Bernhard ANGLEMASTER 3000DX User manual

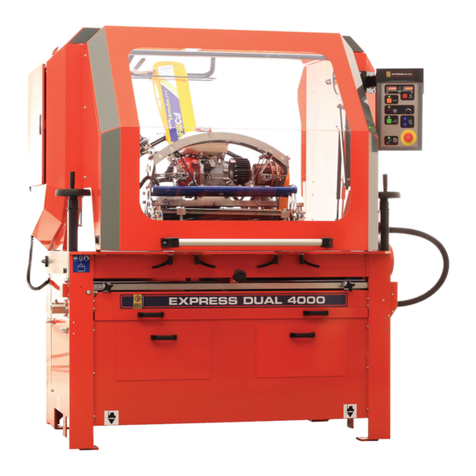

ANGLEMASTER 3000DX

Please read this manual carefully before using the Anglemaster.

This manual should be kept in a safe place so that it can be used for future reference.

User’s Guide &

Instruction Manual

ANGLEMASTER

3000DX

Anglemaster 3000DX Bedknife Grinder

AM3000DX_2007/02/ENG/Membrane Control Panel

ANGLEMASTER • AM3000DX

2

ANGLEMASTER

AM3000DX Precison Bedknife Grinder

You are now the owner/operator of a Bernhard’s Anglemaster 3000DX which,

if cared for and operated correctly, will give you years of good service.

This manual will enable you to obtain the best results from your Anglemaster so

please read it thoroughly before using your machine.

If you have any service or operational problems contact your distributor,

or phone our

Technical Helpline (USA only) – 1-888 474 6348

or

Bernhard and Company Ltd, England – (+44) 1788 811600

or email

or use the technical support feedback form on our web site

www.expressdual.com or www.bernhard.co.uk

Contents

Identication of Pictograms 3

Control Box Layout 4

Understanding the Machine 5

Safety 6

Set Up and Installation 7

Setting Up 9

Setting Angles of Cut 15

Grinding the Blade 17

Electrical Fault Finding 18

Maintenance 20

Parts List 21

Wiring Diagrams 37

Bedknife Mounting Guide 40

BERNHARD AND COMPANY LTD

Bilton Road • Rugby • England • CV22 7DT

Tel +44 1788 811600 • Fax +44 1788 812640

Email: info@bernhard.co.uk

USA Toll Free 1-888 GRIND IT (

1-888 474 6348)

When ordering spare parts please quote the machine type and serial number.

THE MANUFACTURERS ACCEPT NO RESPONSIBILITY FOR ANY SITUATION

ARISING FROM THE FITTING AND/OR USE OF NON-GENUINE SPARE PARTS.

AM3000DX_2007/02

Please quote this serial number on all

correspondence:

Serial #:

3

ANGLEMASTER • AM3000DX

© Bernhard and Company Limited

BEWARE!

HIGH VOLTAGE

BEWARE!

MOVING COMPONENTS KEEP HANDS

AND OTHER OBJECTS CLEAR

1. LIFT HERE

2. DO NOT LIFT HERE

TOTAL WEIGHT OF MACHINE (KG)

WEAR EYE, EAR AND BREATHING

PROTECTION

MAXIMUM GRINDSTONE

DIAMETER 150mm

MAXIMUM SPEED 3800 Rev/Min

BEWARE!

