NOTE: GROUND RING TERMINAL MUST BE SITUATED OR

BEND SUCH THAT IT DOES NOT TOUCH ANY TRACES ON

THE CONTROL BOARD

11. Continue installing the new control board into the unit

by carefully sliding the two tabs at the top of the

control board into the two corresponding slots in the

unit frame. Attach with new plastic push-rivets

provided. Note: when the tabs of the board hit the unit

frame tip the board up and angle the tabs into the slots.

12. Reconnect all wires to the control board.

13. Reinstall display faceplate by attaching the ribbon

cable (with red stripe positioned on the top left) to

the back of display board. Place the face plate against

the mounting bracket, insert and tighten the two

Phillips head screws.

C. INTELLISWITCH SPEED SENSOR REPLACEMENT

1. Set Intelliswitch mode to o.

2. Disconnect power to the unit

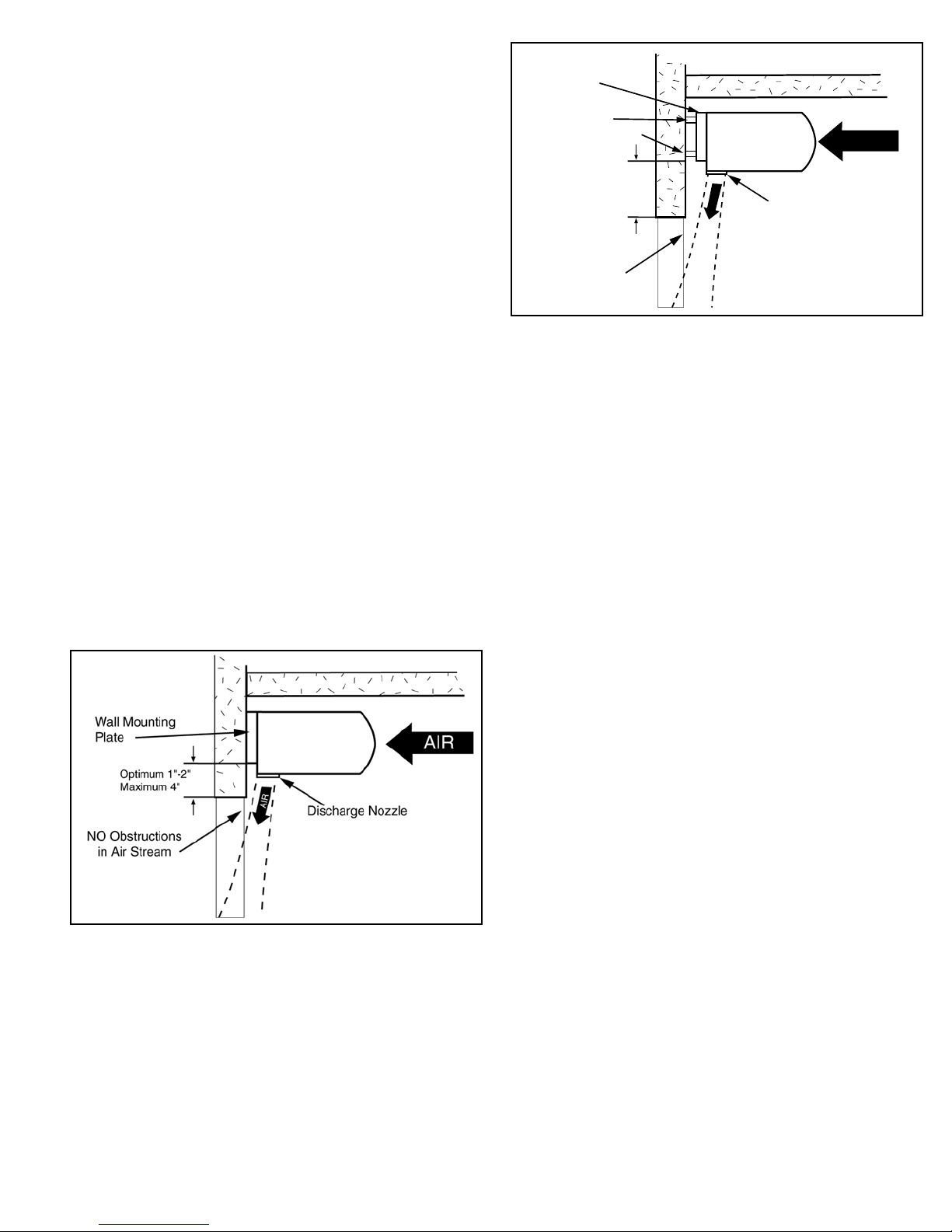

3. Remove the intake grille by removing the locking

screws on each end of the unit. Lift the intake grille up

and then away from the unit.

4. Remove the bottom access panel by removing the

Phillips head screws on the bottom of the unit.

5. Remove the two Phillips head screws from the

Intelliswitch display faceplate.

6. Remove the faceplate from the unit by gently pulling it

away from the unit and unplugging the ribbon

cable from the back.

7. Disconnect the speed sensor from the control board by

locating the pin connection marked J5 and

labeled PROXIMITY. Grasp the socket and carefully pull

away from the control board.

8. Remove the 13 mm hex nut and washer closest to the

fan from the sensor.

9. Remove the sensor.

10. Connect the new sensor to the control board; secure all

loose wires from rotating parts.

11. Install new sensor into mounting bracket. Use the

13 mm nuts to position the tip of the sensor a

maximum of 1/16” (2 mm) away from the rotating

trigger located on the motor shaft. When the unit is

energized, the LED on the back of the sensor will illumi

nate when the trigger passes if the correct distance has

been set.

CAUTION: Do not mount the speed sensor too close to

the trigger, the sensor will be ruined if it is struck by the

trigger.

12. Reinstall display faceplate by attaching the ribbon

cable (with red stripe positioned on the top left) to the

back of display board. Place the face plate against the

mounting bracket, insert and tighten the two Phillips

head screws.

13. Reinstall remaining components in reverse order of

removal.

