Bernard T-Gun 350 amp System manual

Other Bernard Welding System manuals

Bernard

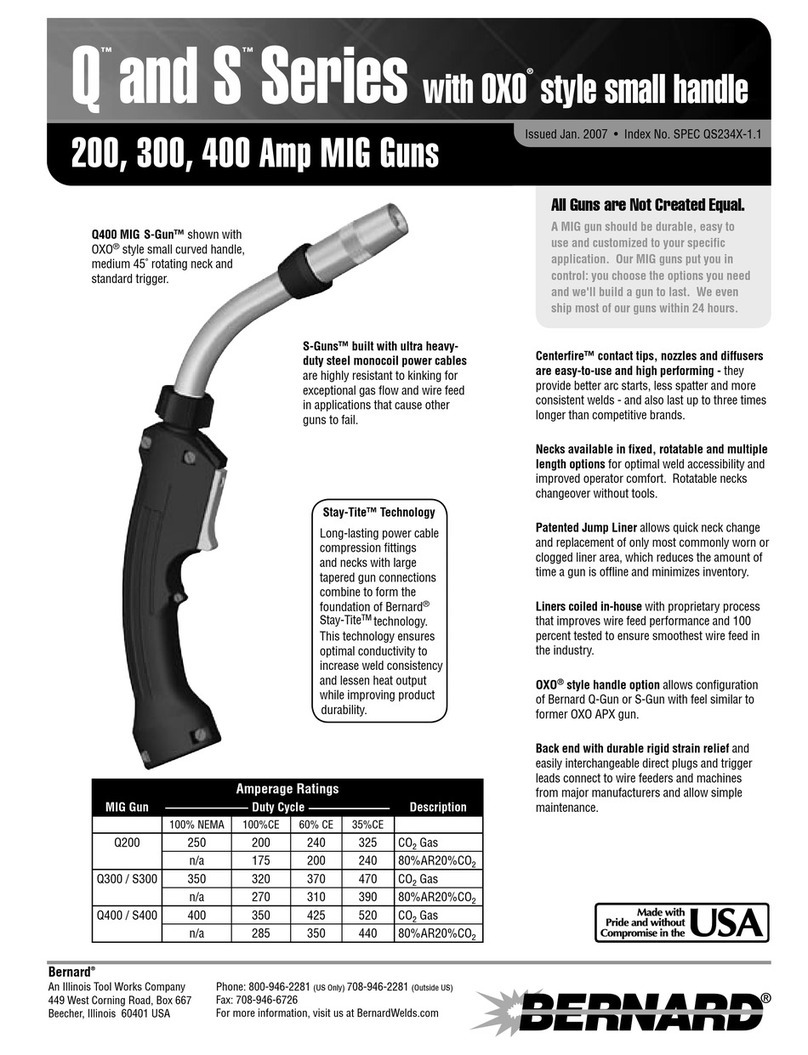

Bernard Q Series User manual

Bernard

Bernard 350 Amps Dura-Flux FLX3515AM User manual

Bernard

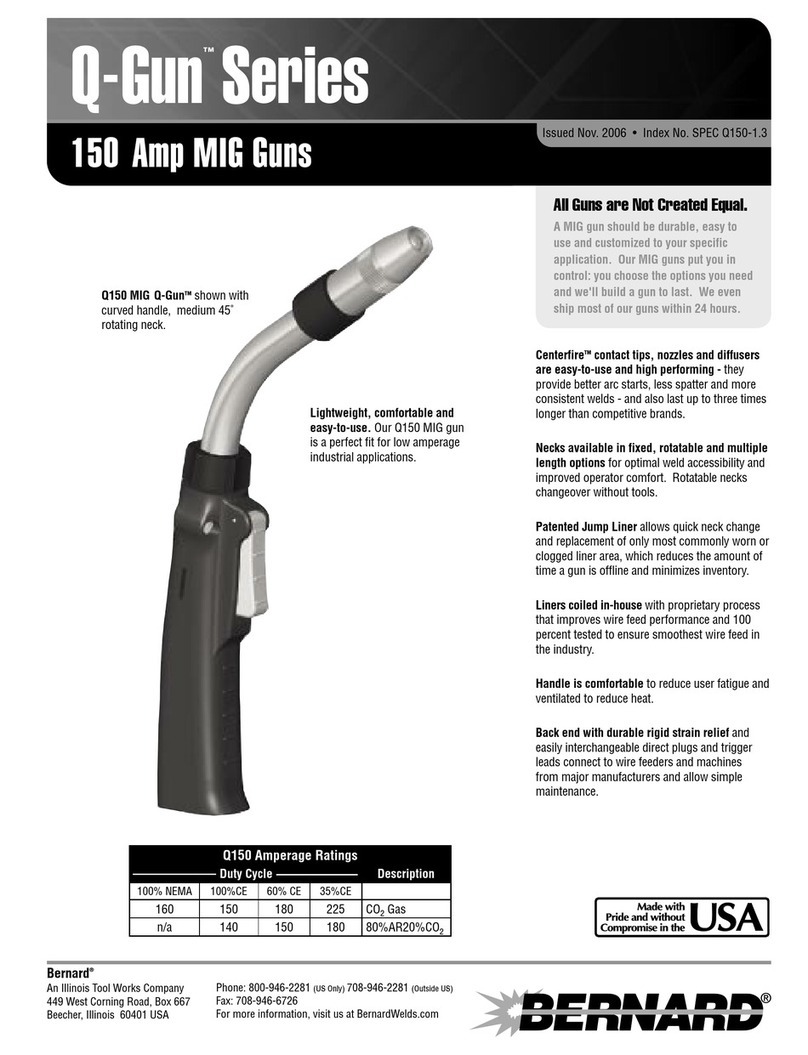

Bernard Q1501.3 User manual

Bernard

Bernard Clean Air CL30 User manual

Bernard

Bernard 600 Amp W-Gun User manual

Bernard

Bernard Air-Cooled Automatics ACAPTS-1.0 User manual

Bernard

Bernard Q20 Series User manual

Bernard

Bernard Q20 Series User manual

Bernard

Bernard T-Gun Quick start guide

Bernard

Bernard MIG Gun Configurator User manual

Bernard

Bernard TGX Series User manual

Bernard

Bernard W-Gun Series User manual

Bernard

Bernard Clean Air MIG Gun Series User manual

Bernard

Bernard TG Series User manual

Bernard

Bernard Q150X-1 Application guide

Bernard

Bernard Dura-Flux Series User manual

Bernard

Bernard S300 Application guide

Bernard

Bernard Q500 Application guide

Bernard

Bernard CLEAN AIR SERIES User manual

Bernard

Bernard OM-BTB-2.7 User manual

Popular Welding System manuals by other brands

Lincoln Electric

Lincoln Electric DUAL VANTAGE 800-I Operator's manual

Summit Racing Equipment

Summit Racing Equipment PC40 owner's manual

Red-D-Arc Welderentals

Red-D-Arc Welderentals LN25 PRO EXTREME DUAL POWER Operator's manual

Abicor Binzel

Abicor Binzel iROB 501 Original operating instructions

EWM

EWM Microplasma 25-2 PG RC operating instructions

JESS WELDING

JESS WELDING G450 S operating instructions