MOVING GRINDSTONE AND SHAFT

Identication of Pictograms

4

ANGLEMASTER • AM3000DX

© Bernhard and Company Limited

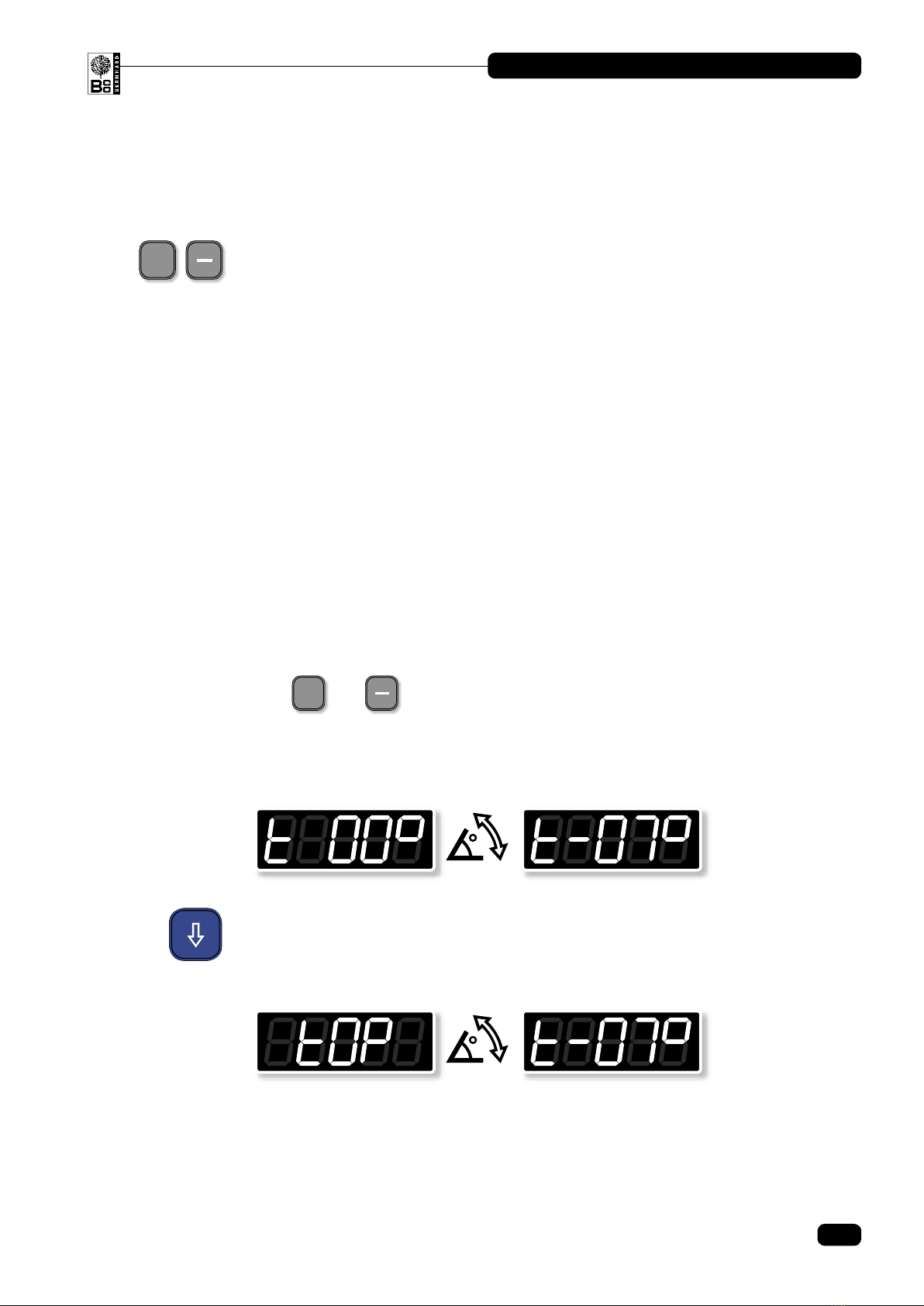

Control Box Layout

TRAVERSE

CONTROL

COOLANT

PUMP

GRINDSTONE

CONTROL

MAGNET

CONTROL

(Bottom)

EMERGENCY STOP

(Twist anti-clockwise to

release)

VARIABLE

SPEED

MOUNTING

BAR

ROTATION

SERVICE

SWITCH

RESET 0° ANGLE

INCREASE/

DECREASE ANGLE

DESIRED ANGLE

“Where you want to be”

CURRENT ANGLE

“Where you are”

5

ANGLEMASTER • AM3000DX

© Bernhard and Company Limited

Machine Functions

The ANGLEMASTER has three separate motors driving the grind stone, traverse and

coolant pump respectively. Each has a separate start/stop button on the control panel.

