- 6 -

L. Reinstall the hinged access cover by positioning one hinge

into the corresponding catch located on the unit. Raise the

other hinge to the unit, when the catch is located press in the

hinge and release it into the catch. Swing the access cover

into place and align the mounting holes with the threaded in-

serts on the unit. Reinstall the two ¼” bolts. See Figure 11.

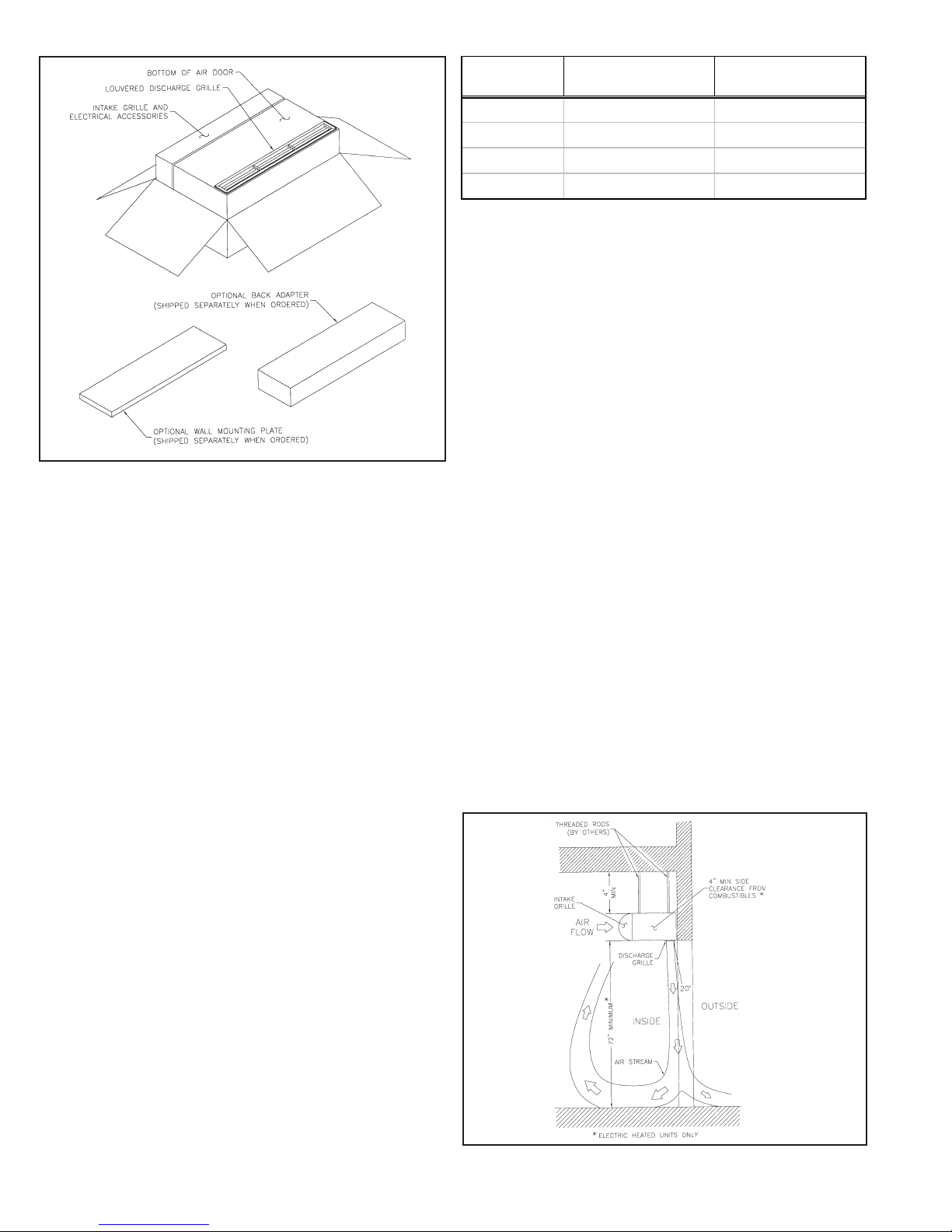

M. Attach the perforated intake grille on the ¼” shoulder bolts of

the unit. See Figure 15. While holding the grille level with

the unit, align the keyhole slots with the shoulder bolts. Press

the grille firmly against the unit and push down until the grille

rests flush with the bottom of the unit.

N. Attach the louvered discharge grille to the unit with the six

(6) No. 6 x ¾” phillips head screws provided. See Figure 14.

O. Switch on the power at the service disconnect. Turn on the

unit at the selector switch and check the sequence of opera-

tion against that provided on the wiring diagram. Proceed to

Section V: Operation and Air Flow Adjustment.

C. Adjusttheairdirectional vanes in the louvered dischargegrille

so the split location is approximately 3” outside the doorway.

FIGURE 13 - Time Delay Adjustment

FIGURE 14 - Louvered Discharge Grille Installation

V. OPERATION AND

AIR FLOW ADJUSTMENT

A. With the air curtain operating on high speed, and the door in

its full open position, check to see that nothing is obstructing

the air flow at the louvered discharge grille.

B. Find the air stream “split” location. Hold a handkerchief, by

its top corners, approximately 12” above the floor. Gently

move the handkerchief back and forth in the doorway. Make

sure the air is being directed to both the inside and the out-

side. The split locations indicated when the handkerchief is

vertical with minimal flutter.

VI. PREVENTIVE MAINTENANCE &

SERVICE

A. CAUTION: ELECTRIC SHOCK HAZARD Disconnect

power whenever servicing unit. More than one discon-

nectmay be required to de-energize unit.

Any service performed on the AURA Series air door MUST

be done by qualified personnel.

Berner air doors require very little servicing. All parts are

easily accessible for periodic inspection and maintenance.

Units should be cleaned at least twice a year. Your particular

application (the amount of dirt and dust in the air) and location

of the unit(s) will determine how often your unit(s) will need

tobecleaned and serviced. All motorshavepermanently lubri-

cated, sealed, sleeve bearings and require no maintenance.

B. TO PERFORM PREVENTIVE MAINTENANCE, RE-

MOVE THE LOUVERED DISCHARGE GRILLE, THE

PERFORATEDINTAKEGRILLEANDTHEBOTTOM

ACCESS COVER.

1. Remove the discharge grille by unscrewing the six (6)

Phillips head screws located on the inside edge of the

grille. See Figure 14.

2. Remove the intake grille by lifting up on both sides with

equal force. Once the grille is detached, pull the grille

away from the unit until it clears the shoulder bolts. This

will expose the bottom access cover mounting bolts and

the heating coils (if applicable).

3. Remove the bottom two ¼” mounting bolts on the intake

side of the unit. Swing the access cover to rest in the

vertical position. Grasp both sides of the access cover

and press in on the spring loaded hinge. This will re

lease theaccesscover from the unitandexposethe blower

mounting plate. See Figure 11.

FIGURE 15 - Attaching Intake Screen or Back Adapter