D. INTELLISWITCH SPEED SENSOR ADJUSTMENT

1. Set Intelliswitch mode to o.

2. Disconnect power to the unit

3. Remove the intake grille by removing the

locking screws on each end of the unit. Lift the intake

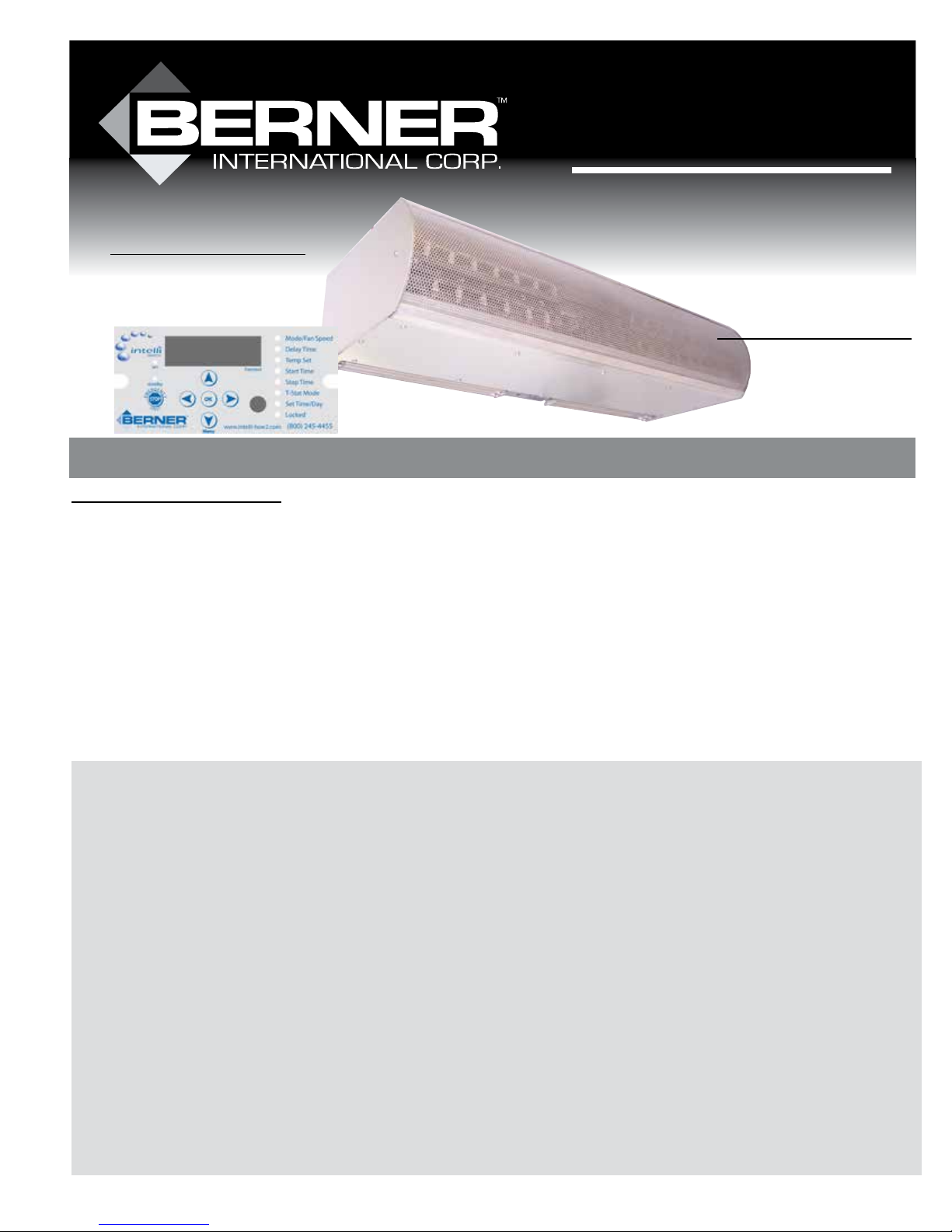

A. INTELLISWITCH DISPLAY BOARD REMOVAL

OR REPLACEMENT

CAUTION: Do not expose the bare board to static electricity,

water, extreme heat or extreme moisture.

1. Set Intelliswitch mode to o.

2. Disconnect power to the unit.

3. Remove the two Phillips head screws from the

Intelliswitch display faceplate.

4. Remove the faceplate from the unit by gently pulling it

away from the unit and unplugging the ribbon

cable from the back.

5. Flip the faceplate over and place it on a clean soft

surface.

6. Remove the two nuts, aluminum shield and at

washers holding the display board to the faceplate.

7. Lift display board o of the studs while leaving the

stand o spacers in place.

8. Install new display board onto faceplate studs, reinstall

washers with aluminum shield and attach with existing

nuts.

9. Reinstall display faceplate by attaching the ribbon

cable (with red stripe positioned on the top left) to the

back of display board. Place the face plate against the

mounting bracket, insert and tighten the two Phillips

head screws.

B. INTELLISWITCH CONTROL BOARD REMOVAL OR REPLACE-

MENT

CAUTION: Do not expose the bare board to static electric-

ity, water, extreme heat or extreme moisture.

NOTE: The Intelliswitch Control Board may be removed

without removing the bottom access cover or transverse.

However removal of the bottom access cover and trans-

verse will simplify the process.

1. Set Intelliswitch mode to o.

2. Disconnect power to the unit.

3. Remove the two Phillips head screws from the

Intelliswitch display faceplate.

4. Remove the faceplate from the unit by gently pulling it

away from the unit and unplugging the ribbon

cable from the back.

5. Mark and remove all wires connected to the control

board.

6. Remove the two plastic push-rivets that attach the

control board to the unit frame by gently prying

a screw driver under the metal bracket attached to the

control board.

7. Carefully maneuver the control board partially out of

the unit by sliding straight down. Avoid contact

between board components and the motor mount.

8. Remove the Phillips head screw that attaches the

control board to the mounting bracket and ground

wire and completely remove the control board from

the unit.

9. Attach mounting bracket to the new control board

with existing screw only on the side that does not

contain the ground wire.

10. Partially insert the board into the unit and attach the

second Phillips head screw and ground wire.

8