Grind Stone

Directly driven by the main motor at up to 3800 rpm.

Traverse

Powered by a motor/gearbox unit under the grinding head carriage. Drives along a xed,

damped chain run. Traverse is physically engaged using the over-centre lever on the left

front of the carriage.

Coolant pump

Fitted into the top of the coolant reservoir/settlement tank which is located inside the

cabinet in the base of the machine.

Emergency stop

Pressing the large red mushroom headed button will stop ALL motors. The button will be

locked into the off position. No motors will start when their buttons are pressed until the

E-stop is released by twisting the knob counter-clockwise.

Understanding the Machine

6

ANGLEMASTER • AM3000DX

© Bernhard and Company Limited

1.1 Always wear eye protection when operating the machine.

1.2 Never leave rags or tools on the machine or wear loose clothing that could become caught

up in the bedknife, grinding stone or shaft.

1.3 Never allow combustible materials to be placed on or around the machine

1.4 Always ensure that all parts of the bedknife being ground are securely xed.

1.5 Never use the machine for any purpose other than that for which it was designed

1.6 If large units are to be ground, ear defenders should ideally be worn.

(The maximum noise, with a heavy cut on a 36” bedknife has been measured at 85

decibels).

1.7 Ensure that all electrical connections are sound and that cables are safely routed.

1.8 NEVER t or use any grinding stone other than those supplied specically for use on the

ANGLEMASTER.

1.9 NEVER t or use a grinding stone that has been dropped or damaged in any other way

1.10 Always mix and use coolant according to the manufacturer’s instructions.

1.11 Never allow coolant to wash over the control box or other electrical parts.

Extreme caution should be used when removing a bedknife from the ANGLEMASTER.

Ideally protective gloves should be worn.

1. Safety

7

ANGLEMASTER • AM3000DX

© Bernhard and Company Limited

2. Set Up and Installation

2.2 Location

The machine should be installed in a well-lit area, set up on a solid oor base of concrete

or similar. Wooden oors should ideally be avoided.

Using a spirit level, laid across / along the traverse rails, the machine can be leveled easily,

suitable metal packing may be placed under the cabinet chassis feet.

2.1 Handling

The weight of the machine is indicated on the plate on

the front of the machine.

If the machine is supplied crated, it can be moved by a

suitable forklift or pallet truck under the crate base (skid).

Once the lid and sides of the crate have been removed,

the machine remains bolted to the base (skid).

LIFTING WITH CHAINS/STRAPS/FORKS MUST ONLY

BE CARRIED OUT AS INDICATED BY LABELS ON

THE MACHINE NOT BY MEANS OF THE TRAVERSE GUIDE RAILS.

Hex head

bolt

2.3 For transit purposes, the blade-mounting bar is locked in position at both ends. Some units

may be shipped with a hex head bolt in the right hand clamp. If so, the clamp lock down

lever is in the tool drawer of the machine cabinet. Remove replace the hex head bolt with

the lever and tighten down.

The hex head bolt on the left-hand clamp should be eased off and adjusted to permit

rotation of the mounting bar with a small amount of resistance.

Do not release the right hand clamp (lock down lever) until the weight has been taken on

the angle control lever. For all subsequent use only the lock down lever will be used to hold

the mounting bar in position. If the lock down lever does not appear to be applying enough

force, the hex head bolt on the left-hand needs to be a little tighter.

8

ANGLEMASTER • AM3000DX

© Bernhard and Company Limited

2. Installation (Continued)

2.4 Electrical Supply

USE A QUALIFIED ELECTRICIAN.

All motors are dual cycle 220-230V 50/60Hz, single phase induction motors (Except

variable speed traverse motor on DX models which is three phase).

