MAINTENANCE

Little or no maintenance to pump is required other than

possible replacement of shaft seal after a reasonable peri-

od of operation (see Page 8).

Lubricate motor according to motor manufacturer’s in-

structions. Periodic greasing is required for most motors.

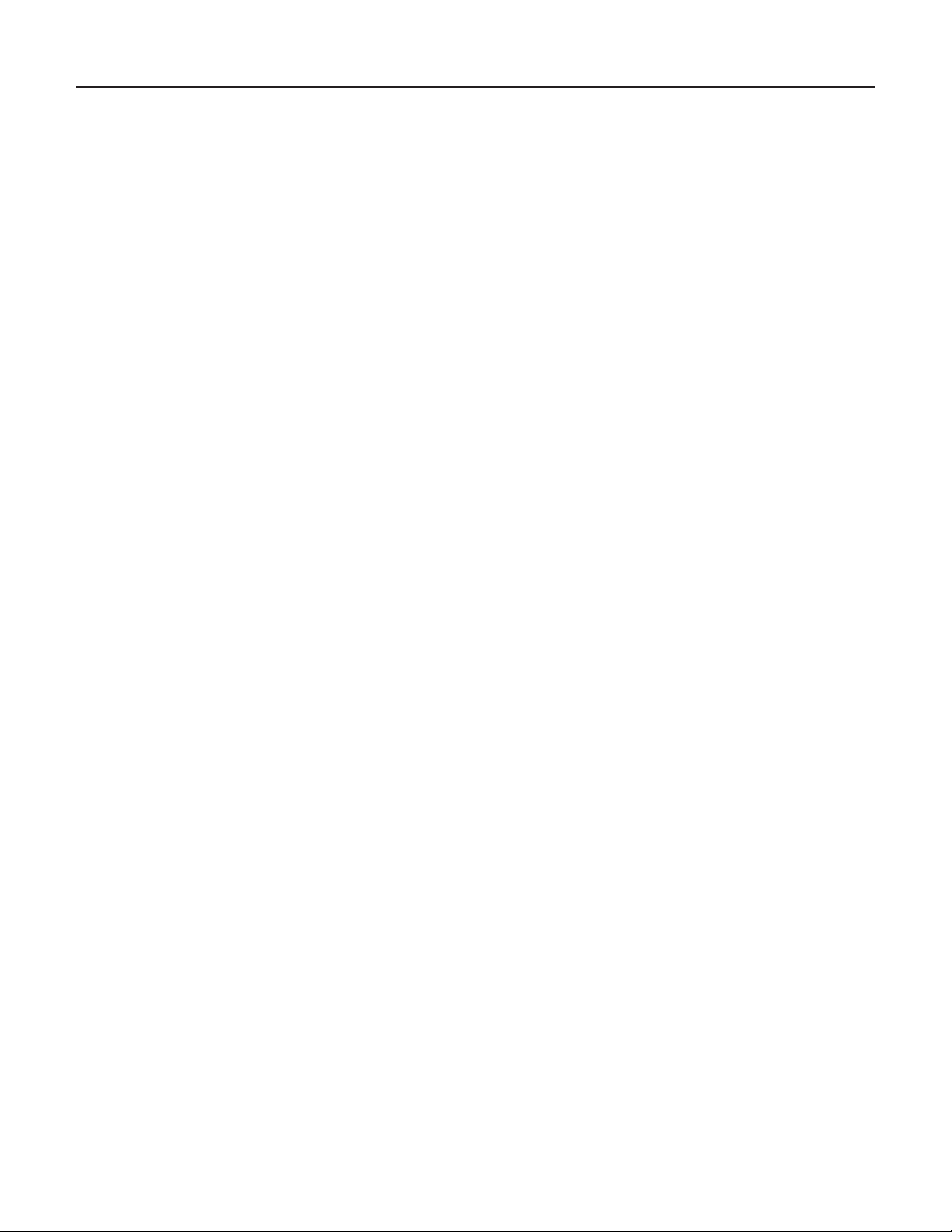

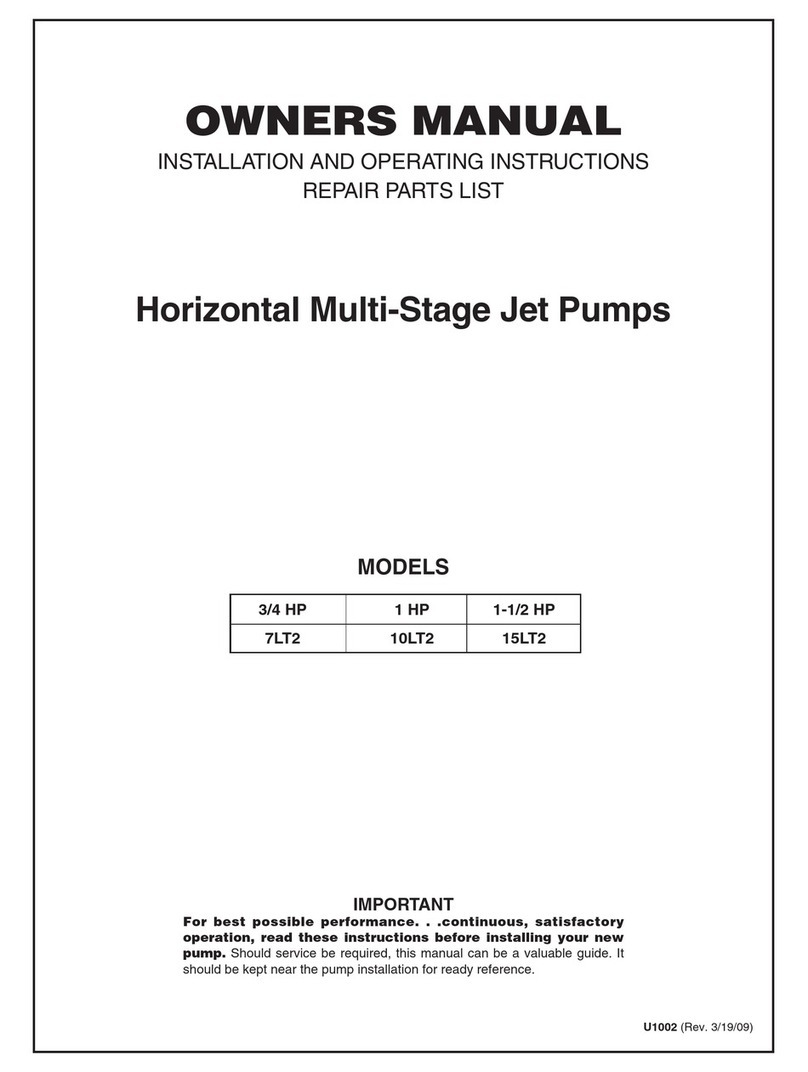

TABLE I – Recommended Wire and Fuse Sizes

DIAMETER IN FEET FROM MOTOR TO METER

BRANCH

0’ 51’ 101’ 201’ 301’ 401’

MAX. FUSE*

TO TO TO TO TO TO

MOTOR LOAD RATING

50’ 100’ 200’ 300’ 400’ 500’

HP PHASE VOLTS AMPS AMPS

WIRE SIZE

31230 17.0 25 12 12 12 10 8 8

33230 9.6 15 14 14 14 12 12 10

33460 4.8 15 14 14 14 14 14 14

51230 28.0 40 8 8 8 8 6 6

51200 32.2 50 8 8 8 8 6 6

53200 17.5 25 10 10 10 10 8 8

53230 15.2 20 12 12 12 10 10 8

53460 7.6 15 14 14 14 14 14 14

*A Fusetron is recommended instead of a fuse in any motor circuit.

IMPORTANT: BE SURE lead wire opening on end of motor is fully sealed when conduit or a pressure switch is not

used. Failure to seal it properly will allow dirt, rain, bugs, etc. to enter back compartment of motor through conduit

opening and cause switch malfunction.