Electrical connection should be via the electrical cable/plug/socket provided and should be

to a 20 Amp breaker.

The main grinding head motor is overload protected, whilst coolant pump and traverse

motors are independently fused.

Ensure that any cable / conduit run to the machine constitutes no hazard to operator or

other personnel.

The machine MUST BE EARTHED.

2.5 Coolant

Check the location of the settlement tray in the

coolant tank on the shelf in the cabinet under

the left-hand side of the machine. Check the

connection of the coolant supply hose to the

pump outlet.

The soluble additive may be used in the coolant

tank and should be mixed according to the

manufacturer’s instructions (at 1 –1 capful of

additive per FULL tank of water). This uid is

suitable for all types of blade grinding and has

good rust inhibiting properties (if used according

to instructions).

Do not exceed the recommended concentration

as this may lead to “loading” of the grindstone

during usage, which may in turn affect grinding

results.

Sediment in the coolant tank should not exceed ”. Surplus liquid should be returned to

the tank and solid deposits removed at regular intervals, depending upon workload.

9

ANGLEMASTER • AM3000DX

© Bernhard and Company Limited

3. Setting Up

1. BRACKET BODY

2. ADJUSTABLE SUPPORT

PLATE

3. LOCKING KNOB A /

ADJUSTABLE LEVER

4. TAPERED SUPPORT PIN

5. SUPPORT CUP

6. LOCKING KNOB

7. CENTRAL JACKING SCREW

8. JACKING SCREW END

EXTENSION

9. KNURLED LOCKING NUT

10. TRUNNION

11. LOCKING KNOB

12. SUPPORT BRACKET

3.1 General

3.1.1 The ANGLEMASTER has a capacity of 40” between mounting brackets for complete

bedknife/bedbar assemblies, or 42” for plain blades clamped directly to the mounting bar.

3.2 Mounting a bedknife

3.2.1 The machine is equipped with adjustable, universal bedknife mounting brackets

(adjustable quadrant brackets may also be supplied) which can easily be set to correspond

with bed-bar xing holes. In this way the bedknife is supported on the machine in a way

that resembles, as closely as possible, its mounting in a cutting unit. Special adapters are

available when required for certain units.

3.2.2 Attach adjustable support plate (2) through horizontal slot using locking knob A /

adjustable “kip” lever (3).

3.2.3 Fix either tapered pin (4) or cup (5) to adjustable support plate (Tapered pin ts all

bedknife assemblies which either bolt on or locate over a male pivot pin; Cup support is for

bedknife assemblies which mount similar to Toro 216, Spartan, 3500, 6500 etc).

OR

1

2

4

5

6

7

8

9

10

12

12

14

3

10

ANGLEMASTER • AM3000DX

© Bernhard and Company Limited

3. Setting Up (Continued)

3.2.4 There are two alignment stops at the front face of the mounting bar. Rotate the tabs so that

they stand above the top face of the mounting bar.

3.2.5 Using the bedknife, draw the stops out as far as they will go

(only slight pressure is required). Adjust the nut on the back

of the stops to adjust the travel.

The bedknife should be set to overhang the mounting bar

such that the back of the trough lines up with the edge of

the mounting bar (the leading edge of the bedknife will be

around 3/8” - 1/2” forward of the front edge of the mounting

bar). This should ensure that the stone will not grind the back of the bedknife.

3.2.6 Switch on the electromagnets. The bedknife assembly is now held so that it can be easily

mounted.

3.2.7 Universal Brackets

If using the Universal Bedknife Mounting Brackets:

Slide the mounting bracket assembly to the bedknife

assembly and locate bedknife using tapered pin or cup

support (according to it’s mounting type).

3.2.8 Lock the bracket end to the Anglemaster mounting bar,

then lock the support plate in position using locking knob

/ adjustable lever.

3.2.9 Rotate the mounting bar forward to improve

to improve access and adjust the height and

angle of the jacking screw assembly so that

the jacking screw end extension aligns with

a suitable point on the back of the bedknife

assembly. Lock in position with 2 knobs.

Loosen locking nut, adjust jacking screw against

the rear of the bedknife assembly with just

enough pressure to keep the lower front of the

bedknife assembly against the Anglemaster

mounting bar (to stop it swinging when the bar is

rotated) re-tighten locknut.

Jacking screw against bedknife

(Bar shown rotated to vertical position for clarity)

11

ANGLEMASTER • AM3000DX

© Bernhard and Company Limited

3. Setting Up (Continued)

3.2.10 Quadrant Brackets

If using the quadrant brackets:

Loosen the ball lever of the left-hand sole plate bracket by pushing down, and slide the

assembly up to the left-hand end of the bedbar.

Slacken the quadrant locking lever and swing the quadrant until a bedbar xing hole aligns

with one of the slots.

Tighten the sole plate and quadrant and fasten the bedbar with a suitable bolt.

Repeat the procedure for the right hand bracket, ensuring that, when both ends are

tightened, the bedknife is still resting on the mounting bar.

(In order to minimize the possibility of distorting very light bedbars, it is advisable to t a

at washer between bedbar and mounting quadrant).

3.2.11 Rotate the two spring loaded alignment stops to that they retract and sit against the front of

the mounting bar (beneath the overhang of the bedknife).

When the grinding motor is started, the electromagnets will de-energize so that they do not

adversely affect the straightness of the bedknife or grind.

When the grinding motor is stopped, the electromagnets will re-energize, holding the

bedknife assembly so that it can be easily unbolted from the quadrant brackets.

12

ANGLEMASTER • AM3000DX

© Bernhard and Company Limited

3.3 Angle of cut

The angle of cut is adjusted by rotating the mounting bar assembly, complete with

bedknife, so that it is presented to the grinding stone at the required angle.

NOTE: The mounting bar cannot be rotated using the switch if the magnets are not switched on

OR the grind motor or traverse motor are running.

3. Setting Up (Continued)

Rotate the mounting bar:

Down to rotate the bar towards

the operator.

Up to rotate the bar away from

the operator.

13

ANGLEMASTER • AM3000DX

© Bernhard and Company Limited

3.4 Applying a cut

The Bedknife blade is adjusted parallel to the grinding access

The mounting bar is paralleled by drawing the mounting bar / bedknife assembly towards

the grinding stone, by means of the two handwheels

Once the bedknife has been set, the cut is applied via the single point feed handwheel on

the grinding head/carriage.

Handwheels must be moved equal amounts. If one is moved considerably more than the

other (during set up for instance) mounting bar misalignment could result in the slide block/

feed screws jamming.

3.5 Grinding stone dressing

A diamond dresser is supplied, tted to the grinding head.

The grinding stone should be dressed periodically,

by adjusting the dresser towards the stone, then

rotating the control knob back and forth making a

few light passes of the dresser, to ensure that the

stone does not become “loaded” (clogged). New

stones should ALWAYS be dressed!

There is no necessity to alter the set up to do this.

The cut can simply be taken off with the single point

feed handwheel and the stone can be dressed mid

way through a grind, if necessary.

Ensure that adequate eye / breathing protection is used.

3. Setting Up (Continued)

14

ANGLEMASTER • AM3000DX

© Bernhard and Company Limited

3.6 Grinding stone replacement

Isolate the electrical supply. Rotate the mounting bar so that the top face (magnets) face

the operator. Wind the grinding head back to it’s rear-most position (nearest the operator)

Insert a 6mm hex key into the socket at the rear of the motor and undo the grindstone nut

with the box spanner provided.

Before tting a replacement stone, the new stone should be carefully examined for

damage. It should be held loosely and “rung” by tapping gently with a non-metallic object

such as a screwdriver handle. A sound stone will make a clear ringing noise. Reject a

stone that sounds “dead”. Ensure that there is no loose grit/debris between the stone and

the mounting anges.

Box spanner

Key

3. Setting Up (Continued)

15

ANGLEMASTER • AM3000DX

© Bernhard and Company Limited

4.1 Push “Down” control button and

rotate the mounting bar so that the

bedknife is vertical (top face towards

the grindstone).

4.2 Applying a cut

Scratch across the top face of the bedknife (by hand with the

grinding motor off, or with experience with the grinding stone

motor running).

Adjust the mounting bar so that the grinding stone scratches

the full worn face of the bedknife from edge to edge in one

spot (You have effectively found the datum relationship

between reel and bedknife).

Make ne adjustments in angle by rotating the manual

control wheel on top of the drive enclosure at the right hand

end of the mounting bar.

NOTE: The mounting bar cannot be rotated using the switch if the

magnets are not switched on OR the grind motor is running.

4.3 Press reset button to set the current position of bedknife

– left hand “Where you are” display shows zero. Now the

bedknife’ blade and machine are both set to 0°

(On a brand new bedknife, scratch across the new face and reset display to 0°, then hold

reset button whilst using the + and - buttons to adjust the “when you are” display to the

correct angle for that bedknife according to it’s size:

–7°, small units; –9°, medium units; –12°, large units.

As the blade has no wear the angle will be correct as applied by the manufacturer).

4. Setting Angles of Cut

Scratch

16

ANGLEMASTER • AM3000DX

© Bernhard and Company Limited

4. Setting Angles of Cut (Continued)

4.4 Grinding the Top Face of the bedknife

Using the + and - buttons adjust the right hand “Where to want to be” display to the

required angle to be applied to the bedknife.

APPLY:

Small blades –5° to -9° (eg. greens mowers)

Medium blades –6° to –12° (tees, surrounds and small fairway)

Heavy blades –7° to –15° (large fairway and gang units)

In each case use the lowest angle for very clean conditions, the highest angle for rough

conditions.

(On new bedknives add max 1° to the scratch setting, ie that angle ground at the factory).

When the “Where you are” value equals the desired “Where you want to be” angle it

changes to read “Top”.

Lower the guard.

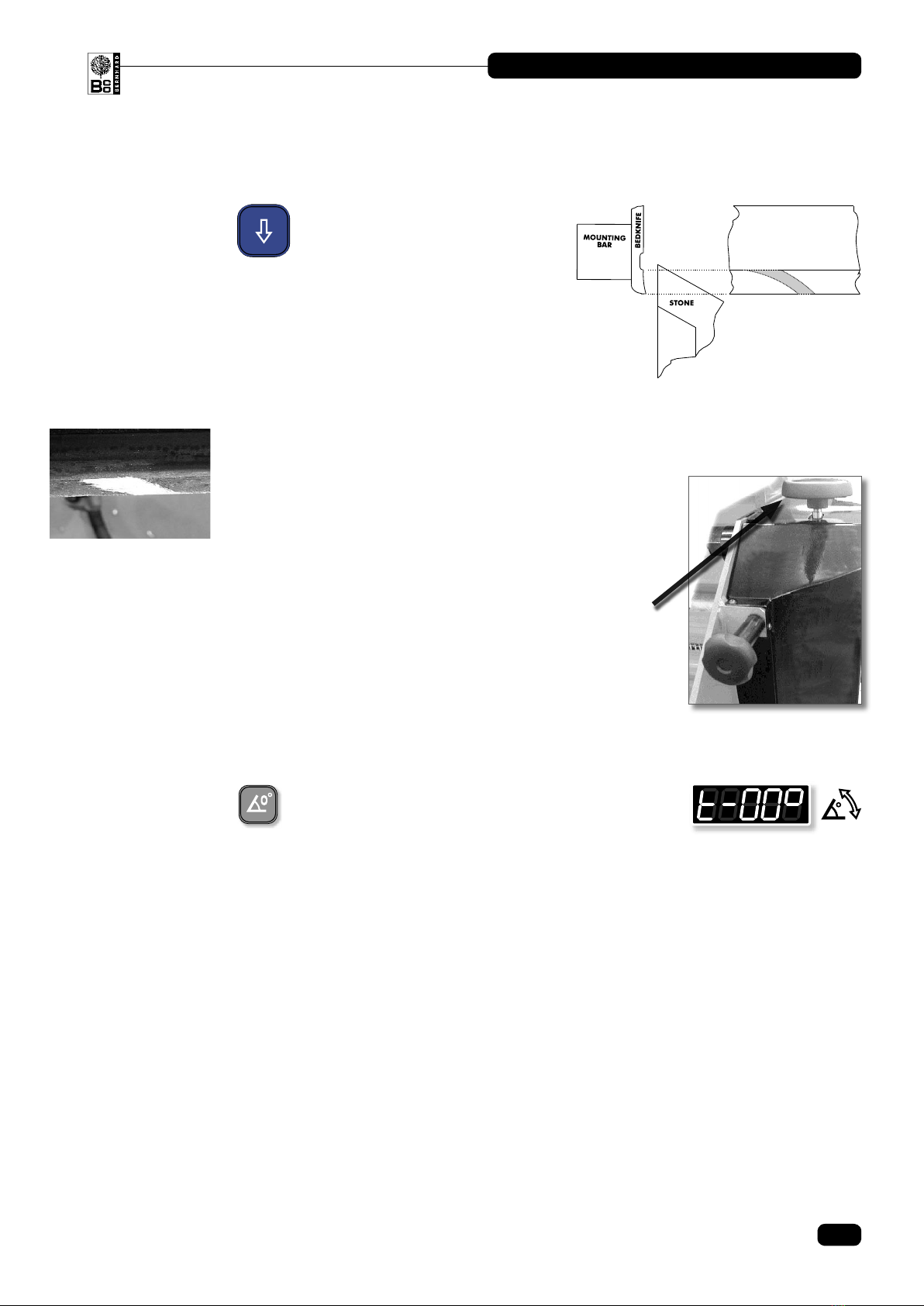

This example: Setting -7° degrees on top face.

a) Use

+ and buttons adjust the right hand “Where to want to be” display to -7°.

b) Display reads t-07°:

c) Now apply a relief grind (reverse angle) to the top face of the bedknife. Rotate mounting

bar by pushing the “Down” button on the control panel so the left “Where you are”

current angle changes from 00º towards -07º. When it reaches -07° the mounting bar

will automatically stop and the “Where you are” display will indicate TOP.

+

17

ANGLEMASTER • AM3000DX

© Bernhard and Company Limited

5. Grinding the Blade

5.1 Start the grinding wheel motor and slowly hand traverse the grinding carriage along the

length of the bedknife, with very light contact.

Set the traverse stops on the front of the machine chassis, so that the grinding stone just

clears the ends of the blade.

Preliminary setting up passes, with hand traverse during set up,thand the rst part of the

grind may be made without coolant. During normal grinding, a moderate ow of coolant

should be directed onto the bedknife, as close as possible to the point of contact with the

grinding stone.

Ensure that the ground surface is parallel along the whole length of the bedknife.

With the auto traverse engaged, grind the bedknife until it “sparks out” (only occasional

sparks seen as grinding stone passes the blade – no real metal removal).

Traverse speed can be adjusted via the potentiometer knob adjacent to the start/stop

button on the control box.

5.2 Grinding the Front Face of the bedknife

Back the grindstone off the bedknife and stop the grinding motor,

Push “Up” control button rotating the mounting bar

upwards through 0°, through 90° until both displays show

Front when the front face has reached 5° where it will

automatically stop.

As with the top face, grind the front face parallel from end to end.

Check that the cutting edge is sharp and remove any burr as necessary.

5.3 Push the “Down” button and rotate the mounting bar (and bedknife assembly)

back to it’s horizontal “Load/Unload” position. Remove the brackets from the

bedbar. Switch off the electromagnets and remove the bedknife assembly from

the Anglemaster.

18

ANGLEMASTER • AM3000DX

© Bernhard and Company Limited

6.1 USE A QUALIFIED ELECTRICIAN

6.1.1 In the event of any motor not starting / magnets not working, the following procedure

should be adopted.

6.1.2 Check voltage at PWR Plug to Control PCB in the electrical drawer.

6.1.3 Check main fuses/breakers feeding machine if voltage is not normal - also check

individually labelled fuses on Control PCB.

6.1.4 Check that EMERGENCY STOP BUTTON on control pendant is not locked in STOP

position.

6.1.5 Check for open circuit on overload terminals 95 and 96, press overload reset button to

correct.

6.1.6 Check that reset button on clear control box lid is not permanently in contact with red

button on overload. Adjust as required.

6.1.7 Listen for the functioning of all contactors/relays in the control box by operating the

individual motor control buttons, and the reversing microswitch.

6.1.8 If the relevant contactor is operating correctly check the voltage on the out going contactor

terminals and then the voltage at the appropriate motor terminals.

6. Electrical Fault Finding

19

ANGLEMASTER • AM3000DX

© Bernhard and Company Limited

6. Electrical Fault Finding (Continued)

6.2 Coolant Pump

If the voltage is correct at the coolant pump a new pump is required.

6.3 Traverse Motor

If the voltage is correct at the traverse motor terminals, check for an error message at the

invertor display before assuming that the motor itself is at fault.

If the traverse jumps at the change in direction, check microswitch and contactor operation

but most likely is a capacitor failure (often resulting from a low voltage supply).

6.4 Mounting Bar Motor

If the voltage is correct at the motor terminals, check for an error message at the invertor

display.

6.5 Grinding Motor

If the voltage is correct at motor terminals check the current/amps at terminals T2 & T3 (on

thermal overload contactor, then at “MAIN” plug on Control PCB). If the current exceeds the

full load current indicated on the motor plate, a new motor is needed. If below full load current

the overload could be set too low (see Service Bulletin #4).

6.6 Magnets

Check for 12V DC at terminals 2 and 3 at the 4 pole socket at the rear of the drawer. If no

volts are present, check output at transformer (Warning: where voltage will be AC!).

20

ANGLEMASTER • AM3000DX

© Bernhard and Company Limited

7. Maintenance

7.1 Maintenance

As with any precision machine, a small amount of time and trouble taken on routine maintenance

and cleaning will pay valuable dividends in terms of overall efciency and component life.

7.2 Lubrication

A small amount of light oil should be applied to the sliding and rotating surfaces of the

feed screws/slides and mounting bar assemblies and to the traverse chain as required, at

approximately 3 monthly intervals, depending on the work load of the machine.

7.3 Traverse Chain

The chain should be adjusted as required by adjusting the bolts where the chain ends are

attached to the machine chassis. The springs at these points should NOT be fully compressed

as they provide damping at the change in traverse direction.

7.4 Rails

Rails should be kept as clean as possible. Although the rear rail is cleaned by wipers attached

to the carriage cover, some dust/debris will still collect on this rail.

Wipe the rails down daily and spray with WD40 at the end of each day’s grinding.

NOTE 1: Always wipe the rails before grinding as oil / WD 40 will cause grinding debris to

stick during operation.

NOTE 2: The rolling action of the carriage bearings along the rails will eventually result in

the appearance of narrow “ats” on the rails where the gearings run. This is perfectly normal

and DOES NOT affect the accuracy of the machine (These narrow ats are actually work-

hardened areas).

Table of contents

Other Bernhard Grinder manuals

Popular Grinder manuals by other brands

EINHELL

EINHELL AXXIO 36/230 Q Original operating instructions

Makita

Makita GA7020 instruction manual

Hitachi

Hitachi G10SR3 Handling instructions

Strasbaugh

Strasbaugh 7AA Operation and maintenance manual

Universal Tool

Universal Tool UT8740A10 Operator instructions

DeWalt

DeWalt DCG406N-XJ Original instructions